用力可AC600量热仪,苯甲酸为标样分析

The gross calorific value of coal, a solid fossil

hydrocarbon fuel material, is most often used when

calculating the total calorific value for a quantity of

coal for fuel value purposes, or when determining the

classification rank of the coal material. The gross

calorific value and sulfur value of the coal material

can also be used to calculate whether or not the coal

material meets regulatory requirements for industrial

fuel use.

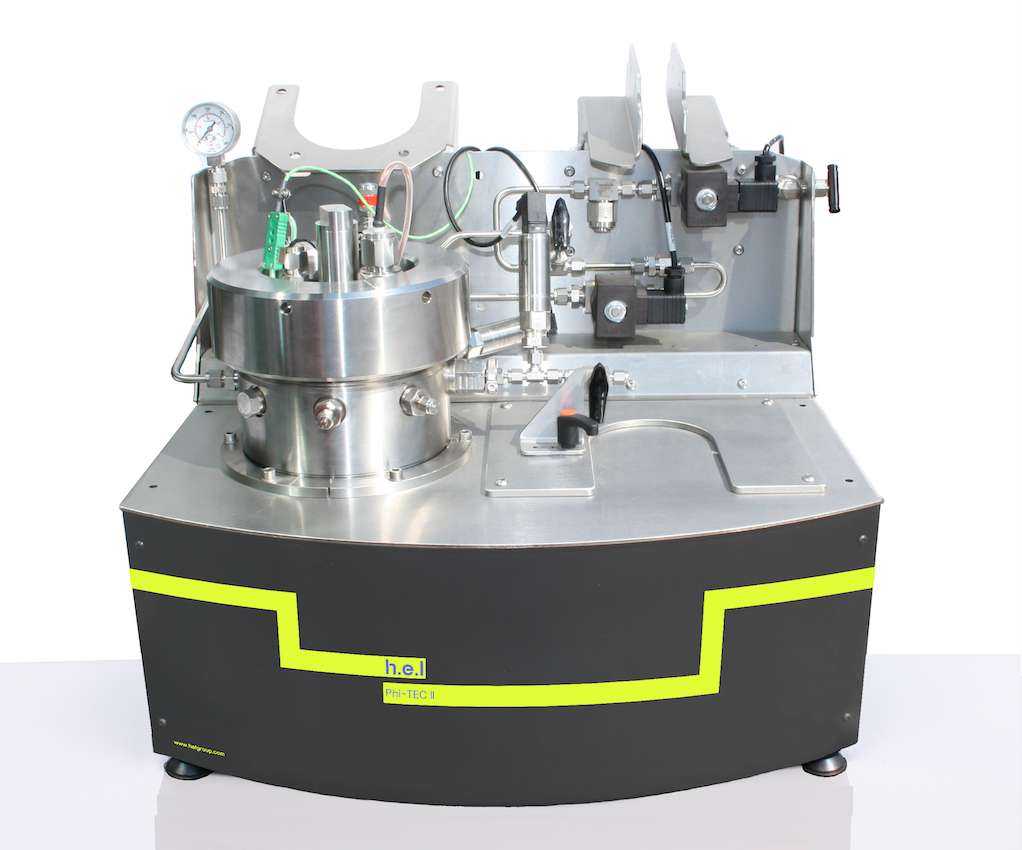

方案详情

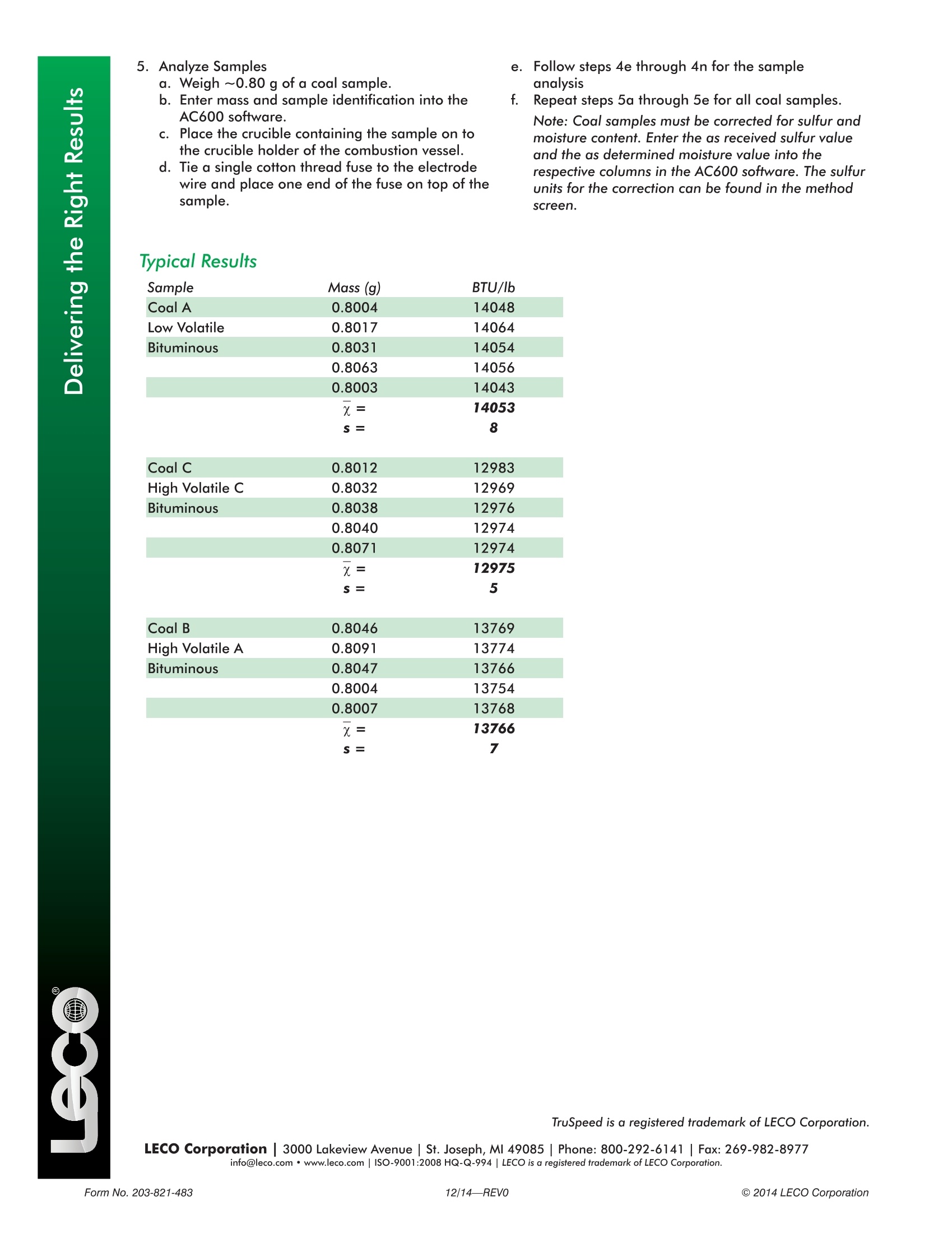

LECO Corporation| 3000 Lakeview Avenue| St. Joseph, MI 49085| Phone: 800-292-6141|Fax: 269-982-8977info@leco.com· www.leco.com|ISO-9001:2008 HQ-Q-994| LECO is a registered trademark of LECO Corporation.C 2014 LECO CorporationForm No. 203-821-48312/14—REVO LECO Corporation; Saint Joseph, Michigan USA Instrument: AC600 lntroduction The gross calorific value of coal, a solid fossilhydrocarbon fuel material, is most often used whencalculating the total calorific value for a quantity ofcoal for fuel value purposes, or when determining theclassification rank of the coal material. The grosscalorific value and sulfur value of the coal materialcan also be used to calculate whether or not the coalmaterial meets regulatory requirements for industrialfuel use. Sample Preparation A representative, uniform sample is required(-60 Mesh). Standard Method ASTM D5865. Accessories 774-204 Nickel Crucibles,776-978 Glass Scoop,502-461 Cotton Thread Fuse, Tweezers Calibration SampleLECO 774-208 Benzoic Acid Pellets, or Benzoic acidpellets made from NIST 39i. Method Parameters Method TruSpeed Standard Mode ASTM D5865 Thermochemical Corrections Titrant Energy Value 0.0039683 BTU/mlSulfur Correction 23.861 BTU/lbCalculation Mode TruSpeedAnalysis Time 5.0 MinutesEquilibrate Time 1.5 MinutesMain Time 2.8 MinutesStir Speed 13.0 System Parameters - Database Fuse Type CottonFuse Length 10 cmFuse Combustion Heat 0.006255562 BTU/cmSignificant Digits 5Result Units BTU/IbSleep Timeout 300 minutesWater Temperature 25℃Auto Increment Sample Name Disable Alarm Yes Procedure 1. Prepare the instrument as outlined in the operator'sinstruction manual. 2. Choose TruSpeed Method for analysis. 3. Condition the system by analyzing LECO 774-208Benzoic Acid Pellet 4.(Calibration a. Weigh~1.0 g Benzoic Acid Pellet into a.774-204 Crucible. b. Enter mass and sample identification into theAC600 software. c. Place the crucible containing the sample ontothe crucible holder of the combustion vessel. d. Tie a single cotton thread fuse to the electrodewire and place one end of the fuse under thesample. e. Carefully close the combustion vessel and securethe closure ring. f.Pressurize the vessel with oxygen. g. Submerge the vessel in a container of distilledwater to check for leaks. h. Place the combustion vessel on the electrodeconnectors of the loading mechanism. 1. Ptress the green analyze button to initiate analysis. i. W\hen the analysis has completed, the loading mechanism will raise. Remove the vessel and depressurize. k. After the vessel has depressurized, rinse the inside of the combustion vessel with distilled water and pour the washings into a clean beaker. l.Add 1-2 drops of indicator. m. Titrate with sodium carbonate until the endpoint is reached. n. Enter the titrated amount in milliliters into the nitrogen correction column of the AC600 software. O.FRepeat steps 4a through 4n a minimum of five times and calibrate the instrument. Note: For the recommended reagents and indicators, see the current version of ASTM D5865. e.Follow steps 4e through 4n for the sampleanalysis Repeat steps 5a through 5e for all coal samples. Note: Coal samples must be corrected for sulfur andmoisture content. Enter the as received sulfur valueand the as determined moisture value into therespective columns in the AC600 software. The sulfurunits for the correction can be found in the methodscreen. c. Place the crucible containing the sample on tothe crucible holder of the combustion vessel. d. Tie a single cotton thread fuse to the electrodewire and place one end of the fuse on top of thesample. Typical Results Sample Mass (g) BTU/lb Coal A 0.8004 14048 Low Volatile 0.8017 14064 Bituminous 0.8031 14054 0.8063 14056 0.8003 14043 X= 14053 S= 8 Coal C 0.8012 12983 High Volatile C 0.8032 12969 Bituminous 0.8038 12976 0.8040 12974 0.8071 12974 X= 12975 S= 5 Coal B 0.8046 13769 High Volatile A 0.8091 13774 Bituminous 0.8047 13766 0.8004 13754 0.8007 13768 X= 13766 s= 7 ( TruSpeed is a registered trademark o f LECO Corporation. ) 使用美国力可公司LECO AC600量热仪 分析煤炭中热量值,采用ASTM D5865标准方法,获得良好结果

确定

还剩1页未读,是否继续阅读?

美国力可公司为您提供《煤炭中热值检测方案(量热仪)》,该方案主要用于煤炭中热值检测,参考标准--,《煤炭中热值检测方案(量热仪)》用到的仪器有力可LECO AC600自动量热仪

推荐专场

相关方案

更多