方案详情

文

辉光放电光发射光谱仪在固体材料的常规分析中占有重要 的、不可替代的一席之地,它可对具有层状结构的材料(如 热处理、锌涂层、镀锌)进行了快速的深度剖面分析。

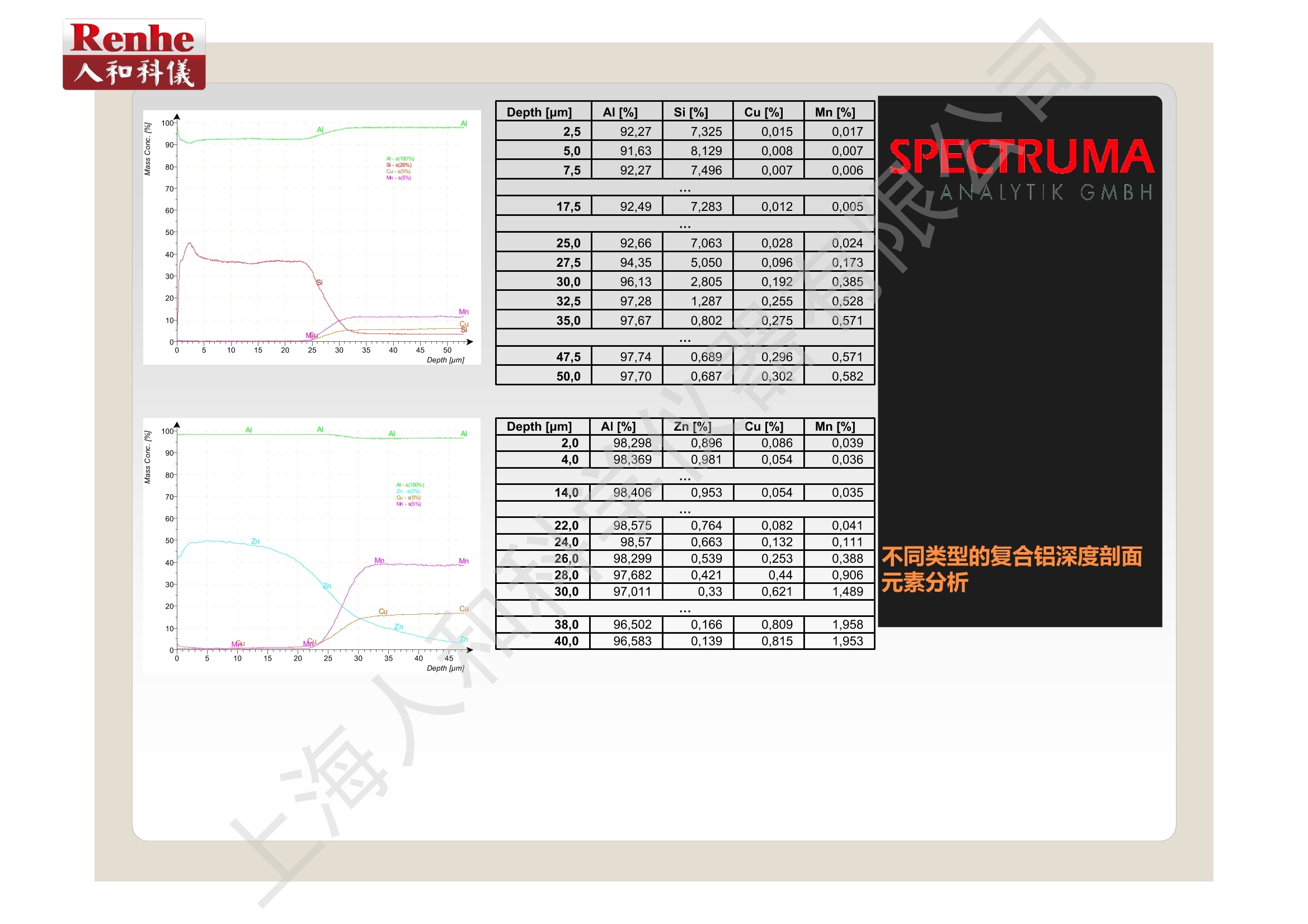

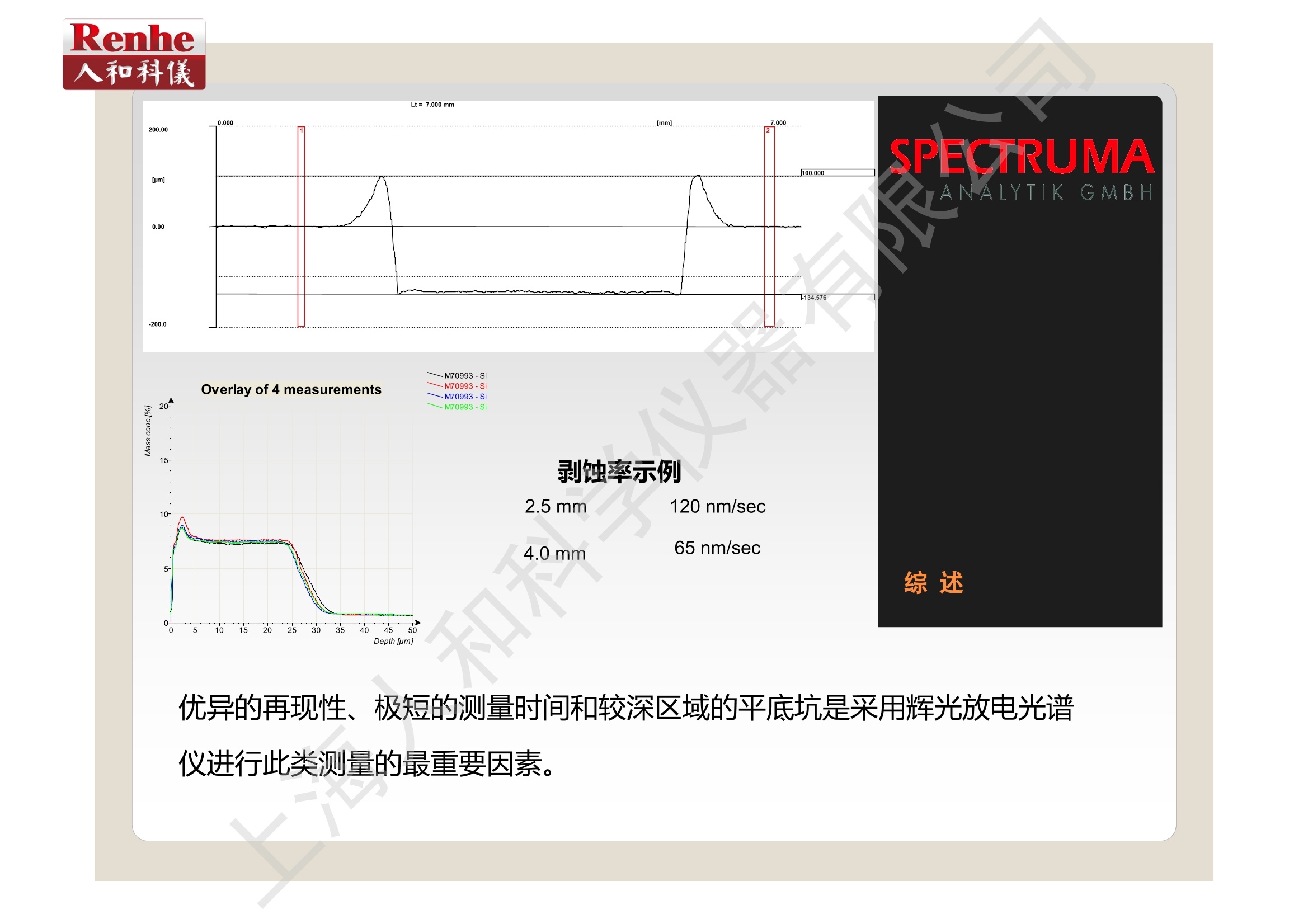

不仅具有基体总量分析的能力,而且还具备深度剖面分析能 力,在生产控制或进货检验中有着广泛的应用。本注释应证 明GDA650在复合铝多元素深度剖面分析中的性能̷̷

方案详情

Renhe人和科儀 Application note SPECTRUMA 限有 ANALYTIK GMBH 复合铝深度剖面元素分布分析 GDA 650/ GDA 150HR SPECTRUMA ANALYTIKGMBH 辉光放电光发射光谱仪在固体材料的常规分析中占有重要的、不可替代的一席之地,它可对具有层状结构的材料(如热处理、锌涂层、镀锌)进行了快速的深度剖面分析。 不仅具有基体总量分析的能力,而且还具备深度剖面分析能力,在生产控制或进货检验中有着广泛的应用。本注释应证明GDA650在复合铝多元素深度剖面分析中的性能。 公厂 科和 介绍 辉光放电源采用Grimm型设计,样品作为电极,密封光源。仪器可配备内径为2.5 mm、4mm和8mm的阳极,以确定溅射束斑的尺寸和所需的样品表面。 高性能CCD探测器用于记录整个光谱的信息。标准光学结构的光谱范围包括从120纳米到550纳米的所有波长。几乎所有元素都在这个范围内。光学系统的扩展使所有波长达到800nm,这是分析钠、钾或锂等碱性元素以及分析777nm氧所必需的。CCD光谱仪的光谱分辨率为22pm (FWHM),非常适合在多基体中的元素谱线分析。 SPECTRUMA ANALYTIKGMBH 介绍 Depth [um] Al%1 Si[%] Cu[%] Mn[%] 2,5 92.27 7,325 0,015 0,017 5,0 91,63 8,129 0,008 0,007 7,5 92.27 7.496 0,007 0,006 m.m 17,5 92,49 7,283 0,012 0,005 25,0 92,66 7,063 0,028 0,024 27,5 94,35 5,050 0,096 0,173 30,0 96,13 2,805 0,192 0,385 32,5 97.28 1,287 0,255 0,528 35,0 97.67 0,802 0,275 0.571 47,5 97.74 0,689 0,296 0,571 50,0 97,70 0,687 0,302 0,582 SPECTRUMA ANALYTIKGMBH Depth [um] AI[%] Zn[%] Cu[%] Mn [%] 2,0 98,298 0,896 0,086 0,039 4,0 98,369 0,981 0,054 0.036 mmm 14,0 98,406 0,953 0,054 0,035 m-m 22,0 98,575 0,764 0,082 0,041 24,0 98,57 0,663 0,132 0,111 26,0 98,299 0,539 0,253 0,388不同类型的复合铝深度剖面 28,0 97,682 0,421 0,44 0,906 30,0 97,011 0,33 0,621 1,489 元素分析 mmm 38,0 96,502 0,166 0,809 1,958 40,0 96,583 0,139 0,815 1,953 优异的再现性、;极短的测量时间和较深区域的平底坑是采用辉光放电光谱仪进行此类测量的最重要因素。 Calibration The GDA650 is factory calibrated using certified reference materials according to the customer’s analytical program. Oneof the big advantages of GD OES is the linearity of these calibrations. Spectruma’s HDS mode for the CCD Chips allowsthe detection of wide concentration ranges using always the best signal evaluation possible and the best line also. SPECTRUMA ANALYTIK GMB H Re-calibration Setting up samples for drift correction or the adoption to a different set of discharge conditions are provided for eachanalytical method ordered with the instrument. A recalibration history offers an easy overview of the conditions of theinstrument. Furthermore it is possible to include control chart samples in the methods to assure the permanent quality ofthe analysis. Sample Preparation The standard sources require a flat sample surface from 20 mm diameter (8 mm anode) to 6 mm (2.5 mm anode). Thissurface has to seal the glow discharge source. The quality of this sealing is determining the analytical results especial yon those elements that are influenced by atmospheric contamination like oxygen and nitrogen. An universal sample unitFor non flat samples is available for each instrument of Spectruma. The sample surface must be dry and free of oil; even low oil contamination will be detected. For bulk analysis a possiblycontaminated surface can be removed by grinding. This should be a dry grinding process using aluminum oxide paperof grain 1200. Measurement EWA The discharge conditions for the various applications will be predefined in the analytical methods. Each bulk method willinclude optimized evacuation and purging time for the source, a preglow time to remove a possibly contaminated samplesurface and the analysis time, where the emission line intensity for the elements of interest is evaluated. Depending on theanalytical task the total time for one run is ranging from 35 s to 80 s. Result Results are presented as a bulk table. They can be stored in an internal database for statistics and printed out using acustomer defined layout. A material quality data base is included in the software, the direct comparison with a givenquality or the search for matching data is possible directly after the measurement. Data export to standard officeapplications or LIMB systems is done easily. Data of depth profiling analysis can be handled in our user friendly software or exported to ASCII files. Software Summary The GDA software allows for the creation of so called“jobs”. The jobs are actually batches of operations or groupsof software instructions linked together which may be user defined or pre-established from the factory. Several separatetasks are combined into one program icon simplifying routine operation. By employing jobs for a given analytical task(analysing heat treated steel sheet for example), even a non-skilled operator can run the instrument and perform all thenecessary operations. This can be summarised by placing the sample on the discharge chamber, starting the analysisprocedure, waiting for the analysis to be finished, printed and analytical results collected, all with one or two mouseclicks. Analytical software features such as coating weight, coating thickness, integrated or averaged concentrations for selectedelements, can be calculated automatically. 上海人和科学仪器有限公司 技术销售热线:: 4008-200-117 15 联系人:13918294437 (吴经理) 邮箱:: info@renhesci.com 网址:: www.renhe. net 辉光放电光发射光谱仪在固体材料的常规分析中占有重要 的、不可替代的一席之地,它可对具有层状结构的材料(如 热处理、锌涂层、镀锌)进行了快速的深度剖面分析。不仅具有基体总量分析的能力,而且还具备深度剖面分析能 力,在生产控制或进货检验中有着广泛的应用。本注释应证 明GDA650在复合铝多元素深度剖面分析中的性能……

确定

还剩4页未读,是否继续阅读?

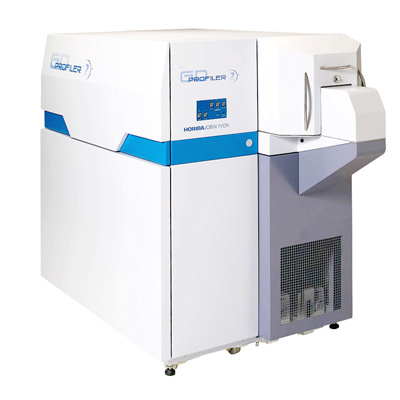

上海人和科学仪器有限公司为您提供《复合铝中深度剖面元素分布检测方案(辉光放电光谱)》,该方案主要用于铝中理化分析检测,参考标准--,《复合铝中深度剖面元素分布检测方案(辉光放电光谱)》用到的仪器有SPECTRUMA 高分辨率辉光放电光谱仪 GDA 650/GDA 150

推荐专场

相关方案

更多