方案详情

文

Starches are natural products used most extensively as thickening agents in the food industry, but are also widely employed in the adhesives, paper coatings, wood, packaging, and pharmaceutical industries. A fundamental rheological measurement conducted routinely on starches is the evaluation of the gelatinization process. This is accomplished by measuring the viscosity of the starch suspension, while heating and cooling under specific testing conditions. The resultant curve, referred to as the pasting curve, yields important starch performance parameters, including the pasting temperature, peak viscosity, holding strength, and final viscosity.

方案详情

pPLICATI (o N N oTEOO / JANUARY 2004·AMERICAN LABORATORY Starches are natural products used most exten-sively as thickening agents in the food industry,but are also widely employed in the adhesives,paper coatings, wood, packaging, and pharma-ceutical industries. A fundamental rheologicalmeasurement conducted routinely on starches isthe evaluation of the gelatinization process. Thisis accomplished by measuring the viscosity ofthe starch suspension, while heating and coolingunder specific testing conditions. The resultantcurve, referred to as the pasting curve, yieldsimportant starchperformanceparameters,including the pasting temperature, peak viscos-ity, holding strength, and final viscosity. The Starch Pasting Rheometer (SPR) (TAInstruments) is a standalone instrument based onAR1000 technology (TA Instruments). Combinedwith Rheology Navigator scripted software (TAInstruments), the rheometer is an effective solutionfor the enhanced routine quality control evaluationof starches. Complementing this is the StarchPasting Cell (SPC) (TA Instruments), a SmartSwapTM option for the research-grade AR2000rheometer (TA Instruments). The traditional viscometric test geometries, suchas cone and plate, parallel plate, and concentriccylinders, are not well suited for starch charac-terization because these dispersions require con-tinuous mixing during the measurement to pre-vent sedimentation of the starch granules. Forthis reason, the instruments that have been usedfor characterizing starch (for example, the amy-lograph and the Rapid Viscosity Analyzer [RVA])measure the torque of the mixing element in a Figure 1 shows a cross-section of the pasting cellwith the impeller in place. Heating is throughresistive elements placed concentrically to thecup; cooling is through water carried in a helicalconduit in close proximity to the cup’s outerwalls. Flow is controlled through relays placedupstream of the cup. The maximum temperatureramp heating rate is 15°℃ per min, and the cool-ing rate is 30°C per min. The temperature is readby a Pt 100 probe in close thermal contact withthe cup bottom. FigureI Cross-section of pasting cell with impeller in place. To enhance the quality of starch measurements, the mixing chamber hasbeen redesigned to minimize moisture loss (which is also of concern duringmeasurements) and is mounted onto the AR series rheometers (TAInstruments, New Castle, DE), allowing for systemic analysis and rheolog-ical characterization. Standard rheological methods based on steady, tran-sient, and oscillatory measurements are offered to evaluate starch duringthe gelatinization process as well as in the final product. The starch cell uses a nonstandard testing geom-etry (mixer element) to measure the rheologicalparameter such as viscosity and modulus in transient and oscillatory test-ing modes. A special evaluation of the geometry coefficients provides adata analysis in terms of correct shear rate and stress for this nonvisco-metric flow geometry. Mr. Franck is a Manager, Application Development Rheology, TA Instruments, Max Planck Strasse11, 63755 Alzenau, Germany; tel.: +49 6023964725; fax: +49 6023964777; e-mail:afranck@tainstruments.com. Starches are natural products used most extensively as thickening agents in the food industry, but are also widely employed in the adhesives, paper coatings, wood, packaging, and pharmaceutical industries. A fundamental rheological measurement conducted routinely on starches is the evaluation of the gelatinization process. This is accomplished by measuring the viscosity of the starch suspension, while heating and cooling under specific testing conditions. The resultant curve, referred to as the pasting curve, yields important starch performance parameters, including the pasting temperature, peak viscosity, holding strength, and final viscosity.

确定

还剩1页未读,是否继续阅读?

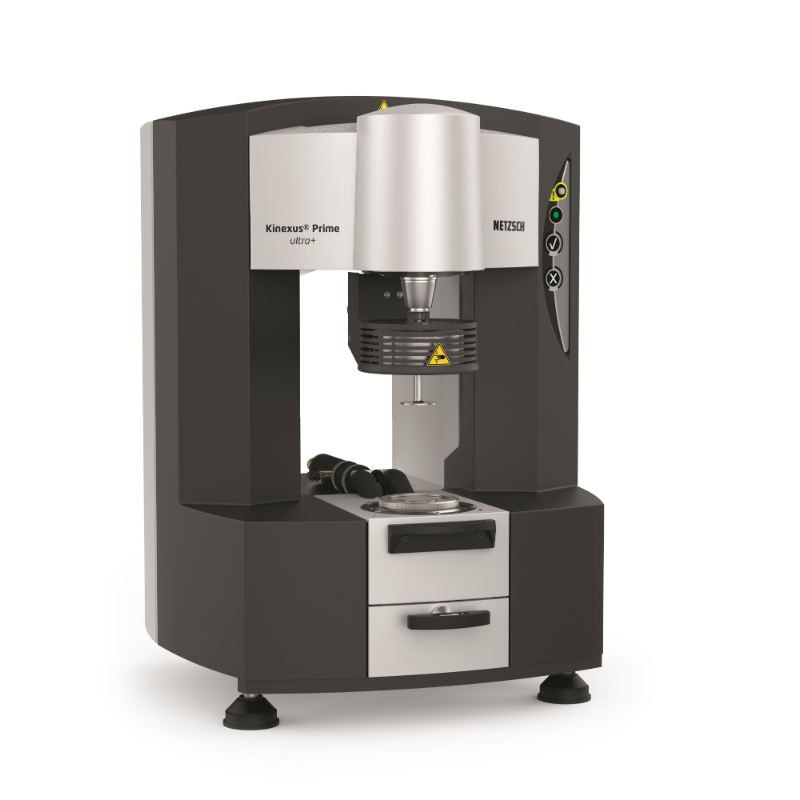

TA仪器为您提供《淀粉中黏弹性检测方案(流变仪)》,该方案主要用于淀粉及淀粉制品中理化分析检测,参考标准--,《淀粉中黏弹性检测方案(流变仪)》用到的仪器有TA仪器ARES-G2 高级流变仪

推荐专场

相关方案

更多