方案详情

文

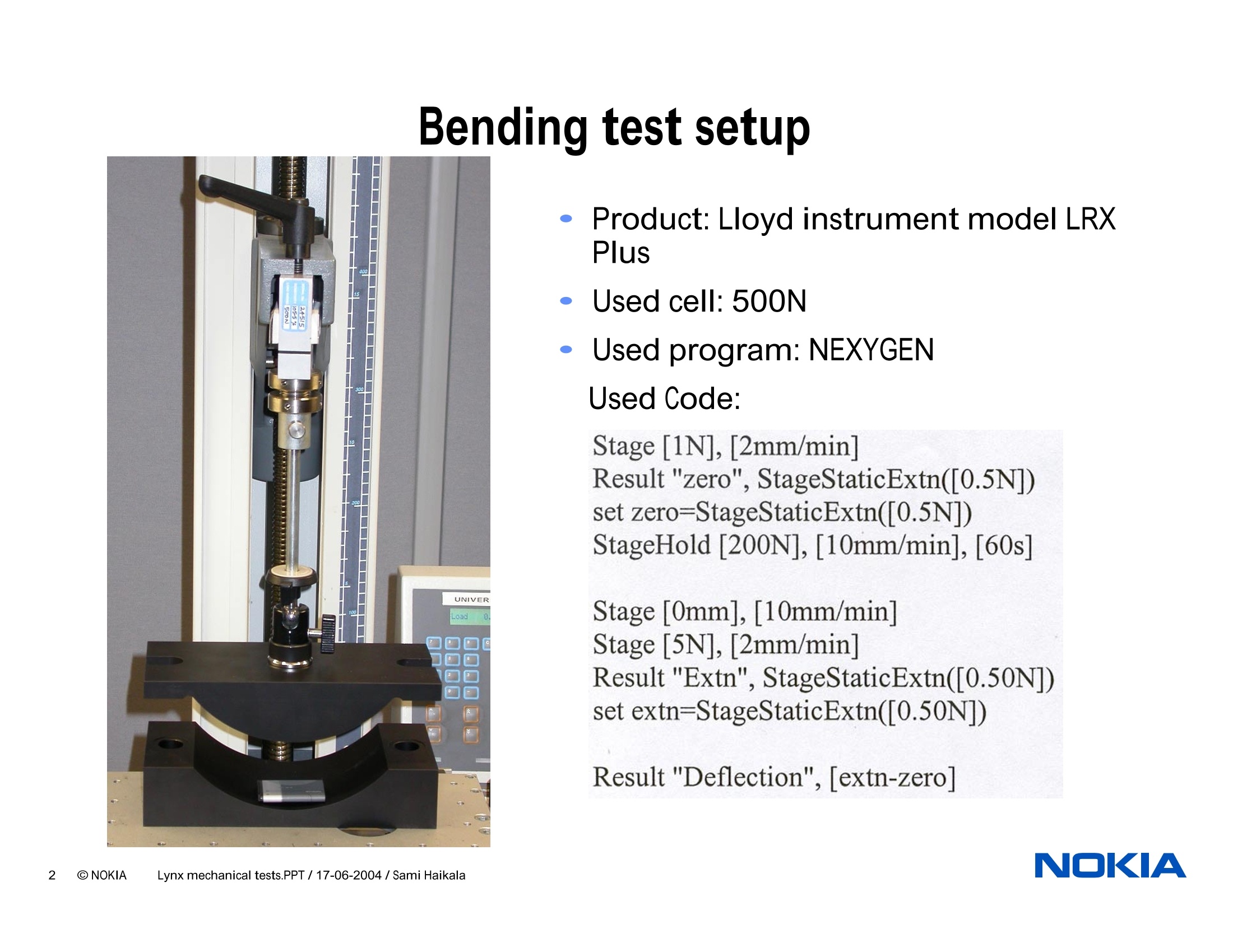

电池弯曲试验设置,扭转试验设置,压力试验设置

电池弯曲试验设置,扭转试验设置,压力试验设置

电池弯曲试验设置,扭转试验设置,压力试验设置

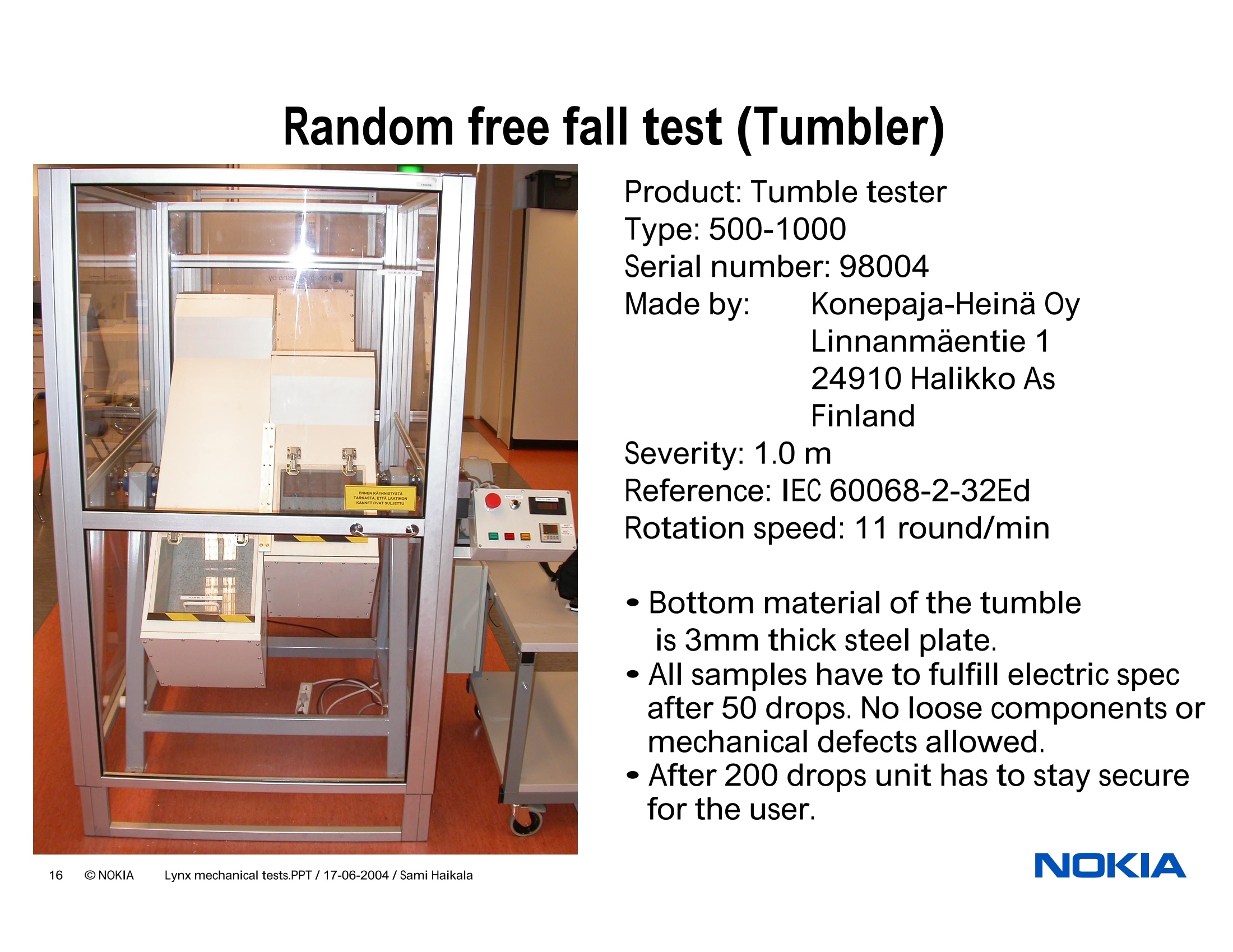

方案详情

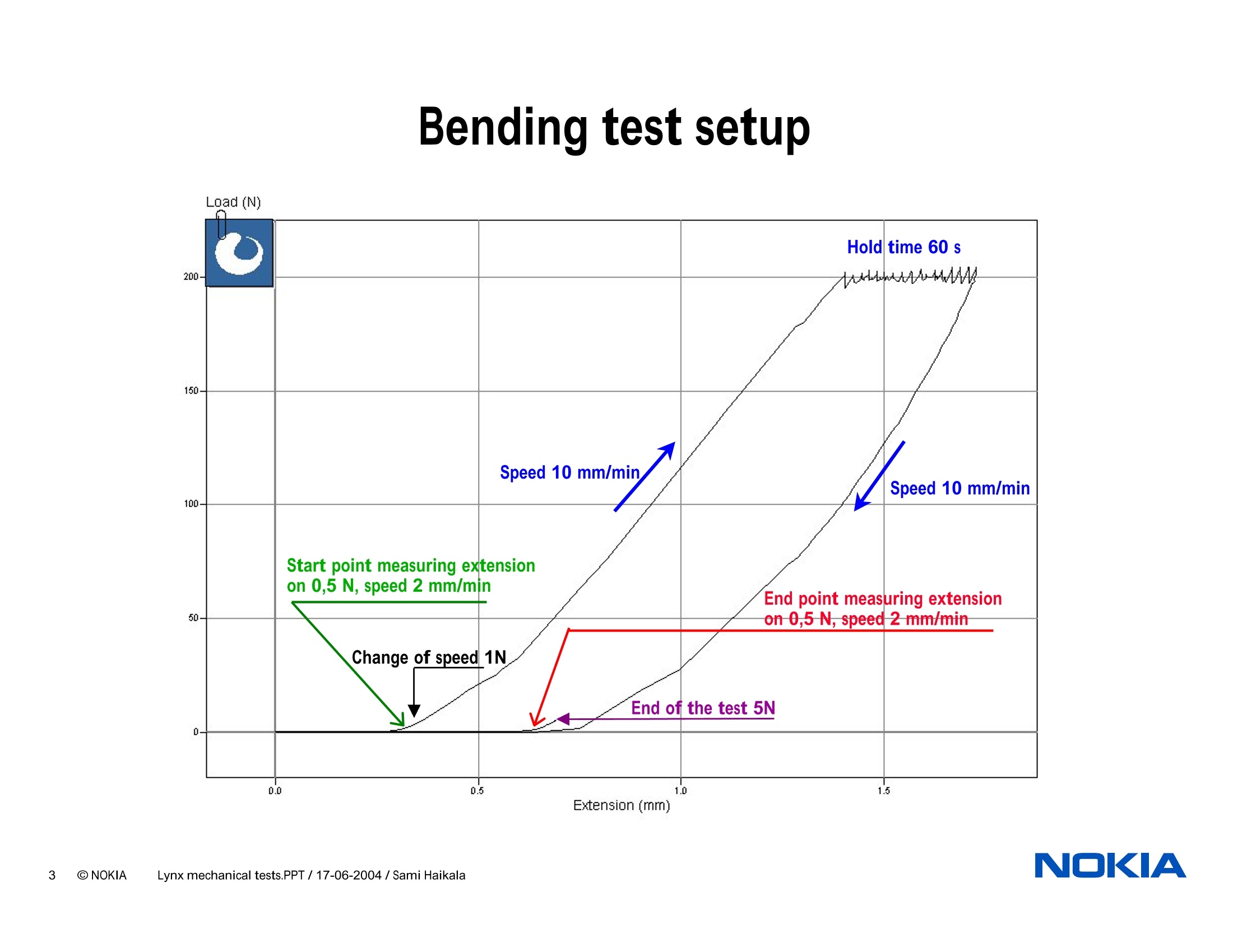

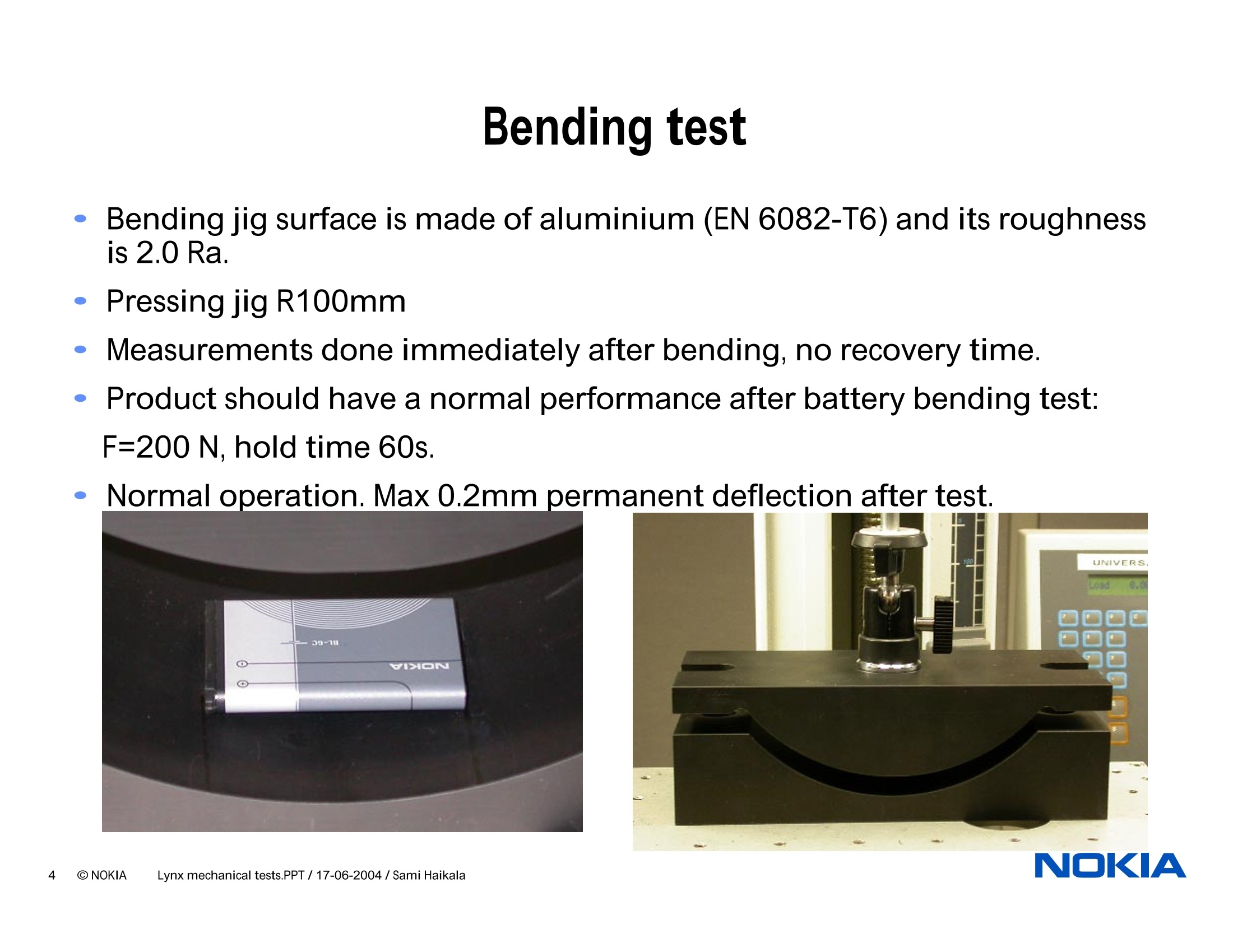

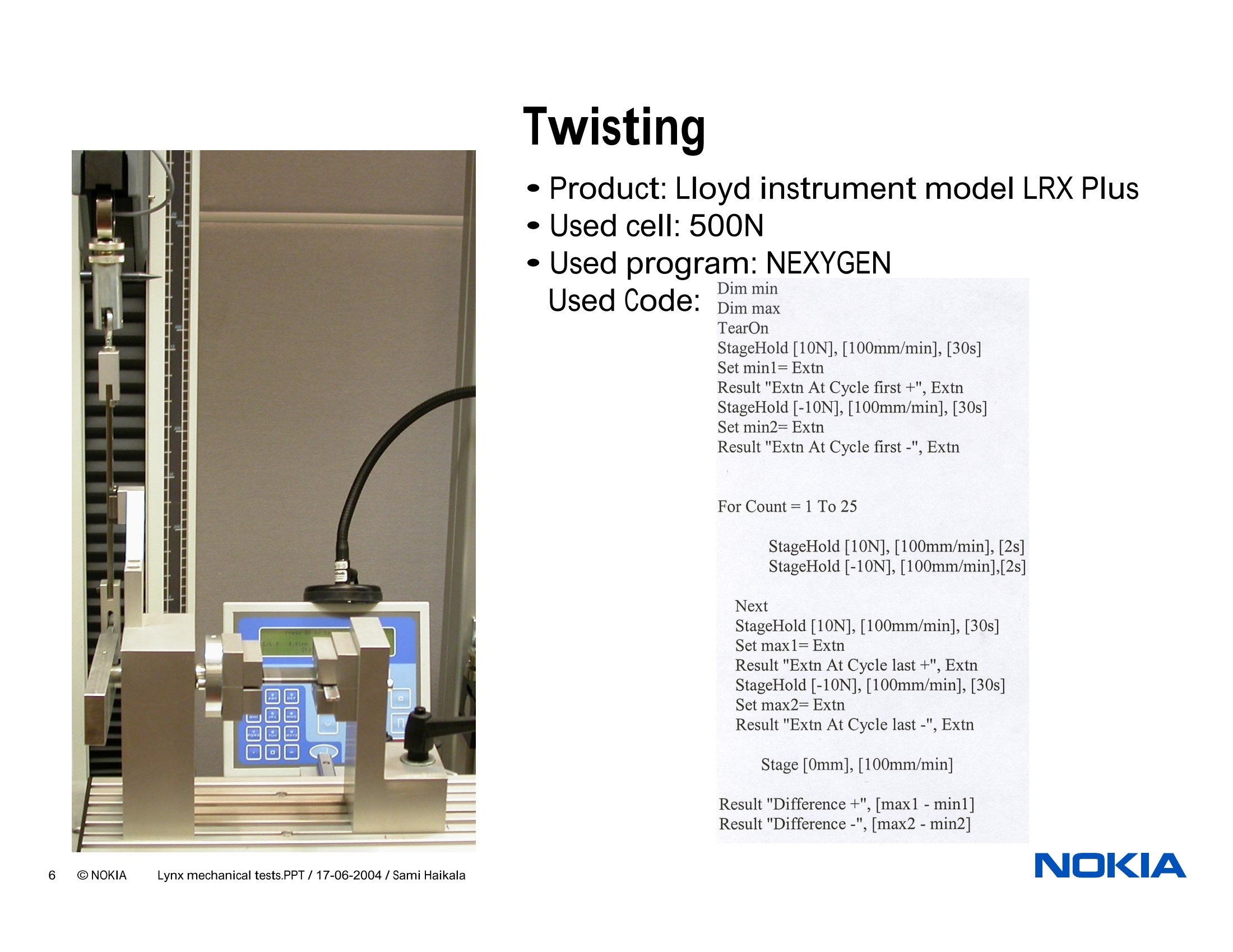

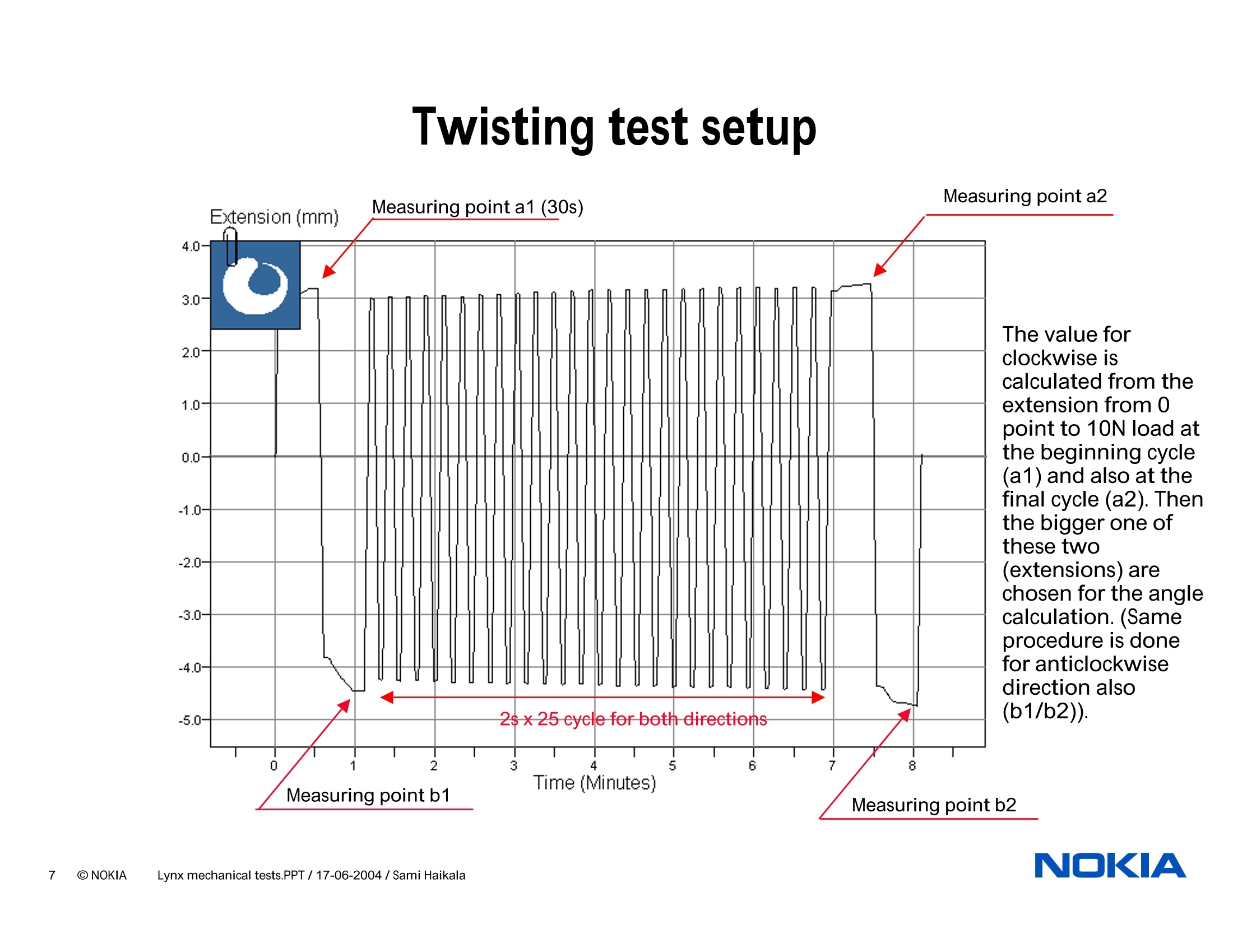

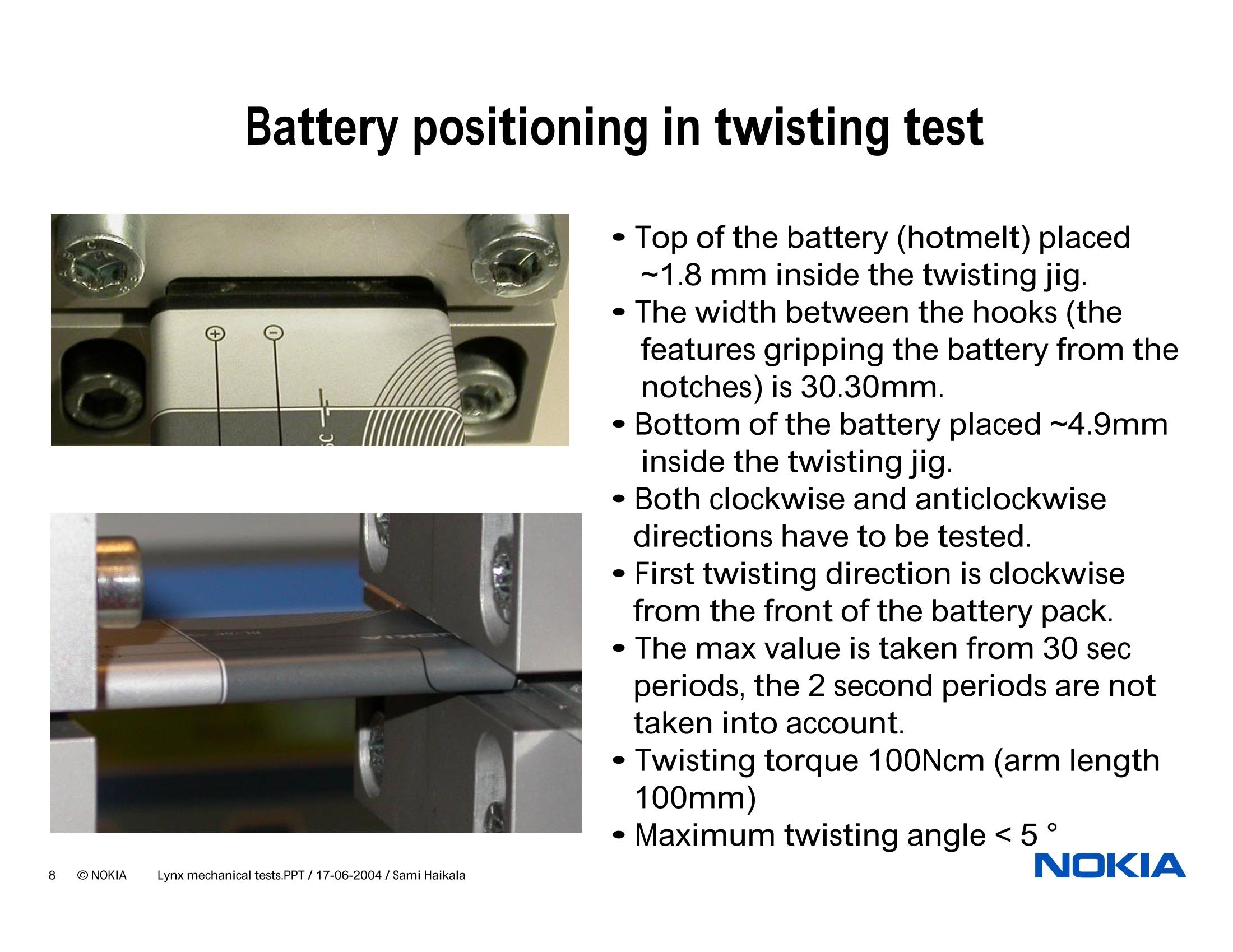

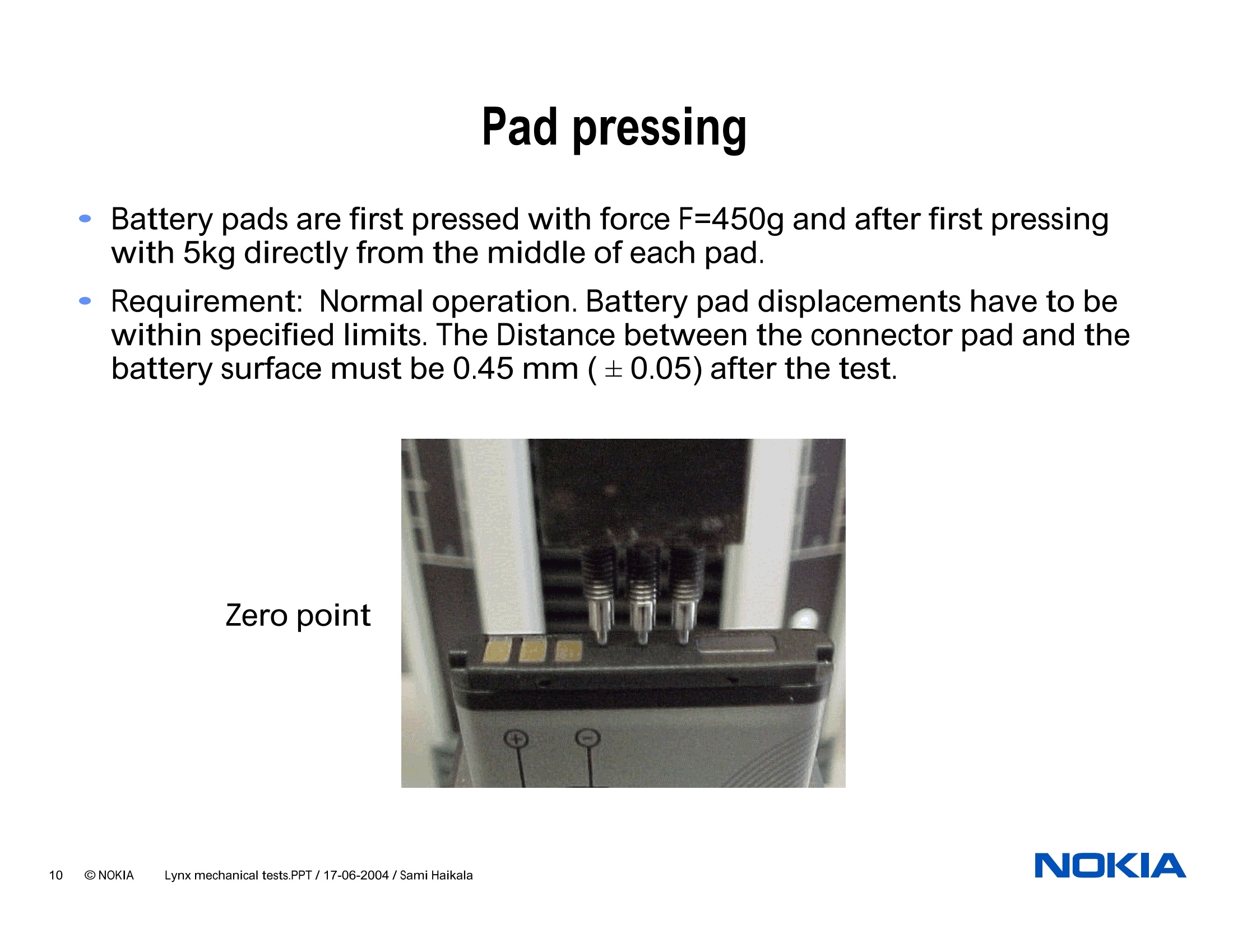

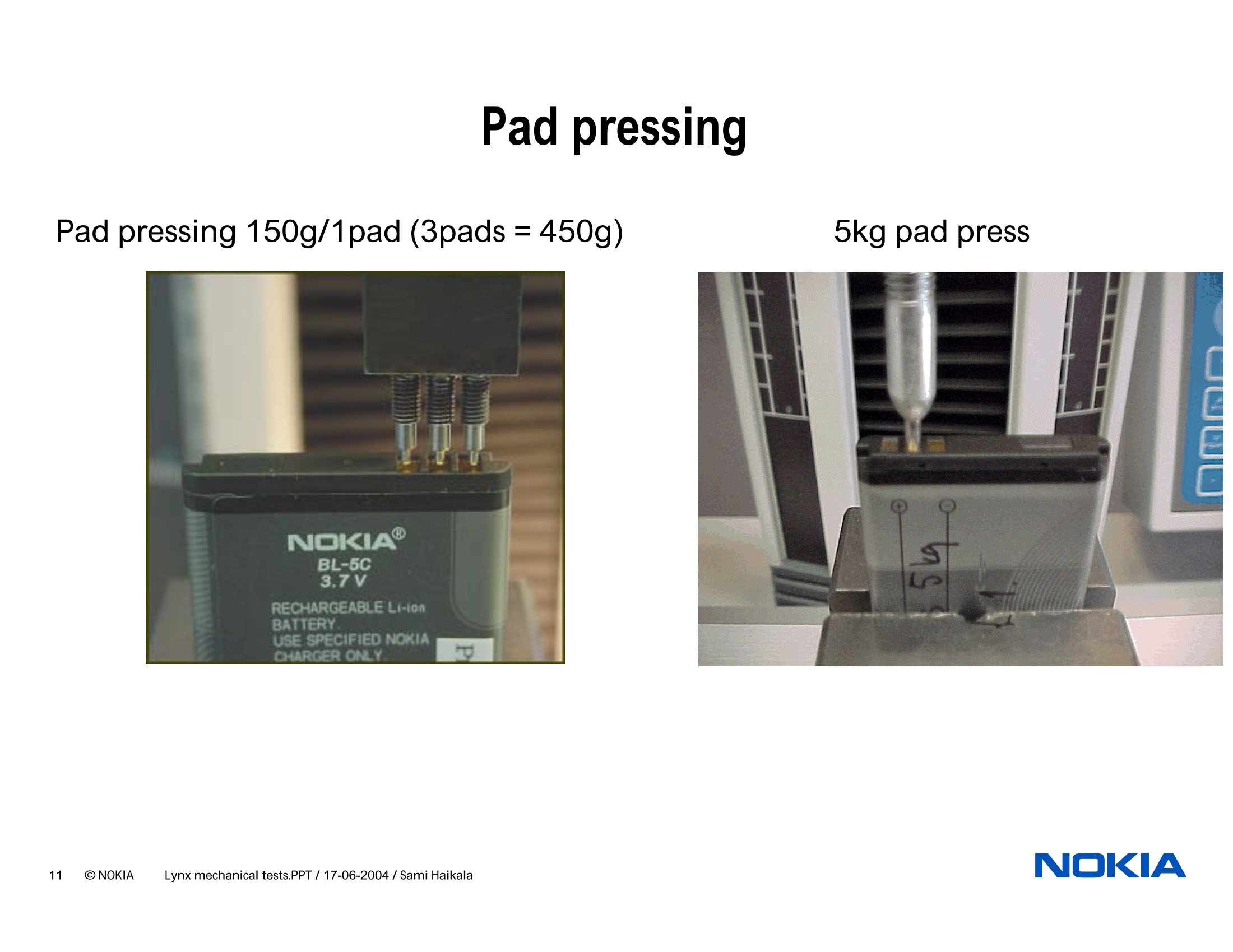

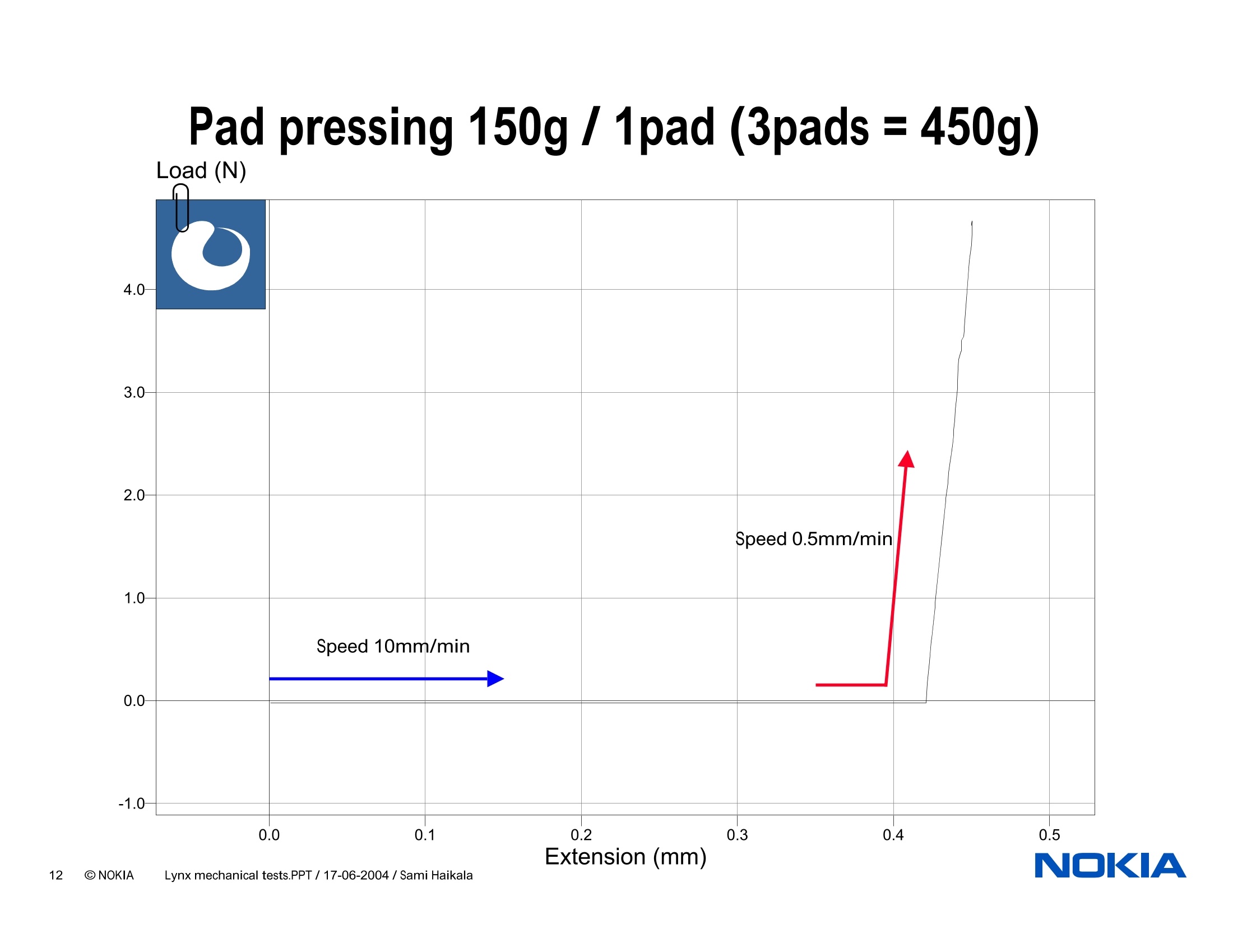

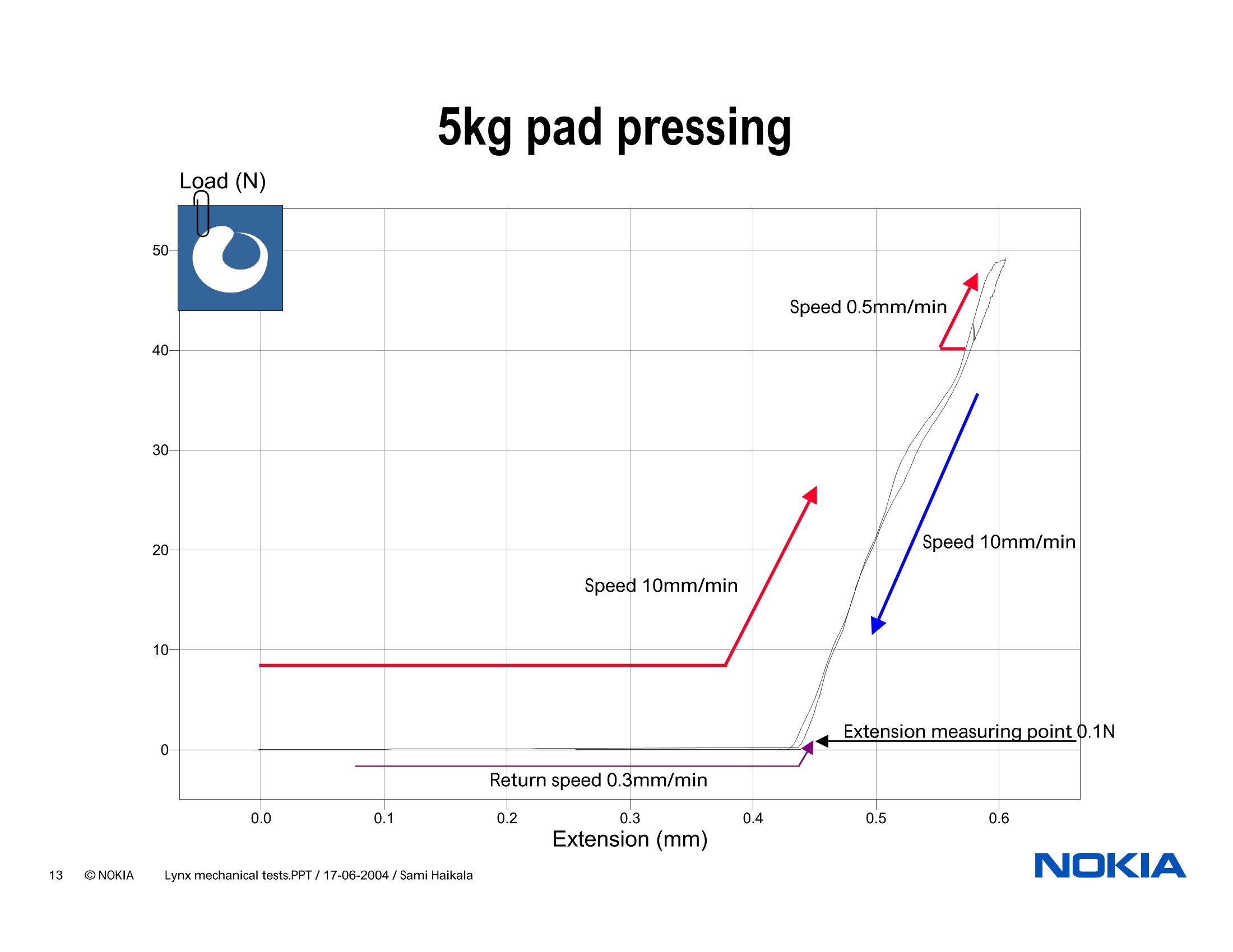

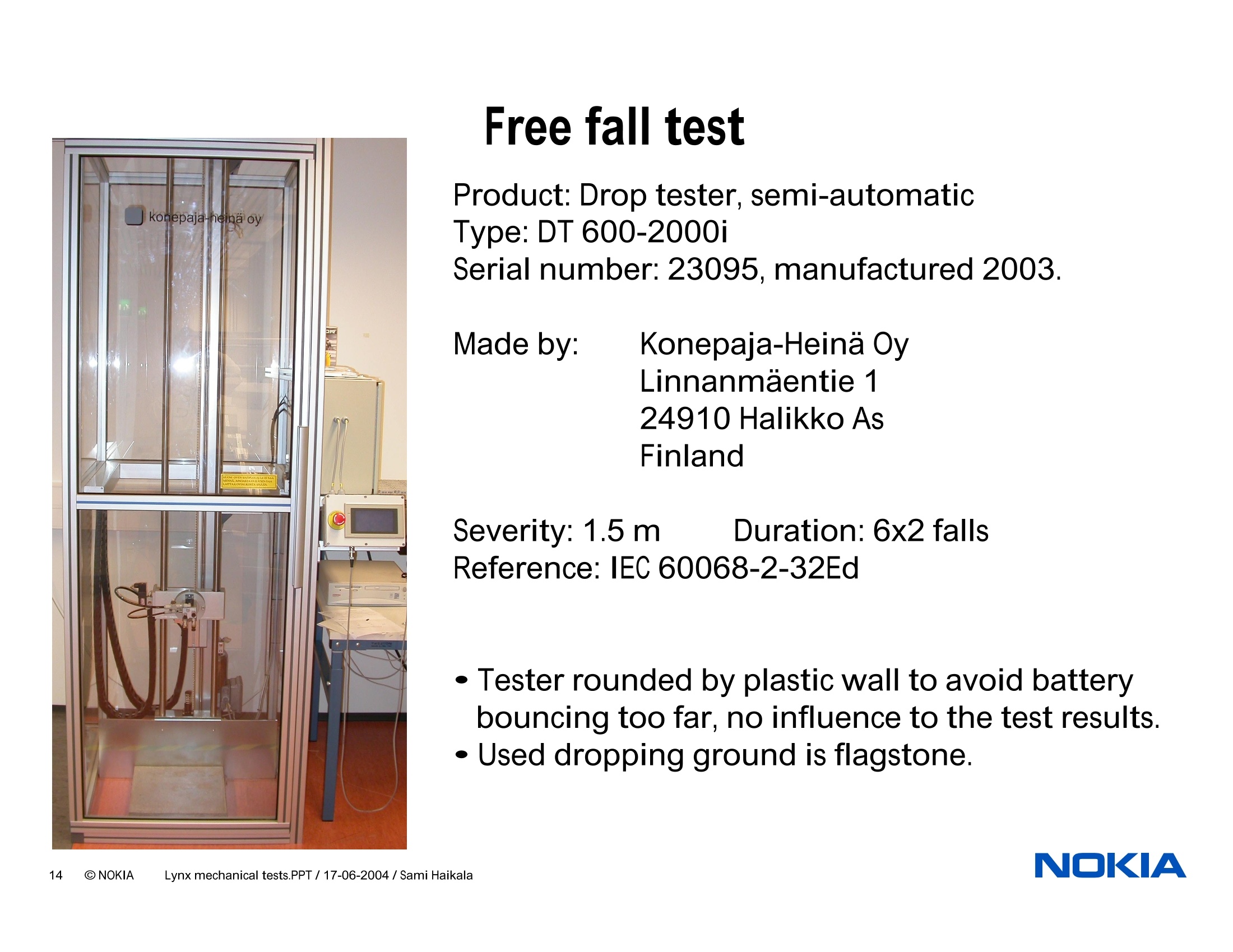

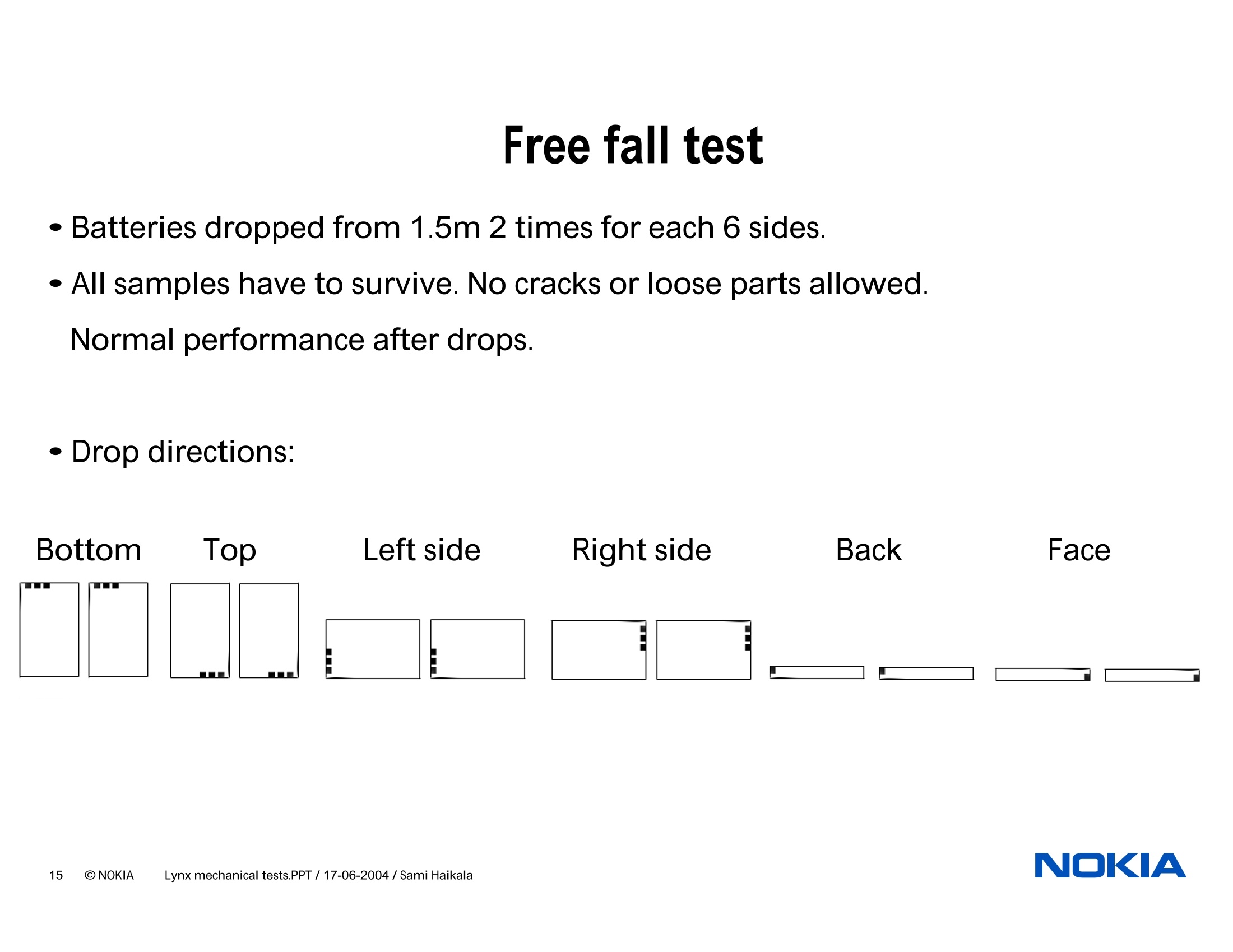

Lynx Mechanical Tests Test equipments in Nokia Owner: Sami Haikala Approver: Aimo Leskela Document ID: 040-005260 Version: 1.0 Status: Approved Change History VersionDateStatusHandled bv15.06.2004DraftSami Haikala17.06.2004ApprovedAimo Leskela Comments Bending test setup Product: Lloyd instrument model LRXPlus ·Used cell: 500N Used program: NEXYGENUsed Code: Stage [1N], [2mm/min] Result "zero", StageStaticExtn([0.5N]) set zero=StageStaticExtn([0.5N]) StageHold [200N],[10mm/min],[60s] Stage [0mm],[10mm/min] Stage [5N], [2mm/min] Result "Extn", StageStaticExtn([0.50N])set extn=StageStaticExtn([0.50N]) Result "Deflection",[extn-zero] Bending test setup Load (N) Extension (mm) Bending test Bending jig surface is made of aluminium (EN 6082-T6) and its roughnessis 2.0 Ra. ●Pressing jig R100mm Measurements done immediately after bending, no recovery time. Product should have anormal performance after battery bending test:F=200 N, hold time 60s. Normal operation. Max 0.2mm permanent deflection after test. Nokia Bending Jig making procedure 1.1Material: Aluminium EN6082-T6 (The marking T6 behind the material number isa grade of tempering. It means heat-treated and then artificially aged.) 2.Milled with NC machine tool. (Surface milled to be as smooth as possible) 3.Manually finished. 4. Surface roughness (2.0 Ra) made with glass shot blasting. 5. B[lack anodizing. (Short time in the alkaline soaker to remove oxide layer. Nomajor influence to the surface roughness). The reference for the bending jig material can be found from JIS H4000. ChemicalComposition of material 6082 are mentioned below. The composition is (unit: %): Si 0.70-1.3. Fe 0.50 max Cu 0.10 max Mn 0.40-1.0 Mg 0.60-1.2 Cr 0.25 max Zn 0.20 max Ti 0.10 max Others, each 0.05 max, total 0.15 max Al, Remainder Twisting ·Product: Lloyd instrument model LRX Plus·Used cell:500N · Used program: NEXYGENDim minUsed Code:Dim max TearOn StageHold [10N],[100mm/min], [30s] Set min1=Extn Result "Extn At Cycle first +", Extn StageHold [-10N],[100mm/min],[30s] Set min2=Extn Result "Extn At Cycle first -",Extn For Count=1 To 25 StageHold [10N],[100mm/min],[2s] StageHold [-10N],[100mm/min],[2s] Next StageHold [10N], [100mm/min],[30s] Set max1=Extn Result "Extn At Cycle last +",Extn StageHold [-10N],[100mm/min],[30s] Set max2=Extn Result "Extn At Cycle last-", Extn Stage [0mm],[100mm/min] Result "Difference +", [max1-min1] Result "Difference-", [max2-min2] Twisting test setup Measuring point a2 The value forclockwise iscalculated from theextension from 0point to 10N load atthe beginning cycle(a1) and also at thefinal cycle (a). Thenthe bigger one ofthese two(extensions)arechosen for the anglecalculation.(Sameprocedure is donefor anticlockwisedirection also(b1/b2)). Battery positioning in twisting test Top of the battery (hotmelt) placed~1.8 mm inside the twisting jig. The width between the hooks (thefeatures gripping the battery from thenotches) is 30.30mm. ·BBottom of the battery placed ~4.9mminside the twisting jig. ·Both clockwise and anticlockwisedirections have to be tested. · First twisting direction is clockwisefrom the front of the battery pack. ·The max value is taken from 30 secperiods, the2 second periods are nottaken into account. Twisting torque 100Ncm (arm length00mm) ·Maximum twisting angle<5 Pad pressing Product: Lloyd instrument model LRX Plus Used cell:500N Used program: NEXYGEN Used Code for 450g: TearOn Stage [0.35mm],[10mm/min] StageHold [450gf], [0.5mm/min], [2s] Result "Distance", ExtnAtStageMax Used Code for 5Kg: TearOn Stage [4kgf], [10mm/min] Stage [5kgf], [0.5mm/min] Stage [0mm], [10mm/min] StageHold [0.1N], [0.3mm/min], [1s] Result "Deflection", Extn Pad pressing Battery pads are first pressed with force F=450g and after first pressingwith 5kg directly from the middle of each pad. ●FRequirement: Normal operation. Battery pad displacements have to beANwithin specified limits. The Distance between the connector pad and thebattery surface must be 0.45 mm (±0.05) after the test. Zero point Pad pressing Pad pressing 150g/1pad (3pads=450g) 5kg pad press Padpressing 150g / 1pad (3pads=450g) Load (N) 0.0 0.1 0.2 0.3 0.4 5kg pad pressing Load (N) Extension (mm) Free fall test Producitc:t :DLrop tester, semi-automaticType: DT 600-2000i Serial number: 23095, manufactured 2003. Made by: Konepaja-Heina OyLinnanmaentie 124910 Halikko AsFinland Severity: 1.5 m Duration: 6x2 falls Reference: IEC 60068-2-32Ed · Tester rounded by plastic wall to avoid batterybouncing too far, no influence to the test results. · Used dropping ground is flagstone. Free fall test ·Batteries dropped from 1.5m 2 times for each 6 sides. ·All samples have to survive. No cracks or loose parts allowed.Normal performance after drops. · Drop directions: Random free fall test (Tumbler Product: Tumble tester Type:500-1000 Serial number: 98004 Made by: Konepaja-Heina OyLinnanmaentie 124910 Halikko AsFinland Severity: 1.0 m Reference:IEC 60068-2-32Ed Rotation speed: 11 round/min ·Bottom material of the tumbleis 3mm thick steel plate. · All samples have to fulfill electric specafter 50 drops. No loose components ormechanical defects allowed. · After 200 drops unit has to stay securefor the user. NOKIALynx mechanical tests.PPT /Sami HaikalaO NOKIA

确定

还剩14页未读,是否继续阅读?

广东越联仪器有限公司为您提供《诺基亚审核电池拉压力测试方案》,该方案主要用于锂电池中--检测,参考标准--,《诺基亚审核电池拉压力测试方案》用到的仪器有拉伸强度测试仪厂家销售、拉伸试验机|拉力试验机|材料试验机 东莞越联仪器

推荐专场

相关方案

更多

该厂商其他方案

更多