方案详情

文

现在多孔、无菌的医疗配件包可以有效地按照ASTM F2054进行测试(以设定的增速往包装内充气增加压力,直到包装封口破裂),无需繁琐的准备工作——节省时间和成本。如果包装密封性有泄露点,ASTM F2054这种方法能够及时检测出来,它准确的测试整个包装的密封强度。

方案详情

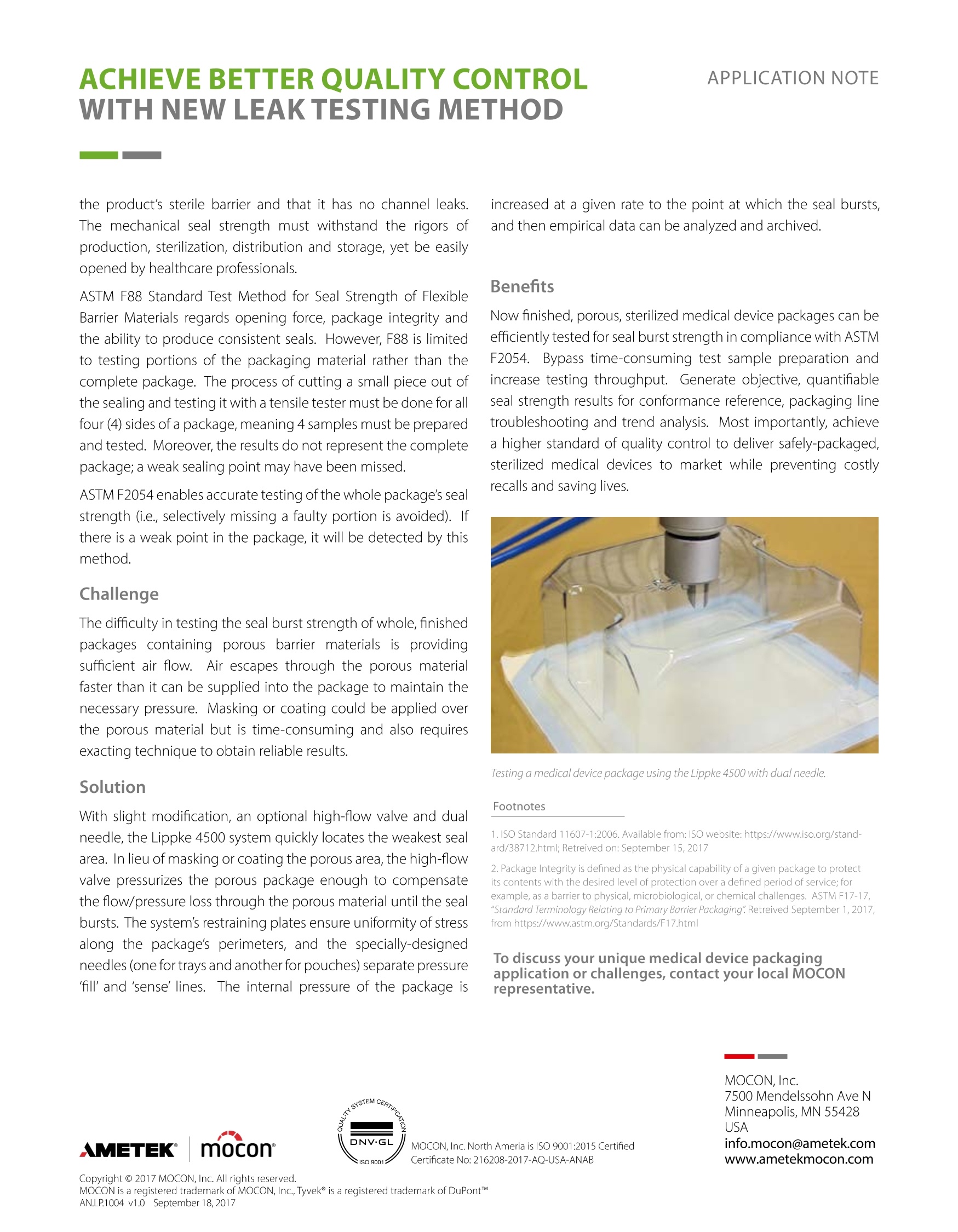

APPLICATION NOTE TESTING THE SEALSTRENGTHOFPOROUS MEDICALDEVICEPACKAGES Now porous, sterilized medical device packagescan be tested efficiently in compliance with ASTMF2054 without tedious preparation - saving timeand lives. After primary packaging, medical devices are sterilized in variousways (e.g., chemically with ethylene oxide (EtO), physically withsteam, irradiation). Some of these processes require a portionof the package to be breathable.This is accomplished withgas-porous materials such as medical-grade paper and Tyvek°which allow penetration of sterilant but not microorganisms,and provide excellent seal and peel functionality when properlyapplied. ISO Standard 11607-1:2006 Packaging for terminally sterilizedmedical devices specify test methods for materials, preformedsterile barrier systems, sterile barrier systems and packagingsystems. Essentially, seal strength and package integritymustbe validated to ensure the protective packaging will uphold ACHIEVE BETTER QUALITY CONTROLWITH NEW LEAKTESTING METHOD the product's sterile barrier and that it has no channel leaks.The mechanical seal strength must withstand the rigors ofproduction, sterilization, distribution and storage, yet be easilyopened by healthcare professionals. ASTM F88 Standard Test Method for Seal Strength of FlexibleBarrier Materials regards opening force, package integrity andthe ability to produce consistent seals. However, F88 is limitedto testing portions of the packaging material rather than thecomplete package. The process of cutting a small piece out ofthe sealing and testing it with a tensile tester must be done for alfour (4) sides of a package, meaning 4 samples must bepreparedand tested. Moreover, the results do not represent the completepackage; a weak sealing point may have been missed. lASTM F2054 enables accurate testing of the whole package's sealstrength (i.e., selectively missing a faulty portion is avoided). Ifthere is a weak point in the package, it will be detected by thismethod. challenge The difficulty in testing the seal burst strength of whole, finishedlpackages containing porous barrier materials is providingsufficient air flow.Air escapes through the porous materialfaster than it can be supplied into the package to maintain thenecessary pressure. Masking or coating could be applied overlthe porous material but is time-consuming and also requiresexacting technique to obtain reliable results. Solution With slight modification, an optional high-flow valve and duaneedle, the Lippke 4500 system quickly locates the weakest sealarea. Inlieu of masking or coating the porous area, the high-flowvalve pressurizes the porous package enough to compensatethe flow/pressure loss through the porous material until the sealbursts. The system's restraining plates ensure uniformity of stressalong the package's perimeters, and the specially-designedneedles (one for trays and another for pouches) separate pressure'fill' and 'sense' lines.S.TThe internal pressure of the package is increased at a given rate to the point at which the seal bursts,. and then empirical data can be analyzed and archived. Benefits Now finished, porous, sterilized medical device packages can beefficiently tested for seal burst strength in compliance with ASTMF2054.Bypass time-consuming test sample preparation andincrease testing throughput. Generate objective, quantifiableseal strength results for conformance reference, packaging linetroubleshooting and trend analysis. Most importantly, achievea higher standard of quality control to deliver safely-packaged,sterilized medical devices to market while preventing costlyrecalls and saving lives. Testing a medical device package using the Lippke 4500 with dual needle Footnotes 1. ISO Standard 11607-1:2006. Available from: ISO website:https://www.iso.org/standard/38712.html; Retreived on: September 15, 2017 , 2. Package Integrity is defined as the physical capability of a given package to protectits contents with the desired level of protection over a defined period of service;forexample, as a barrier to physical, microbiological, or chemical challenges. ASTM F17-17"Standard Terminology Relating to Primary Barrier Packaging" Retreived September 1, 2017,from https://www.astm.org/Standards/F17.html To discuss your unique medical device packagingapplication or challenges, contact your local MOCONrepresentative. MOCON,Inc. ( 7500 Mendelssohn Ave N Minneapolis, MN 55428 USA ) info.mocon@ametek.comwww.ametekmocon.com AMETEK°mocon° MOCON,Inc. North Ameria is ISO CertifiedCertificate No: AQ-USA-ANABCopyright ◎ MOCON, Inc. All rights reserved.MOCON is a registered trademark of MOCON,Inc., Tyvek" is a registered trademark of DuPont"AN.LP.v. September ISO标准11607-1:2006最终灭菌医疗器械的包装规定了材料、预制无菌屏障系统、无菌阻隔系统和包装系统的测试方法。从本质上讲,在包装检测线上,密封强度和包装完整性必须进行验证,确保保护性包装符合质量控制,形成质量保护的闭环。

确定

还剩1页未读,是否继续阅读?

阿美特克膜康为您提供《爆破测试如何检测医疗包装密封性》,该方案主要用于塑料中密封性测试检测,参考标准--,《爆破测试如何检测医疗包装密封性》用到的仪器有膜康(MOCON)医疗包装件密封测试仪、Dansensor 负压法密封性测试仪、膜康氧气透过率测试仪OX-TRAN® Model 2/22 、膜康水蒸气透过率测试仪PERMATRAN-W® Model 3/34

推荐专场

相关方案

更多