方案详情

文

Traditionally, pure gum rubber rheological properties are tested and certified using the well-known Mooney viscometer according to ISO 289. This test is, in most of the cases, used for polymer choice for a specific recipe. Most rubber technologists recognize that this method fails to provide compound flow behavior information, especially when comparing polymers of identical ML(1+4) from various sources. Money Stress Relaxation has improved polymer source discrimination but is not widely adopted by polymer users although an increasing number of polymer suppliers are now providing this characteristic.

方案详情

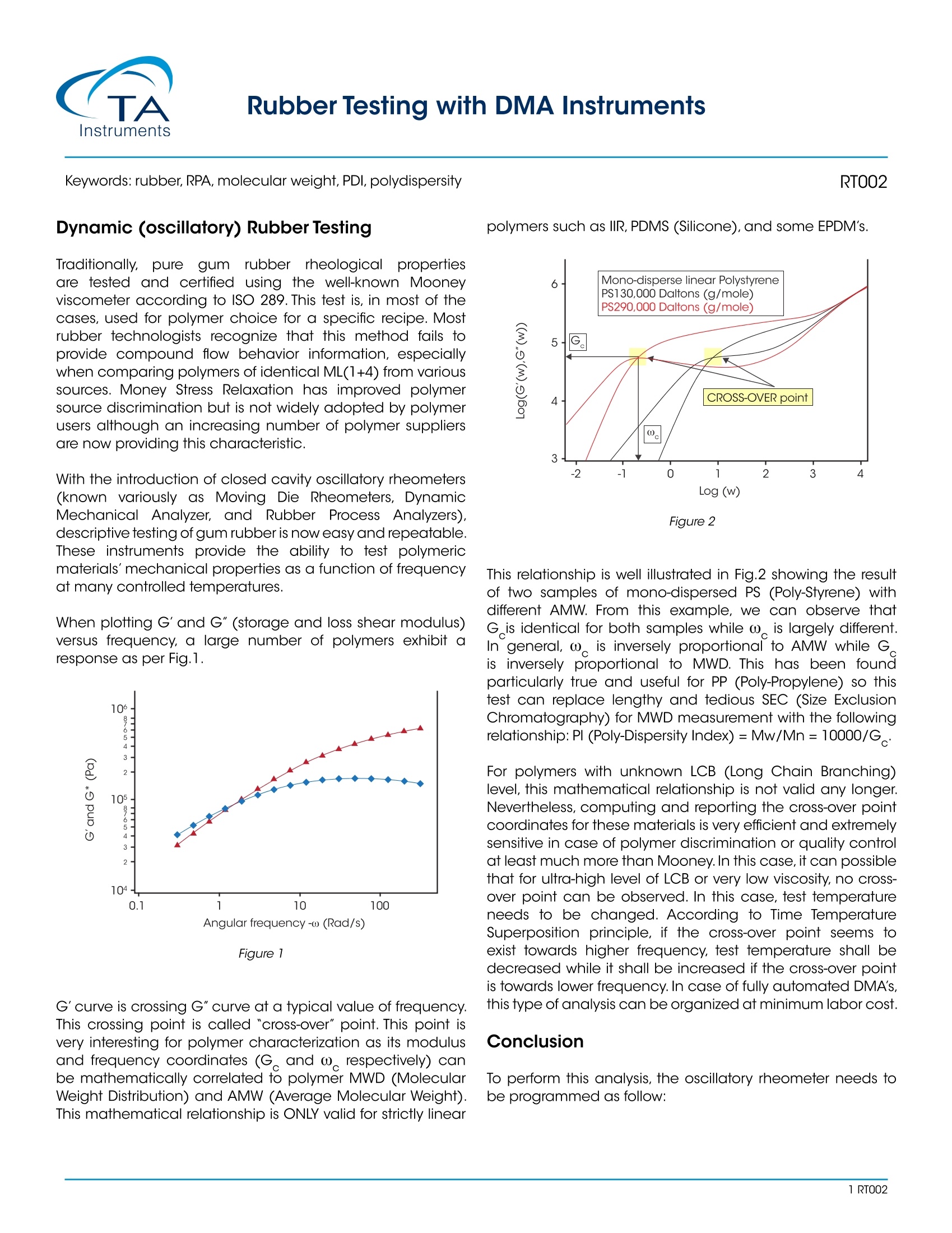

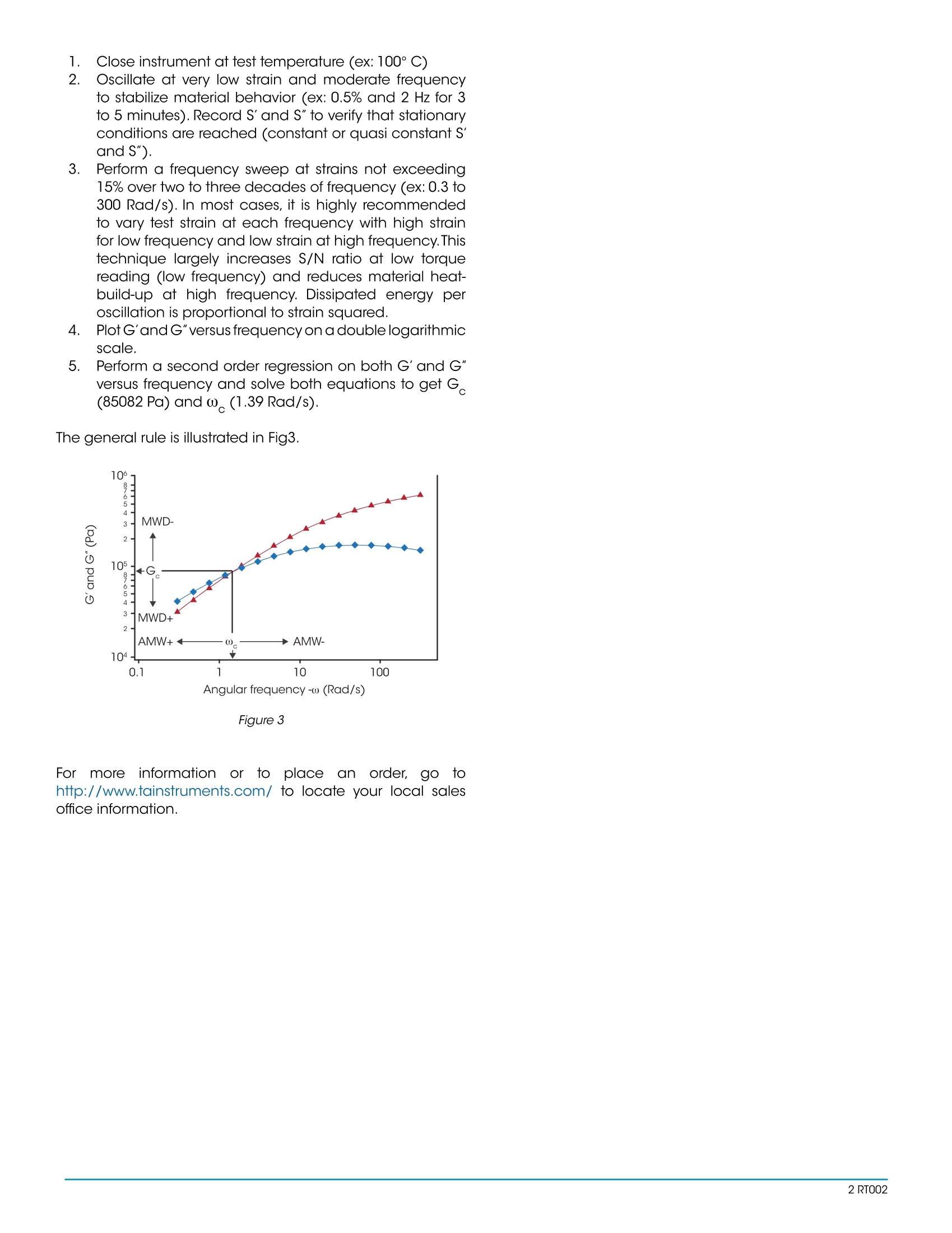

Rubber Testing with DMA Instruments Dynamic (oscillatory) Rubber Testing Traditionally,puregumrubberrrlrheologicalpropertiesare tested and certified using the well-known Mooneyviscometer according to ISO 289. This test is, in most of thecases, used for polymer choice for a specific recipe. Mostrubber technologists recognize that this method fails toprovide compound flow behavior information, especiallywhen comparing polymers of identical ML(1+4) from varioussources. Money Stress Relaxation has improved polymersource discrimination but is not widely adopted by polymerusers although an increasing number of polymer suppliersare now providing this characteristic. With the introduction of closed cavity oscillatory rheometers(known variously as Moving Die Rheometers, DynamicMechanical Analyzer, and Rubber Process Analyzers),descriptive testing of gum rubber is now easy and repeatable.These instruments provide the ability to test polymericmaterials'mechanical properties as a function of frequencyat many controlled temperatures. When plotting G'and G" (storage and loss shear modulus)versus frequency, a large number of polymers exhibit aresponse as per Fig.1. Figure 1 G'curve is crossing G"curve at a typical value of frequency.This crossing point is called "cross-over"point. This point isvery interesting for polymer characterization as its modulusand frequency coordinates (Gand ω respectively) canbe mathematically correlated to polymer MWD (MolecularWeight Distribution) and AMW (Average Molecular Weight).This mathematical relationship is ONLY valid for strictly linear polymers such as IIR, PDMS (Silicone), and some EPDM's. Figure 2 This relationship is well illustrated in Fig.2 showing the resultof two samples of mono-dispersed PS (Poly-Styrene) withdifferent AMW. From this example, we can observe thatG is identical for both samples while ω is largely different.In general, ωis inversely proportional to AMW while Gis inversely proportional to MWD. This has been foundparticularly true and useful for PP (Poly-Propylene) so thistest can replace lengthy and tedious SEC (Size ExclusionChromatography) for MWD measurement with the followingrelationship: PI (Poly-Dispersity Index)=Mw/Mn=10000/G. For polymers with unknown LCB (Long Chain Branching)level, this mathematical relationship is not valid any longer.Nevertheless, computing and reporting the cross-over pointcoordinates for these materials is very efficient and extremelysensitive in case of polymer discrimination or quality controlat least much more than Mooney. In this case, it can possiblethat for ultra-high level of LCB or very low viscosity, no cross-over point can be observed. In this case, test temperatureneeds to be changed. According to Time TemperatureSuperposition principle, if the cross-over point seems toexist towards higher frequency, test temperature shall bedecreased while it shall be increased if the cross-over pointis towards lower frequency. In case of fully automated DMA's,this type of analysis can be organized at minimum labor cost. Conclusion To perform this analysis, the oscillatory rheometer needs tobe programmed as follow: 1.(Close instrument at test temperature (ex: 100°C)2 2.(Oscillate at very low strain and moderate frequencyto stabilize material behavior (ex: 0.5% and 2 Hz for 3to 5 minutes). Record S'and S"to verify that stationaryconditions are reached (constant or quasi constant S'andS"). 3. Perform a frequency sweep at strains not exceeding15% overtwo to three decades of frequency (ex: 0.3 to300 Rad/s). In most cases, it is highly recommendedto vary test strain at each frequency with high strainfor low frequency and low strain at high frequency.Thistechnique largely increases S/N ratio at low torquereading (low frequency) and reduces material heat-build-up at high frequency. Dissipated energy peroscillation is proportional to strain squared. 4. Plot G'andG"versus frequency on a double logarithmicscale. 5. Perform a second order regression on both G'and G"versus frequency and solve both equations to get G(85082 Pa) and0(1.39Rad/s). The general rule is illustrated in Fig3. Figure 3 For moreinformation or to place an order, go tohttp://www.tainstruments.com/ to locate your local salesoffice information. RTO Traditionally, pure gum rubber rheological properties are tested and certified using the well-known Mooney viscometer according to ISO 289. This test is, in most of the cases, used for polymer choice for a specific recipe. Most rubber technologists recognize that this method fails to provide compound flow behavior information, especially when comparing polymers of identical ML(1+4) from various sources. Money Stress Relaxation has improved polymer source discrimination but is not widely adopted by polymer users although an increasing number of polymer suppliers are now providing this characteristic.

确定

还剩1页未读,是否继续阅读?

TA仪器为您提供《橡胶中流变特性检测方案(动态热机械)》,该方案主要用于橡胶制品中流变特性检测,参考标准--,《橡胶中流变特性检测方案(动态热机械)》用到的仪器有

相关方案

更多

该厂商其他方案

更多