方案详情

文

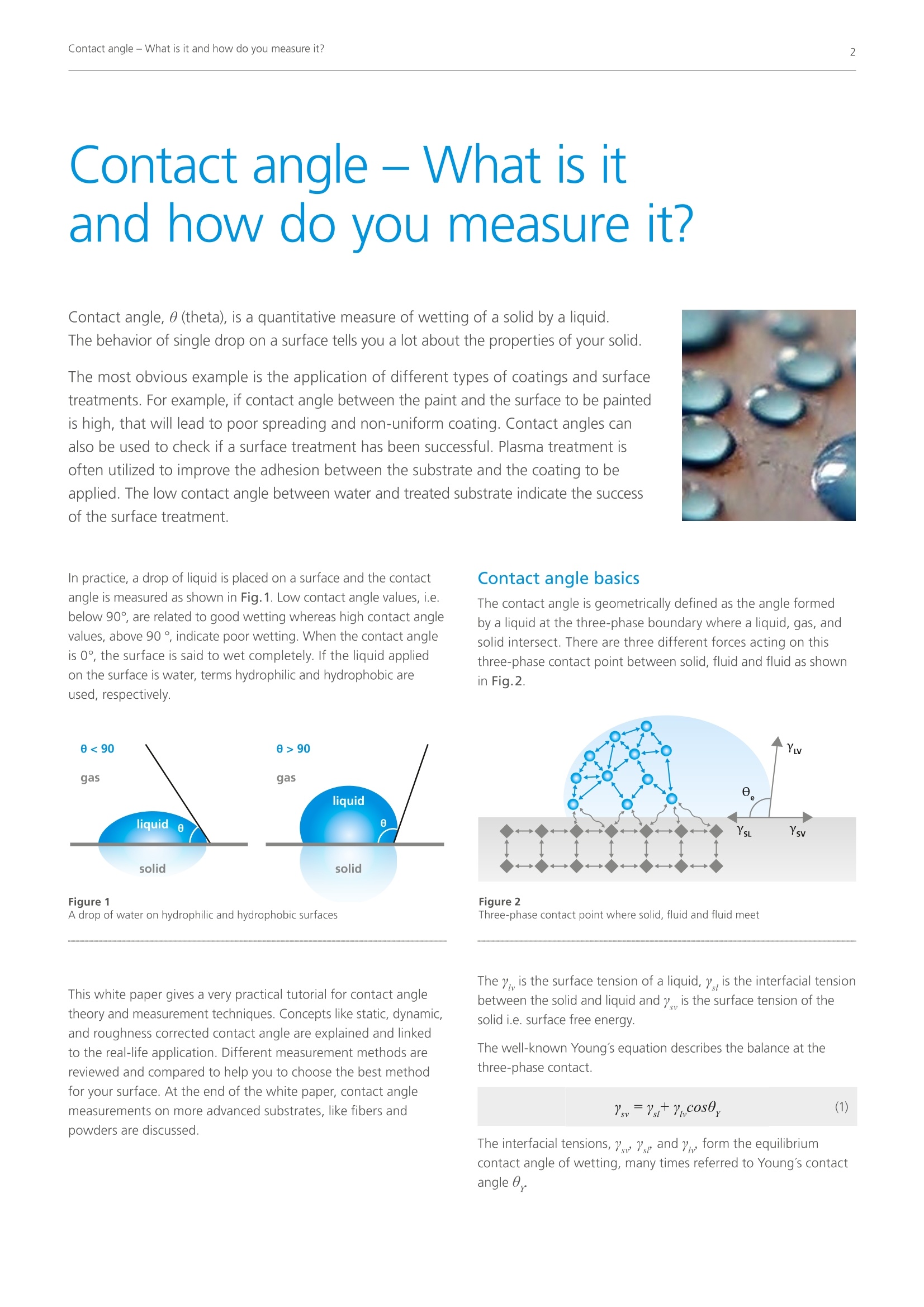

接触角基础知识以及如何测量接触角:接触角在几何上定义为液滴在固液气的三相边界处形成的角度。在固液气相之间的三相接触点上有三种不同的作用力作用于该点。

γlv是液体的表面张力,γsl是固体和液体之间的界面张力,γsv是固体的表面张力,即表面自由能。

众所周知的杨氏方程式描述了三相接触处的平衡:

γsv=γsl+ γlv cosθY

界面张力γsv,γsl和γlv形成了润湿的平衡接触角,通常称为杨氏接触角θY。

杨氏方程式假设表面是理想的。这意味着表面是平坦、刚性、完全光滑和化学性质均一的。此外,它还假设系统是稳定的,即液体与固体表面之间没有相互作用。由于上述两个标准在现实测试中均无法满足,因此经常进行前进和后退接触角的测量(动态角)。使用特殊的仪器得到的表面粗糙度也可以用来校正接触角。因此,接触角可分为三类:静态,动态和粗糙度校正接触角。

方案详情

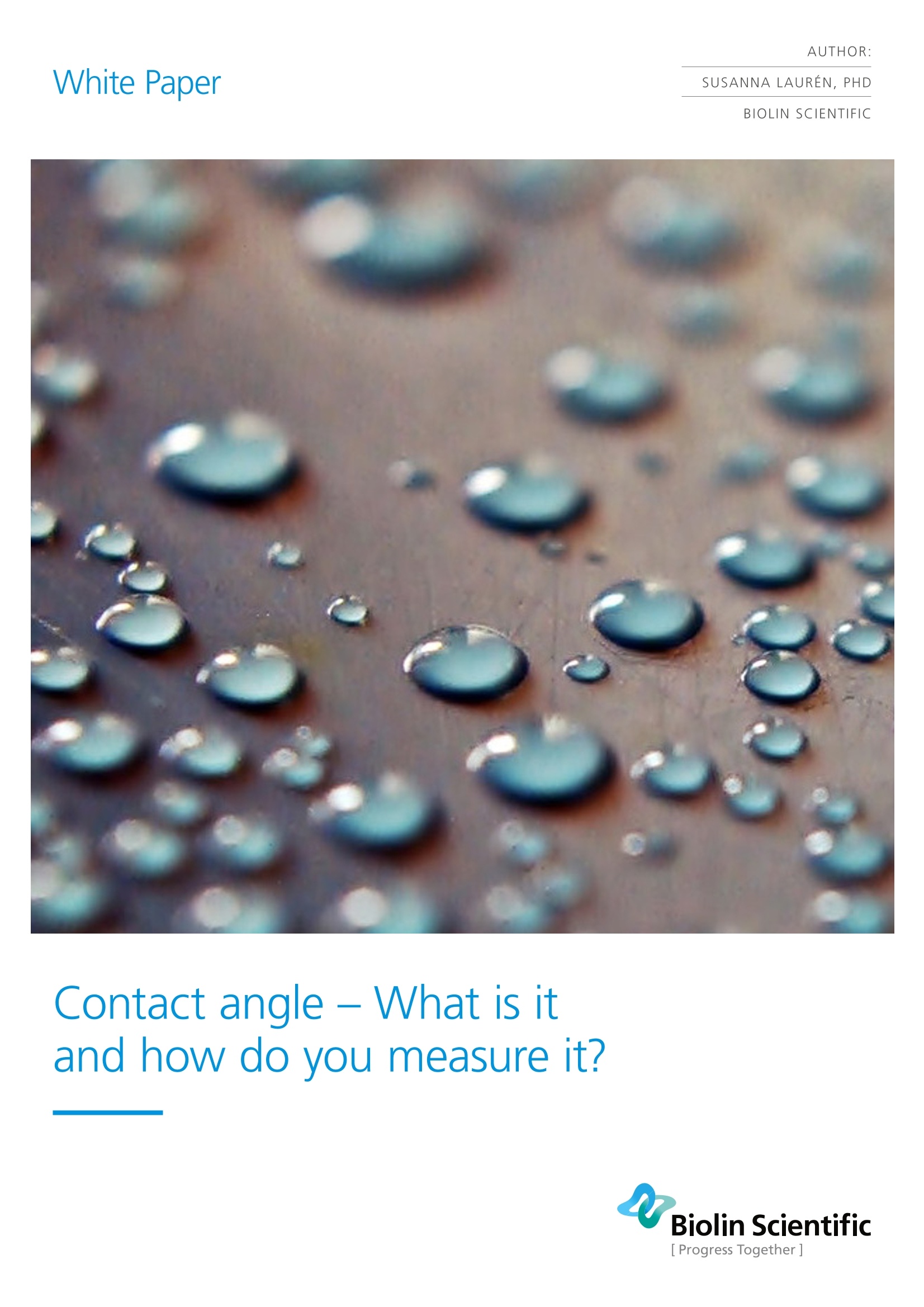

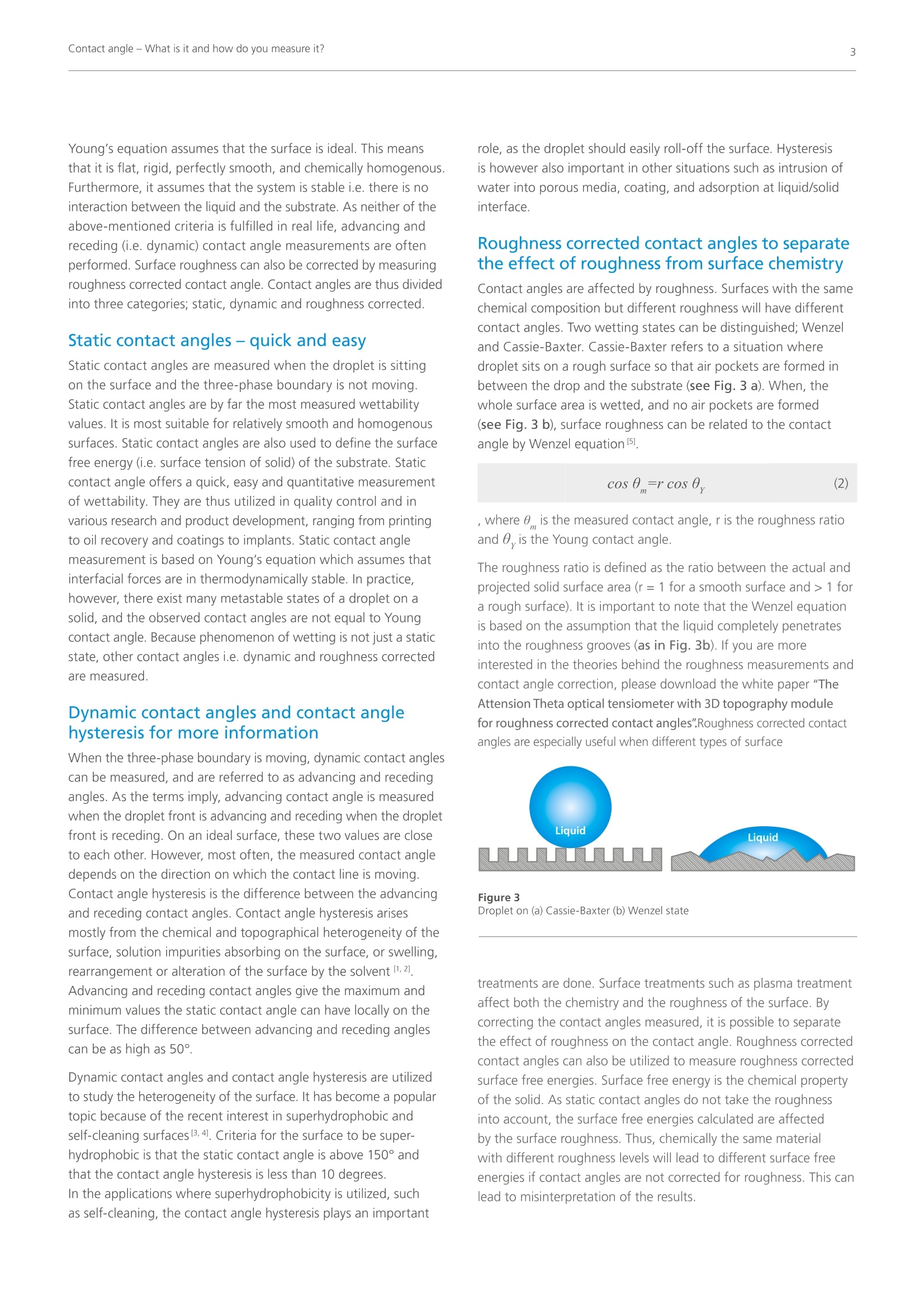

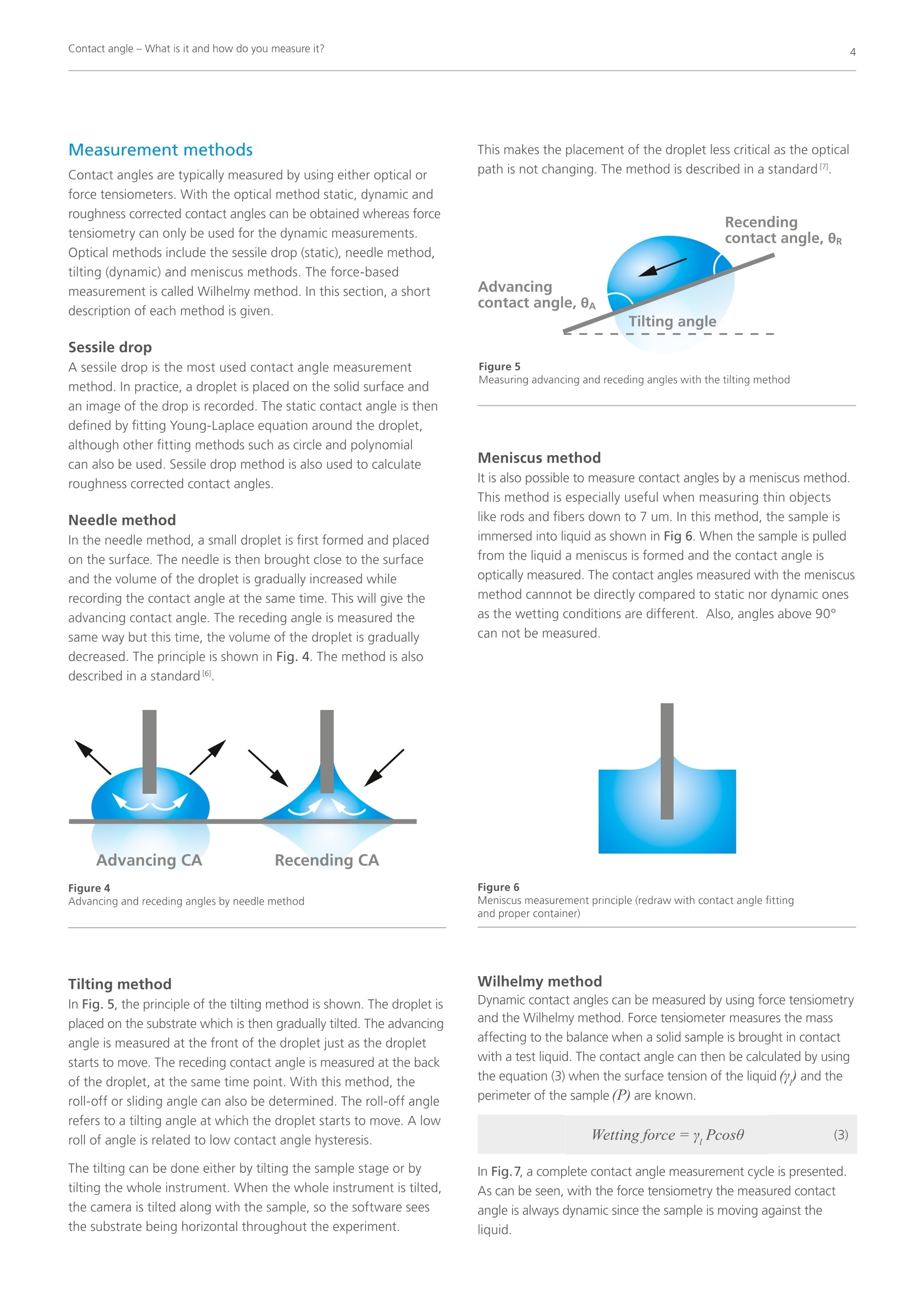

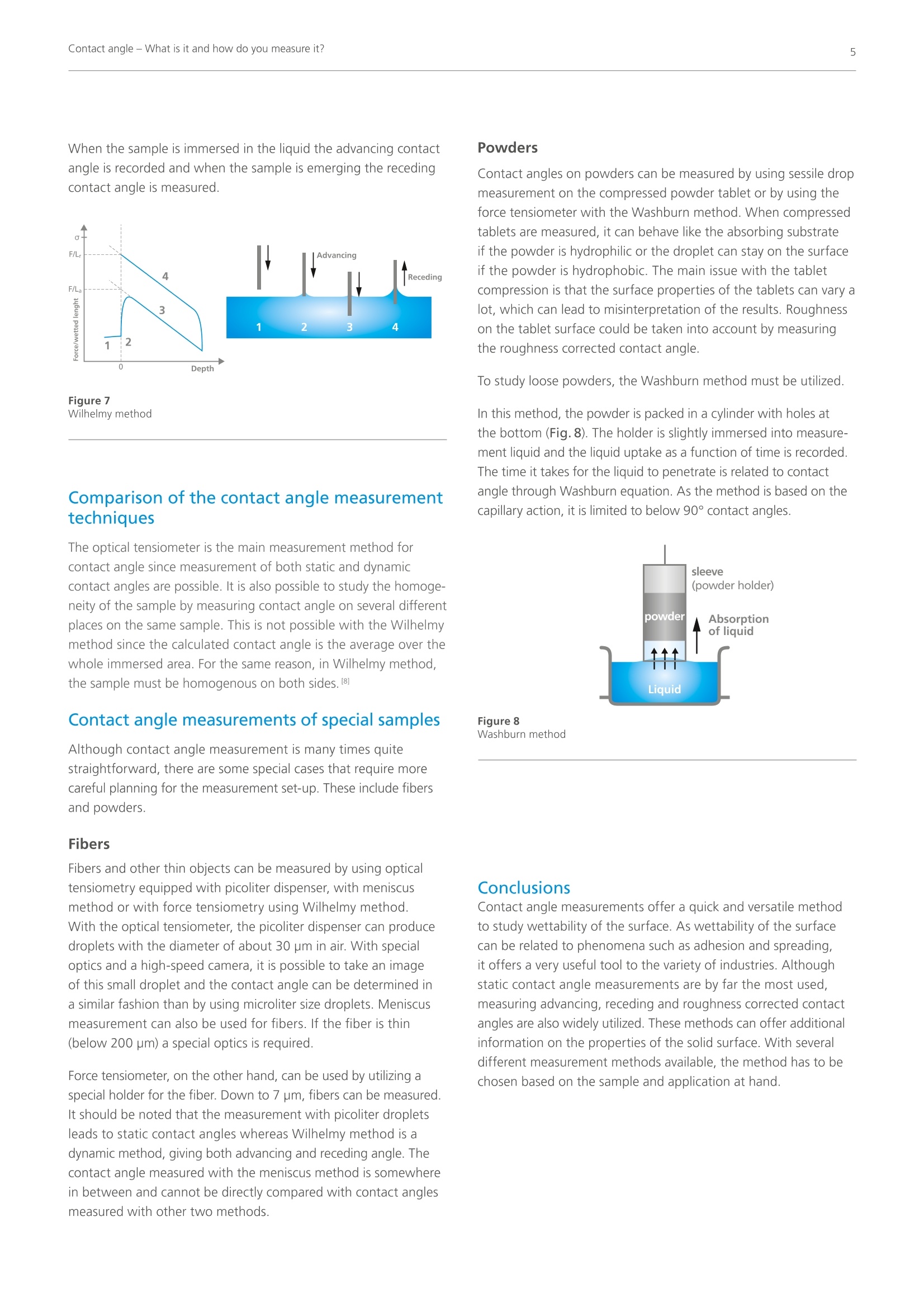

AUTHOR:White PaperSUSANNA LAUREN, PHD Contact angle -What is it and how do you measure it?2 Contact us at info@biolinscientific.com[ Progress Together] BIOLIN SCIENTIFIC Contact angle- What is itand how do vou measure it? [ Progress Together] Contact angle, 0 (theta), is a quantitative measure of wetting of a solid by a liquid. The behavior of single drop on a surface tells you a lot about the properties of your solid. The most obvious example is the application of different types of coatings and surfacetreatments. For example, if contact angle between the paint and the surface to be paintedis high, that will lead to poor spreading and non-uniform coating. Contact angles canalso be used to check if a surface treatment has been successful. Plasma treatment isoften utilized to improve the adhesion between the substrate and the coating to beapplied. The low contact angle between water and treated substrate indicate the successof the surface treatment. In practice, a drop of liquid is placed on a surface and the contactangle is measured as shown in Fig. 1. Low contact angle values, i.e.below 90°, are related to good wetting whereas high contact anglevalues, above 90°, indicate poor wetting. When the contact angleis 0°, the surface is said to wet completely. If the liquid appliedon the surface is water, terms hydrophilic and hydrophobic areused, respectively. A drop of water on hydrophilic and hydrophobic surfaces This white paper gives a very practical tutorial for contact angletheory and measurement techniques. Concepts like static, dynamic,and roughness corrected contact angle are explained and linkedto the real-life application. Different measurement methods arereviewed and compared to help you to choose the best methodfor your surface. At the end of the white paper, contact anglemeasurements on more advanced substrates, like fibers andpowders are discussed. Contact angle basics The contact angle is geometrically defined as the angle formedby a liquid at the three-phase boundary where a liquid, gas, andsolid intersect. There are three different forces acting on thisthree-phase contact point between solid, fluid and fluid as shownin Fig.2. Figure 2 Three-phase contact point where solid, fluid and fluid meet They, is the surface tension of a liquid,yis the interfacial tensionbetween the solid and liquid and yis the surface tension of thesolid i.e. surface free energy. The well-known Young's equation describes the balance at thethree-phase contact. The interfacial tensions,y ,y, andy, form the equilibriumcontact angle of wetting, many times referred to Young's contactangle 0 Young's equation assumes that the surface is ideal. This meansthat it is flat, rigid, perfectly smooth, and chemically homogenous.Furthermore, it assumes that the system is stable i.e. there is nointeraction between the liquid and the substrate. As neither of theabove-mentioned criteria is fulfilled in real life, advancing andreceding (i.e. dynamic) contact angle measurements are oftenperformed. Surface roughness can also be corrected by measuringroughness corrected contact angle. Contact angles are thus dividedinto three categories; static, dynamic and roughness corrected. Static contact angles - quick and easy Static contact angles are measured when the droplet is sittingon the surface and the three-phase boundary is not moving.Static contact angles are by far the most measured wettabilityvalues. It is most suitable for relatively smooth and homogenoussurfaces. Static contact angles are also used to define the surfacefree energy (i.e. surface tension of solid) of the substrate. Staticcontact angle offers a quick, easy and quantitative measurementof wettability. They are thus utilized in quality control and invarious research and product development, ranging from printingto oil recovery and coatings to implants. Static contact anglemeasurement is based on Young's equation which assumes thatinterfacial forces are in thermodynamically stable. In practice,however, there exist many metastable states of a droplet on asolid, and the observed contact angles are not equal to Youngcontact angle. Because phenomenon of wetting is not just a staticstate, other contact angles i.e. dynamic and roughness correctedare measured. Dynamic contact angles and contact anglehysteresis for more information When the three-phase boundary is moving, dynamic contact anglescan be measured, and are referred to as advancing and recedingangles. As the terms imply, advancing contact angle is measuredwhen the droplet front is advancing and receding when the dropletfront is receding. On an ideal surface, these two values are closeto each other.However, most often, the measured contact angledepends on the direction on which the contact line is moving.Contact angle hysteresis is the difference between the advancingand receding contact angles. Contact angle hysteresis arisesmostly from the chemical and topographical heterogeneity of thesurface, solution impurities absorbing on the surface, or swelling,rearrangement or alteration of the surface by the solvent 11,2).Advancing and receding contact angles give the maximum andminimum values the static contact angle can have locally on thesurface. The difference between advancing and receding angles can be as high as 50°. Dynamic contact angles and contact angle hysteresis are utilizedto study the heterogeneity of the surface. It has become a populartopic because of the recent interest in superhydrophobic andself-cleaning surfaces 3,4. Criteria for the surface to be super-hydrophobic is that the static contact angle is above 150°andthat the contact angle hysteresis is less than 10 degrees.In the applications where superhydrophobicity is utilized, suchas self-cleaning, the contact angle hysteresis plays an important role, as the droplet should easily roll-off the surface. Hysteresisis however also important in other situations such as intrusion ofwater into porous media, coating, and adsorption at liquid/solidinterface. Roughness corrected contact angles to separatethe effect of roughness from surface chemistry Contact angles are affected by roughness. Surfaces with the samechemical composition but different roughness will have differentcontact angles. Two wetting states can be distinguished; Wenzeland Cassie-Baxter.Cassie-Baxter refers to a situation wheredroplet sits on a rough surface so that air pockets are formed inbetween the drop and the substrate (see Fig.3 a). When, thewhole surface area is wetted, and no air pockets are formed(see Fig. 3 b), surface roughness can be related to the contactangle by Wenzel equation. , where 0 is the measured contact angle, r is the roughness ratioand 0, is the Young contact angle. The roughness ratio is defined as the ratio between the actual andprojected solid surface area (r =1 for a smooth surface and > 1 fora rough surface). It is important to note that the Wenzel equationis based on the assumption that the liquid completely penetratesinto the roughness grooves (as in Fig.3b). If you are moreinterested in the theories behind the roughness measurements andcontact angle correction, please download the white paper"TheAttension Theta optical tensiometer with 3D topography modulefor roughness corrected contact angles".Roughness corrected contactangles are especially useful when different types of surface Figure 3 Droplet on (a) Cassie-Baxter (b) Wenzel state treatments are done. Surface treatments such as plasma treatmentaffect both the chemistry and the roughness of the surface. Bycorrecting the contact angles measured, it is possible to separatethe effect of roughness on the contact angle. Roughness correctedcontact angles can also be utilized to measure roughness correctedsurface free energies. Surface free energy is the chemical propertyof the solid. As static contact angles do not take the roughnessinto account, the surface free energies calculated are affectedby the surface roughness. Thus, chemically the same materialwith different roughness levels will lead to different surface freeenergies if contact angles are not corrected for roughness. This canlead to misinterpretation of the results. Measurement methods Contact angles are typically measured by using either optical orforce tensiometers. With the optical method static, dynamic androughness corrected contact angles can be obtained whereas forcetensiometry can only be used for the dynamic measurements.Optical methods include the sessile drop (static), needle method,tilting (dynamic) and meniscus methods. The force-basedmeasurement is called Wilhelmy method. In this section, a shortdescription of each method is given. Sessile drop A sessile drop is the most used contact angle measurementmethod. In practice, a droplet is placed on the solid surface andan image of the drop is recorded. The static contact angle is thendefined by fitting Young-Laplace equation around the droplet,although other fitting methods such as circle and polynomialcan also be used. Sessile drop method is also used to calculateroughness corrected contact angles. Needle method In the needle method, a small droplet is first formed and placedon the surface. The needle is then brought close to the surfaceand the volume of the droplet is gradually increased whilerecording the contact angle at the same time. This will give theadvancing contact angle. The receding angle is measured thesame way but this time, the volume of the droplet is graduallydecreased. The principle is shown in Fig. 4. The method is alsodescribed in a standard [6] Figure 4 Advancing and receding angles by needle method Tilting method In Fig. 5, the principle of the tilting method is shown. The droplet isplaced on the substrate which is then gradually tilted. The advancingangle is measured at the front of the droplet just as the dropletstarts to move. The receding contact angle is measured at the backof the droplet, at the same time point. With this method, theroll-off or sliding angle can also be determined. The roll-off anglerefers to a tilting angle at which the droplet starts to move. A lowroll of angle is related to low contact angle hysteresis. The tilting can be done either by tilting the sample stage or bytilting the whole instrument. When the whole instrument is tilted,the camera is tilted along with the sample, so the software seesthe substrate being horizontal throughout the experiment. This makes the placement of the droplet less critical as the opticalpath is not changing. The method is described in a standard7. Figure 5 Measuring advancing and receding angles with the tilting method Meniscus method It is also possible to measure contact angles by a meniscus method.This method is especially useful when measuring thin objectslike rods and fibers down to 7 um. In this method, the sample isimmersed into liquid as shown in Fig 6. When the sample is pulledfrom the liquid a meniscus is formed and the contact angle isoptically measured. The contact angles measured with the meniscusmethod cannnot be directly compared to static nor dynamic onesas the wetting conditions are different. Also, angles above 90°can not be measured. Figure 6 Meniscus measurement principle (redraw with contact angle fittingand proper container) Wilhelmy method Dynamic contact angles can be measured by using force tensiometryand the Wilhelmy method. Force tensiometer measures the massaffecting to the balance when a solid sample is brought in contactwith a test liquid. The contact angle can then be calculated by usingthe equation (3) when the surface tension of the liquid (),) and theperimeter of the sample (P) are known. In Fig. 7, a complete contact angle measurement cycle is presented.As can be seen, with the force tensiometry the measured contactangle is always dynamic since the sample is moving against theliquid. When the sample is immersed in the liquid the advancing contactangle is recorded and when the sample is emerging the recedingcontact angle is measured. Comparison of the contact angle measurementtechniques The optical tensiometer is the main measurement method forcontact angle since measurement of both static and dynamiccontact angles are possible. It is also possible to study the homoge-neity of the sample by measuring contact angle on several differentplaces on the same sample. This is not possible with the Wilhelmymethod since the calculated contact angle is the average over thewhole immersed area. For the same reason, in Wilhelmy method,the sample must be homogenous on both sides. [8 Contact angle measurements of special samples Although contact angle measurement is many times quitestraightforward, there are some special cases that require morecareful planning for the measurement set-up. These include fibersand powders. Fibers Fibers and other thin objects can be measured by using opticaltensiometry equipped with picoliter dispenser, with meniscusmethod or with force tensiometry using Wilhelmy method.With the optical tensiometer, the picoliter dispenser can producedroplets with the diameter of about 30 um in air. With specialoptics and a high-speed camera, it is possible to take an imageof this small droplet and the contact angle can be determined ina similar fashion than by using microliter size droplets. Meniscusmeasurement can also be used for fibers. If the fiber is thin(below 200 um) a special optics is required. Force tensiometer, on the other hand, can be used by utilizing aspecial holder for the fiber. Down to 7 um, fibers can be measured.It should be noted that the measurement with picoliter dropletsleads to static contact angles whereas Wilhelmy method is adynamic method, giving both advancing and receding angle. Thecontact angle measured with the meniscus method is somewherein between and cannot be directly compared with contact anglesmeasured with other two methods. Contact angles on powders can be measured by using sessile dropmeasurement on the compressed powder tablet or by using theforce tensiometer with the Washburn method. When compressedtablets are measured, it can behave like the absorbing substrateif the powder is hydrophilic or the droplet can stay on the surfaceif the powder is hydrophobic. The main issue with the tabletcompression is that the surface properties of the tablets can vary alot, which can lead to misinterpretation of the results. Roughnesson the tablet surface could be taken into account by measuringthe roughness corrected contact angle. To study loose powders, the Washburn method must be utilized. In this method, the powder is packed in a cylinder with holes atthe bottom (Fig.8). The holder is slightly immersed into measure-ment liquid and the liquid uptake as a function of time is recorded.The time it takes for the liquid to penetrate is related to contactangle through Washburn equation. As the method is based on thecapillary action, it is limited to below 90°contact angles. Figure 8 FIgWashburn method Conclusions Contact angle measurements offer a quick and versatile methodto study wettability of the surface. As wettability of the surfacecan be related to phenomena such as adhesion and spreading,it offers a very useful tool to the variety of industries. Althoughstatic contact angle measurements are by far the most used,measuring advancing, receding and roughness corrected contactangles are also widely utilized. These methods can offer additionalinformation on the properties of the solid surface. With severaldifferent measurement methods available, the method has to bechosen based on the sample and application at hand. References 1. A. Marmur, "Thermodynamic aspects of contact angle hysteresis", Advances in Colloidand Interface Science 50 (1994), 121-141. 2. I. Gao and T. J. McCarthy,"Contact angle hysteresis explained", Langmuir 22 (2006),6234-6237. 3. L. Feng, S. Li, Y. Li, H. Li, L. Zhang, J. Zhai, Y. Song, B. Liu, L. Jiang and D. Zhu, "Super-hydrophobic surfaces: From natural to artificial", Advanced Materials 14 (2002), 1857-1860. 4. R. Blossey, "Self-cleaning surfaces - virtual realities", Nature Materials 2 (2003), 301-306. 5. R.W.Wenzel, "Resistance of solid surfaces to wetting by water", Industrial and engineeringchemistry 28 (1936) 988. 6. International standard.(2017). Paints and varnishes - wettability - Part 6: Measurement ofdynamic contact angle (ISO 19403-6:2017(E)). Switzerland. ISO. 7. International standard. (2017). Paints and varnishes - wettability - Part 7: Measurement ofcontact angle on a tilt stage (roll-off angle) (ISO 19403-7:2017(E)). Switzerland. ISO. 8. L.M. Lander, L.M. Siewierski, W.J. Brittain, and E.A. Vogler,"A systematic comparison ofcontact angle methods", Langmuir 9 (1993), 2237-2239. 表面张力和接触角测量可用于确定优选的润湿剂,并优化配方中的润湿剂含量。涂层通常通过实验室刮膜等方法对涂层外观进行定性评估。表面张力和接触角的测量可以提供更加数字化的结果。这些测量值不会完全取代视觉评估,但可以用来确定优选的候选配方。接触角基础知识接触角在几何上定义为液滴在固液气的三相边界处形成的角度。在固液气相之间的三相接触点上有三种不同的作用力作用于该点。γlv是液体的表面张力,γsl是固体和液体之间的界面张力,γsv是固体的表面张力,即表面自由能。众所周知的杨氏方程式描述了三相接触处的平衡:γsv=γsl+ γlv cosθY界面张力γsv,γsl和γlv形成了润湿的平衡接触角,通常称为杨氏接触角θY。杨氏方程式假设表面是理想的。这意味着表面是平坦、刚性、完全光滑和化学性质均一的。此外,它还假设系统是稳定的,即液体与固体表面之间没有相互作用。由于上述两个标准在现实测试中均无法满足,因此经常进行前进和后退接触角的测量(动态角)。使用特殊的仪器得到的表面粗糙度也可以用来校正接触角。因此,接触角可分为三类:静态,动态和粗糙度校正接触角。接触角可以为选择固体基材提供信息单独测量表面张力不失为比较添加剂总体效果的好方法。然而,对特定的基材表面涂层的接触角测试则可以告知哪种添加剂效果更好。低的接触角表示基材的润湿性会更好。并且,还可以测量接触角随时间的变化。想了解更多有关接触角及其测量方法的信息,请下载相关白皮书。

确定

还剩4页未读,是否继续阅读?

瑞典百欧林科技有限公司为您提供《物体表面中接触角检测方案(接触角测量仪)》,该方案主要用于其他中接触角检测,参考标准--,《物体表面中接触角检测方案(接触角测量仪)》用到的仪器有Attension Theta Flex 光学接触角仪

推荐专场

相关方案

更多

该厂商其他方案

更多