方案详情

文

对于金属粉末, 在生产的过程中,不仅要考虑到它的含水量的问题,还需要考虑它的流动性和活动性的问题,尤其是需要避免同大气接触的问题,在线直接取样和分析就可以避免同大气接触,对于对人体或环境有害的粉末来讲, 是更加适合不过的。

方案详情

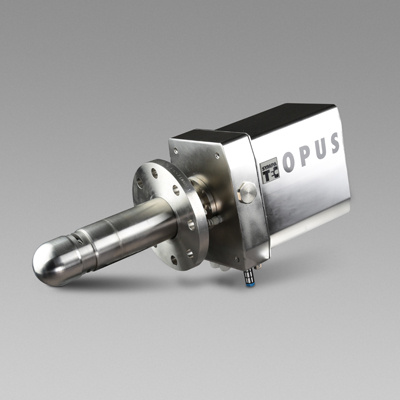

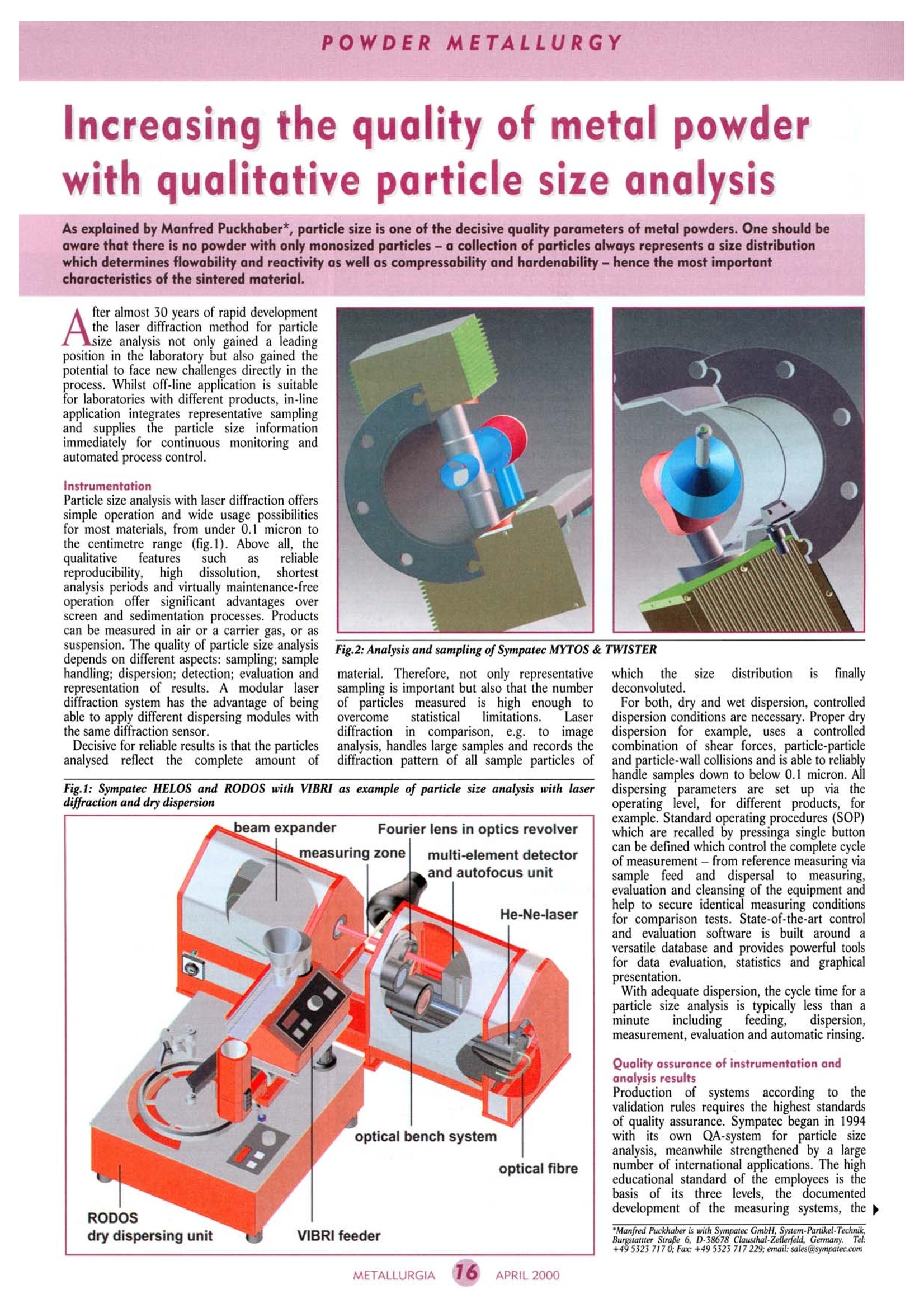

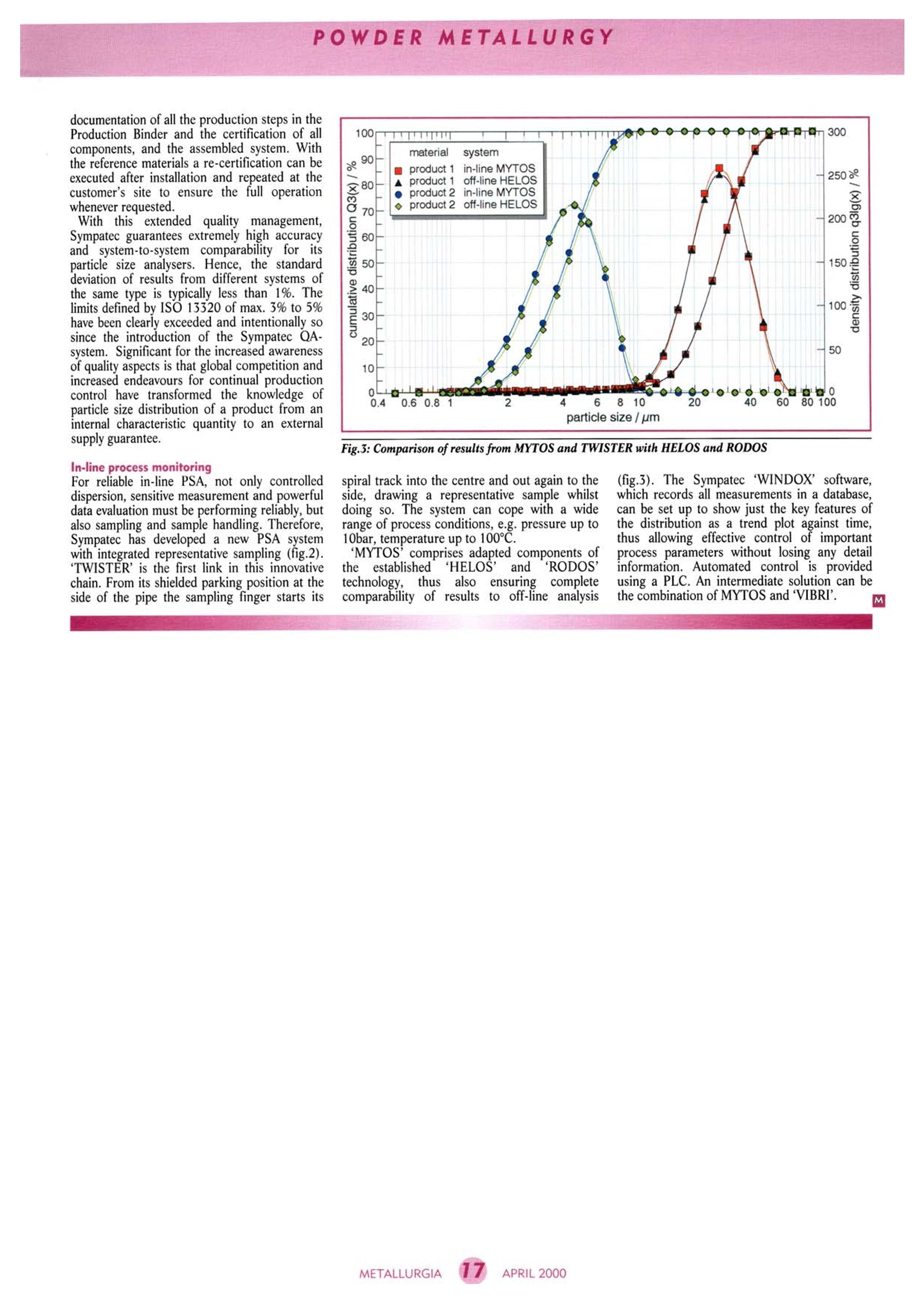

POWDERMETALLURGY fter almost 30 years of rapid developmentthe laser diffraction method for particlesize analysis not only gained a leadingposition in the laboratory but also gained thepotential to face new challenges directly in theprocess. Whilst off-line application is suitablefor laboratories with different products, in-lineapplication integrates representative samplingand supplies the particle size informationimmediately for continuous monitoring andautomated process control. Instrumentation Particle size analysis with laser diffraction offerssimple operation and wide usage possibilitiesme centimetre range (fng). Above al, thequalitativefeatures suchhaS reliablereproducibility, highdissolution.n,Sshortestanalysis periods and virtually maintenance-freeoperation offer significant advantages overscreen and sedimentation processes. Productscan be measured in air or a carrier gas, or assuspension. The quality of particle size analysisdepends on different aspects: sampling; samplehandling; dispersion; detection; evaluation andrepresentation of results. A modular laserdiffraction system has the advantage of beingable to apply different dispersing modules withthe same diffraction sensor. Decisive for reliable results is that the particlesanalysed reflect the: complete amountt of Fig.2: Analysis and sampling of Sympatec MYTOS & TWISTER Fig.1: Sympatec HELOS and RODOS with VIBRI as example of particle size analysis with laser which thessize distribution is finallydeconvoluted. For both, dry and wet dispersion, controlleddispersion conditions are necessary. Proper drydispersion for example, uses a controlledcombination of shear forces, particle-particleand particle-wall collisions and is able to reliablyhandle samples down to below 0.1 micron. Alldispersing parameters are set up via theoperating level, for different products, forexample. Standard operating procedures (SOP)which are recalled by pressinga single buttoncan be defined which control the complete cycleof measurement -from reference measuring viasample feed and dispersaltomeasuring,evaluation and cleansing of the equipment andhelp to secure identical measuring conditionsfor comparison tests. State-of-the-art controland evaluation software is built around aversatile database and provides powerful toolsfor data evaluation, statistics and graphicalpresentation. With adequate dispersion, the cycle time for aparticle size analysis is typically less than aminute includingfeeding, dispersion,measurement, evaluation and automatic rinsing. Quality assurance of instrumentation andanalysis results Productionl of:systems according; to thevalidation rules requires the highest standardsof quality assurance. Sympatec began in 1994with its own QA-system for particle sizeanalysis, meanwhile strengthened by a largenumber of international applications. The higheducational standard of the employees is thebasis of its three levels, the documenteddevelopment of the measuring systems, the ( " Manfred P u ckha b er is w i th S y mpatec Gm b H, Syst e m- P a r tikel-Te c hnik , B urgstattter Strape 6 , D -3 8 678 Cl a u s thal-Zellerfeld , G e rmany. Te l : + 4 9 5 3 23 71 7 0; Fax: +4 9 5 32 3 717 229; e m ail: s a les@sympatec.c om ) documentation of all the production steps in theProduction Binder and the certification of allcomponents, and the assembled system. Withthe reference materials a re-certification can beexecuted after installation and repeated at thecustomer’s site to ensure the full operationwhenever requested. Withh thisSCextendedqquality management,Sympatec guarantees extremely high accuracyand system-to-system comparability for itsparticle size analysers. Hence, the standarddeviation of results from different systems ofthe same type is typically less than 1%. Thelimits defined by ISO 13320 of max. 3% to 5%have been clearly exceeded and intentionally sosince the introduction of the Sympatec QA-system. Significant for the increased awarenessof quality aspects is that global competition andincreased endeavours for continual productioncontrol have transformed the knowledge ofparticle size distribution of a product from aninternal characteristic quantity to an externalsupply guarantee. In-line process monitoring For reliable in-line PSA, not only controlleddispersion,sensitive measurement and powerfuldata evaluation must be performing reliably, butalso sampling and sample handling. Therefore,Sympatec has developed a new PSA systemwith integrated representative sampling (fig.2).‘TWISTER’ is the first link in this innovativechain. From its shielded parking position at theside of the pipe the sampling finger starts its spiral track into the centre and out again to theside, drawing a representative sample whilstdoing so. The system can cope with a widerange of process conditions, e.g. pressure up to10bar, temperature up to 100℃. ‘MYTOS’comprises adapted components ofthe established ‘HELOS’aand‘RODOS’technology, thus also ensuring completecomparability of results to off-line analysis (fig.3). The Sympatec “WINDOX’ software,which records all measurements in a database,the distribution as a trend plot against time,thus allowing effective control of importantprocess parameters without losing any detailinformation. Automated control is providedusing a PLC. An intermediate solution can bethe combination of MYTOS and VIBRI’.M PRIL ETALLURGIA ETALLURGIAAPRIL

确定

还剩1页未读,是否继续阅读?

德国新帕泰克有限公司苏州代表处为您提供《金属粉末中粒度检测方案(在线粒度仪)》,该方案主要用于其他中粒度检测,参考标准--,《金属粉末中粒度检测方案(在线粒度仪)》用到的仪器有德国工业在线干法激光粒度分析和过程控制系统

推荐专场

相关方案

更多

该厂商其他方案

更多