方案详情

文

EDGE 能够与QuEChERS方法在标准基质(如草莓)上的效率相匹配,证明它可以成为一种合适的替代方法。QuEChERS方法是一个繁琐的手工操作过程,而EDGE提供了一个简单的自动提取优势,它们回收率相当。

方案详情

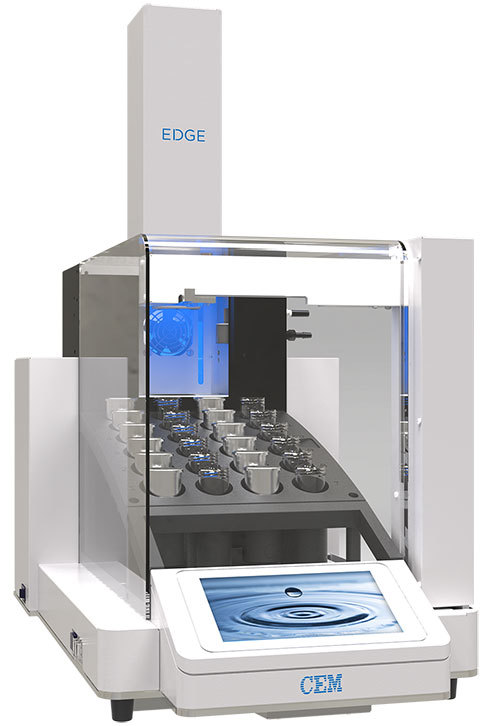

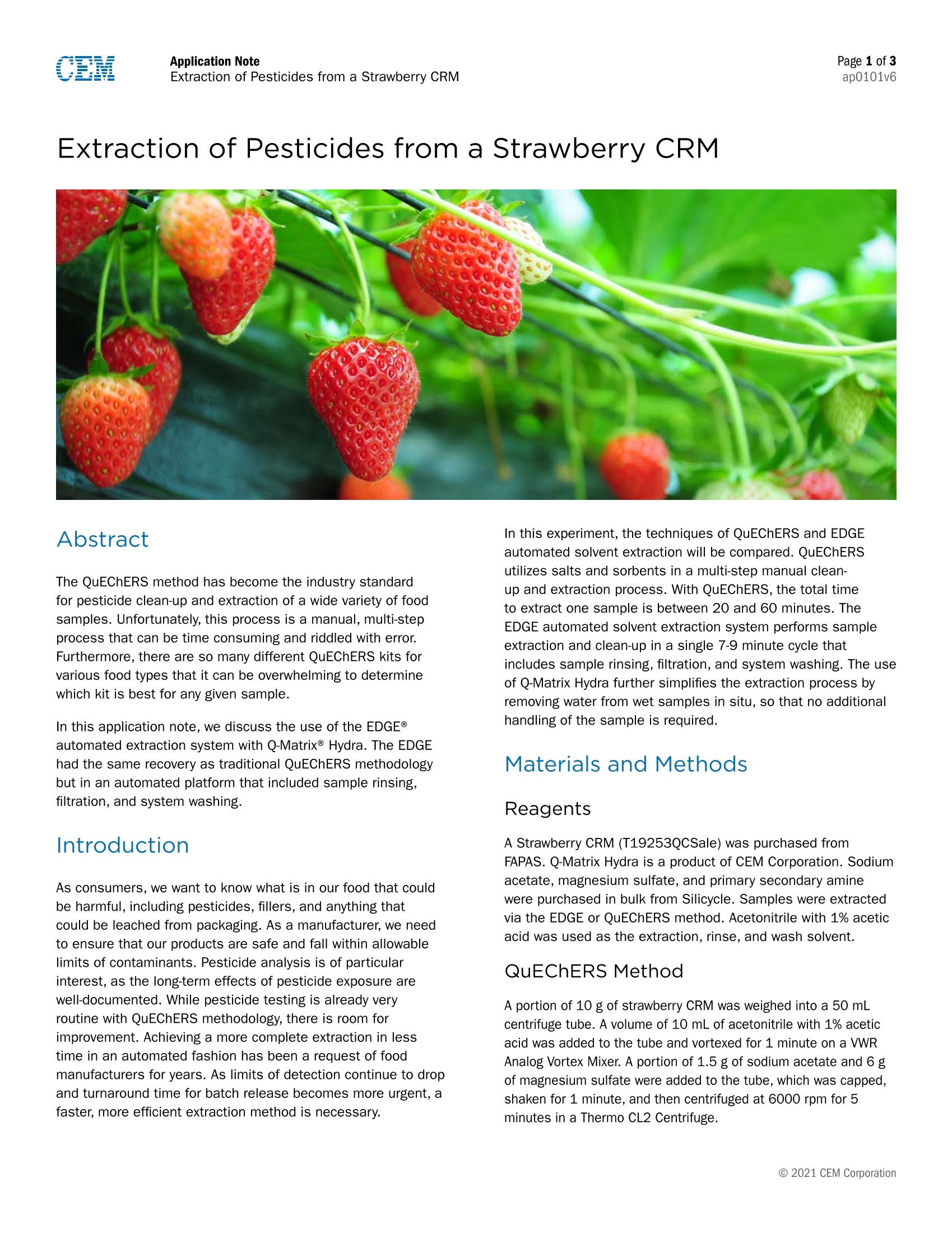

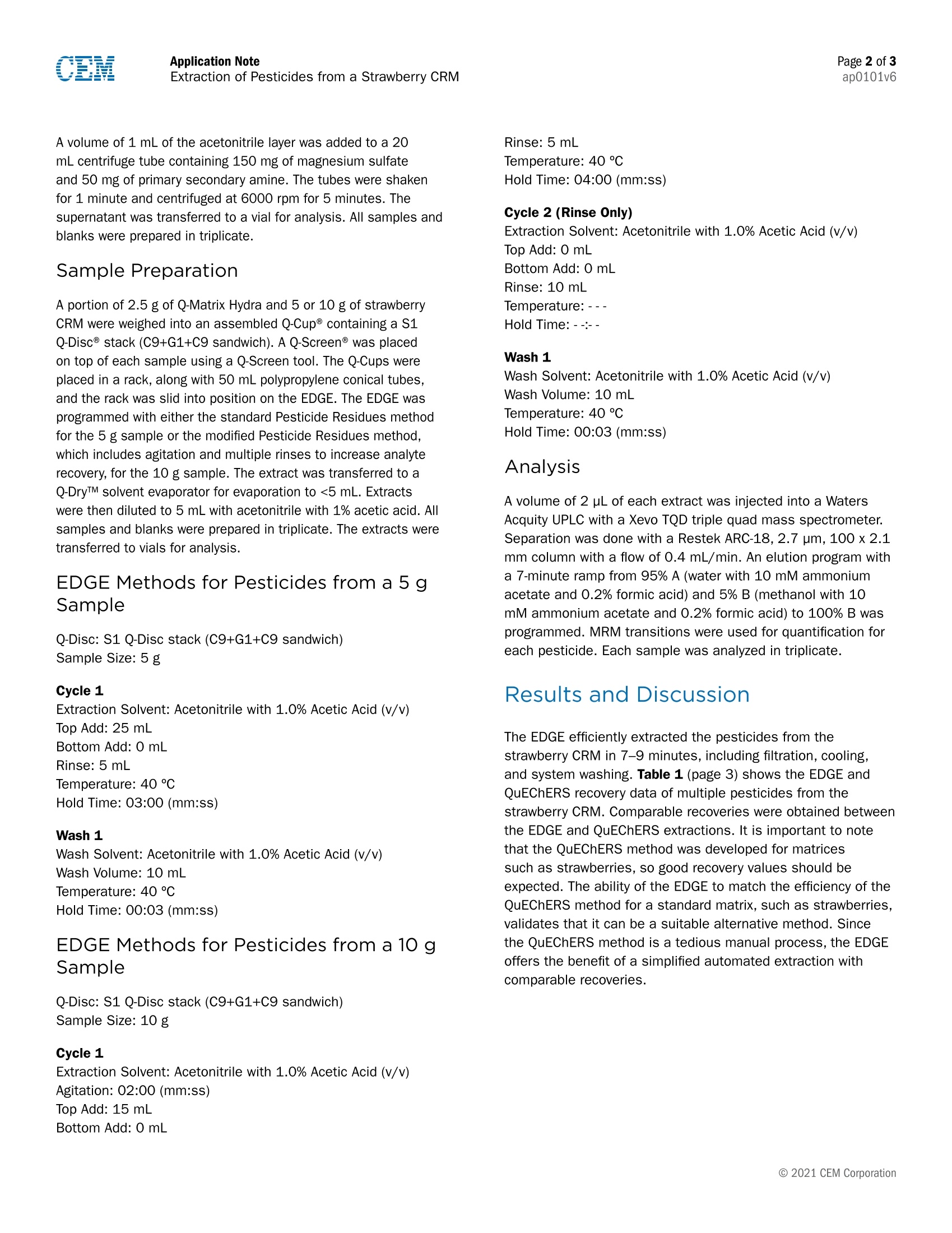

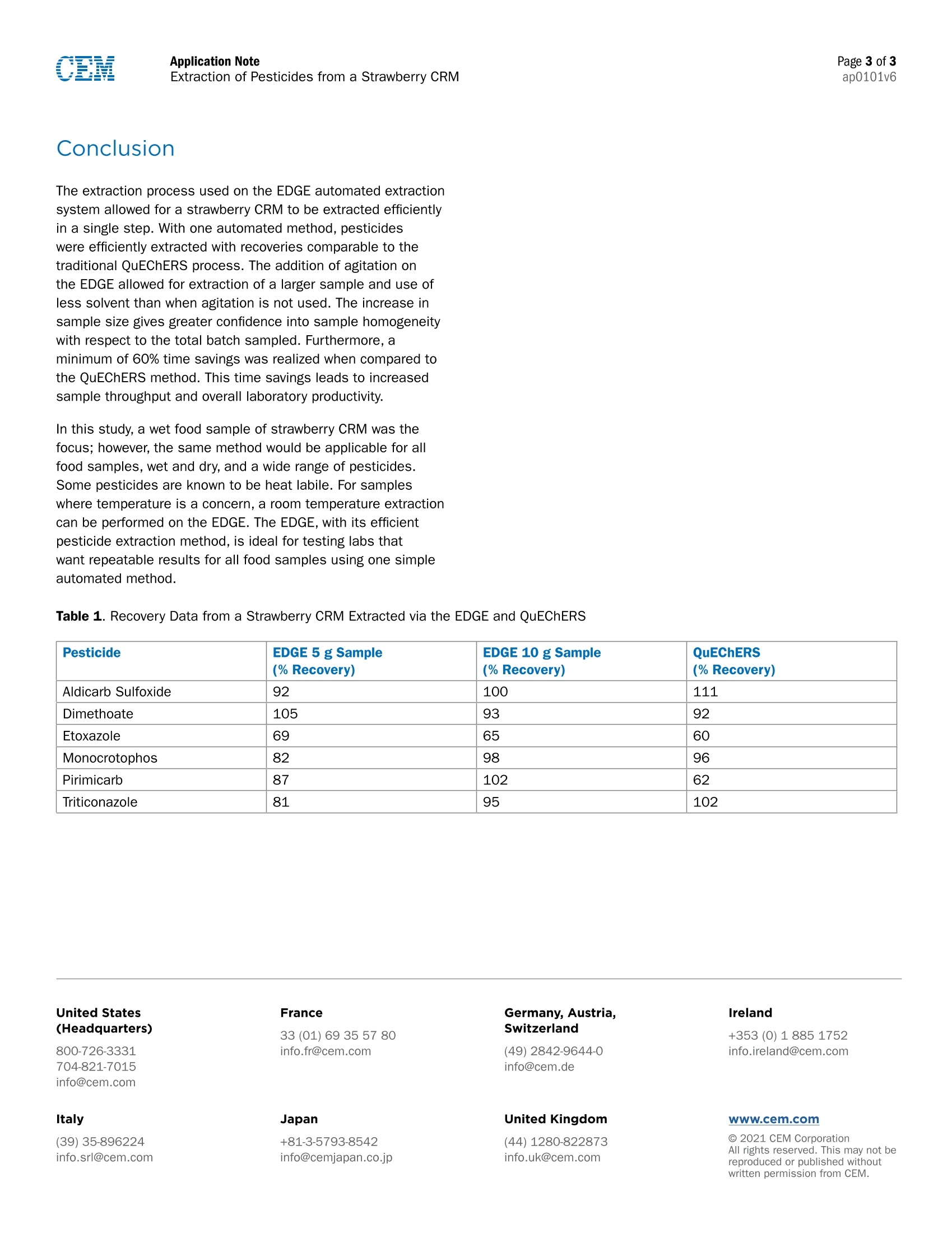

摘要 QuEChERS方法已经成为工业标准、净化和提取各种食品样品农药的行业标准。不幸的是,这个过程是手动的、多步骤的,可能很耗时,而且充满了错误。此外,有许多不同的QuEChERS试剂盒适用于各种食物类型,以至于让人不知所措。各种食物类型的QuEChERS试剂盒,要确定哪种试剂盒最适合一些特定的样品,也可能会让人无从下手。 在本应用说明中,我们讨论了EDGE®自动萃取系统与Q-Matrix®Hydra的使用。EDGE的回收率与传统的QuEChERS方法相同,不同之处在于EDGE在一个自动平台上,包括样品冲洗、过滤和系统清洗。 简介 作为消费者,我们想知道食品中哪些东西可能是有害的,包括杀虫剂、填充物和任何可能从包装中浸出的东西。作为一个制造商,我们需要确保我们的产品是安全的,并且在污染物的允许范围内。农药分析尤其值得关注,因为接触农药的长期影响是有据可查的。虽然使用QuEChERS方法进行农药测试已经非常常规,但仍有改进的空间。以自动化的方式在更短的时间内实现更完整的提取,多年来一直是食品制造商的要求。随着检测限的不断降低,批量发布的周转时间变得更加紧迫,一种更快更有效的提取方法是必要的。在这个实验中,QuEChERS和EDGE自动溶剂萃取技术将被比较。QuEChERS 在一个多步骤的手工清理和提取过程中使用盐和吸附剂。使用QuEChERS,提取一个样品的总时间为20至60分钟。EDGE自动溶剂萃取系统在一次7分钟内完成了样品的萃取和清理。EDGE自动溶剂萃取系统在一个7-9分钟的周期内完成样品萃取和清理,包括样品漂洗、过滤和系统清洗。Q-Matrix Hydra的使用进一步简化了提取过程,它能就地去除湿样品中的水分,因此不需要对样品进行额外处理。 材料和方法 试剂 一个草莓CRM(T19253QCSale)购自FAPAS。Q-Matrix Hydra是CEM公司的产品。乙酸钠、硫酸镁和伯仲胺是从Silicycle公司批量购买的。样品通过EDGE或QuEChERS方法进行提取。使用含1%乙酸的乙腈作为提取、冲洗和洗涤溶剂。QuEChERS方法将一部分10克的草莓CRM称量到一个50毫升的离心管中。向该管中加入体积为10 mL的含1%乙酸的乙腈,并在VWR模拟涡旋混合器上涡旋1分钟。将1.5克醋酸钠和6克硫酸镁加入管中,盖上盖子,摇晃1分钟,然后在Thermo CL2离心机上以6000rpm离心5分钟。将1mL的乙腈加入到一个20mL的离心管中,其中含有150mg的硫酸镁和50mg的伯胺。摇动试管1分钟,并以6000rpm离心5分钟。上清液转移到一个小瓶中进行分析。所有的样品和空白都是一式三份。 样品制备 将2.5克的Q-Matrix Hydra和5或10克的草莓CRM称量到装有S1 Q-Disc®组合(C9+G1+C9夹层)的Q Cup®中。使用Q-Screen®工具将一个Q-Screen®放置在每个样品的顶部。将Q-Cups和50mL聚丙烯锥形管放在一个架子上,然后将架子滑到EDGE的位置。对EDGE进行编程,对5克样品采用标准的农药残留法,对10克样品采用改良的农药残留法,其中包括搅拌和多次漂洗以提高分析物的回收率。提取物被转移到Q-Dry™溶剂蒸发器中,蒸发到<5毫升。然后用含1%乙酸的乙腈将提取液稀释到5毫升。所有的样品和空白都是一式三份。提取物被转移到小瓶中进行分析。 用EDGE方法检测5克样品中的杀虫剂 Q-Disc: S1 Q-Disc stack (C9+G1+C9 夹层) 样品量: 5 g循环1 提取溶剂:乙腈加1.0%醋酸(v/v) 顶部添加:25毫升 底部加入:0 mL 冲洗:5 mL 温度:40 ºC 保持时间: 03:00 (mm:ss)洗涤1 洗涤溶剂:乙腈加1.0%乙酸(v/v) 洗净量:10mL 温度:40 ºC 保持时间:00:03 (mm:ss) 用EDGE方法检测10克样品中的杀虫剂 Q-Disc: S1 Q-Disc stack (C9+G1+C9 夹层) 样品量: 10 g 循环1 提取溶剂:乙腈加1.0%醋酸(v/v) 搅拌:02:00 (mm:ss) 顶部添加:15mL 底部添加:0毫升冲洗:5 mL 温度:40 ºC 保持时间: 04:00 (mm:ss)循环2(仅漂洗) 提取溶剂:乙腈加1.0%醋酸(v/v) 顶部添加:0毫升 底部添加:0 mL 冲洗:10 mL温度: - - - 保持时间:- -:- - 洗涤1 洗涤溶剂:乙腈加1.0%乙酸(v/v) 洗净量:10mL 温度:40 ºC 保持时间:00:03 (mm:ss) 分析 每种提取物的体积为2μL,被注入带有Xevo TQD三重四级质谱仪的Waters Acquity UPLC中。使用Restek ARC-18, 2.7 µm, 100x2.1 mm色谱柱进行分离,流速为0.4 mL/min。洗脱程序为7分钟,从95%的A(水加10mM乙酸铵和0.2%甲酸)和5%的B(甲醇加10mM乙酸铵和0.2%甲酸)到100%的B。每种农药的定量都使用了MRM转换。每个样品都进行了一式三份的分析。 结果和讨论 EDGE在7-9分钟内有效的提取了草莓CRM中的杀虫剂,包括过滤、冷却和系统清洗。表1(第3页)显示了EDGE和QuEChERS对草莓CRM中多种农药的回收数据。在EDGE和QuEChERS的提取过程中,获得了可比的回收率。值得注意的是,QuEChERS方法是为草莓这样的基质开发的,所以应该有良好的回收率。EDGE能够与QuEChERS方法在标准基质(如草莓)上的效率相匹配,证明它可以成为一种合适的替代方法。QuEChERS方法是一个繁琐的手工操作过程,而EDGE提供了一个简单的自动提取优势,它们回收率相当。 总结 在EDGE自动提取系统上使用的提取过程允许在一个步骤中有效的提取草莓的CRM。通过一种自动化方法,农药被有效的提取出来,其回收率与传统的QuEChERS工艺相当。在EDGE上增加搅拌功能,与不使用搅拌时相比,EDGE增加了搅拌功能,可以提取更多的样品,使用更少的溶剂。样品数量的增加使人们对样品的均匀性有了更大的信心。此外,与QuEChERS方法相比,至少实现了节省60%的时间,促使样品产量的增加和实验室整体生产率的提高。在这项研究中,草莓CRM的湿食品样品是重点。然而,同样的方法也适用于所有的食品样品,湿的和干的,以及广泛的农药。一些农药是众所周知易受温度影响的。对于温度敏感的样品,可以在EDGE上进行室温提取。EDGE具有高效的农药提取方法,是那些希望拥有简单的自动化、对所有食品样品可实现重复结果的测试实验室的理想选择。表1.通过EDGE和QuEChERS提取的草莓CRM回收数据 毒 Application NoteExtraction of Pesticides from a Strawberry CRMPage 1 of 3ap0101v6 Extraction of Pesticides from a Strawberry CRM Abstract The QuEChERS method has become the industry standardfor pesticide clean-up and extraction of a wide variety of foodsamples. Unfortunately, this process is a manual, multi-stepprocess that can be time consuming and riddled with error.Furthermore, there are so many different QuEChERS kits forvarious food types that it can be overwhelming to determinewhich kit is best for any given sample. In this application note, we discuss the use of the EDGE@automated extraction system with Q-Matrix@ Hydra. The EDGEhad the same recovery as traditional QuEChERS methodologybut in an automated platform that included sample rinsing,filtration, and system washing. Introduction As consumers, we want to know what is in our food that couldbe harmful, including pesticides, fillers, and anything thatcould be leached from packaging. As a manufacturer, we needto ensure that our products are safe and fall within allowablelimits of contaminants. Pesticide analysis is of particularinterest, as the long-term effects of pesticide exposure arewell-documented. While pesticide testing is already veryroutine with QuEChERS methodology, there is room forimprovement. Achieving a more complete extraction in lesstime in an automated fashion has been a request of foodmanufacturers for years. As limits of detection continue to dropand turnaround time for batch release becomes more urgent, afaster, more efficient extraction method is necessary. In this experiment, the techniques of QuEChERS and EDGEautomated solvent extraction will be compared. QuEChERSutilizes salts and sorbents in a multi-step manual clean-up and extraction process. With QuEChERS, the total timeto extract one sample is between 20 and 60 minutes. TheEDGE automated solvent extraction system performs sampleextraction and clean-up in a single 7-9 minute cycle thatincludes sample rinsing, filtration, and system washing. The useof Q-Matrix Hydra further simplifies the extraction process byremoving water from wet samples in situ, so that no additionalhandling of the sample is required. Materials and Methods Reagents A Strawberry CRM (T19253QCSale) was purchased fromFAPAS. Q-Matrix Hydra is a product of CEM Corporation. Sodiumacetate, magnesium sulfate, and primary secondary aminewere purchased in bulk from Silicycle. Samples were extractedvia the EDGE or QuEChERS method. Acetonitrile with 1% aceticacid was used as the extraction, rinse, and wash solvent. QuEChERS Method A portion of 10 g of strawberry CRM was weighed into a 50 mLcentrifuge tube. A volume of 10 mL of acetonitrile with 1% aceticacid was added to the tube and vortexed for 1 minute on a VWRAnalog Vortex Mixer. A portion of 1.5 g of sodium acetate and 6 gof magnesium sulfate were added to the tube, which was capped,shaken for 1 minute, and then centrifuged at 6000 rpm for 5minutes in a Thermo CL2 Centrifuge. A volume of 1 mL of the acetonitrile layer was added to a 20mL centrifuge tube containing 150 mg of magnesium sulfateand 50 mg of primary secondary amine. The tubes were shakenfor 1 minute and centrifuged at 6000 rpm for 5 minutes. Thesupernatant was transferred to a vial for analysis. All samples andblanks were prepared in triplicate. Sample Preparation A portion of 2.5 g of Q-Matrix Hydra and 5 or 10 g of strawberryCRM were weighed into an assembled Q-Cup containing a S1Q-Disc@ stack (C9+G1+C9 sandwich). A Q-Screen@ was placedon top of each sample using a Q-Screen tool. The Q-Cups wereplaced in a rack, along with 50 mL polypropylene conical tubes,and the rack was slid into position on the EDGE. The EDGE wasprogrammed with either the standard Pesticide Residues methodfor the 5 g sample or the modified Pesticide Residues method,which includes agitation and multiple rinses to increase analyterecovery, for the 10 g sample. The extract was transferred to aQ-DryTM solvent evaporator for evaporation to <5 mL. Extractswere then diluted to 5 mL with acetonitrile with 1% acetic acid. Allsamples and blanks were prepared in triplicate. The extracts weretransferred to vials for analysis. EDGE Methods for Pesticides from a 5gSample Q-Disc: S1 Q-Disc stack (C9+G1+C9 sandwich)Sample Size: 5 g Cycle 1 Extraction Solvent: Acetonitrile with 1.0% Acetic Acid (v/v) Top Add: 25 mL Bottom Add: 0 mL Rinse: 5 mL Temperature: 40 ℃ Hold Time: 03:00 (mm:ss) Wash 1 Wash Solvent: Acetonitrile with 1.0% Acetic Acid (v/v)Wash Volume: 10 mLTemperature: 40℃Hold Time: 00:03 (mm:ss) EDGE Methods for Pesticides from a 10 gSample Q-Disc: S1 Q-Disc stack (C9+G1+C9 sandwich)Sample Size: 10 g Cycle 1 Extraction Solvent: Acetonitrile with 1.0% Acetic Acid (v/v)Agitation: 02:00 (mm:ss)Top Add: 15 mLBottom Add: 0mL Rinse: 5 mL Temperature: 40℃ Hold Time: 04:00 (mm:ss) Cycle 2 (Rinse Only) Extraction Solvent: Acetonitrile with 1.0% Acetic Acid (v/v) Top Add: 0 mL Bottom Add: 0 mL Rinse: 10 mL Temperature:--- Hold Time:--:-- Wash 1 Wash Solvent: Acetonitrile with 1.0% Acetic Acid (v/v)Wash Volume: 10 mLTemperature: 40℃Hold Time: 00:03 (mm:ss) Analysis A volume of 2 pL of each extract was injected into a WatersAcquity UPLC with a Xevo TQD triple quad mass spectrometer.Separation was done with a Restek ARC-18, 2.7 pm, 100x2.1mm column with a flow of 0.4 mL/min. An elution program witha 7-minute ramp from 95% A (water with 10 mM ammoniumacetate and 0.2% formic acid) and 5% B (methanol with 10mM ammonium acetate and 0.2% formic acid) to 100% B wasprogrammed. MRM transitions were used for quantification foreach pesticide. Each sample was analyzed in triplicate. Results and Discussion The EDGE efficiently extracted the pesticides from thestrawberry CRM in 7-9 minutes, including filtration, cooling,and system washing. Table 1 (page 3) shows the EDGE andQuEChERS recovery data of multiple pesticides from thestrawberry CRM. Comparable recoveries were obtained betweenthe EDGE and QuEChERS extractions. It is important to notethat the QuEChERS method was developed for matricessuch as strawberries, so good recovery values should beexpected. The ability of the EDGE to match the efficiency of theQuEChERS method for a standard matrix, such as strawberries,validates that it can be a suitable alternative method. Sincethe QuEChERS method is a tedious manual process, the EDGEoffers the benefit of a simplified automated extraction withcomparable recoveries. Conclusion The extraction process used on the EDGE automated extractionsystem allowed for a strawberry CRM to be extracted efficientlyin a single step. With one automated method, pesticideswere efficiently extracted with recoveries comparable to thetraditional QuEChERS process. The addition of agitation onthe EDGE allowed for extraction of a larger sample and use ofless solvent than when agitation is not used. The increase insample size gives greater confidence into sample homogeneitywith respect to the total batch sampled. Furthermore,aminimum of 60% time savings was realized when compared tothe QuEChERS method. This time savings leads to increasedsample throughput and overall laboratory productivity. In this study, a wet food sample of strawberry CRM was thefocus; however, the same method would be applicable for allfood samples, wet and dry, and a wide range of pesticides.Some pesticides are known to be heat labile. For sampleswhere temperature is a concern, a room temperature extractioncan be performed on the EDGE. The EDGE, with its efficientpesticide extraction method, is ideal for testing labs thatwant repeatable results for all food samples using one simpleautomated method. Table 1. Recovery Data from a Strawberry CRM Extracted via the EDGE and QuEChERS Pesticide EDGE 5 g Sample(% Recovery) EDGE 10 g Sample (% Recovery) QuEChERS (% Recovery) Aldicarb Sulfoxide 92 100 111 Dimethoate 105 93 92 Etoxazole 69 65 60 Monocrotophos 82 98 96 Pirimicarb 87 102 62 Triticonazole 81 95 102 United States France Germany, Austria, Switzerland Ireland (Headquarters) 33 (01)69 35 57 80 +353 (0)18851752info.ireland@cem.com 800-726-3331 info.fr@cem.com (49) 2842-9644-0 info@cem.de 704-821-7015 info@cem.com Italy Japan United Kingdom www.cem.com (39) 35-896224 +81-3-5793-8542 info.uk@cem.com C 2021 CEM Corporation All rights reserved. This may not be reproduced or published without written permission from CEM. info.srl@cem.com info@cemjapan.co.jp C CEM Corporation

确定

还剩1页未读,是否继续阅读?

培安有限公司为您提供《【Application Note】从草莓的CRM中提取杀虫剂》,该方案主要用于水果中从草莓的CRM中提取杀虫剂检测,参考标准--,《【Application Note】从草莓的CRM中提取杀虫剂》用到的仪器有EDGE全自动快速溶剂萃取仪

推荐专场

相关方案

更多

该厂商其他方案

更多