初级和二次成核以及晶体生长动力学对结晶过程影响很大,尤其是对目标产品的质量方面影响更大.如何准确的分析该过程并选择最佳的结晶条件是结晶研究的关键。该文以PVC、二氧化硅、碳酸氢钠为模型,选择常见的仪器对该过程测量,为生产和科研提供一些比较。

研究表明,3D ORM技术对于结晶初期小颗粒的检测有明显的优势

方案详情

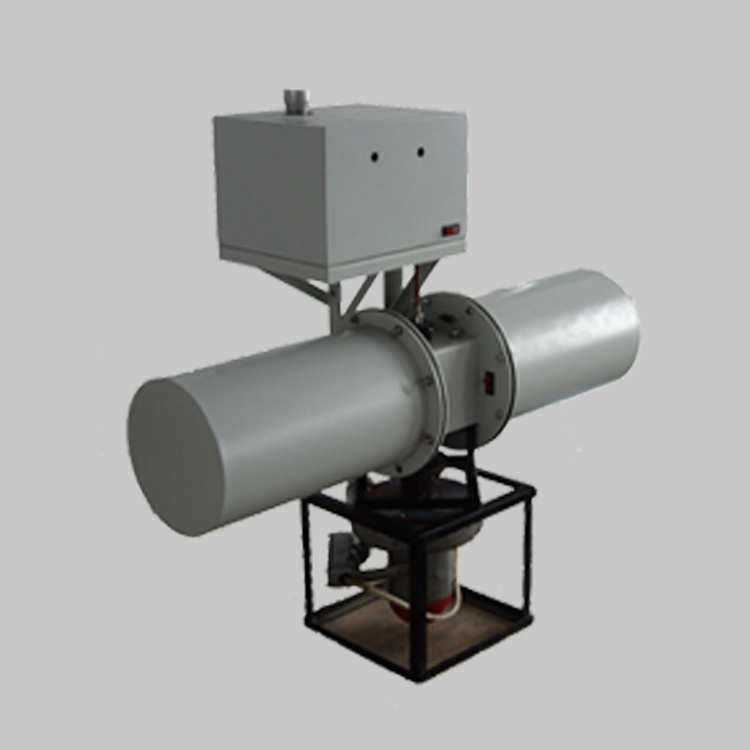

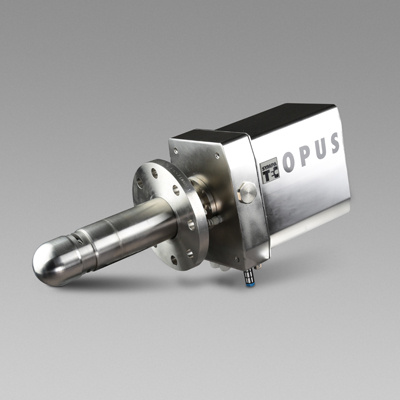

INTERPRETATION OF FBRM AND 3D ORM SMF DATA VIASIMULATED NUCLEATION AND CRYSTAL GROWTH S. Peda,M. Smieszek, C. Stollberg, P. Ay2 Hochschule Wismar, Faculty of Engineering, Process Engineering of Biogenous Raw Materials, Malchow, Germany ?Brandenburg University of Technology, Faculty of Environmental Sciences and Process Engineering, Cottbus, Germany Abstract The primary and secondary nucleation as well as the kinetics of crystal growth affect the crystallization process significantly, especially on the quality of the target product. The basicidea of real-time analysis of crystallization kinetics has been carried out with the help of two laser backscattering instruments 1) FocUSED BEAM REFLECTANCE MEASUREMENT (FBRM) and2) 3-FOLD DYNAMICAL REFLECTANCE MEASUREMENT WITH SELECTIVE MULTI DEPTH Focus (3D ORM SMF). Both instruments are compared using the example of a homogeneous,crystalline and heterogeneous, particulate model material system. This paper demonstrates the different, device-specific representation of the crystalline and particulate model Introduction Regarding to the thermal separation process the crystallization, data acquisition of thetrend of the process is realisable with considerable effort by means of offline and onlinemeasurement techniques. The continuous recording of the particles or crystal sizeswithout sampling is realizable with the optical laser in-situ measurement technique. THEAIM OF THIS STUDY IS THE CHARACTERIZATION OF SMALL OBJECTS WITH THE LASER-ASSISTED MEASUREMENT SYSTEMS FBRM (METTLER TOLEDO) AND 3D ORM SMF (SEQUIP). Materials To simulate a stationary state of a crystallization process, the materials crystalline sodiumbicarbonate (NaHCO,), particulate polyvinyl chloride (PVC) and silica (SiO,) are utilized (tab. 1). Tab. 1: Material properties of NaHC0,, SiO,and PVC Material Solid concentration Refractive index [kg/m Density[g/cm] Sodium bicarbonate (NaHCO,) 20,18 1,50-1,58 2,20 Silicium dioxide (SiO,),SF300, Quarzwerke GmbH 6,08 1,54-1,55 2,67 Polyvinyl chloride (PVC),Solvin 271PC, Solvay GmbH 14,18 1,55 1,38 MEASUREMENT TECHNIQUES The measurement principle of the FBRM D6ooL (fig. 1a) and 3D ORM SMF (fig. 1b) is basedon the physical effect of reflection. Starting from the control unit of the FBRM or3D ORM SMF, a laser beam (78o nm) launched through a single-mode fibre in thecylindrical part of the apparatus. With the help of a rotating optical system, the incominglaser beam is deflected on a circular-shaped path and focused in the suspension. At thesurfaces and edges of the targets contained in the suspension, the laser beam is reflectedand the chord length of the particles or crystals can be measured. The STATIONARY FOCALPOINT OF THE FBRM is located inside the sapphire window with the distance of -20 pmreferring to the interface measurement system - surrounding fluid. In contrast to theFBRM, the 3D ORM SMF USES A DYNAMIC FOCAL POINT outside of the instrument. Fig. 1: Schematic representation of the laser backscattering instruments a) FBRM b) 3D ORM SMF EXPERIMENTAL PROCEDURE The FBRM and the 3D ORM SMF were simultaneous positioned with a 30° angle above thestirrer in a glass beaker. The stirrer speed was set to 300 rpm. For the investigations, Fig. 2: Overview of the investigations and LM-micrograph (dry) of the used substances in theoriginal state RESULTS AND DISCUSSION The logarithmic distribution density (90,i) of NaHCO, in the sieve fractions 40, 100-125and 200-250 um are displayed in Fig. 3. The FBRM could not present precisely the finecrystals < 20 pm (fig.3a). The increasing size of the coarse crystals lead in to a shift ofthe crystal size distribution. In contrast, the dominating fine crystals are detected bythe 3D ORM SMF (fig. 3b, tab.2). Fig.3: Distribution density go,i) of the crystalline NaHCO,a)FBRM b)3D ORM SMF Tab. 2: Characteristic values of the determined chord length distributions ofNaHCO, Material Sieve fraction[pm] FBRMXcip,so,olum] AQr-20pml%] 3D ORM SMFxcib,5o,olum] AQ-20pml%/ <40 18,20 58,24 7,07 96,10 NaHCO, 100-125 30,40 35,22 6,84 95,00 200-250 38,90 33,37 7.92 92,75 The fine PVC particles from 1-20 pm are not determined with the FBRM (fig.4a). Thedetection of the dominant fine particles is given by the 3D ORM SMF (fig. 4b and 4d,tab. 3). The cause of the reduced representation of the fine fraction of the modelmaterial system (SiO,+ PVC) with the FBRM is the decrease of the counting rates (Z) inthe particle size range of o-5o um after addition of PVC (fig. 4c). a) 1.00 -0-300pm -51-300pm Fig. 4: Distribution density do.) of the particulate materials (SiO,, PVC) and the countingrates (Z) as a function of the solid concentration and -type of the FBRM (a, c) and3D ORM SMF(b, d) Tab.3: Characteristic values of the determined chord length distributions of SiO, and PVC Material FBRM 3D ORM SMF XcL0.5o.olpm] AQ+-20um[%] XcD.5o.oljur] AQ-20pm[%] sio. 9.77 85,84 5,80 99,42 PVC 86,13 13,30 5,74 88,97 Sio,+PVC 27,54 42,31 6,01 95,15 CONCLUSIONS The aim of the investigations was to identify the fine crystals or particles,corresponding to the “crystal nuclei”, crystal abrasion or crystal break in a realcrystallization. The in-situ measurement methods 3D ORM SMF and FBRM are able torecord the fine crystals and particles qualitatively. However, the quantitativecharacterization of the fine crystals and particles is more precise with 3D ORM SMF.

确定

还剩1页未读,是否继续阅读?

产品配置单

博盛技术(中国)有限公司为您提供《化学药中注射剂及特殊剂型相关检测方案 》,该方案主要用于化药新药研发中其他检测,参考标准--,《化学药中注射剂及特殊剂型相关检测方案 》用到的仪器有在线粒度仪PAT (激光粒度)、在线粒度分析仪、粒度粒形分析仪、可移动粒度分析支架

推荐专场

相关方案

更多