方案详情

文

表面性能控制在包装、电子、医学及生命科学等多个领域中至关重要。在包装过程中,粘附和润湿性在许多步骤中都有着很大的影响。包装材料一般包含多层不同物质以达到保护和提升被包装产品的目的,这些物质的粘附性和润湿性不能满足打印要求,因此需要利用各种表面处理技术。该应用说明了Biolin Theta接触角测量仪在包装工业表面处理评价中的应用。

方案详情

ATTENSION AN 12 attension APPLICATIONNOTE 12 Contact angle measurement forsurface treatment evaluation inpackaging industry This application note illustrates how Theta optical tensiometers canbe used for evaluation of surface treatments in packaging industryprocesses. Introduction Control of surface properties is very important for variety ofindustries such as packaging,electronics, medical and life sci-ences. In the packaging industry, adhesion and wettability play akey role in many processes. Packaging material typically includesvarious layers of different materials to fulfill all the requirementsto protect and promote the product inside the package. Adhe-sion and wettability properties of these materials are often notsufficient for printing, and therefore different surface treatmentsare utilized. This application note describes how contact anglemeasurement can be used to evaluate the quality of plasma andflame surface treatments in packaging processes. Plasma surface modification is an effective way to control the sur-faceenergy and chemical properties of substrates without affect-ing the bulk material. Plasma is a state of ionized gas, sometimesreferred as "fourth-state-of-matter",consisting of reactive particlessuch as electrons,ions and radicals.Plasma-solid interactions canbe roughly divided into three sub categories; (i) plasma etching orcleaning, where material is removed from the surface (ii) plasmaactivation, where the surface is physically or chemically modifiedby species present in plasma and (iii) plasma coating, where mate-rial is deposited in the form of a thin film on the surface.Depend-ing on the conditions in which the plasma is created, plasmas canbe categorized into vacuum or atmospheric plasmas. Vacuumplasma treatments are widely used for example in microelectronicsapplications, but on-line processes require atmospheric methods. One kind of atmospheric plasma activation, so-called industrialcorona treatment, has already been used for decades in the con-verting and printing industry, for example to improve adhesionbetween paper and polymers in extrusion processes. In additionto plasma treatments, flame treatment is many times utilized inpackaging industry. Flame treaters work by burning gas, whoseexcess oxygen becomes reactive by the high temperature. Whenthe substrate passes through the plasma activation or flame state,various chemical reactions occur increasing the surface energyof substrate. It is well-known that atmospheric pressure plasmaactivation and flame treatments creates polar molecular groupson the surface, and thus increases the surface energy. Changes inthe topography properties have also been reported. In packaging industry, wide range of materials, such as paper andboard, plastic, metal and glass, are used depending on demandsfor the package.Fiber-based materials are many times preferredsince they are environmental friendly choice due to recyclableand compostable properties, while being cost effective at thesame time. Paper or board by itself is often not suitable as pack-aging material since it has poor barrier properties for exampleagainst moisture. For this reason one or several plastic layers areoften applied to provide better barrier properties and increasesthe durability of the packages. Extrusion coating and laminationare typically used processes to combine paper and plastic layerstogether.In the lamination process at least two different solidstate materials are combined with adhesive such as primers.Con-tact angles can be used to check the cleanliness and homogene-ity of the lamination materials or wettability of chosen adhesiveon the lamination materials. In the extrusion coating, moving webis coated with molten polymer film. Next case study illustrates how Attension optical tensiometerscan be utillized in development and quality control for surfacetreated packaging materials. Laboratory instruments, Theta andTheta Lite are excellent for process development whereas ThetaQC offers a convenient tool for quality control. Small size andintegrated data analysis makes it truly stand-alone instrument forproduction site. Case study: Evaluation of plasma treat-ments on extrusion coated paper bycontact angle measurement Extrusion coated papers and paperboards are used in variousconsumer packages such as food, medical and cosmetic pack-ages. Plasma and corona treatments are often utilized to promoteadhesion between paper and polymer melt in this process, andcontact angles can be used to evaluate the level and homogene-ity of the treatment. Apart from protecting the product, anotherimportant feature of the package is its appearance; packagescontain product information and contribute to the buyingdecision. When non-absorbing and low surface energy plasticsurfaces are printed,adhesion between ink and substrate is achallenge. It is well-known that surface free energy of substrateshould be higher than that of the ink. Therefore, prior to print-ing, the surface free energy of the coated substrates has to beincreased by using some surface treatment methods, such asplasma and flame treatments. Contact information AttensionBiolin ScientificTietajantie 2FIN-02130 Espoo,Finland ( T E L +35 89 5 497 3 30 0 FAX + 3 58 9 54 97 3 3 33 in f o @ a tt ensio n .c om ww w.atten s ion.com ) Tuominen et al. studied different surface treatments on low den-sity polyethylene (LDPE) and polypropylene (PP) extrusion coatedpaper and their effect on printability [1]. Attension (formerly KSVInstruments) CAM200 Optical tensiometer was used to measurecontact angle of native and corona, flame and helium and argonon-line plasma treated surfaces (see table 1). NATIVE CORONA FLAME HELIUMPLASMA ARGONPLASMA LDPE 103 75 77 75 76 PP 108 81 83 86 89 Table 1. Contact angles in degrees of native and surface treatedLDPE and PP surfaces Contact angle results showed that all the surface treatment meth-ods improved wettability and increased surface free energy ofthe extrusion coated paper surfaces and therefore improved theink-substrate adhesion. In Table 1 can be seen that corona treat-ment provided better wettability than argon plasma treatment onPP surface. The morphological changes in micro and nano scalewere observed only on the flame treated LDPE surface and theywere found to be beneficial for printing quality. References [1] M. Tuominen, J. Lahti, J. Lavonen, T. Penttinen, J.P.Rasanen andJ. Kuusipalo, The influence of flame, corona and athmosphericplasma treatments on surface properties and digital print qualityof extrusion coated paper, J. Adhes. Sci. Technol. 24, 471-492(2010). 瑞典百欧林科技有限公司是一家先进科研仪器生产商,在北欧的瑞典,丹麦和芬兰都有主要产品的研发和生产基地。我们为用户提供高科技、高精度的科研设备,可用于表界面、材料科学、生物科学、药物开发与诊断等研究领域。

确定

还剩1页未读,是否继续阅读?

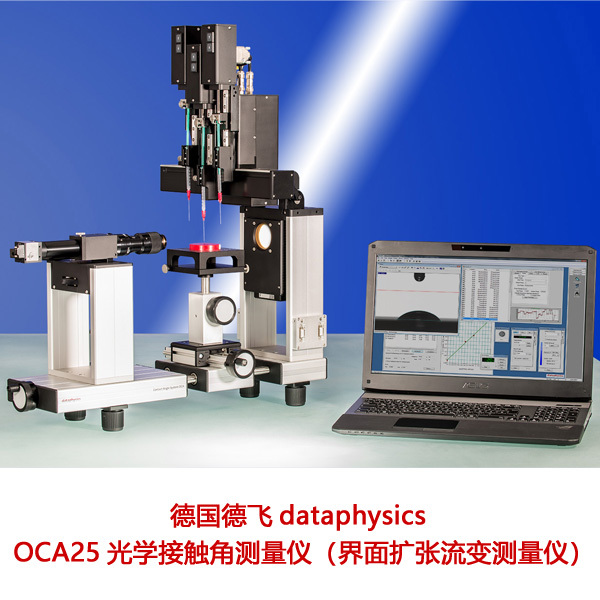

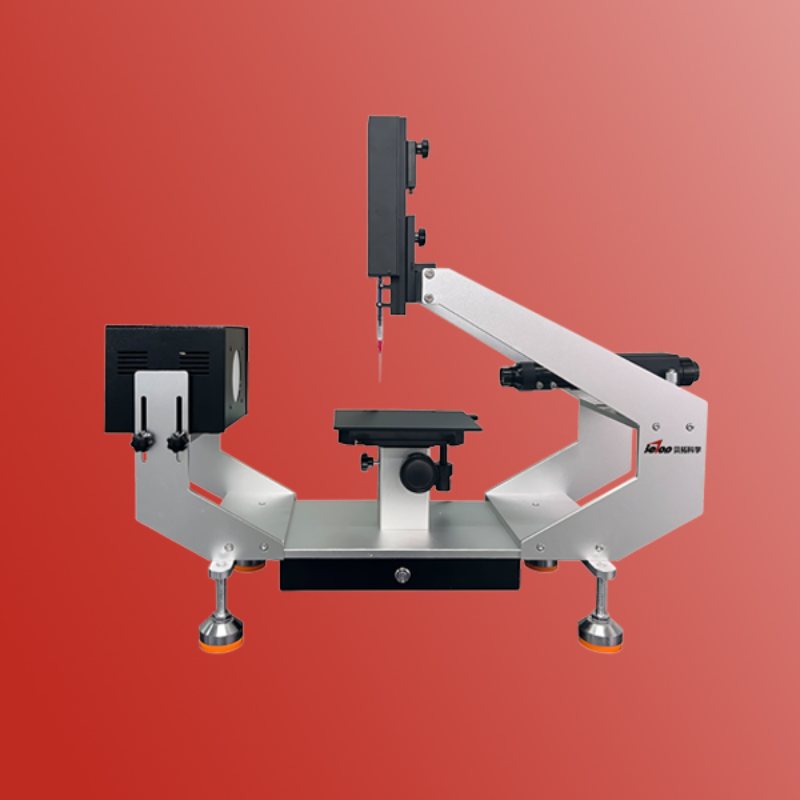

大昌华嘉科学仪器为您提供《包装中接触角检测方案(接触角测量仪)》,该方案主要用于包装中接触角检测,参考标准--,《包装中接触角检测方案(接触角测量仪)》用到的仪器有光学接触角测量仪(水滴角测量仪) Theta Flex、水滴角测量仪 Theta Lite

推荐专场

相关方案

更多