方案详情

文

滴眼液不溶性微粒检测是检查滴眼液中不溶性颗粒物的大小和数量。

1、仪器

使用显微镜,用于保留不溶性颗粒物的过滤器组件和用于测定的过滤膜。

(i)显微镜:配有测微尺系统、移动台和照明器的显微镜,并可调整到100倍放大倍率。

(ii)用于保留不溶性微粒的过滤器的组成:用于保留不溶性微粒的过滤器组成包括一个由玻璃或适当材料制成的过滤器支架,该材料不能在试验中造成任何故障,以及一个夹子。该装置需能够安装直径为25 mm或13 mm的滤膜,并可在减压下使用。

(iii)试验用过滤膜:滤膜为白色,直径为25 mm或13 mm,标称孔径不超过10 μm,并压印有约3 mm的网格标记。初步试验后,过滤膜上不应发现尺寸等于或大于25 μm的不溶性颗粒物。必要时,用水清洗过滤器以进行颗粒物测试。

方案详情

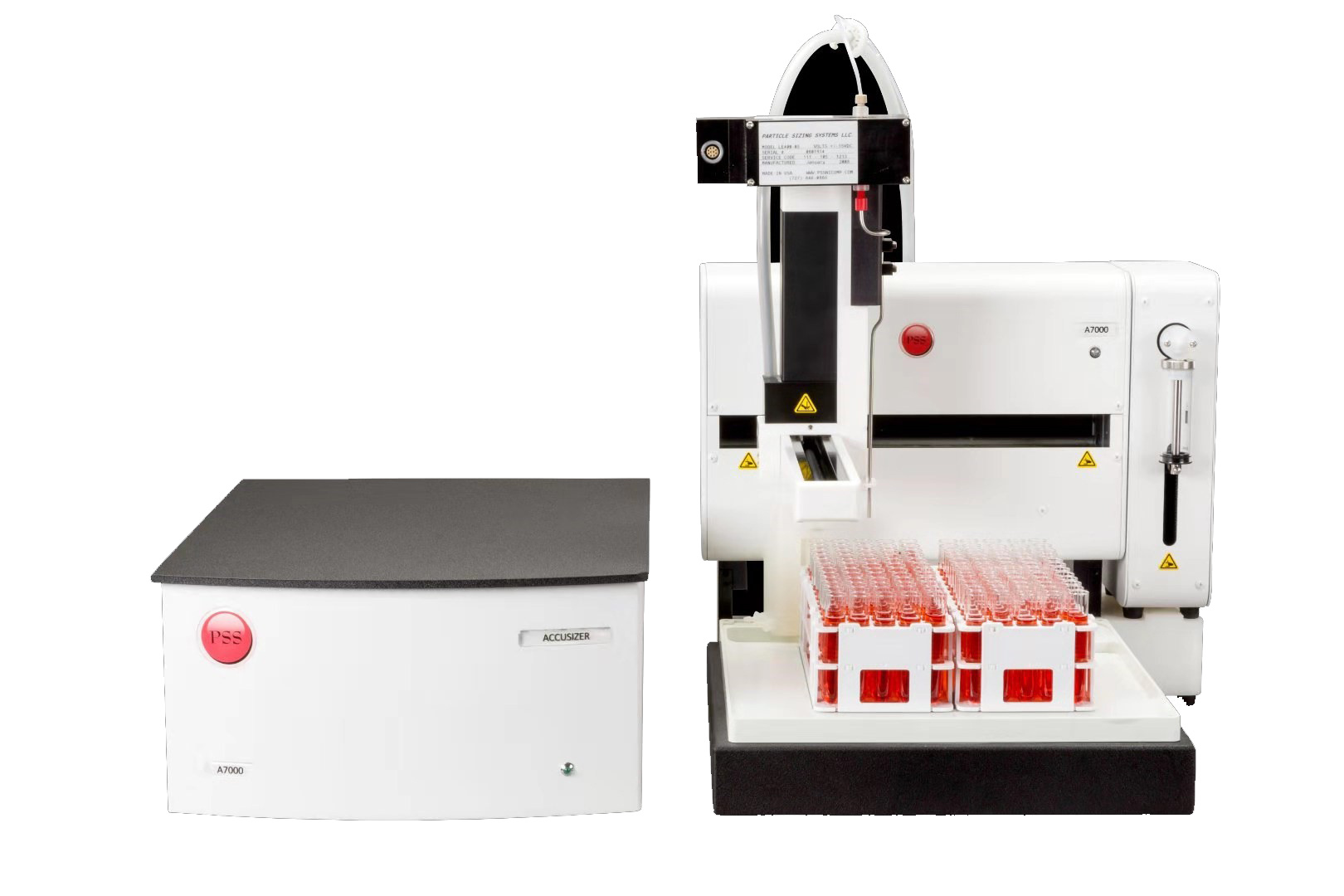

1546.08Insoluble Particulate Matter Test for Ophthalmic Solutions / General TestsJP XVII JP XVIIGeneral Tests / 6.09 Disintegration Test155 The number of test specimens must be adequate to providea statistically sound assessment. For large-volume parenter-als or for small-volume parenterals havinga volume of 25mL or more, fewer than 10 units may be tested, based on anappropriate sampling plan. Wet the inside of the filter holder fitted with the mem-brane filter with several milliliter of particle-free water.Transfer to the filtration funnel the total volume of a solu-tion pool or of a single unit, and apply vacuum. If neededadd stepwise a portion of the solution until the entire volumeis filtered. After the last addition of solution, begin rinsingthe inner walls of the filter holder by using a jet of particle-free water. Maintain the vacuum until the surface of themembrane filter is free from liquid. Place the filter in a petridish and allow the filter to air-dry with the cover slightlyajar. After the filter has been dried, place the petri dish onthe stage of the microscope, scan the entire membrane filterunder the reflected light from the illuminating device, andcount the number of particles that are equal to or greaterthan 10 um and the number of particles that are equal to orgreater than 25 um. Alternatively, partial filter count anddetermination of the total filter count by calculation isallowed. Calculate the mean number of particles for thepreparation to be examined. The particle sizing process with the use of the circular di-ameter graticule is carried out by transforming mentally theimage of each particle into a circle and then comparing it tothe 10 um and 25 um graticule reference circles. Thereby theparticles are not moved from their initial locations within thegraticule field of view and are not superimposed on the refer-ence circles for comparison. The inner diameter of the trans-parent graticule reference circles is used to size white andtransparent particles, while dark particles are sized by usingthe outer diameter of the black opaque graticule referencecircles. In performing the microscopic particle count test (Method2) do not attempt to size or enumerate amorphous, semi-liquid, or otherwise morphologically indistinct materials thathave the appearance of a stain or discoloration on the mem-brane filter. These materials show little or no surface reliefand present a gelatinous or film-like appearance. In suchcases the interpretation of enumeration may be aided by test-ing a sample of the solution by Method 1. 2.4.Evaluation Test 2.A-Solutions for injection supplied in containers witha nominal content ofequal to ors more than 100 mL The preparation complies with the test if the average numberof particles present in the units tested does not exceed 12 permilliliter equal to or greater than 10 um and does not exceed2 per milliliter equal to or greater than 25 um. Test 2.B-Solutions for injection supplied in containers witha nominal content of less than 100 mL The preparation complies with the test if the average numberof particles present in the units tested does not exceed 3000per container equal to or greater than 10 um and does notexceed 300 per container equal to or greater than 25 um. *3. Reagents Particle-free water: The filtered water through a mem-brane filter with a pore size not exceeding 0.45 um, contain-ing not more than 5 particles of 10 um or greater size, andnot more than 2 particles of 25 um or greater size in 10 mLof the insoluble particle number measured by the light ob-scuration particle counter.。 6.08 Insoluble Particulate MatterTest for Ophthalmic Solutions Insoluble Particulate Matter Test for Ophthalmic Solu-tions is to examine for the size and the number of insolubleparticulate matter in Ophthalmic Solutions. 1.Apparatus Use a microscope, filter assembly for retaining insolubleparticulate matter and membrane filter for determination. (i)Microscope: The microscope is equipped withn amicrometer system, a mobile stage and an illuminator, and isadjusted to 100 magnifications. (ii)Filter assembly for retaining insoluble particulatematter: The filter assembly for retaining insoluble particu-late matter consists of a filter holder made of glass or aproper material uncapable of causing any trouble in testing,and a clip. The unit is capable of fitting with a membranefilter 25 mm or 13 mm in diameter and can be used underreduced pressure. (iii)Membrane filter for testing: The membrane filter iswhite in color, 25 mm or 13 mm in diameter, not more than10 um in nominal pore size and is imprinted with about 3mm grid marks. Upon preliminary testing, the insoluble par-ticulate matter equal to or greater than 25 um in size shouldnot be found on the filter. When necessary, wash the filterwith water for particulate matter test. 2. Reagents Water for particulate matter test: Water prepared be-fore use by filtering through a membrane filter with a poresize not exceeding 0.45 um. It contains not more than 10 par-ticles of 10 um or grater size in 100 mL. 3. Procedure 3.1. Aqueous ophthalmic solutions Carry out all operations carefully in clean equipment andfacilities which are low in dust. Fit the membrane filter ontothe membrane filter holder, and fix them with the clip.Thoroughly rinse the holder inside with water for particulatematter test, and filter under reduced pressure with 200 mL ofwater for particulate matter test at a rate of 20 to 30 mL perminute. Apply the vacuum until the surface of the mem-brane filter is free from water, and remove the membranefilter. Place the filter in a flat-bottomed petri dish with thecover slightly ajar, and dry the filter fully at a temperaturenot exceeding 50°C. After the filter has been dried, place thepetri dish on the stage of the microscope. Under a down-light from an illuminating device, adjust the grid of themembrane filter to the coordinate axes of the microscope,adjust the microscope so as to get the best view of the insolu-ble particulate matter, then count the number of particlesthat are equal to or greater than 150 um within the effectivefiltering area of the filter, moving the mobile stage, andascertain that the number is not more than 1. In this case theparticle is sized on the longest axis. Fit another membrane filter to the filtration device, andfix them with the clip, then wet the inside of the filter holderwith several mL of water for particulate matter test. Cleanthe outer surface of the container, and mix the sample solu-tion gently by inverting the container several times. Removethe cap, clean the outer surface of the nozzle, and pour thesample solution into a measuring cylinder which has beenrinsed well with water for particulate matter test. Repeat theprocess to prepare 25 mL of the test solution. Pour the testsolution into the filter holder along the inner wall of the holder. Apply the vacuum and filter mildly so as to keep the so- lution always on the filter. As for viscous sample solution,dilute suitably with water for particulate matter test or suita-ble diluent and then filter as described above. When theamount of the solution on the filter becomes small, add 30mL of water for particulate matter test or suitable diluent insuch manner as to wash the inner wall of the filter holder.Repeat the process 3 times with 30 mL of the water. Applythe vacuum gently until the surface of the membrane filter isfree from water. Place the filter in a petri dish, and dry thefilter at a temperature below 50°C with the cover slightlyajar. After the filter has been dried, place the petri dish onthe stage of the microscope, and count the number of parti-cles which are equal to or larger than 300 um within the ef-fective filtering area of the filter according to the sameprocedure of the microscope as described above. In this casethe particle is sized on the longest axis. 3.2.O(phthalmic solutions which are dissolved before useProceed as directed in Aqueous Ophthalmic Solutionsafter dissolving the sample with the constituted solution. 3.3. Suspension type ophthalmic solutions Proceed as directed in Aqueous Ophthalmic Solutions.Take 25 mL of the sample in a vessel, which has been rinsedwell with water for particulate matter test, add a suitableamount of a suspension-solubilizing solvent or an adequatesolvent, shake to dissolve the suspending particles, and usethis solution as the sample solution. Use a membrane filterwhich is not affected by the solvent to be used.3.4.(Ophthalmic solutions contained in a single-dose con- tainer Proceed as directed in Aqueous Ophthalmic Solutions,using 10 samples for the test. A 13-mm diameter membranefilter and a 4-mm diameter filter holder for retaining insolu-ble particulate matter are used. 4. Evaluation The preparation complies with the test if the calculatednumber per mL of insoluble particles of a size equal to orgreater than 300 um is not more than 1. 6.0)9 Disintegration Test This test is harmonized with the European Pharmacopoeiaand the U. S. Pharmacopeia. The parts of the text that arenot harmonized are marked with symbols (*). Disintegration Test is provided to determine whethertablets, capsules,granules, dry syrups or pills。 disintegratewithin the prescribed time when placed in a liquid medium atthe experimental conditions presented below. For the purposes of this test, disintegration does not implycomplete solution of the unit or even of its active con-stituent. l。AApparatus The apparatus consists of a basket-rack assembly,a1000-mL, low-form beaker, 138 to 160 mm in height andhaving an inside diameter of 97 to 115 mm for the immersionfluid, a thermostatic arrangement for heating the fluid be-tween 35° and 39°, and a device for raising and lowering thebasket in the immersion fluid at a constant frequency ratebetween 29 and 32 cycles per minute through a distance ofnot less than 53 mm and not more than 57 mm. The volumeof the fluid in the vessel is such that at the highest point ofthe upward stroke the wire mesh remains at least 15 mmbelow the surface of the fluid and descends to not less than25 mm from the bottom of the vessel on the downwardstroke. At no time should the top of the basket-rack assem- bly become submerged. The time required for the upwardstroke is equal to the time required for the downward stroke,and the change in stroke direction is a smooth transition,rather than an abrupt reversal of motion. The basket-rackassembly moves vertically along its axis. There is no appreci-able horizontal motion or movement of the axis from thevertical. )Basket-rack assembly: The basket-rack assembly con-sists of six open-ended transparent tubes, each 77.5 ± 2.5mm long and having an inside diameter of 20.7 to 23 mmand a wall 1.0 to 2.8 mm thick; the tubes are held in a verti-cal position by two plates, each 88 to 92 mm in diameter and5 to 8.5 mm in thickness, with six holes, each 22 to 26 mm indiameter, equidistant from the center of the plate andequally spaced from one another. Attached to the under sur-face of the lower plate is a woven stainless steel wire cloth,which has a plain square weave with 1.8- to 2.2-mm aper-tures and with a wire diameter of 0.57 to 0.66 mm. The partsof the apparatus are assembled and rigidly held by means ofthree bolts passing through the two plates. A suitable meansis provided to suspend the basket-rack assembly from theraising and lowering device using a point on its axis. Thebasket-rack assembly conforms to the dimensions found inFig. 6.09-1. The design of the basket-rack assembly may bevaried somewhat provided the specifications for the glasstubes and the screen mesh size are maintained: ◆for exam-ple, in order to secure the glass tubes and the upper and thelower plastic plates in position at the top or the bottom, anacid-resistant metal plate, 88-92 mm in diameter and 0.5 -1 mm in thickness, having 6 perforations, each about 22 to26 mm in diameter, may be used which coincide with thoseof the upper plastic plate and upper open ends of the glasstubes.。 (ii) Disks: The use of disks is permitted only where speci-fied or allowed. Each tube is provided with a cylindrical disk9.5±0.15mm thick and 20.7±0.15 mm in diameter. Thedisk is made of a suitable, transparent plastic material hav-ing a specific gravity of between 1.18 and 1.20. Five parallel2± 0.1 mm holes extend between the ends of the cylinder.One of the holes is centered on the cylindrical axis. The otherholes are centered 6 ± 0.2 mm from the axis on imaginarylines perpendicular to the axis and parallel to each other.Four identical trapezoidal-shaped planes are cut into the wall Fig. 6.09-1 Disintegration apparatus The JP Drugs are to be tested according to the provisions given in the pertinent monographs, General Notices, General Rules for Crude Drugs,General Rules for Preparations, and General Tests for their conformity to the Japanese Pharmacopoeia. (See the General Notices .) 日本药典6.08对滴眼液的不溶性颗粒检测规范 滴眼液不溶性微粒检测是检查滴眼液中不溶性颗粒物的大小和数量。1、仪器使用显微镜,用于保留不溶性颗粒物的过滤器组件和用于测定的过滤膜。(i)显微镜:配有测微尺系统、移动台和照明器的显微镜,并可调整到100倍放大倍率。(ii)用于保留不溶性微粒的过滤器的组成:用于保留不溶性微粒的过滤器组成包括一个由玻璃或适当材料制成的过滤器支架,该材料不能在试验中造成任何故障,以及一个夹子。该装置需能够安装直径为25 mm或13 mm的滤膜,并可在减压下使用。(iii)试验用过滤膜:滤膜为白色,直径为25 mm或13 mm,标称孔径不超过10 μm,并压印有约3 mm的网格标记。初步试验后,过滤膜上不应发现尺寸等于或大于25 μm的不溶性颗粒物。必要时,用水清洗过滤器以进行颗粒物测试。2、试剂颗粒物测试用水:使用前通过孔径不超过0.45 μm的过滤膜过滤制备的水。在100 mL水中,尺寸大于等于10 μm的粒子不超过10个。3、步骤3.1滴眼液溶液在低粉尘的干净设备和设施中仔细执行所有操作。将过滤膜安装到过滤器支架上,并用夹子固定。用不溶性微粒测试用水彻底冲洗支架内部,并在减压下用200 mL不溶性微粒测试用水以20-30 mL/min的速度进行过滤。施加真空,直到过滤膜表面无水,然后拆下过滤膜。将过滤膜放置在平底皮氏培养皿中,盖子稍微半开,并在不超过50℃的温度下完全干燥过滤膜。过滤膜干燥后,将皮氏培养皿放在显微镜台上。在照明装置的筒灯下,将过滤膜的网格调整至显微镜的坐标轴,调整显微镜以获得不溶性颗粒物的最佳视图,然后计算过滤膜有效过滤区域内的尺寸等于或大于150 μm的不溶性微粒数量,对移动台进行移动,并确定数量不超过1。在这种情况下,粒子在最长轴上进行尺寸测量。将另一个过滤膜安装到过滤装置上,并用夹子固定,然后用几毫升水湿润过滤器支架的内部,以进行颗粒物测试。清洁容器外表面,将容器倒置几次,轻轻混合样品溶液。取下盖子,清洁喷嘴外表面,并将样品溶液倒入已用水冲洗干净的量筒中,以进行颗粒物测试。重复该过程以制备25 mL试验溶液。将试液沿过滤器支架内壁倒入过滤器支架。施加真空并轻轻过滤,以保持溶液始终在过滤膜上。对于粘性样品溶液,用颗粒物试验用水或适当稀释剂进行稀释,然后按上述方法过滤。当过滤器上的溶液量变小时,添加30 mL颗粒物测试用水或适当的稀释剂,以清洗过滤器支架的内壁。用30mL水重复该过程3次。轻轻地施加真空,直到过滤膜表面无水为止。将过滤膜放置在皮氏培养皿中,并在低于50℃的温度下干燥过滤膜,盖子稍微微开。过滤膜干燥后,将皮氏培养皿放在显微镜台上,按照上述相同的显微镜操作步骤,计算过滤膜有效过滤区域内等于或大于300 μm的颗粒数量。在这种情况下,粒子在最长轴上进行尺寸测量。3.2.使用前溶解的滴眼液用配制的溶液溶解样品后,按照眼用水溶液中的指示进行检测。3.3.悬液型滴眼液按照眼用水溶液中的指示进行。在已用水充分冲洗过的容器中取25 mL样品进行颗粒物测试,添加适量的悬浮剂或足够的溶剂,摇动以溶解悬浮颗粒,并将此溶液用作样品溶液。使用不受所用溶剂影响的过滤膜。3.4.单剂量容器中的滴眼液按照眼用水溶液中的指示进行,使用10个样品进行测试。使用直径为13 mm的薄膜过滤器和直径为4 mm的过滤器支架,用于保留不溶性颗粒物。 4.评估如果每毫升不溶性颗粒(尺寸等于或大于300 μm)的计算数量不超过1,则制剂符合测试要求。 解决方案:上海胤煌科技有限公司为滴眼液中的不溶性微粒检测提供了如下产品: YH-MIP-0103显微计数法不溶性微粒分析仪技术优势:√全自动的测试系统、自动扫描、自动计数、自动出具报告、减少人为操作误差;√全自动检测系统,减少在使用过程中对测试人员眼睛的伤害;√可以区分颗粒性质,鉴别不溶性微粒的来源,判断颗粒是金属还是纤维;√符合中国药典、美国药典、欧洲药典、日本药典等各国药典对于不溶性微粒检查的要求。

确定

还剩1页未读,是否继续阅读?

上海胤煌科技有限公司为您提供《日本产眼药水中不溶性微粒检测方案(不溶性微粒)》,该方案主要用于化药制剂中其他检测,参考标准--,《日本产眼药水中不溶性微粒检测方案(不溶性微粒)》用到的仪器有0903显微计数法-不溶性微粒分析仪

推荐专场

相关方案

更多

该厂商其他方案

更多