方案详情

文

热机械分析仪(TMA)历来都是被用来测量固体材料的尺寸变化。然而,这项技术也可扩展到评估液体样品上,提供一种替代差示扫描量热仪(DSC)确定相变和玻璃化转变温度的方法。

方案详情

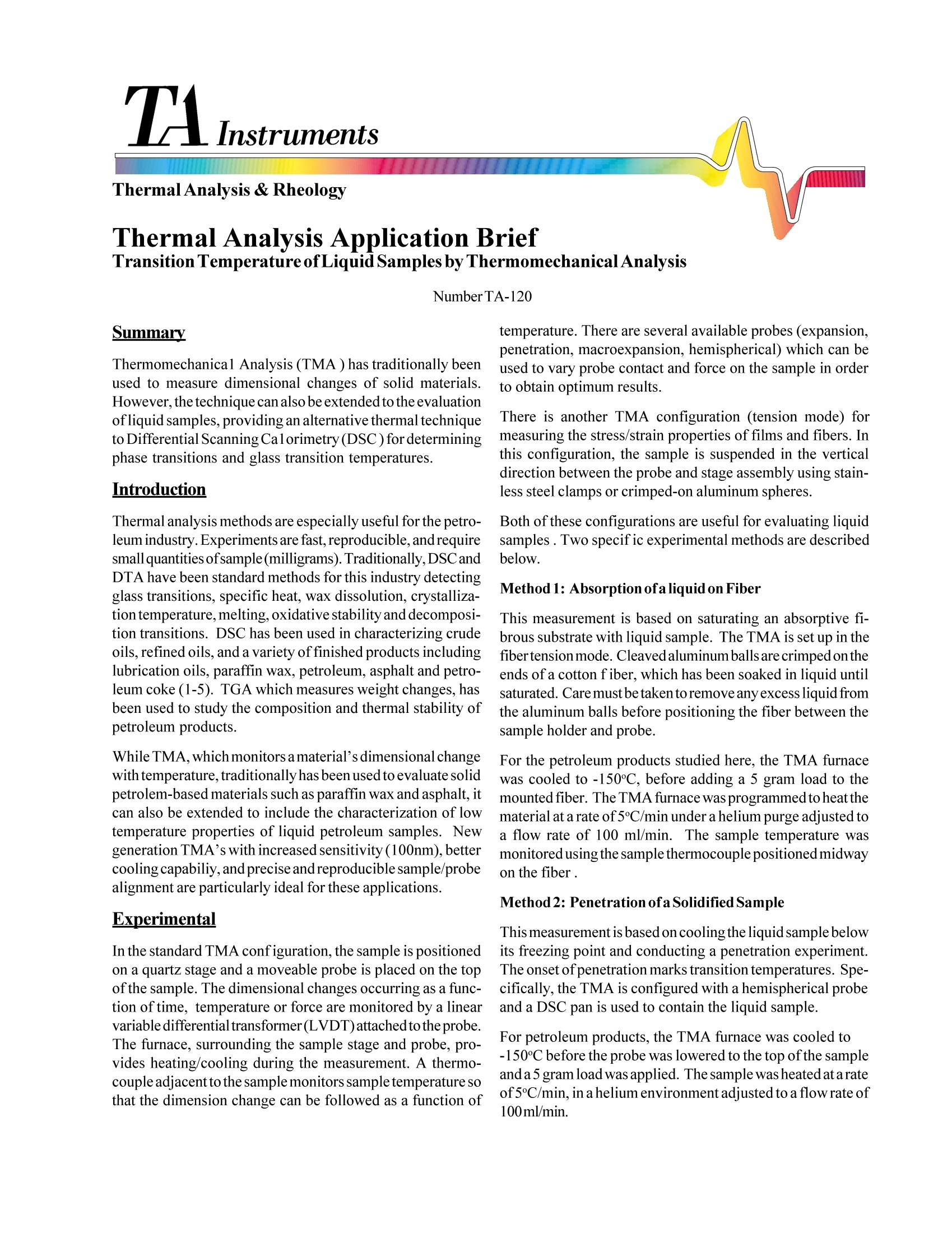

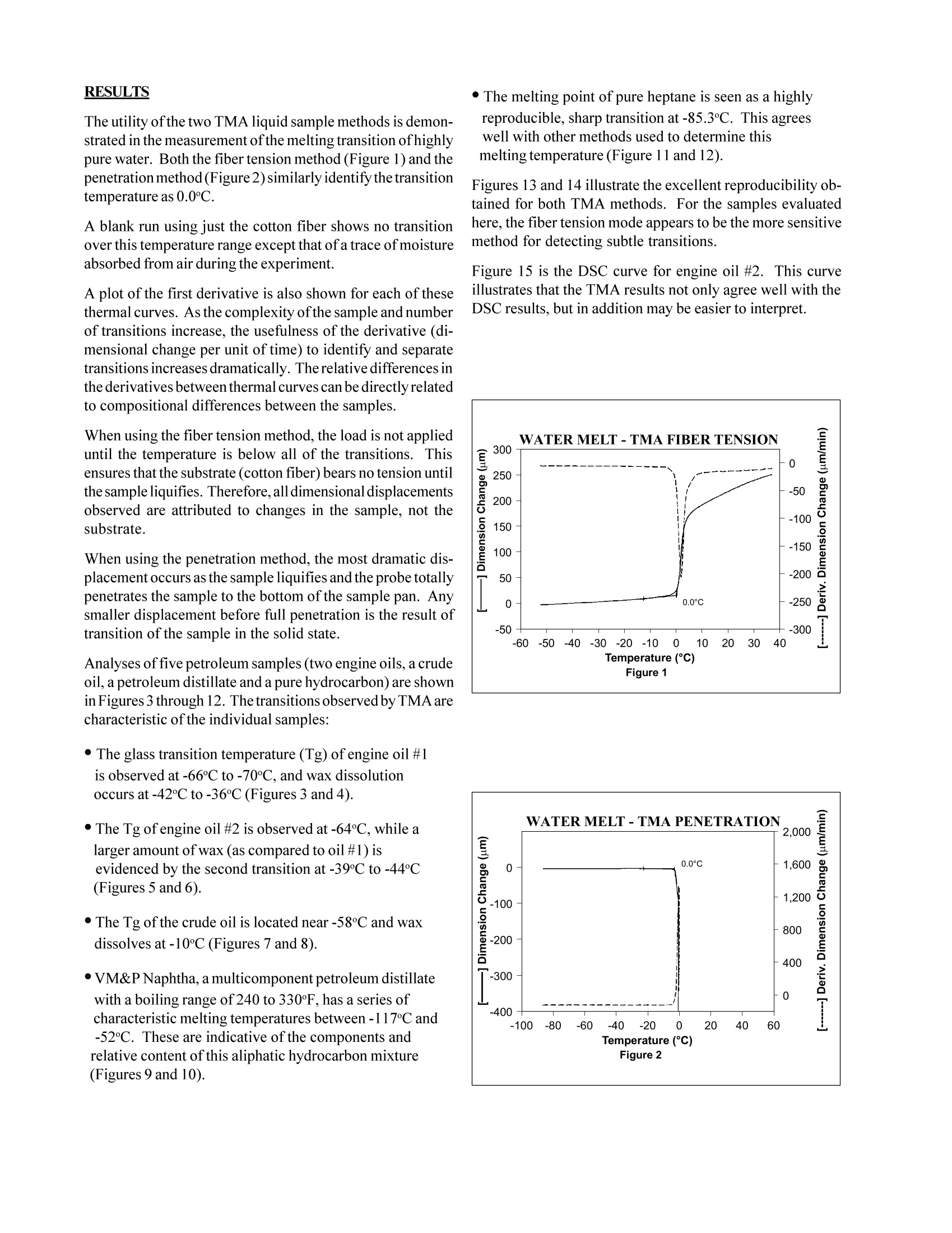

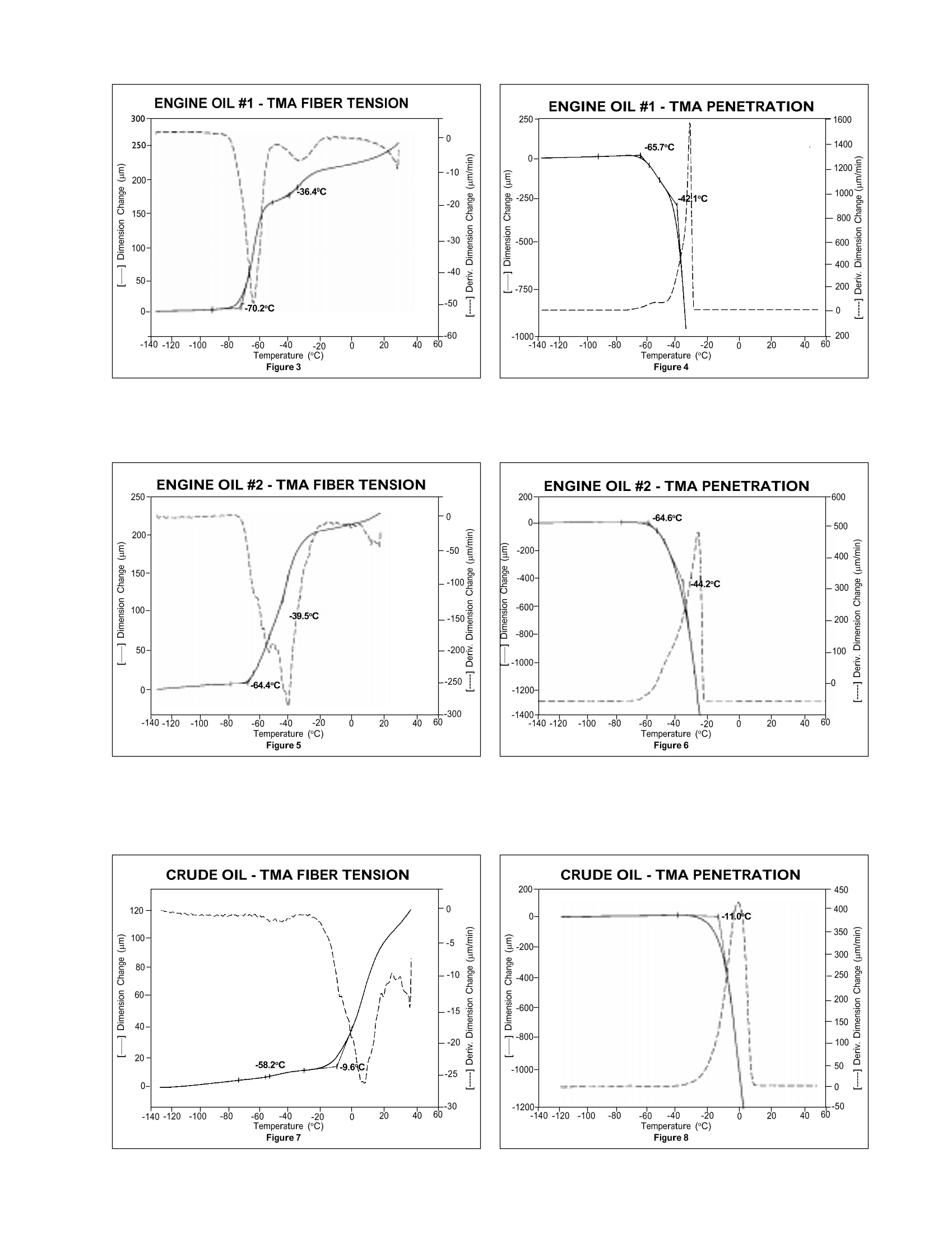

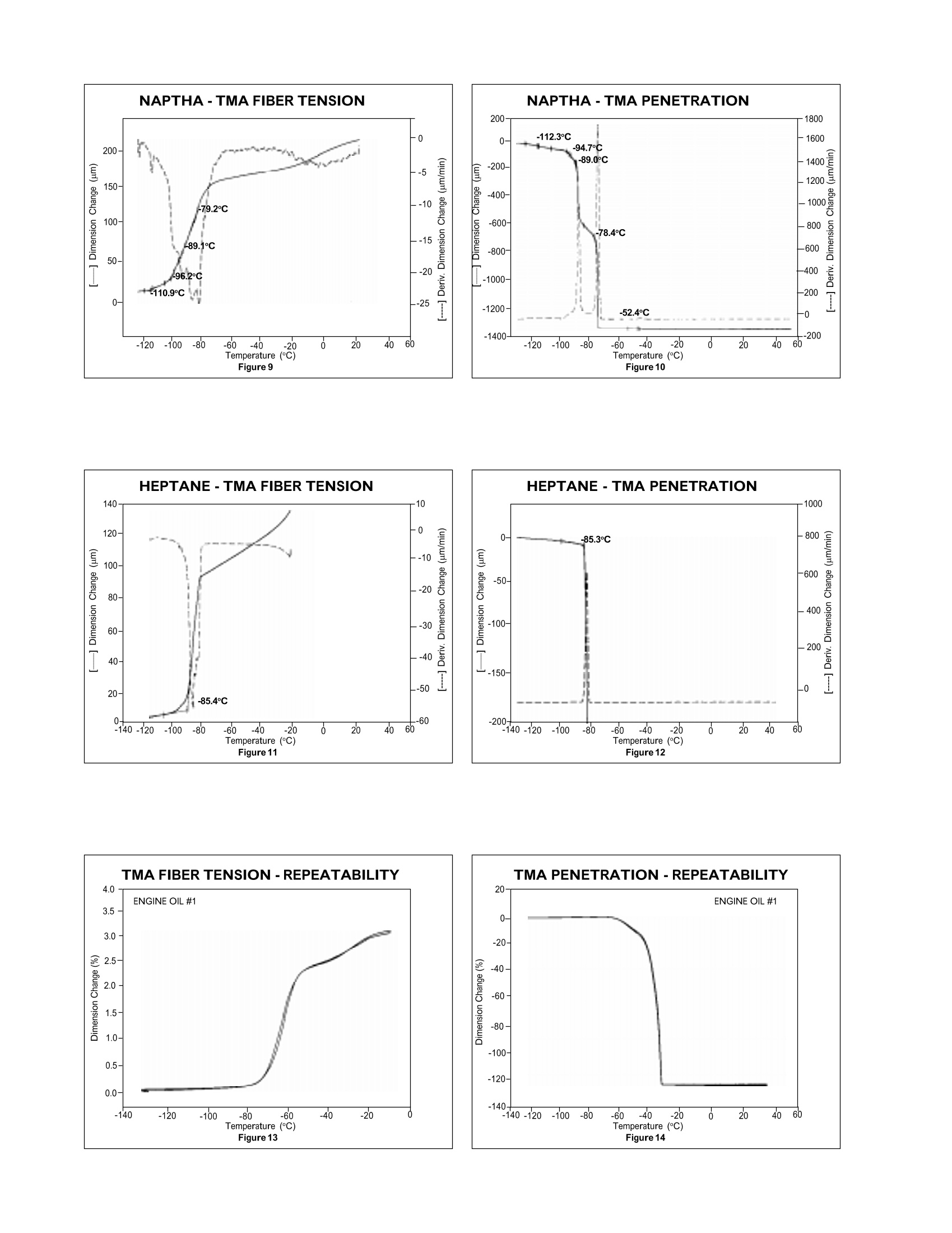

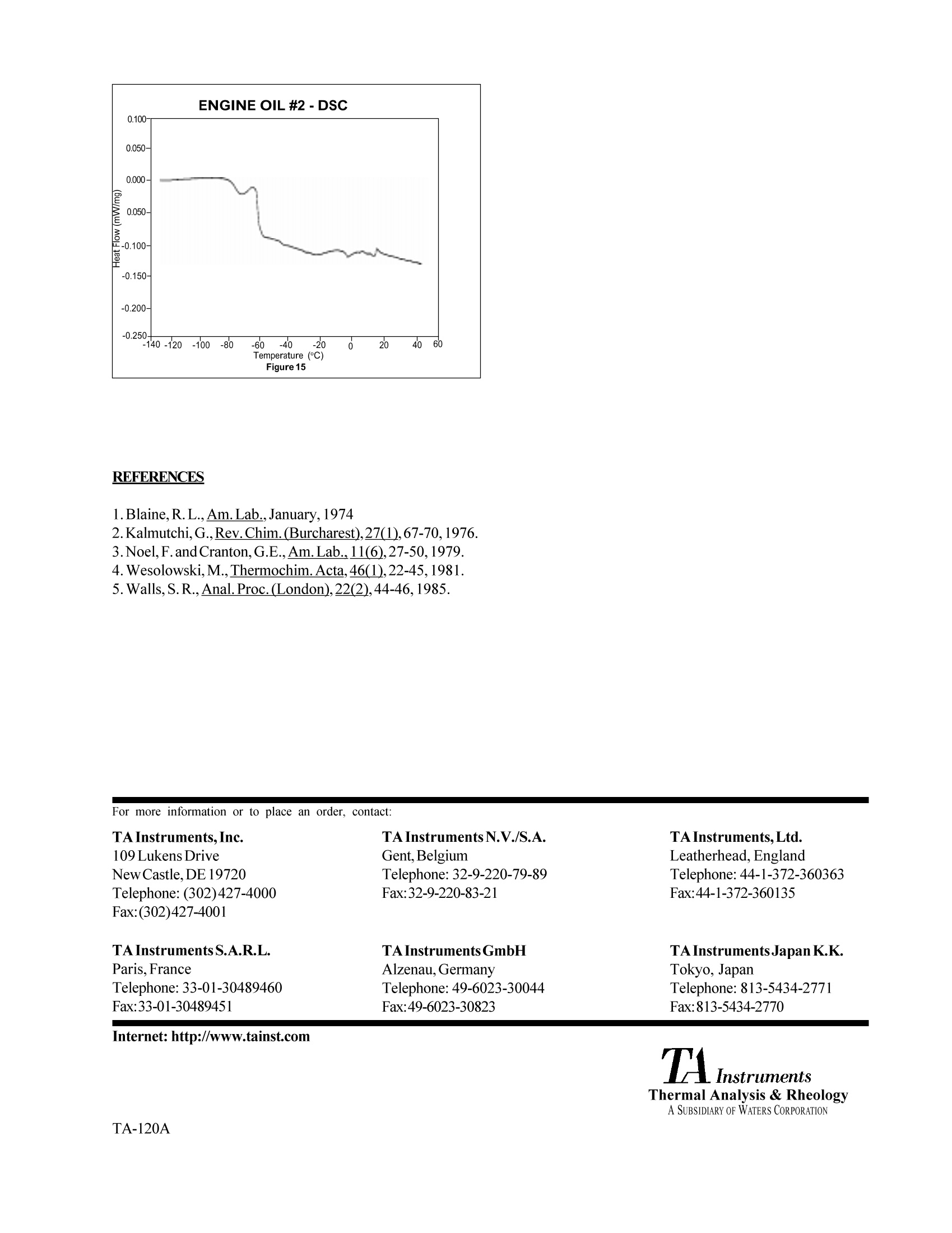

InstrumentsThermalAnalysis & RheologyT. InstrumentsThermal Analysis & RheologyA SUBSIDIARY OF WATERS CORPORATIONTA-120A Thermal Analysis Application Brief TransitionTemperature ofLiquid Samples by ThermomechanicalAnalysis NumberTA-120 Summary Thermomechanica1 Analysis (TMA) has traditionally beenused to measure dimensional changes of solid materials.However, the techniquecan also be extended to the evaluationof liquid samples, providing an alternative thermal techniqueto Differential Scanning Calorimetry (DSC) for determiningphase transitions and glass transition temperatures. Introduction Thermal analysis methods are especially useful for the petro-leum industry.Experiments are fast, reproducible, andrequiresmall quantities ofsample(milligrams). Traditionally,DSCandDTA have been standard methods for this industry detectingglass transitions, specific heat, wax dissolution, crystalliza-tiontemperature,melting, oxidative stability and decomposi-tion transitions. DSC has been used in characterizing crudeoils, refined oils, and a variety of finished products includinglubrication oils, paraffin wax, petroleum, asphalt and petro-leum coke (1-5). TGA which measures weight changes, hasbeen used to study the composition and thermal stability ofpetroleum products. While TMA, which monitors amaterial's dimensional changewith temperature, traditionally has been used to evaluate solidpetrolem-based materials such as paraffin wax and asphalt, itcan also be extended to include the characterization of lowtemperature properties of liquid petroleum samples. Newgeneration TMA’s with increased sensitivity (100nm), bettercooling capabiliy, and precise andreproducible sample/probealignment are particularly ideal for these applications. Experimental In the standard TMA configuration, the sample is positionedon a quartz stage and a moveable probe is placed on the topof the sample. The dimensional changes occurring as a func-tion of time, temperature or force are monitored by a linearvariable differentialtransformer(LVDT)attachedto theprobe.The furnace, surrounding the sample stage and probe, pro-vides heating/cooling during the measurement. A thermo-couple adjacentto the sample monitors sample temperature sothat the dimension change can be followed as a function of temperature. There are several available probes (expansion,penetration, macroexpansion, hemispherical) which can beused to vary probe contact and force on the sample in orderto obtain optimum results. There is another TMA configuration (tension mode) formeasuring the stress/strain properties of films and fibers. Inthis configuration, the sample is suspended in the verticaldirection between the probe and stage assembly using stain-less steel clamps or crimped-on aluminum spheres. Both of these configurations are useful for evaluating liquidsamples. Two specif ic experimental methods are describedbelow. Method1: Absorption ofa liquid on Fiber This measurement is based on saturating an absorptive fi-brous substrate with liquid sample. The TMA is set up in thefibertensionmode. Cleaved aluminum balls are crimped on theends of a cotton fiber, which has been soaked in liquid untilsaturated. Care mustbe taken to remove any excess liquid fromthe aluminum balls before positioning the fiber between thesample holder and probe. For the petroleum products studied here, the TMA furnacewas cooled to -150℃, before adding a 5 gram load to themounted fiber.The TMA furnace was programmedto heatthematerial at a rate of5℃/min under a helium purge adjusted toa flow rate of 100 ml/min. The sample temperature wasmonitoredusing the sample thermocouple positioned midwayon the fiber. Method2: Penetration ofa Solidified Sample This measurement is based on cooling the liquid sample belowits freezing point and conducting a penetration experiment.The onset of penetration marks transition temperatures. Spe-cifically, the TMA is configured with a hemispherical probeand a DSC pan is used to contain the liquid sample. For petroleum products, the TMA furnace was cooled to-150℃ before the probe was lowered to the top of the sampleanda 5 gramload was applied. The sample was heated at a rateof5℃/min, in a helium environment adjusted to a flow rate of100ml/min. The utility ofthe two TMA liquid sample methods is demon-strated in the measurement ofthe melting transition ofhighlypure water. Both the fiber tension method (Figure1) and thepenetration method (Figure 2) similarly identify the transitiontemperature as 0.0C. A blank run using just the cotton fiber shows no transitionover this temperature range except that of a trace of moistureabsorbed from air during the experiment. A plot of the first derivative is also shown for each of thesethermal curves. As the complexity ofthe sample and numberof transitions increase,the usefulness of the derivative (di-mensional change per unit of time) to identify and separatetransitions increases dramatically. Therelative differences inthe derivatives between thermal curves can be directly relatedto compositional differences between the samples. When using the fiber tension method, the load is not applieduntil the temperature is below all of the transitions. Thisensures that the substrate (cotton fiber) bears no tension untilthe sample liquifies. Therefore, all dimensional displacementsobserved are attributed to changes in the sample, not thesubstrate. When using the penetration method, the most dramatic dis-placement occurs as the sample liquifies and the probe totallypenetrates the sample to the bottom of the sample pan. Anysmaller displacement before full penetration is the result oftransition of the sample in the solid state. Analyses of five petroleum samples (two engine oils, a crudeoil, a petroleum distillate and a pure hydrocarbon) are showninFigures 3 through 12. The transitions observed by TMA arecharacteristic of the individual samples: The glass transition temperature (Tg) of engine oil #1is observed at -66℃ to-70C, and wax dissolutionoccurs at -42℃ to-36℃ (Figures 3 and 4). The Tg of engine oil #2 is observed at -64℃, while alarger amount of wax (as compared to oil #1) isevidenced by the second transition at -39℃ to-44°℃(Figures 5 and6). · The Tg ofthe crude oil is located near -58℃ and waxdissolves at-10℃ (Figures 7 and 8). VM&PNaphtha, a multicomponent petroleum distillatewith a boiling range of 240 to 330°F, has a series ofcharacteristic melting temperatures between-117℃ and-52℃. These are indicative of the components andrelative content of this aliphatic hydrocarbon mixture(Figures 9 and 10). ·The melting point of pure heptane is seen as a highlyreproducible, sharp transition at-85.3℃. This agreeswell with other methods used to determine thismelting temperature (Figure 11 and 12). Figures 13 and 14 illustrate the excellent reproducibility ob-tained for both TMA methods. For the samples evaluatedhere, the fiber tension mode appears to be the more sensitivemethod for detecting subtle transitions. Figure 15 is the DSC curve for engine oil #2. This curveillustrates that the TMA results not only agree well with theDSC results, but in addition may be easier to interpret. REFERENCES 1.Blaine,R. L.,Am.Lab.,January, 1974 2.Kalmutchi,G.,Rev.Chim.(Burcharest),27(1),67-70,1976. 3.Noel,F.andCranton,G.E.,Am.Lab..11(6),27-50,1979. 4.Wesolowski,M.,Thermochim.Acta,46(1),22-45,1981. 5.Walls,S.R.,Anal. Proc. (London),22(2),44-46,1985. For more information or to place an order, contact: TAInstrumentsN.V./S.A. TAInstruments,Inc. TAInstruments,Ltd. Gent, Belgium 109 Lukens Drive Leatherhead,England Telephone: 32-9-220-79-89 New Castle,DE 19720 Telephone: 44-1-372-360363 Fax:32-9-220-83-21 Telephone: (302)427-4000 Fax:44-1-372-360135 Fax:(302)427-4001 TAInstruments GmbH TAInstruments S.A.R.L. TAInstruments JapanK.K. Alzenau, Germany Paris, France Tokyo, Japan Telephone: 49-6023-30044 Telephone: 33-01-30489460 Telephone:813-5434-2771 Fax:49-6023-30823 Fax:33-01-30489451 Fax:813-5434-2770 Internet: http://www.tainst.com Thermomechanica1 Analysis (TMA) has traditionally been used to measure dimensional changes of solid materials. However, the technique can also be extended to the evaluation of liquid samples, providing an alternative thermal technique to Differential Scanning Ca1orimetry (DSC) for determining phase transitions and glass transition temperatures.

确定

还剩3页未读,是否继续阅读?

TA仪器为您提供《液体中转变温度检测方案(动态热机械)》,该方案主要用于其他中转变温度检测,参考标准--,《液体中转变温度检测方案(动态热机械)》用到的仪器有

相关方案

更多

该厂商其他方案

更多