动态图像法是在样品运动的状态下进行颗粒表征,获取粒度粒形信息的一种方法。采用动态图像法能够全方位获取颗粒的形貌和粒径信息,例如纤维颗粒长度和宽度、长径比、卷曲度等。而静态法只能观察到颗粒的部分形貌和粒径,激光法等粒度分析法是将颗粒视做球形进行分析,因此,动态图像分析法是全方位获取颗粒形貌和粒径分布的最佳方法。

方案详情

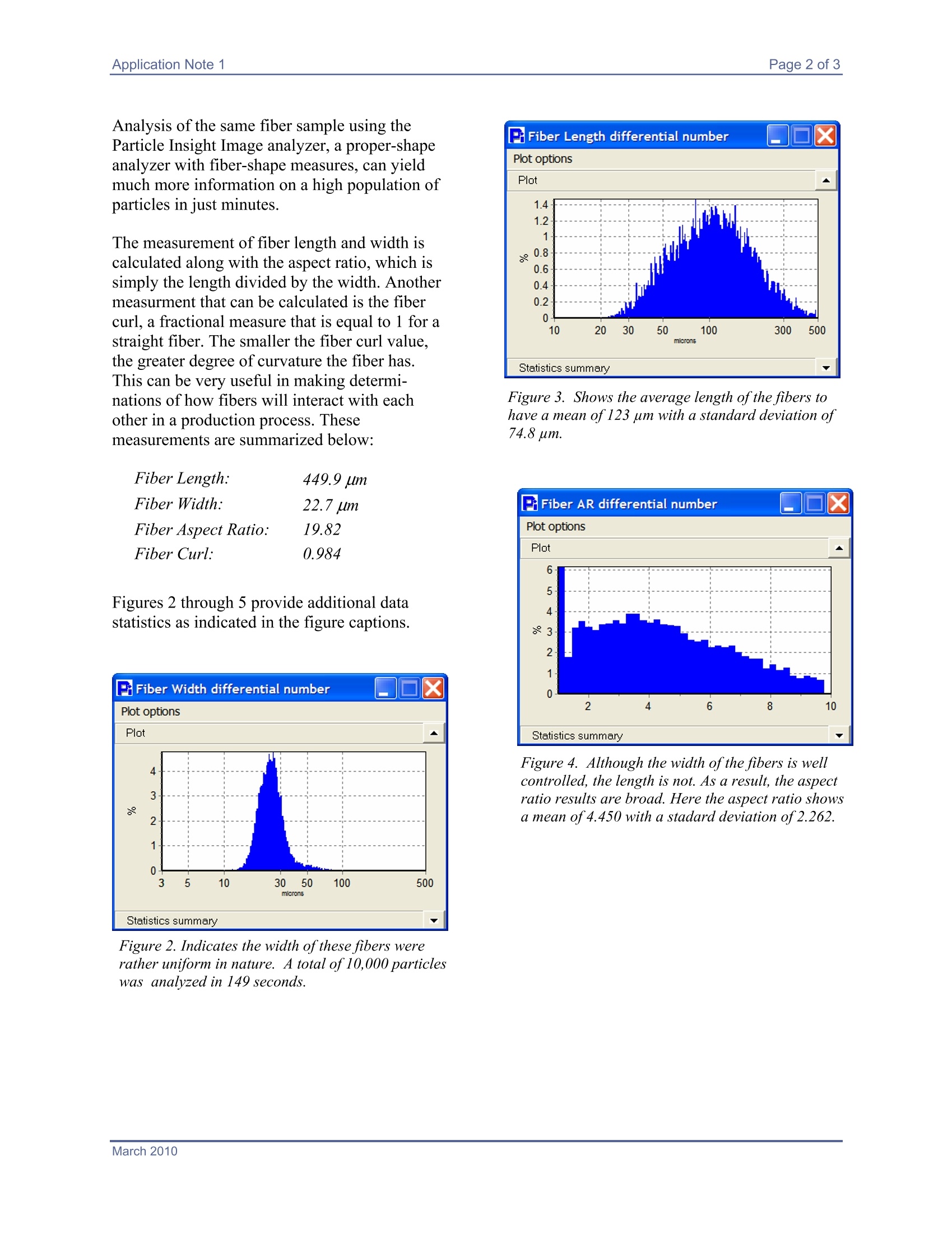

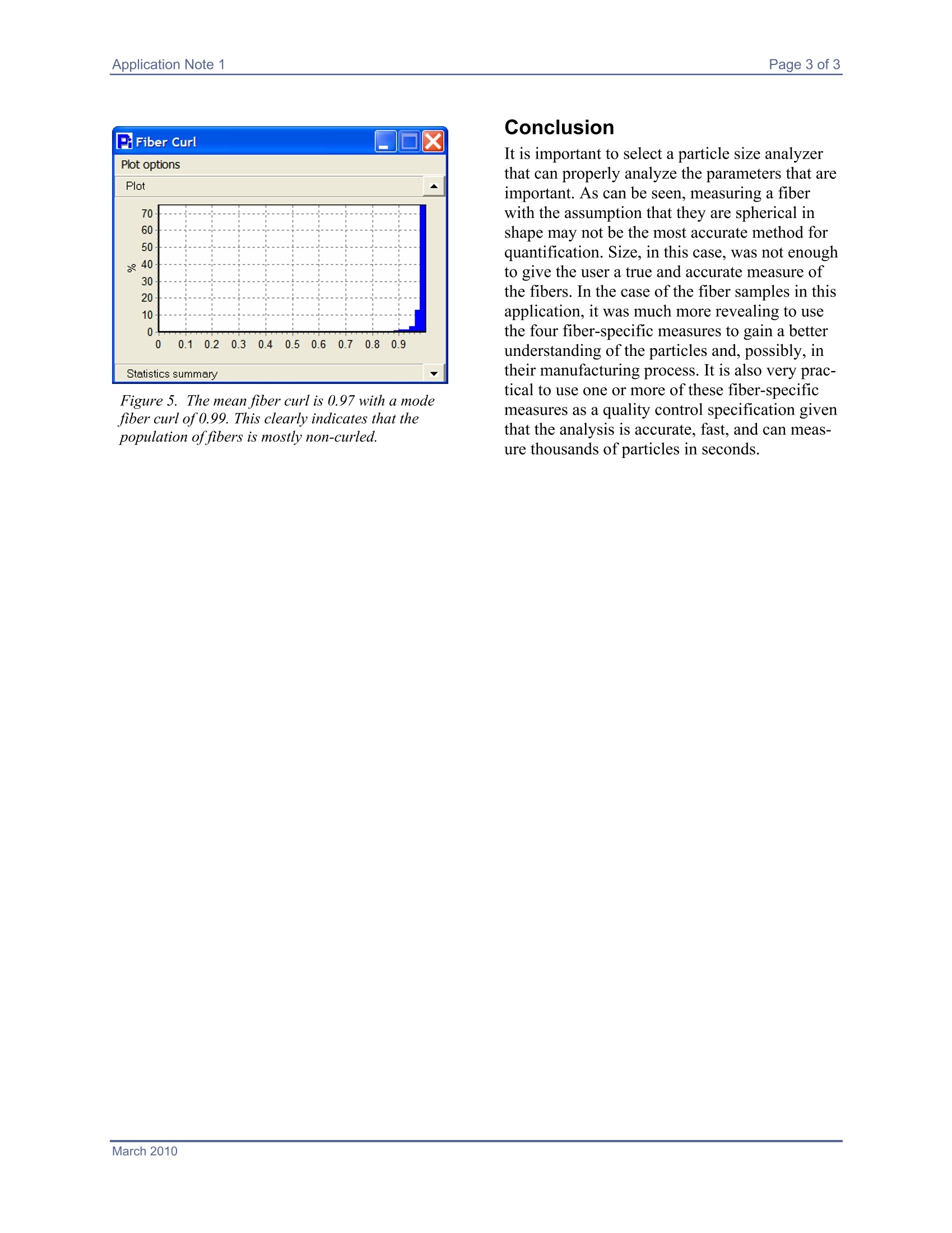

Application Note Application Note 1Page 2 of 3 Using Dynamic Image Analysisto Measure Fiber Particles Analysis of fiber particles requires numerousmeasurement parameters to fully qualify theirtrue shape. Introduction Automated image analysis has been developedto provide users with a more accurate measure-ment of their particles. For many years,particlesize analyzers have rendered results with theassumption that all measured particles arespherical. However, in many applications, thecircularity of particles can affect both per-formance and flowability in manufacturing. Insome cases, for example, measuring surfacesmoothness can impact how well abrasivesperform. Those in industry who have realized that theirregularity of their particles impact bothmanufacturability and efficacy have resorted tomicroscopy for shape analysis.Manual micros-copy, by its very nature, is a slow and tediousmethod for particle analysis and becomesimpractical to analyze a large number ofpar-ticles. Therefore, the end-user potentially is leftwith a poor representation of the sample. Thismakes microscopy acceptable for obtaining ageneral idea of particle shape, but is unaccept-able when using particle shape analysis as ameans to control a process. One raw material which lends itself to be idealymeasured by shape analysis is fibers. Fiberparticles are used in a vast array of applicationsfrom adding strength to building materials tomaking effective filtration media. In all cases where raw fibers are used, there hasbeen an expressed need to know the fiber length,width, and aspect ratio, as well as the curl of thefiber. Particle analysis results expressed inequivalent spherical diameter do not come closeto giving the user critical informatB1gion about theirfibers, and how they will perform in their finalstate. Measuring such particles with manualmicroscopy is also impractical in a quality con-trol environment where fast and representativeanalysis is required. Figure 1 shows a typical fiber in the sampleanalyzed using the Particle Insight DynamicImage Analyzer from Particulate Systems. Figure 1. Fiber sample used for analysis. Analysis of this fiber sample with a conventionalparticle size analyzer assumes all particles arespheres, and reports minimal information; in thisinstance, a size of 112.1 um. A Micromeritics Brand T. (770)662-3620 www.particulatesystems.com Analysis of the same fiber sample using theParticle Insight Image analyzer, a proper-shapeanalyzer with fiber-shape measures, can yieldmuch more information on a high population ofparticles in just minutes. The measurement of fiber length and width iscalculated along with the aspect ratio, which issimply the length divided by the width. Anothermeasurment that can be calculated is the fibercurl, a fractional measure that is equal to 1 for astraight fiber. The smaller the fiber curl value,the greater degree of curvature the fiber has.This can be very useful in making determi-nations of how fibers will interact with eachother in a production process. Thesemeasurements are summarized below: Fiber Length: 449.9 um Fiber Width:22.7 umFiber Aspect Ratio:19.82Fiber Curl:0.984 Figures 2 through 5 provide additional datastatistics as indicated in the figure captions. Figure 2. Indicates the width of these fibers wererather uniform in nature. A total of 10,000 particleswas analyzed in 149 seconds. Figure 3. Shows the average length ofthe fibers tohave a mean of 123 um with a standard deviation of74.8 um. Figure 4. Although the width of the fibers is wellcontrolled,the length is not. As a result, the aspectratio results are broad. Here the aspect ratio showsa mean of 4.450 with a stadard deviation of2.262. Figure 5. The mean fiber curl is 0.97 with a modefiber curl of 0.99. This clearly indicates that thepopulation of fibers is mostly non-curled. Conclusion It is important to select a particle size analyzerthat can properly analyze the parameters that areimportant. As can be seen, measuring a tiberwith the assumption that they are spherical inshape may not be the most accurate method forquantification. Size, in this case, was not enoughto give the user a true and accurate measure ofthe fibers. In the case of the fiber samples in thisapplication, it was much more revealing to usethe four fiber-specific measures to gain a betterunderstanding of the particles and, possibly, intheir manufacturing process. It is also very prac-tical to use one or more of these fiber-specificmeasures as a quality control specification giventhat the analysis is accurate, fast, and can meas-ure thousands of particles in seconds. Communications Drive, Norcross, GA March

确定

还剩1页未读,是否继续阅读?

麦克默瑞提克(上海)仪器有限公司为您提供《使用动态图像法测试纤维颗粒粒径粒形》,该方案主要用于其他中--检测,参考标准--,《使用动态图像法测试纤维颗粒粒径粒形》用到的仪器有

相关方案

更多

该厂商其他方案

更多