利用力可LECO SC832碳硫分析仪分析水泥、土壤、石灰石等样品中的碳硫含量获得良好效果,该仪器采用电阻炉,最高温度1550℃。

方案详情

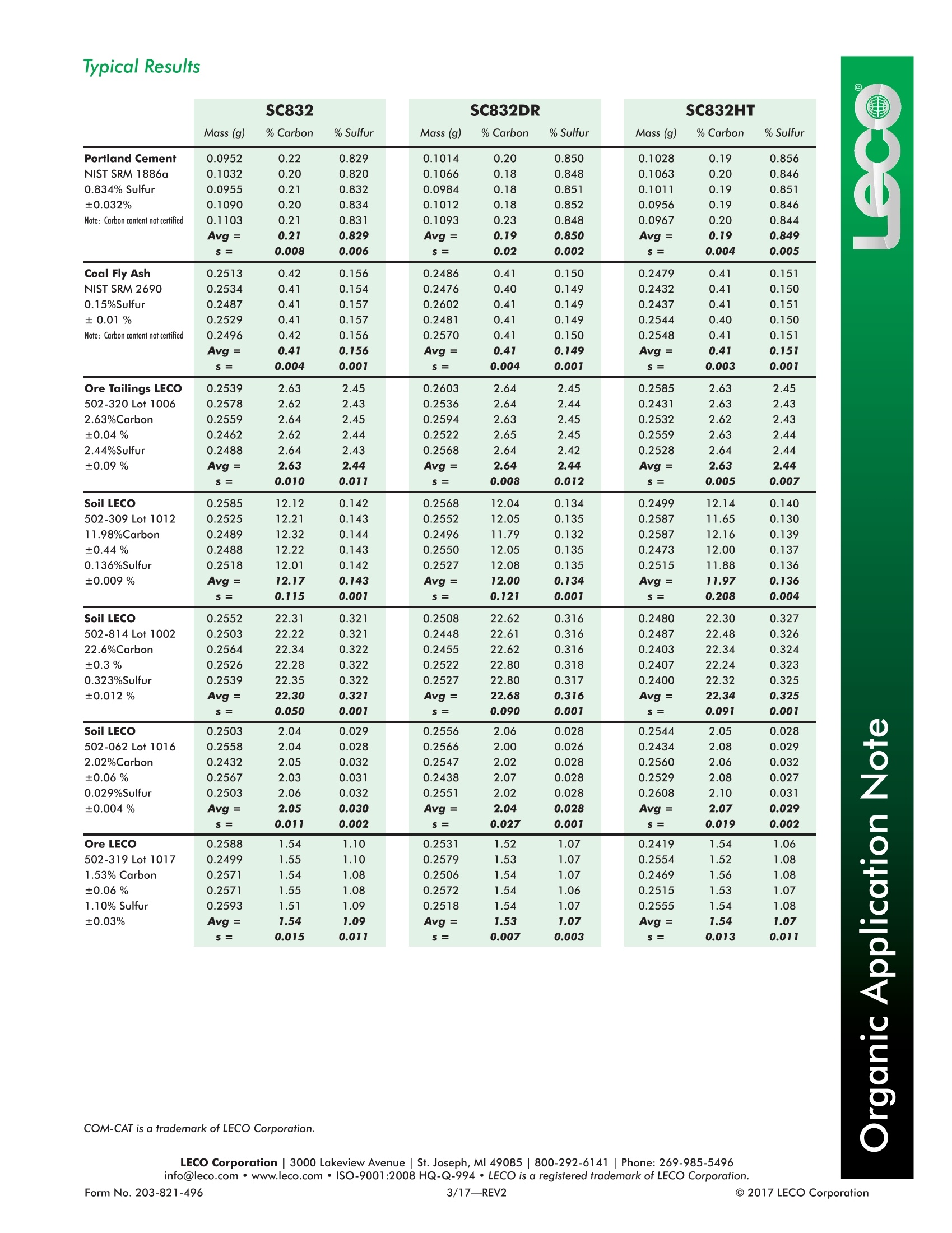

Typical ResultsLECO Corporation| 3000 Lakeview Avenue| St. Joseph, MI 49085|800-292-6141|Phone:269-985-5496info@leco.com·www.leco.com·ISO-9001:2008 HQ-Q-994·LECO is a registered trademark of LECO Corporation.Form No. 203-821-496 3/17-REV2C 2017 LECO Corporation Sulfur and Carbon Determination in Cement,Clay, Fly Ash, Limestone, Soil, and Ore LECO Corporation; Saint Joseph, Michigan USA Instrument: SC832 Series Introduction Both carbon and sulfur measurement in cement, and inthe raw materials utilized in the production of cementsuch as limestone and fly ash materials, play significantroles in characterizing the materials and ensuring thequality of both the final and in-process products. Carbon and sulfur content in soils play important roles incharacterizing the quality of arable soils. Determining the amount of carbon and sulfur present inmetal-bearing ores is a necessary step in the metalrecovery process. This information is used by mineoperations to control metallurgical process kinetics, andto support environmental monitoring of the processwaste. Sample Preparation A representative, uniform sample is required. Samplesshould be ground to pass through No.100(150 micron) sieve. NOTE: Carbon and sulfur results forore and soil are typicallyreported on a dry basis. Samples are normally dried at 105 Cfor 1 hour; alternately, moisture can be determined on aseparate portion of the sample and results corrected to a drybasis. Some Reference Materials require drying; see theCertificate of Analysis for drying instructions if applicable. Accessories 528-203 Ceramic Boat*Required for SC832 and SC832DR models. Calibration Samples LECO, NIST, or other suitable cement, fly ash, ore, orlimestone reference materials. Instrument Model The SC832 Series has three instrument models thatinclude the base SC832, the dual range sulfur SC832(SC832DR) and the high-temperature dual rangesulfur SC832 (SC832HT). All of the SC832 models areapplicable to this application and will offer differentadvantages, with some impacting the instrumentsmethod parameters, precision of results, requiredreagents, and resulting costs associated with theapplication. The base SC832 model has a single sulfur IR cell anda furnace maximum temperature of 1450°C. Thesingle IR cell covers the range required for thisapplication and simplifies the instrument setup andcalibration. The SC832DR model has two sulfur IR cells providingthe widest sulfur range and generally improvedprecision in samples with lower sulfur compositions.The maximum temperature of 1450 °C for the furnace is utilized for the applicationand also requires theaddition of the COM-CATto the sample. The SC832HT model also has two sulfur IR cellsproviding the widest sulfur range and generally improvedprecision in samples with lower sulfur compositions.In addition, the SC832HT has the ability to support afurnace temperature of 1550°C for this application. Method Parameters* SC832/SC832DRSC832HT Furnace TemperatureLance On DelayManual Analysis ModelNominal Blank Mass 1450°C20 secondsSingle Sample 1550℃20 secondsSingle Sample 1.0000 g 1.0000 g Automatically Started Analysis Manually Started AnalysisIntegration Delay 0 sec 0 sec *Refer to SC832 Operator's Instruction Manual for MethodParameter definitions. 1. Prepare instrument for operation as outlined in theoperator's instruction manual. 2. CCondition the system by following the procedureoutlined in step 5, using three replicates. 3.CDetermine instrument blank. a.LLogin a minimum of three blanks. b.Add COM into a 528-203 Ceramic Boat. C.Place the ceramic boat in front of the furnace entrance or in the appropriate autoloader position. d.Initiate the analysis by pressing the Analyze button. e. FFor manual systems, when prompted by thesoftware, load the sample into thefurnace and press the Analyze button. f. Repeat steps 3b through 3e a minimum of threetimes. g.Set the Blank according to the procedure outlinedin the operator's instruction manual. 4.Instrument calibration/drift correction. a. Login a minimum of three Standard reps for eachcalibration/drift reference material to be used forcalibration/drift. b. Weigh ~0.1 to 0.25 g of a calibration/driftreference material into the ceramic boat and enterthe mass and reference material identification intothe standard login. C.Add COM into a 528-203 Ceramic Boat andthoroughly mix with the sample. d. Place the ceramic boat in front of the furnaceentrance or in the appropriate autoloader position. e. Initiate the analysis by pressing the Analyzebutton. f.For manual systems, when prompted by thesoftware, load the sample into thefurnace and press the Analyze button. g Repeat steps 4b through 4f a minimum ofthree times. h.Calibrate/drift correct by following the procedurein the operator's instruction manual. 5. SSample Analysis a. LLogin a Sample with a desired number of reps. b.Weigh~0.1 to 0.25 g of sample into the ceramicboat and enter the mass and sample identificationinto the sample login. c. Afdd COM into a 528-203 Ceramic Boat andthoroughly mix with the sample. d. PFlace the ceramic boat in front of the furnaceentrance or in the appropriate autoloader position. eInitiate the analysis by pressing the Analyze button.f For manual systems, when prompted by thesoftware, load the sample into thefurnace and press the Analyze button. ( g. Repeat steps 5b through 5f as necessary. ) Procedure-SC832HT 1. Prepare instrument for operation as outlined in theoperator's instruction manual. 2. Condition the system by following the procedureoutlined in step 5, using three replicates. 3. Determine instrument blank. a. Login a minimum of three blanks. b. Place the ceramic boat in front of the furnaceentrance or in the appropriate autoloaderposition. c. lIinitiate the analysis by pressing the Analyzebutton. d. For manual systems, when prompted by thesoftware, load the sample into thefurnace and press the Analyze button. e. Repeat steps 3b through 3d a minimum of threetimes. f Set the Blank according to the procedure outlinedin the operator's instruction manual. 4.Instrument calibration/drift correction. a.Login a minimum of three Standard reps for eachcalibration/drift reference material to be used forcalibration/drift. b. Weigh ~0.1 to 0.25 g of a calibration/driftreference material into the ceramic boat and enterthe mass and reference material identification intothe standard login. c. Place the ceramic boat in front of the furnaceentrance or in the appropriate autoloaderposition. d. lIinitiate the analysis by pressing the Analyzebutton. e. For manual systems, when prompted by the software, load the sample into the furnace and press the Analyze button. f Repeat steps 4b through 4e a minimum of three times. g. Calibrate/drift correct by following the procedure in the operator's instruction manual. 5. Sample Analysis a. Login a Sample with a desired number of reps. b. Weigh ~0.1 to 0.25 g of sample into the ceramic boat and enter the mass and sample identification into the sample login. c. PPlace the ceramic boat in front of the furnace entrance or in the appropriate autoloader position. d. lIinitiate the analysis by pressing the Analyze button. e. For manual systems, when prompted by thesoftware, load the sample into thefurnace and press the Analyze button. f Repeat steps 5b through 5e as necessary. SC832 SC832DR SC832HT Mass (g) % Carbon %Sulfur Mass (g) % Carbon % Sulfur Mass (g) % Carbon % Sulfur Portland Cement 0.0952 0.22 0.829 0.1014 0.20 0.850 0.1028 0.19 0.856 NIST SRM 1886a 0.1032 0.20 0.820 0.1066 0.18 0.848 0.1063 0.20 0.846 0.834% Sulfur 0.0955 0.21 0.832 0.0984 0.18 0.851 0.1011 0.19 0.851 ±0.032% 0.1090 0.20 0.834 0.1012 0.18 0.852 0.0956 0.19 0.846 Note: Carbon content not certified 0.1103 0.21 0.831 0.1093 0.23 0.848 0.0967 0.20 0.844 Avg = 0.21 0.829 Avg = 0.19 0.850 Avg= 0.19 0.849 s= 0.008 0.006 S= 0.02 0.002 S= 0.004 0.005 Coal Fly Ash 0.2513 0.42 0.156 0.2486 0.41 0.150 0.2479 0.41 0.151 NIST SRM 2690 0.2534 0.41 0.154 0.2476 0.40 0.149 0.2432 0.41 0.150 0.15%Sulfur 0.2487 0.41 0.157 0.2602 0.41 0.149 0.2437 0.41 0.151 ±0.01% 0.2529 0.41 0.157 0.2481 0.41 0.149 0.2544 0.40 0.150 Note: Carbon content not certified 0.2496 0.42 0.156 0.2570 0.41 0.150 0.2548 0.41 0.151 Avg = 0.41 0.156 Avg= 0.41 0.149 Avg = 0.41 0.151 S= 0.004 0.001 S= 0.004 0.001 s= 0.003 0.001 Ore Tailings LECO 0.2539 2.63 2.45 0.2603 2.64 2.45 0.2585 2.63 2.45 502-320 Lot 1006 0.2578 2.62 2.43 0.2536 2.64 2.44 0.2431 2.63 2.43 2.63%Carbon 0.2559 2.64 2.45 0.2594 2.63 2.45 0.2532 2.62 2.43 ±0.04% 0.2462 2.62 2.44 0.2522 2.65 2.45 0.2559 2.63 2.44 2.44%Sulfur 0.2488 2.64 2.43 0.2568 2.64 2.42 0.2528 2.64 2.44 ±0.09% Avg = 2.63 2.44 Avg = 2.64 2.44 Avg = 2.63 2.44 S= 0.010 0.011 S= 0.008 0.012 S= 0.005 0.007 Soil LECO 0.2585 12.12 0.142 0.2568 12.04 0.134 0.2499 12.14 0.140 502-309 Lot 1012 0.2525 12.21 0.143 0.2552 12.05 0.135 0.2587 11.65 0.130 11.98%Carbon 0.2489 12.32 0.144 0.2496 11.79 0.132 0.2587 12.16 0.139 ±0.44% 0.2488 12.22 0.143 0.2550 12.05 0.135 0.2473 12.00 ( COM-CAT is a trademark of LECO Corporation. ) 利用力可LECO SC832碳硫分析仪分析水泥、土壤、石灰石等样品中的碳硫含量获得良好效果,该仪器采用电阻炉,最高温度1550℃

确定

还剩1页未读,是否继续阅读?

美国力可公司为您提供《水泥、土壤、石灰石等中碳硫元素含量检测方案(红外碳硫仪)》,该方案主要用于水泥/混凝土中碳硫元素含量检测,参考标准--,《水泥、土壤、石灰石等中碳硫元素含量检测方案(红外碳硫仪)》用到的仪器有美国力可LECO SC832碳硫分析仪

推荐专场

相关方案

更多