市售调味汁的流动曲线

市场上销售的调味汁中,一般添加黄原胶(Xanthan Gum)作为分散剂以及增稠剂。由于黄原胶与水混合会产生粘性,因此在食品中,作为增稠剂、增粘稳定剂,被广泛应用于各种酱汁、袋装食品和冷冻食品等。使用可以在密封、灭菌、非接触下进行测量的EMS粘度计,测量市场上销售调味汁绝对粘度的例子。

采用程序模式,可在约3分钟半测量流动曲线。在程序模式的测量中,由于剪切速率的增加和降粘的基本相同,可以在不破坏样品分子的高阶结构情况下产生流动曲线。

方案详情

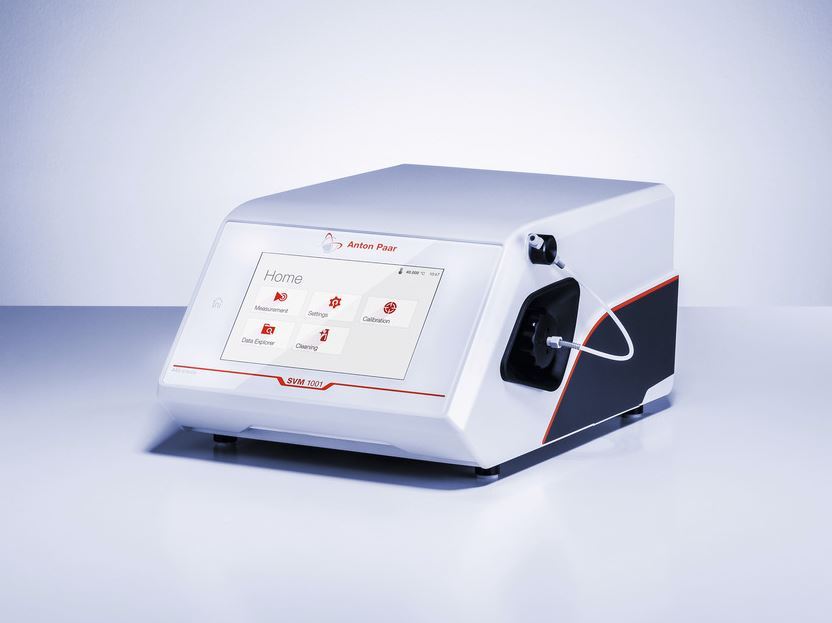

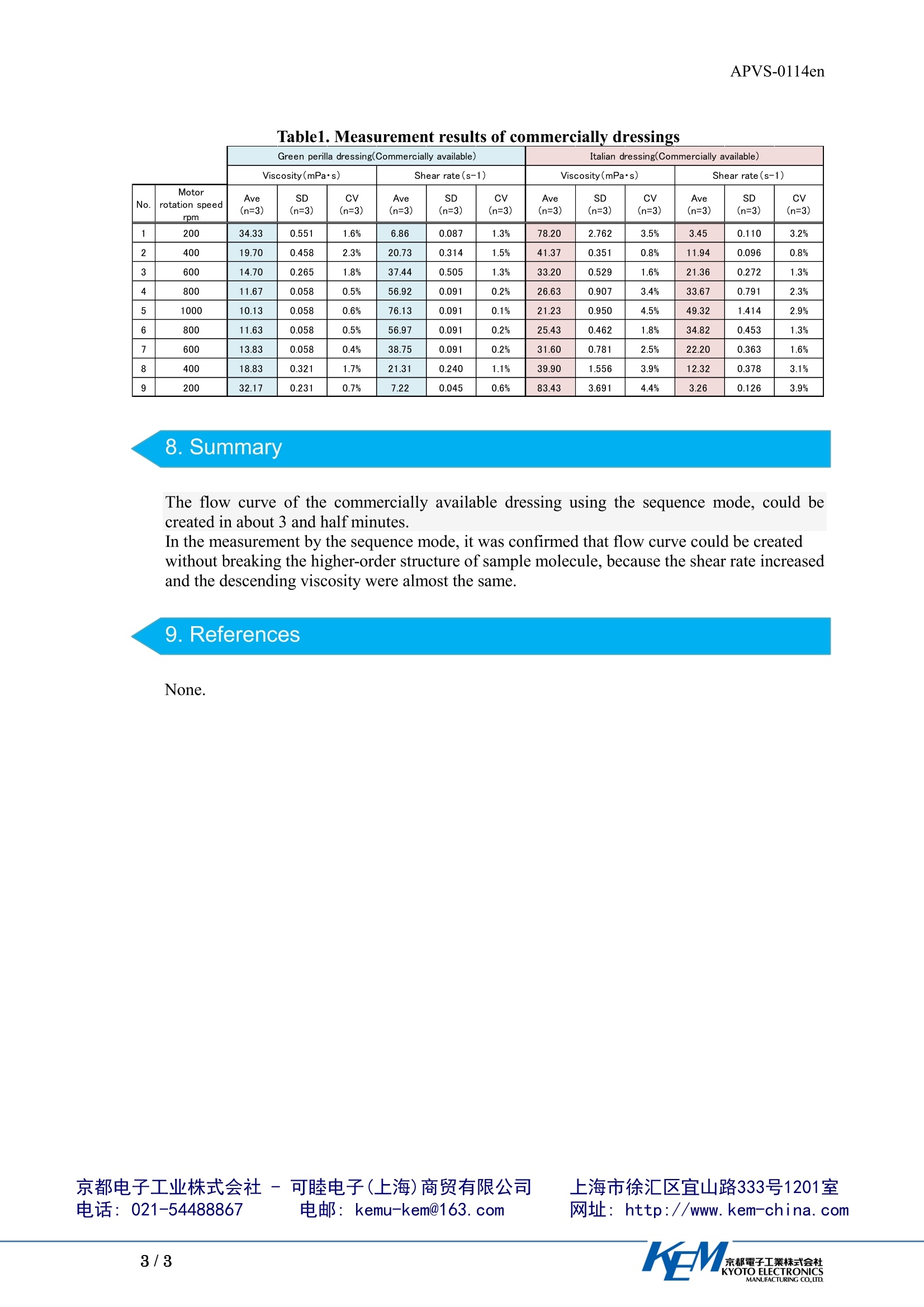

京都電子工業株式会社KYOTO ELECTRONICSAPVS-0114enMANUFACTURING CO.,LTD. APVS-0114en6. Procedure Application Note Flow curve of commercial dressing Industry FoodInstrument ViscometerMeasurement method: Electro Magnetically Spinning MethodStandards 1.Scope Xanthan gum is generally added as a dispersant and a thickener to most of commercialdressings. Since xanthan gum is viscous when mixed with water, it is used in foods as a thickener andthickening stabilizer for dressing, various sauces, retort pouch foods and frozen foods etc. for awide range of applications. An example of measuring Change in viscosity of the solution, containing xanthan gum, using anEMS viscometer that can be measured by sealing, sterilization and non-contact will be shownbelow. 2.Precautions None. 3.Post-measurement procedure The sample container and the sample are discarded appropriately. 4. Apparatus EMS Viscometer Control Laptop PC 5.Reagents Sample :Green perilla dressing(Commercially available),Italian dressing(Commercially available) 京都电子工业株式会社-可睦电子(上海)商贸有限公司 上海市徐汇区宜山路333号1201室电话:021-54488867 电邮: kemu-kem@163.com 网址: http://www. kem-china. com 1) Enter the following conditions in measurement condition of the sequence mode of controlsoftware. Measurement mode :Sequence mode Measurement temperature :25℃ Motor rotation speed :I; Rise(200→400→600→800→1,000rpm) II; Descent (800→600→400→200rpm) Measurement time :I (1second)~II(10 seconds) Repeat count :3 times Measurement interval :1 second Waiting time for temperature stability :0 minute 2) Place an aluminum spherical probe of p 2 mm and a sample of 300 pL in a container, coverwith a cap and packing, set the sample container in the EMS Viscometer, and click themeasurement button. 3) Measure another samples on the same condition when the measurement of the first sample iscompleted. 7.Example The flow curve of the commercial dressing was shown in Figure 1, and the measurement resultwas shown in Table 1. Both of the samples were able to measure with a variation coefficient of 5% or less under anymotor rotational speed condition. In the Italian dressing, the coefficient of variation (CV%) of viscosity measurement at eachmotor revolution speed slightly increased. It was speculated that the shredded vegetables (solid matter) included in the Italian dressingmight have been influenced by colliding with the spherical probe. For reference, by using sequence measurement, it was possible to measure (to create a flowcurve) in about 3 and half minutes in these samples. Figure 1.L。Flow curves of commercially dressings Table1.Measurement results of commercially dressings Green perilla dressing(Commercially available) Italian dressing(Commercially available) Viscosity (mPa's) Shear rate(s-1) Viscosity(mPa's) Shear rate(s-1) No. Motorrotation speedrpm Ave(n=3) SD(n=3) CV(n=3) Ave(n=3) SD(n=3) CV(n=3) Ave(n=3) SD(n=3) CV(n=3) Ave(n=3) SD(n=3) CV(n=3) 1 200 34.33 0.551 1.6% 6.86 0.087 1.3% 78.20 2.762 3.5% 3.45 0.110 3.2% 2 400 19.70 0.458 2.3% 20.73 0.314 1.5% 41.37 0.351 0.8% 11.94 0.096 0.8% 3 600 14.70 0.265 1.8% 37.44 0.505 1.3% 33.20 0.529 1.6% 21.36 0.272 1.3% 4 800 11.67 0.058 0.5% 56.92 0.091 0.2% 26.63 0.907 3.4% 33.67 0.791 2.3% 5 1000 10.13 0.058 0.6% 76.13 0.091 0.1% 21.23 0.950 4.5% 49.32 1.414 2.9% 6 800 11.63 0.058 0.5% 56.97 0.091 0.2% 25.43 0.462 1.8% 34.82 0.453 1.3% 7 600 13.83 0.058 0.4% 38.75 0.091 0.2% 31.60 0.781 2.5% 22.20 0.363 1.6% 8 400 18.83 0.321 1.7% 21.31 0.240 1.1% 39.90 1.556 3.9% 12.32 0.378 3.1% 9 200 32.17 0.231 0.7% 7.22 0.045 0.6% 83.43 3.691 4.4% 3.26 0.126 3.9% 8. Summary The flow curve of the commercially available dressing using the sequence mode, could becreated in about 3 and half minutes. In the measurement by the sequence mode, it was confirmed that flow curve could be createdwithout breaking the higher-order structure of sample molecule, because the shear rate increasedand the descending viscosity were almost the same. 9.References None. 都電子工業株式会社KYOTO ELECTRONICSMANUFACTURING CO.,LTD 市售调味汁的流动曲线 市场上销售的调味汁中,一般添加黄原胶(Xanthan Gum)作为分散剂以及增稠剂。由于黄原胶与水混合会产生粘性,因此在食品中,作为增稠剂、增粘稳定剂,被广泛应用于各种酱汁、袋装食品和冷冻食品等。使用可以在密封、灭菌、非接触下进行测量的EMS粘度计,测量市场上销售调味汁绝对粘度的例子。 采用程序模式,可在约3分钟半测量流动曲线。在程序模式的测量中,由于剪切速率的增加和降粘的基本相同,可以在不破坏样品分子的高阶结构情况下产生流动曲线。

确定

还剩1页未读,是否继续阅读?

可睦电子(上海)商贸有限公司-日本京都电子(KEM)为您提供《调味汁中黏度检测方案(粘度计)》,该方案主要用于液体复合调味料中理化分析检测,参考标准--,《调味汁中黏度检测方案(粘度计)》用到的仪器有EMS-1000S电磁旋转粘度计

推荐专场

该厂商其他方案

更多