在本方案中,热障涂层材料的平均线膨胀系数测量采用的是光学投影法热膨胀仪,测试温度范围为室温~1600K,气氛为空气。测试试样为矩形棒状,尺寸为3×4×15mm,测试15mm长度方向上的热膨胀。

方案详情

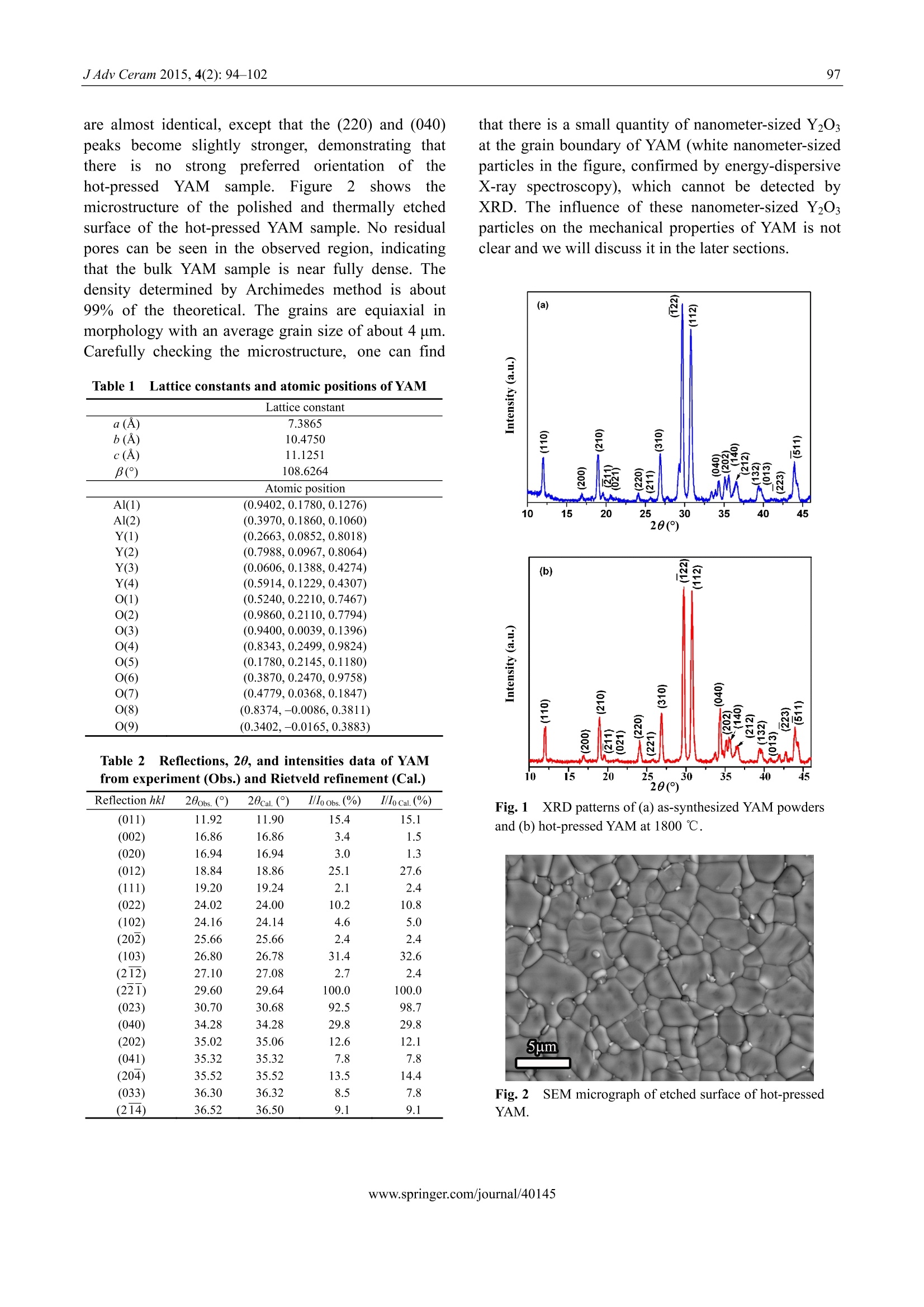

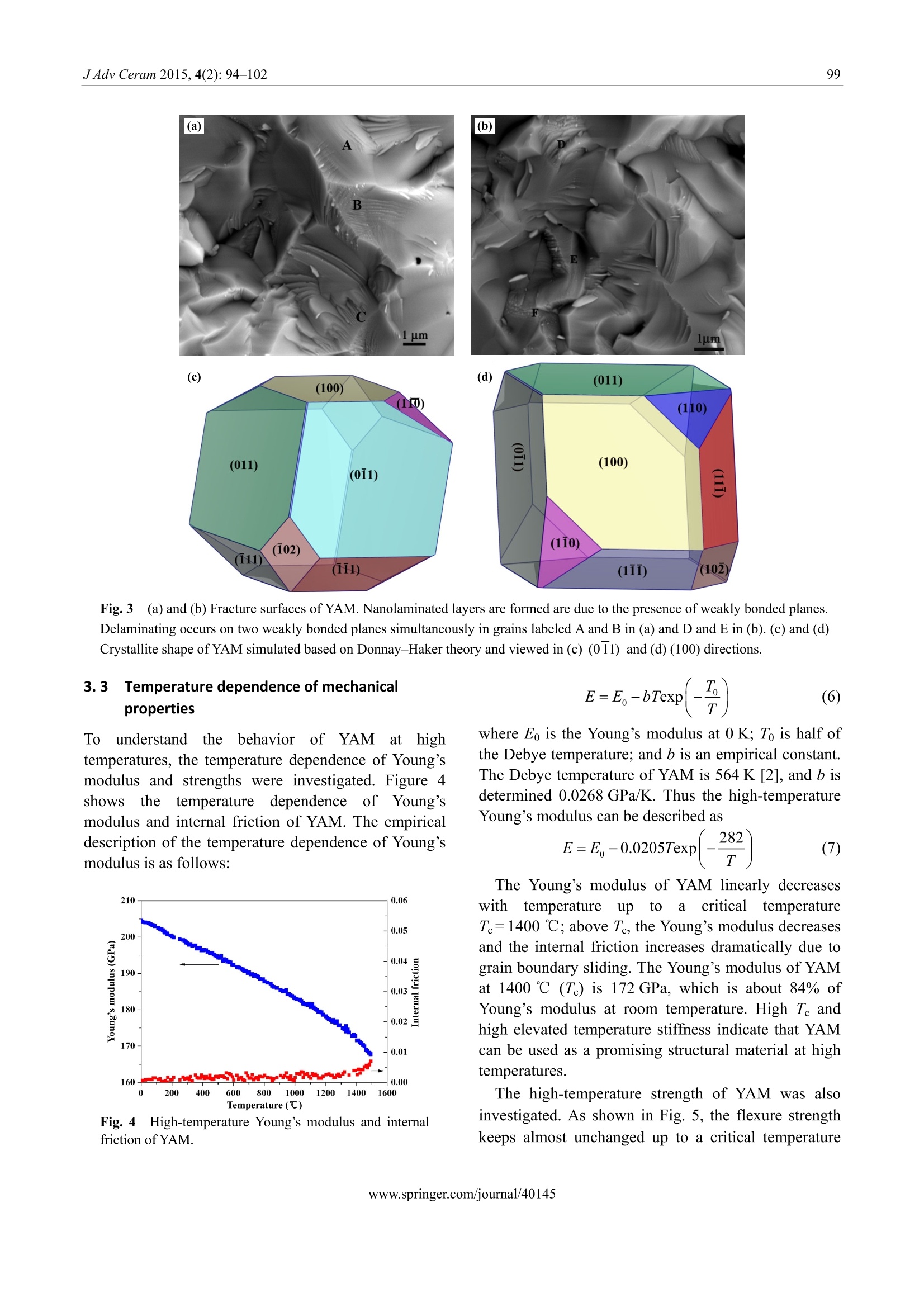

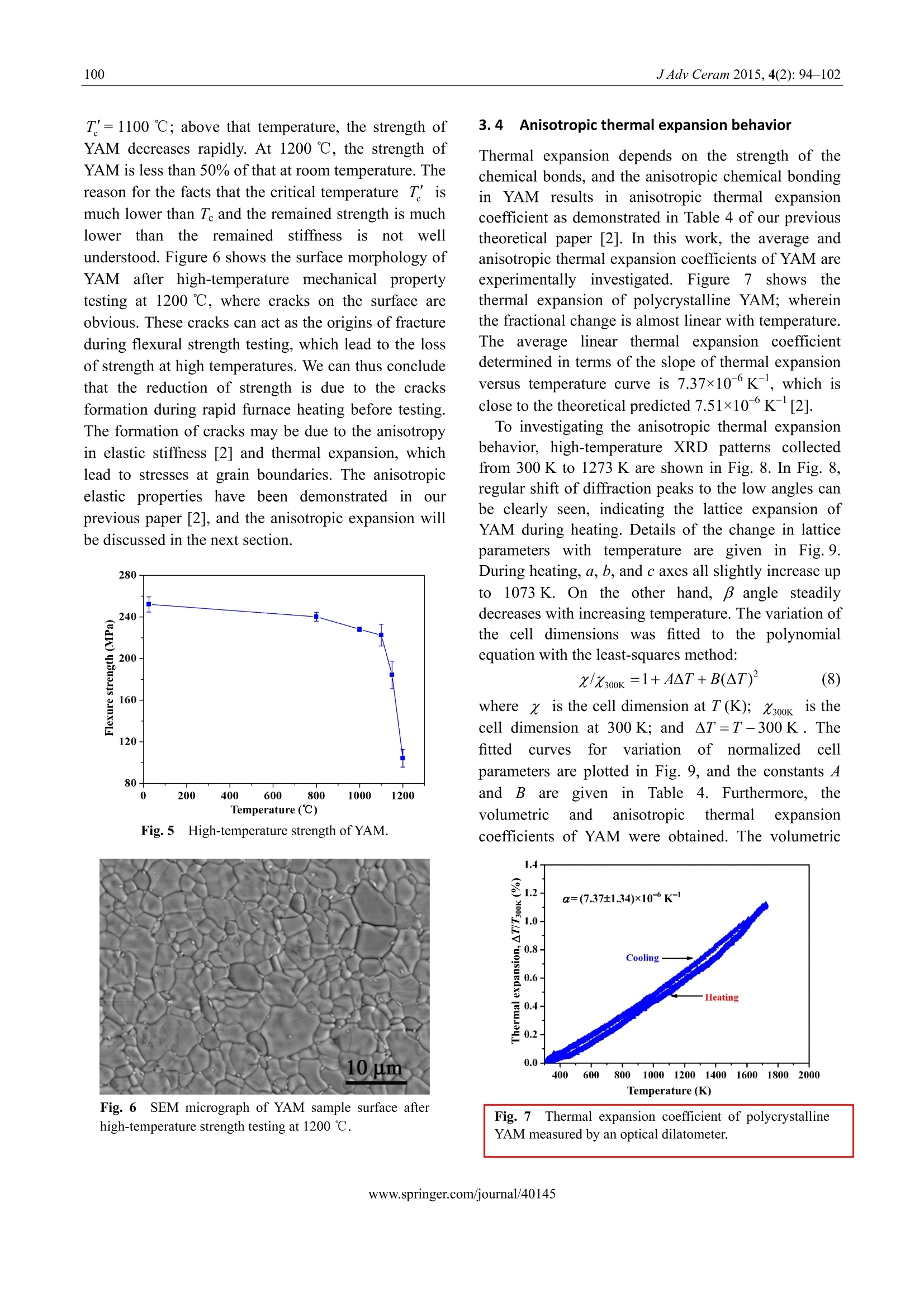

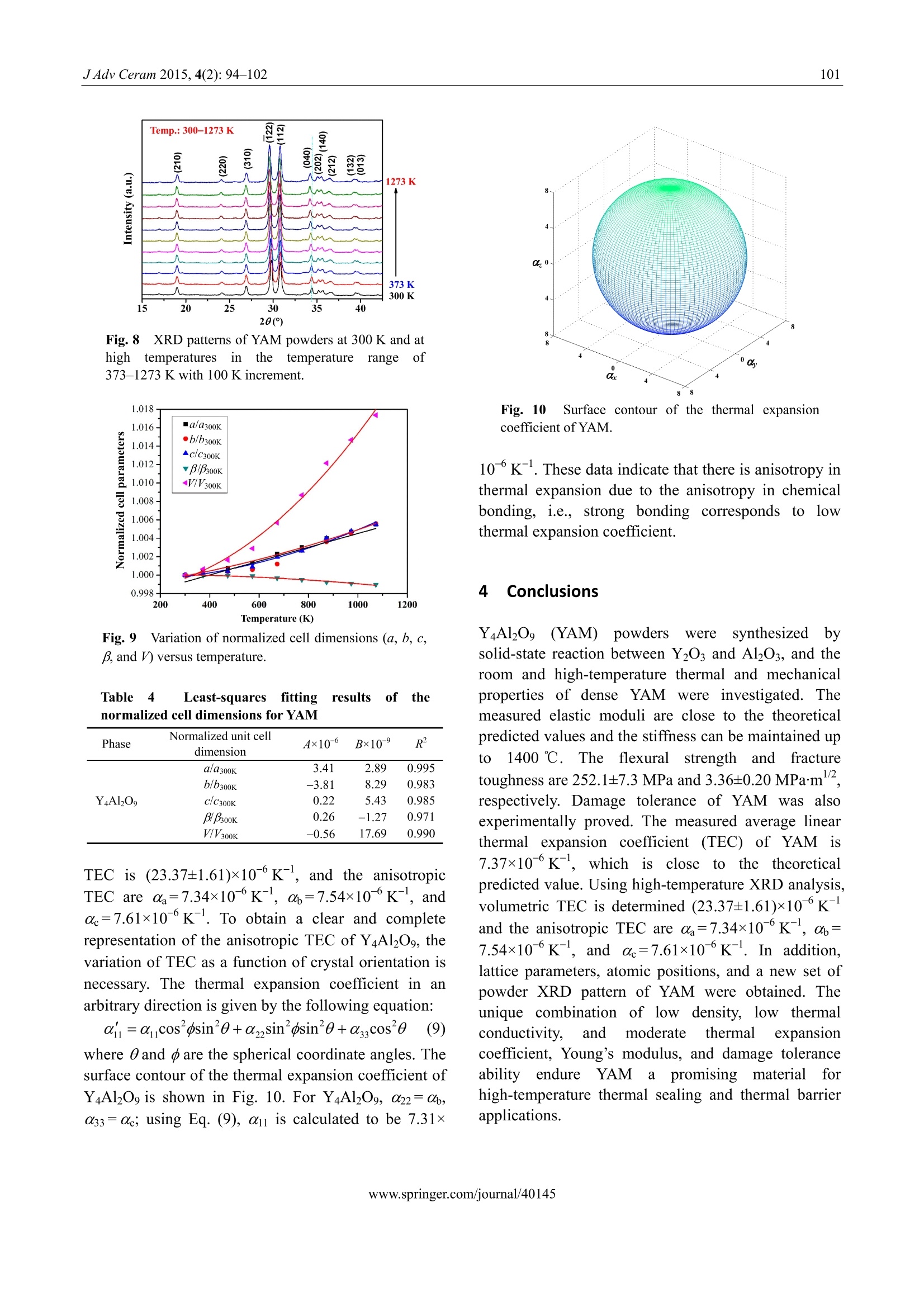

Journal of Advanced CeramicsISSN 2226-4108CN 10-1154/TQ2015,4(2):94-102DOI: 10.1007/s40145-015-0141-5Research Article J Adv Ceram 2015,4(2):94-10295 Preparation, mechanical, and thermal properties of a promisingthermal barrier material:YAl,0, Yanchun ZHOU*, Xinpo LU, Huimin XIANG, Zhihai FENG Science and Technology of Advanced Functional Composite Laboratory, Aerospace Research Institute ofMaterialsand Processing Technology,No. 1 South Dahongmen Road, Beijing 100076, China Received: January 26, 2015; Accepted: February 02, 2015 C The Author(s) 2015. This article is published with open access at Springerlink.com Abstract: In our previous work, anisotropic chemical bonding, low shear deformation resistance,damage tolerance ability, low thermal conductivity, and moderate thermal expansion coefficient ofY4Al209 (YAM) were predicted. In this work, phase-pure YAM powders were synthesized bysolid-state reaction between Y203 and Al2O3 and bulk YAM ceramics were prepared by hot-pressingmethod. Lattice parameters and a new set of X-ray powder diffraction data were obtained by Rietveldrefinement. The mechanical and thermal properties of dense YAM ceramics were investigated. Themeasured elastic moduli are close to the theoretical predicted values and the stiffness can bemaintained up to 1400℃. The flexural strength and fracture toughness are 252.1±7.3 MPa and3.36±0.20MPam, respectively. Damage tolerance of YAM was also experimentally proved. Themeasured average linear thermal expansion coefficient (TEC) of YAM is 7.37×10K, which is veryclose to the theoretical predicted value. Using high-temperature X-ray diffraction (XRD) analysis,volumetric TEC is determined (23.37±1.61)×10Kand the anisotropic TEC are oa=7.34×10K-,0=7.54×10K-,and dg=7.61×10-K-. Keywords: Y4Al2O9; X-ray diffraction (XRD) pattern; mechanical properties; thermal expansion;damage tolerance 1 Introduction Previoustheoretical1-3] and experimental[4,5]investigations have demonstrated that Y4Al209 (YAM)has a unique combination of high melting point(2020℃), low density (4.44 g/cm’), lowhigh-temperature thermal conductivity (the minimumthermal conductivity is 1.13 WmK),relative lowYoung’s modulus (191 GPa), and moderate thermalexpansion coefficient (7.51×10K-l) and damagetolerant ability, which endure it as a prospective ( * Corresponding author. ) materialfor thermal1and/or environmentalrbarriercoating a p p li c a t io n s . 3 However. besides Young’smodulus and thermal conductivity, other mechanicaland thermal properties have not been experimentallyexplored..Irln addition.,tthe experimental latticeparameters are from high-temperature neutrondiffraction study at 1791 K, which are obviously largerthan the room temperature data. Since these propertiesare indispensable for the selection and application ofYAM as aa candidate material for thermalbarrieroating (TBC) aapprplications,it is necessaryttosystematically investigate the structural, thermal, andmechanical properties of YAM. Theipurposeeof this work is toprovidee the experimentaldetermined lattice parameters andmechanical and thermal properties of dense phase-pureYAM. To achieve such a goal, single-phase YAMpowders were prepared by solid-state reaction betweenY203 and Al203 first. Then near fully dense YAMsamplewas prepareddbby hot-pressing tltheYAMpowders at1800℃. The lattice constants, atomicpositions, and a new set of X-ray powder diffractionpatterns were obtained by Rietveld refinement. Theaverage linear thermal expansion coefficient (TEC)was measured by using an optical dilatometer, and theanisotropic thermal expansion coefficients at differentdirections were determined by high-temperature X-raydiffraction. The Vickers hardness, flexural strength,fracture toughness, and dynamic Young’s moduluswereealsoio measured.Theseieifundamental dataare helpful for promoting the applications of YAMisiaTBC materiall or high-temperature structuralComponent. 2 Experimental procedure To investigate the thermal and mechanical propertiesof YAM, near fully dense and phase-pure samples areneeded. These samples were prepared by the followingsteps. First. phase-pure YAM powders weresynthesized by a solid-state reaction method usingyttria powders (Y203, 99.9% purity; Yuelong ReagentCo., Shanghai, China) and alumina powders (Al2O3.99.9% purity; Yuelong Reagent Co., Shanghai, China)as starting materials. To synthesize single-phase YAM,powders with the mole ratio of Y203: Al203=2:1 weremixed and then calcined at 1500℃ for 2 h in air. BulkYAM samples with 50 mm in diameter were preparedby hot-pressing the as-synthesized YAM powders at1800℃ under a pressure of 30 MPa for 60 min in aflowing Ar atmosphere. Phase compositions of the as-synthesized YAMpowders and bulk YAM samples were identified by astep-scanningxX-ray(diffractometerr((Brook D8:Germany) with Cu Ko radiation (a=1.54178 A). Thelattice parameters, atomic positions, 20, hkl, and peakintensities of YAM were refined by the Rietveldmethod [6,7] (Topas software, Bruker, Germany). Thereliability factors R and Rwp were calculated by (2) where w=1/Iexp(20) is a weighting function; c theconstant scaling factor optimized to obtain the lowestvalue of:ARw;; lexp(20) the measured experimentalspectrum;Yack (20,) the background intensity of themeasuredspectrum; aand(20)the; simulateddiffraction iintensity withoutitthiee backgroundcontribution. The intensity was calculated by where b(20)is the background intensity; S thescaling factor; Lk contains the Lorentz polarization andmultiplicity factors; othe profile function; Pk thepreferred orientation function; Ak absorption factor;and F the structure factor. The index k presents Millerindices for the Bragg reflections. Microstructure observations were conducted in anApollo 300)sscanning electron microscope (SEM;CamScan Co... EIngland)..Before microstructureinvestigation,the samples were polished and thermallyetched at 1100℃ for 1 h in air. The density of the bulk YAMceramics wasmeasured by the Archimedes method. The Vickershardness was measured at a load of 10 N with a dwelltime of 15 s. The flexural strength was determined viaan three-point bending test method using samples withthe dimension of 3 mm×4mm×36mm. The fracturetoughness Kic was measured using single-edge notchbeamn(SENB) specimens with the dimension of4 mm×8mm×36mm. The notch with the size of4 mm in length and 0.10 mm in width was made by adiamond coated wheel slotting. The crosshead speedwas 0.5mm/minaand 0.05 mm/minfor flexuralstrength andd ifracturee toughness measurement.respectively. The elastic modulus was evaluated by theimpulse excitation technique usingarectangularsample with the dimension of 3 mmx15 mmx40 mm.The sample was given a mechanical impulse, and thevibration was detected by a microphone and thenanalyzed with the resonance frequency and dampinganalyzer (ResonanceFrequency and DampingAnalyzer, IMCE, Diepenbeek, Belgium), which is astandard testing method for dynamic Young’s modulus,shear modulus, and Poisson’s ratio by sonic resonance. The Young’s modulus was calculated from the flexural resonate frequency,fr, according to ASTM E 1876-978]: with E the dynamic elastic modulus; fe the fundamentalflexural resonant frequency; m, w, L, and t the mass,width, length, and thickness of the specimen. Ti is acorrection factor, depending on the Poisson’s ratio uand the thickness/length ratio t/L. Temperature dependence of Young’s modulus andinternal friction of YAM ceramics was measured in agraphite furnace at a heating rate of 4 ℃/min inflowing argon atmosphere. The sample was suspendedin the nodes of their first bending vibration mode(0.024L apart from both ends of rectangular beam,where L is the sample length). The vibration signalcaptured by a laser vibrometer was analyzed with thefrequency and damping analyzer [9]. The internalfriction corresponding to the flexural vibration modewas calculated asg =k/(nf), where kis theexponential decay parameter of the amplitude of theflexural vibration component. Detailed testing processcan be found in our previous work [10]. The average linear thermal expansion coefficient(TEC) of YAM was obtained from the temperaturedependent changes of the length of the specimen fromroom temperature to 1600 K in air by using a verticalhigh-temperature optical dilatometer (ODHT-1600-50,Expert System Solutions, Modena, Italy). Thespecimen usedwas a rectangular bar with thedimension of 3 mm in width, 4 mm in length, and15 mm in height. The height direction is perpendicularto the hot-pressing direction. A sharp edge was madeon top end of the height of the test specimen. Duringtesting, the sample was put in a furnace using Pt asheating element and the top sharp end of the specimenwas aligned by one optical path, and the sample holderwas focused by another optical path, which was takenas a reference beam to correct the mechanical drift ofthe instrument. The data were continuously collectedby a personal computer during heating at a rate of5 K/min. To investigate the anisotropic thermal expansionbehavior of YAM, high-temperature X-ray diffraction(XRD) was performed on YAM powder samplesutilizing Cu Ka radiation with a step size of 0.02°at scanning rrate of 11 ()/min..Thedata werecollected from a high-temperature diffractometer (X’ Pert-ProMPD; PANalytical, Almelo, the Netherland) in20 range between15° and 45° during a stepwiseheating to 1273 K with a step width of 100 K. Theheating rate was 10 K/min and the dwell time was15 min before each test. The XRD patterns for each100 K interval in temperature were refined using theRietveld method (TOPAS software; Bruker, Germany)anddthellatticeparameters wereeobtained. Theanisotropic TECs of YAM were determined by fittingthe lattice constants versus temperature curves. 3 Results and discussion 3. 1 Phase composition and microstructure The XXRD patterni of Y4Al209 ((YAM)ppowdersprepared by solid-state reaction method at 1500℃ for2h is shown in Fig. 1(a). One can see from the figurethat the as-prepared YAM is phase-pure without anyimpurities detectable by XRD. Since the previousdetermined lattice parameters and atomic positions arefrom high-temperature neutron diffraction at 1791 K[11], which are different from the room temperaturedata due to thermal expansion, Rietveld refinementwas performed to obtain the lattice constants, atomicpositions, and intensities of YAM. The lattice constantsare a=7.3865 A, b=10.4750 A, c=11.1251 A, andB=108.6264°. The final reliability factors for Rietveldrefinement are Rp=5.89% and Rwp=8.39%. The latticeconstants are slightly smaller than the previouslyneutron diffraction determined values, which is due tothe temperature caused expansion in previous work[11]. The atomic positions are given in Table 1. Sincethese data are obtained at room temperature, it is morereliable and useful in further phase identification andstructure analysis. The reflections and intensities forthe experimental and calculated XRD patterns arelisted in Table 2. It is seen from Table 2 that thecalculated peak positions are agreed well with theobserved ones. The intensities are also agreed with theexperimental observed ones. Thus this new set of XRDdata1isreliable anduuseful forrffurther phaseidentifications. Figure 1(b) shows the XRD pattern of the bulk YAMhot-pressed at 1800℃. It is obvious that the bulkYAM sample is also phase-pure, which indicates thatYAM is stablewithout cdecompositionn atthightemperaturessevennup tto 1800℃. The relativeintensities of the reflections in Fig. 1(a) and Fig. 1(b) are almost identical, except that the (220) and (040)peaks become slightly stronger, demonstrating thatthere is nostrongpreferred orientation of thehot-pressedYAMsample. Figure 2shows tlthemicrostructure of the polished and thermally etchedsurface of the hot-pressed YAM sample. No residualpores can be seen in the observed region, indicatingthat the bulk YAM sample is near fully dense. Thedensity determined by Archimedes method is about99% of the theoretical. The grains are equiaxial 99700inmorphology with an average grain size of about 4 um.Carefully checking the microstructure, one can find Table 1 Lattice constants and atomic positions of YAM Lattice constant a(A) 7.3865 b (A) 10.4750 c (A) 11.1251 β() 108.6264 Atomic position Al(1) (0.9402,0.1780,0.1276) Al(2) (0.3970,0.1860,0.1060) Y(1) (0.2663,0.0852,0.8018) Y(2) (0.7988, 0.0967, 0.8064) Y(3) (0.0606,0.1388,0.4274) Y(4) (0.5914,0.1229,0.4307) 0(1) (0.5240,0.2210,0.7467) 0(2) (0.9860,0.2110, 0.7794) O(3) (0.9400,0.0039,0.1396) O(4) (0.8343,0.2499,0.9824) 0(5) (0.1780,0.2145,0.1180) 0(6) (0.3870,0.2470,0.9758) O(7) (0.4779,0.0368,0.1847) 0(8) (0.8374,-0.0086,0.3811) O(9) (0.3402,-0.0165, 0.3883) Table 2 Reflections, 20, and intensities data of YAMfrom experiment (Obs.) and Rietveld refinement (Cal.) Reflection hkl 20obs.() 20cal.(°) I/Io Obs.(%) I/Io Cal.(%) (011) 11.92 11.90 15.4 15.1 (002) 16.86 16.86 3.4 1.5 (020) 16.94 16.94 3.0 1.3 (012) 18.84 18.86 25.1 27.6 (111) 19.20 19.24 2.1 2.4 (022) 24.02 24.00 10.2 10.8 (102) 24.16 24.14 4.6 5.0 (202) 25.66 25.66 2.4 2.4 (103) 26.80 26.78 31.4 32.6 (212) 27.10 27.08 2.7 2.4 (221) 29.60 29.64 100.0 100.0 (023) 30.70 30.68 92.5 98.7 (040) 34.28 34.28 29.8 29.8 (202) 35.02 35.06 12.6 12.1 (041) 35.32 35.32 7.8 7.8 (204) 35.52 35.52 13.5 14.4 (033) 36.30 36.32 8.5 7.8 (214) 36.52 36.50 9.1 9.1 that there is a small quantity of nanometer-sized Y203at the grain boundary of YAM (white nanometer-sizedparticles in the figure, confirmed by energy-dispersiveX-ray spectroscopy), which cannot be detected byXRD. The influence of these nanometer-sized Y203particles on the mechanical properties of YAM is notclear and we will discuss it in the later sections. Fig.1 XRD patterns of (a) as-synthesized YAM powdersand (b) hot-pressed YAM at 1800℃. Fig.2SEM micrograph of etched surface of hot-pressedYAM 3. 2 Room temperature mechanical properties The measured mechanical and thermal properties ofY4Al2O9 are summarized in Table 3. The measuredroom temperature Young’s modulus E and shearmodulus G are 204 GPa and 80 GPa, respectively,which are slightly higher than but still close to thetheoretical predicted values of 191 GPa and 76 GPa,respectively. The higher Young’s modulus can beattributed to the presence of a small amount of Y203 atthe grain boundary, because Y20s has higher Young’smodulus. The measured Poisson’s ratio u is 0.27.which is also close to the theoretical predicted value of0.26.).Theieconsistencybetween the theoreticalcalculated and the experimental measured elasticproperties demonstrates the high reliability of ourdensity functional theory (DFT) calculations [2]. In ourprevious work [2],YAM was predicted to be a damagetolerant ceramic based on the low Pugh’s ratio G/B=0.576.uUsing theexperimentally measuredshearmodulus and bulk modulus, the Pugh’s ratio iscalculated to be G/B=0.530, which is also close to thetheoretical value, confirming the damage tolerance ofYAM. The measured Vickersshhardness offYAM is11.02±0.33 GPa, which almost equals to the average ofthe hardness of Y203(6.8 GPa) and Al2O3 (21 GPa)and is close to the theoretical value of 10.2 GPapredicted using the empirical model of Chen et al. [12].The flexural strength and fracture toughness were alsomeasured. The flexural strength is 252.1±7.3 MPa andthe fractureetoughness is 3.36±0.20MPa·mRelatively high fracture toughness to strength ratioindicates the damage tolerance ability of YAM. Bao etal.[13] proposed an equation as a quantitative measureof damage tolerance: High D. indicates good damage tolerance. Putting themeasured hardness, Young’s modulus, strength, andfracture toughness data into Eq. (5), the damagetolerance of YAM is determined 0.25. This value isslightly lower than those of β-Yb2Si207(0.39) [14] andy-Y2Si2O7 (0.37) [15], but still warants the damagetolerance of YAM. To understand the mechanism of damge tolerance,the fracture surfaces were examined by SEM. Figure 3shows the fracture surfaces of YAM; wherein layeredcharacteristics are obvious, which are similar to thoseobserved on the fracture surfaces of TigSiC2[16]andother layered ternary carbides and nitrides [17-20].The delamination of YAMgrains results in theformation of nanolaminated layers on the fracturesurfaces, such as the area labeled A, B, and C inFig. 3(a) and D, E, and F in Fig. 3(b). The formation ofnanolayered layers on the fracture surfaces is mainlydue to anisotropic bonding and the presence of weaklybonded atomic planes [2]. We have shown throughDFT calculations that the anisotropic elastic moduli areEx=208 GPa,E =179 GPa, and E =176 GPa. Themaximumnaandd minimumYoung’smodulus are210 GPa and 170 GPa, respectively. The high- andlow-directions correspond to the high- andlow-fracture-energy directions. Thus, shear-inducedsliding along the low Young’s modulus directions like(011)/[011] or (011)/[011]lfforms nanolayeredcleavage steps on the fracture surfaces [2]. From thecrystal structure shown in our previous work [2] andthe crystallite shape of YAM simulated based on theDonnay-Haker theory [21-23], {011},{011}, and{100} planes are of morphological importance incrystal morphology of YAM. The crystallite shapesobserved by SEM in Fig. 2, Fig.3(a), and Fig. 3(b) areidentical to those viewed in different directions asshown in Fig. 3(c) and Fig. 3(d). The angle betweenthe weakly bonded (011) and (011) planes is 86.7°. Ingrains labeled A and B in Fig. 3(a) and D and E in Fig.3(b), delamination occurs on the two weakly bonded(011)and (011) planes simultaneously. Also thenanolaminated layers formed by shear-induced slidingalong the first weakly bonded planes ((011)/[011] or(011)/[011]) are “cut”by the second weakly bondedplanes ((011)/[011] or (011)/[011]). The formation ofnanolaminated grains and sliding of the nanometer-thickthin slabs along the weakly bonded planesconsumesenergy anddcontributesstto the damagetolerance of YAM [21. Table 3 Summary of mechanical and thermal properties of YAM o(MPa) Hv(GPa) Kic (MPam2) E (GPa) G (GPa) U TEC (10-K-) R.T. 1200℃ R.T. R.T. R.T. R.T. R.T. 300-1500 K 252.1±7.3 104.2±8.6 11.02±0.33 3.36±0.20 204 80 0.27 7.37 (d) Fig. 3 (a) and (b) Fracture surfaces of YAM. Nanolaminated layers are formed are due to the presence of weakly bonded planes.Delaminating occurs on two weakly bonded planes simultaneously in grains labeled A and B in (a) and D and E in (b). (c) and (d)Crystallite shape of YAM simulated based on Donnay-Haker theory and viewed in (c) (011) and (d) (100) directions. 3.3 Temperature dependence of mechanicalproperties Tounderstand thebehavior of YAM at hightemperatures, the temperature dependence of Young’smodulus and strengths were investigated. Figure 4shows thetemperaturedependenceof Young’smodulus and internal friction of YAM. The empiricaldescription of the temperature dependence of Young’smodulus is as follows: Fig. 4 High-temperature Young’s modulus and internalfriction of YAM. where Eo is the Young’s modulus at 0 K; To is half ofthe Debye temperature; and b is an empirical constant.The Debye temperature of YAM is 564 K [2], and b isdetermined 0.0268 GPa/K. Thus the high-temperatureYoung’s modulus can be described as The Young’s modulus of YAM linearly decreaseswith temperature up to acritical temperatureTe=1400℃; above Te, the Young’s modulus decreasesand the internal friction increases dramatically due tograin boundary sliding. The Young’s modulus of YAMat 1400℃(T) is 172 GPa, which is about 84% ofYoung’s modulus at room temperature. High Te andhigh elevated temperature stiffness indicate that YAMcan be used as a promising structural material at hightemperatures. The high-temperature strength of YAM was alsoinvestigated. As shown in Fig.5, the flexure strengthkeeps almost unchanged up to a critical temperature T=1100 ℃; above that temperature, the strength ofYAM decreases rapidly. At 1200 ℃, the strength ofYAM is less than 50% of that at room temperature. Thereason for the facts that the critical temperature Tismuch lower than Te and the remained strength is muchlower thanthe remainedstiffness is not wellunderstood. Figure 6 shows the surface morphology ofYAMafter high-temperature mechanicall1propertytesting at 1200 ℃, where cracks on the surface areobvious. These cracks can act as the origins of fractureduring flexural strength testing, which lead to the lossof strength at high temperatures. We can thus concludethat the reduction of strength is due to the cracksformation during rapid furnace heating before testing.The formation of cracks may be due to the anisotropyin elastic stiffness [2] and thermal expansion, whichlead to stresses at grain boundaries. The anisotropicelastic properties have been demonstrated in ourprevious paper [2], and the anisotropic expansion willbe discussed in the next section. Fig. 5High-temperature strength of YAM. Fig. 66SEM micrograph of YAM sample surface afterhigh-temperature strength testing at 1200 ℃. 3.4 Anisotropic thermal expansion behavior Thermal expansion depends on the strength of thechemical bonds, and the anisotropic chemical bondinginnYAM resultss in anisotropic thermal expansioncoefficient as demonstrated in Table 4 of our previoustheoretical paper [2]. In this work, the average andanisotropic thermal expansion coefficients of YAM areexperimentally iitnvestigated. Figure 7 showsthethermal expansion of polycrystalline YAM; whereinthe fractional change is almost linear with temperature.The average linear thermal expansion coefficientdetermined in terms of the slope of thermal expansionversus temperature curve is 7.37×10-K, which isclose to the theoretical predicted 7.51×10 °K[2]. To investigating the anisotropic thermal expansionbehavior, high-temperature XRD patterns collectedfrom 300 K to 1273 K are shown in Fig. 8. In Fig. 8,regular shift of diffraction peaks to the low angles canbe clearly seen, indicating the lattice expansion ofYAM during heating. Details of the change in latticeparameters with temperature are given in Fig. 9.During heating, a, b, and c axes all slightly increase upto01073 K. On the other hand, angle steadilydecreases with increasing temperature.The variation ofthe cell dimensions was fitted to the polynomialequation with the least-squares method: where x is the cell dimension at T(K); X300Kiis thecell dimension at 300K; and AT=T-300K. Thefittedcurves forrvariationofnormalized cellparameters are plotted in Fig. 9, and the constants Aand BaaregiveninTable FFurthermore, the4volumetric and anisotropicthermaiall expansioncoefficients of YAM were obtained. The volumetric Fig. 7 Thermal expansion coefficient of polycrystallineYAM measured by an optical dilatometer. Fig. 8 XRD patterns of YAM powders at 300 K and athightemperatures in the temperature range of373-1273 K with 100 K increment. Fig. 9 Variation of normalized cell dimensions (a, b, c,B, and V) versus temperature. Table 4 Least-squares fitting results of thenormalized cell dimensions for YAM Phase Normalized unit cell dimension a/a300K A×10° Bx10 R Y4A1209 3.41 2.89 0.995 b/b300K -3.81 8.29 0.983 c/C300K 0,22 5.43 0.985 B/B300K 0.26 -1.27 0.971 v/V300K -0.56 17.69 0.990 TEC is (23.37±1.61)x10K-, and the anisotropicTEC are 0a=7.34×10K-,06=7.54×10-K-, andc=7.61×10K. To obtain a clear and completerepresentation of the anisotropic TEC of Y4Al2O9, thevariation of TEC as a function of crystal orientation isnecessary. The thermal expansion coefficient in anarbitrary direction is given by the following equation: a=acos sin0+asin osin0+agcos0 9)where 0 and are the spherical coordinate angles. Thesurface contour of the thermal expansion coefficient ofY4Al2O9 is shown in Fig. 10. For Y4Al2O9, 022=0b,&33=Cc; using Eq. (9), on is calculated to be 7.31x 8 Fig. 10 Surface contour of the thermal expansioncoefficient of YAM. 10K-. These data indicate that there is anisotropy inthermal expansion due to the anisotropy in chemicalbonding, i.e., strong bonding corresponds to lowthermal expansion coefficient. 4 Conclusions Y4Al2Og9((YAM)I)powders weree synthesizedbbysolid-state reaction between Y203 and Al2O3, and theroom and high-temperature thermal and mechanicalproperties of dense YAM4 were investigated. Themeasured elastic moduli are close to the theoreticalpredicted values and the stiffness can be maintained upto 1400℃. Thee flexural strengthand fracturetoughness are 252.1±7.3 MPa and 3.36±0.20 MPam,respectively. Damage tolerance of YAM was also,experimentally proved. The measured average linearthermalexpansion coefficient (TEC) of YAMis7.37×10-K-, which is5(closeeto) thee theoreticalpredicted value. Using high-temperature XRD analysis,volumetric TEC is determined (23.37±1.61)×10-K-and the anisotropic TEC are a=7.34×10K,o=7.54×10K-, and o=7.61×10K. In addition,lattice parameters, atomic positions, and a new set ofpowder XRD pattern of YAM were obtained. Theunique combination of low density, low thermalconductivity,1, and imoderate thermall expansioncoefficient, Young’s modulus, and damage toleranceabilityendureYAM apromising materialforhigh-temperature thermal sealing and thermal barrierapplications. Acknowledgements This work was supported by the National OutstandingYoung Scientist Foundation for Y. C. Zhou under GrantNo. 59925208, and the National Natural ScienceFoundation of China under Grant Nos. 50832008 andU1435206. Open Access: This article is distributed under theterms of the Creative Commons Attribution Licensewhich permits any use, distribution, and reproductionin any medium, provided the original author(s) and thesource are credited. ( References ) ( [1 ]Z 2han X , Li Z , Liu B, et a l . T heoretical prediction of elasticstiffnes s and minimum l a ttice t hermal conductivity of Y3Al5O12, YAlO3 and Y4Al2Og. J Am C e ram Soc 2012, 95:1429-1434. ) ( [2] Zhou Y , X i ang H, Lu X, et al. Theoretical prediction o n mechanical and thermal properties of a promising thermalbarrier materi al :Y4Al20 9 . J Ad v Ceram 2015, DOI 10.1007/s40145-015-0140-6. ) ( [3] L i Z , L iu B , W ang JM, et al. F i rst-principle study o f pointdefects in stoichiometric and nonstoichiometric Y4AlOg. J Mater Sci Technol 2013, 29: 1161- 1 165. ) ( [41 Mah T-I, Petry MD. Eu tectic composition in the pseudobinary of Y4Al2Og and Y203. J Am C e ram Soc 1992,75:2006-2009. ) ( [5] Zhou X, Xu Z , F a n X , e t al. Y4Al2O9 ceramics as a novelthermal b arrier coating material for h i gh temperatureapplications. Mater Lett 2014,134:146-1 4 8. ) ( [6] R ietveld H M. L i ne profiles of neutron powder-diffraction peaks f or s tructure r efinement. A cta C r yst 1967, 22:151 - 152. ) ( [7] Rietveld HM. A profile refinement method for nuclear and magnetic structures. J Appl Cryst 1969, 2: 65-71. ) ( 81 ASTM I nt ernational. ASTM E 1 876-97 Standard te s t method for dynamic Young’s modulus, shear modulus, a ndPoisson’s r atio b y impulse excitation of vi b ration. W e st Conshohocken, PA, 1998. ) ( [9 ] R o ebben G, Bollen B, Brebels A, et al . I m pulse excitation apparatus t o m easure resonant f r equencies, elastic moduli, and internal friction at room and high temperature. Rev Sci Instrum 1997, 68:4511. ) ( [10] He L -F, B ao Y-W, Wang J-Y, et al . M e chanical andthermophysical p roperties of Zr-Al-Si-C ceramics. J Am Ceram Soc 2009, 92: 445-451. ) ( [11] Yamane H, Shimada M , Hunter BA. H i gh t e mperature neutron d iffraction study of Y4Al2Og. J Solid State Chem1998, 141:466-474. ) ( [12] Chen X-Q, N iu H, Li D, e t al. M odeling hardness of polycrystallin e materials and b ulk k m etallic : g glasses. Intermetallics 20 1 1 , 19:1275 - 1281. ) ( [13] Bao YW, Hu CF, Zhou YC. Damage tolerance of nanolayer grained ceramic a nd q u antitative e stimation. M ater S c i Tech 2006.22: 227-230. ) ( [141 Z hou Y - C, Zhao C, Wa n g F, et al. T h eoretical prediction and . experimental i nvestigationinon the t hermaland mechanical p roperties of bulk B-Yb2Si207. J Am C e ramSoc 2013, 96:3891-3900. ) ( [ 1 5] Sun Z , Zhou YC, W a ng JY, et al.y-Y2SizOz, a machinablesilicate ceramic: Mechanical properties and machinability. J Am Ceram Soc 2007,90: 2 535-2541. ) ( [16] Zhou Y, Sun Z. Microstructure and mechanism of damagetolerance f or Ti,SiC, bulk ceramics. Mater Res Innov 1 9 99,2:360-363. ) ( [17] Barsoum MW, El-Raghy T, Ali M. P r ocessing and characterization of T izAlC, T izAlN, a n d TizAlC0.5N0.5. Metall Mater Trans A2000,31:1857-1865. ) ( [18] Li F, Liu B, Wang J, et al. Hf AlN: A novel layered ternary ceramic with excellent damage tolerance. J Am Ceram Soc2010,93:228-234. ) ( [19] Li n ZJ, Zhuo MJ, Lii M S, e t a l ul . SSynthesis and microstructure o f layered-ternary T izAlN c e ramic. ScriptaMater 2007, 56: 1 115-1118. ) ( [20] Wang XH, Zhou YC. Lay e red machinable and electricallyconductive TizAlC and T i gAlC2 ceramics: A review.J Mater Sci Technol 2010, 26: 385-416. ) ( [21] Donnay JDH, Haker D. A new law o f crystal morphologyextending th e law of B ravais. Am Mineral 1 9 37,22: 446-447. ) ( [22] Wells A F. Crystal habit and i n ternal structure. Phil Mag1946,37:184-199. ) ( [23] Berkovitch-Yellin Z. Toward a n a b i n itio d erivation o fcrystal morphology. J Am Chem Soc 1 985,107:8 2 39-8253. ) www.springer.com/journal/ 在本方案中,热障涂层材料的平均线膨胀系数测量采用的是光学投影法热膨胀仪,测试温度范围为室温~1600K,气氛为空气。测试试样为矩形棒状,尺寸为3×4×15mm,测试15mm长度方向上的热膨胀。

确定

还剩7页未读,是否继续阅读?

上海依阳实业有限公司为您提供《热障涂层材料中热膨胀系数,变形,位移,膨胀系数检测方案(热膨胀仪)》,该方案主要用于其他中热膨胀系数,变形,位移,膨胀系数检测,参考标准--,《热障涂层材料中热膨胀系数,变形,位移,膨胀系数检测方案(热膨胀仪)》用到的仪器有光学投影法高温热膨胀仪

推荐专场

相关方案

更多

该厂商其他方案

更多