方案详情

文

世界贸易改变了食品零售,推动了园艺产品运输和储存技术的发展,提供全年供应的水果和蔬菜。园艺产品极易腐烂,因为水果和蔬菜继续其代谢过程,导致采后成熟和衰老,使它们最终无法进入市场。先进的采后技术对于减少食物浪费至关重要,同时保持高标准的安全和质量。与冷藏,可控气氛(CA)和气调包装(MAP)一起应用于改变农产品的内部和外部环境,降低其代谢活动和延长保质期。CA和MAP都受益于技术创新。呼吸商控制改善了传统和最近开发的CA系统的管理; 天然气清除剂使MAP更有效率; 天然添加剂的加入提高了整个供应链的食品安全性。本文回顾了新的采后技术在操纵气体环境中的应用,并突出了需要进一步研究的领域

方案详情

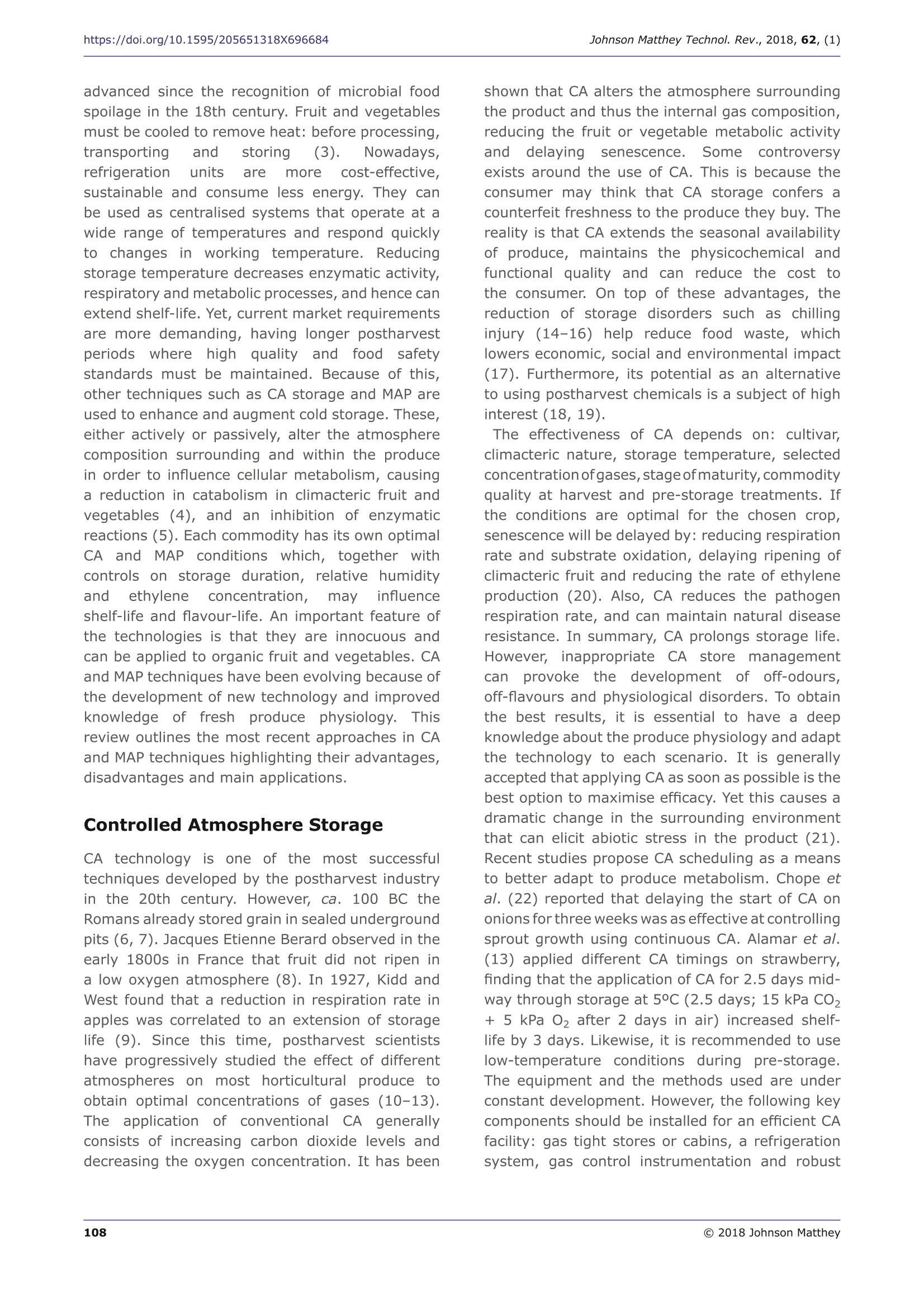

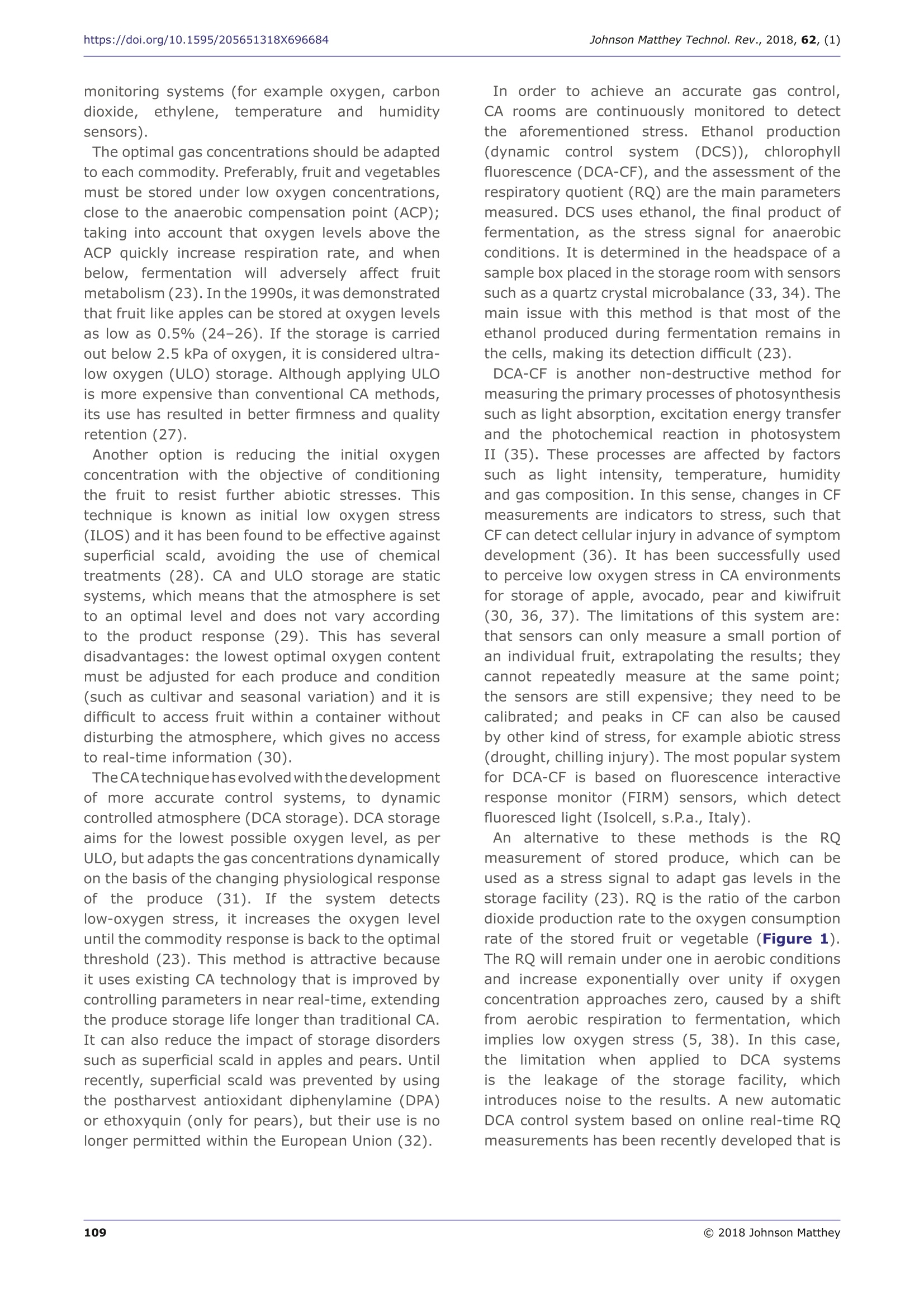

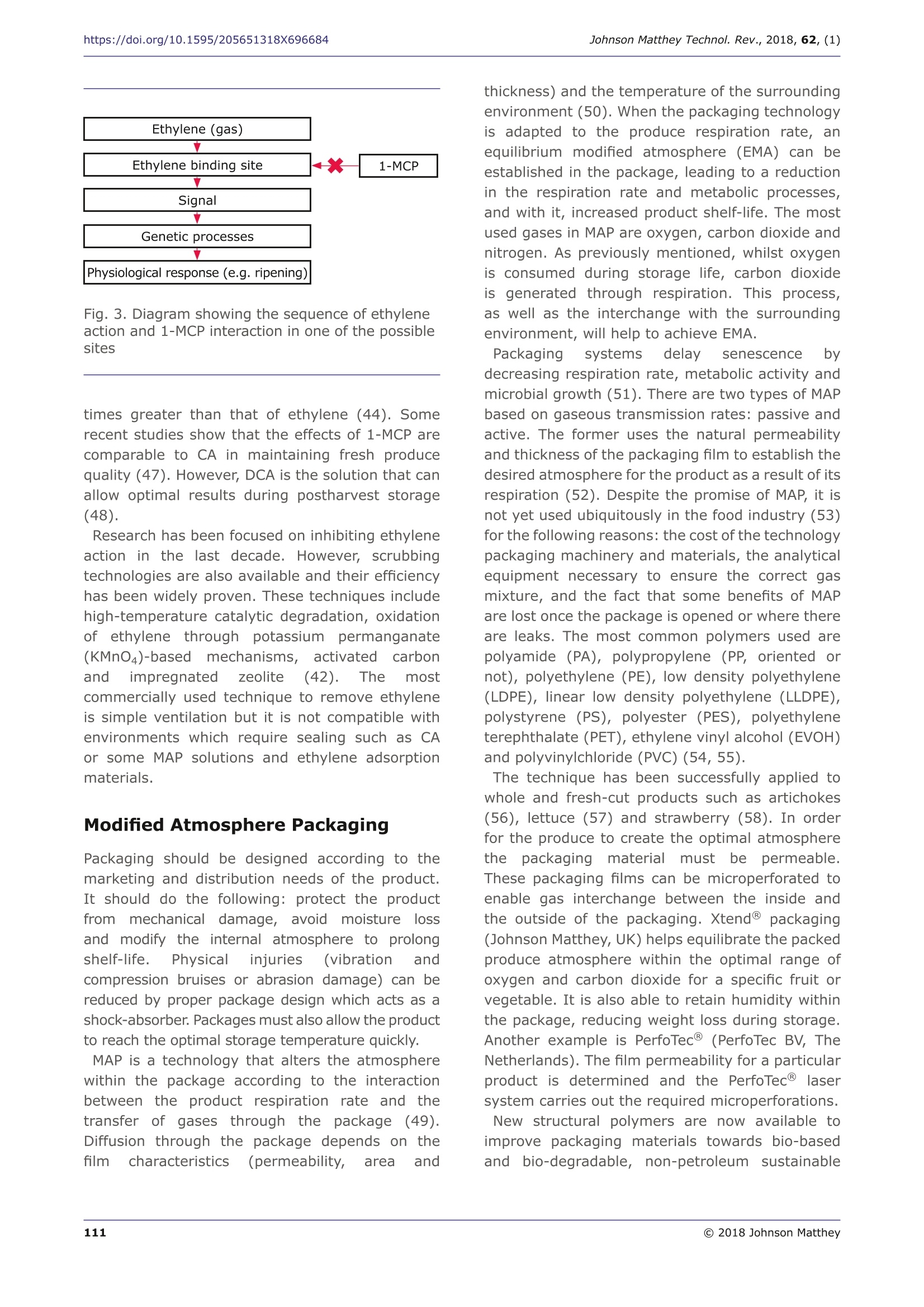

https://doi.org/10.1595/205651318X696684Johnson Matthey Technol. Rev., 2018, 62, (1), 107-117JOHNSON MATTHEYTECHNOLOGYREVIEW Johnson Matthey Technol. Rev., 2018, 62, (1)https://doi.org/10.1595/205651318X696684 Recent Advances in Controlled and ModifiedAtmosphere of Fresh Produce Postharvest technologies to reduce food waste and maintain freshproduce quality By Natalia Falagan and Leon A.Terry* Plant Science Laboratory, CranfieldUniversity,Bedfordshire, UK, MK43 0AL *Email: l.a.terry@cranfield.ac.uk Worldtradeehastransformedfood retailingand driven the development of technology forthe transportation and storage of horticulturalproducts, providing year-round supply of fruitand vegetables. Horticultural produce is highlyperishable, as fruit and vegetables continuetheir metabolic processes that lead to ripeningand senescence after harvest, making themultimately unmarketable. Advanced postharvesttechnologies are essential for reducing food wastewhile maintaining high standards of safety andquality. Together with cold storage, controlledatmosphere (CA)and modified atmospherepackaging (MAP) have been applied to alter theproduce's internal and external environment,decreasing its metabolic activity and extendingshelf-life. Both CA and MAP have benefittedfrom technological iirnnovation. Respiratoryquotient control has improved the managementof conventionaland recently developedCAsystems; gas scavengers have made MAP moreefficient; and the inclusion of natural additiveshas enhanced food safety across the supply chain. This paper critically reviews the applicationof new postharvest techniques to manipulategaseous environments and highlights areas thatrequire further study. Introduction Over thee ipast decades, the: nature of foodretailinghas been transformed by worldwidetrade. The developmentit of infrastructure,facilities and technology across the supply chain,together withhithe liberalisation of the globaleconomy, have driven consumers’ expectationsforryear-roundavailability of freshffiruit andvegetables (1). Maintaining freshness requiresthe efficient transport anddstorage of highlyperishable horticultural produce. After harvest,fruit and vegetables maintain their physiologicalsystems andcontinue with their metabolicactivity. Respiration andttranspiration lead tothe consumption of substrates, such as sugarsand organic acids, and the loss of water, whichaccompanies ripening and senescence, eventuallymaking the produce non-marketable. Food wasteis a global problem that has increased in the lastten years. In developed countries, access to advancedpostharvest technology is essential for reducingloss and waste while maintaining food safety andquality. Historically, cold storage such as cellars,basements, caves and ice houses have been usedto preserve fresh produce (2). The technology has advanced since the recognition of microbial foodspoilage in the 18th century. Fruit and vegetablesmust be cooled to remove heat: before processing,transporting and storing (3). Nowadays,refrigeration units are more cost-effective,sustainable and consume less energy. They canbe used as centralised systems that operate at awide range of temperatures and respond quicklyto changes in working temperature. Reducingstorage temperature decreases enzymatic activity,respiratory and metabolic processes, and hence canextend shelf-life. Yet, current market requirementsare more demanding, having longer postharvestperiodssWwherehighhquality anddfood safetystandards must be maintained. Because of this,other techniques such as CA storage and MAP areused to enhance and augment cold storage. These,either actively or passively, alter the atmospherecomposition surrounding and within the producein order to influence cellular metabolism, causinga reduction in catabolism in climacteric fruit andvegetables (4), and an inhibition of enzymaticreactions (5). Each commodity has its own optimalCAAandMAP conditions which, together withcontrols on storage duration, relative humidityand ethylene concentration, may influenceshelf-life and flavour-life. An important feature ofthe technologies is that they are innocuous andcan be applied to organic fruit and vegetables. CAand MAP techniques have been evolving because ofthe development of new technology and improvedknowledge of freshproducephysiology.Thisreview outlines the most recent approaches in CAand MAP techniques highlighting their advantages,disadvantages and main applications. Controlled Atmosphere Storage CAAtechnology is one of the most successfultechniques developed by the postharvest industryin the 20th century. However, ca. 100 BC theRomans already stored grain in sealed undergroundpits (6, 7). Jacques Etienne Berard observed in theearly 1800s in France that fruit did not ripen ina low oxygen atmosphere (8). In 1927, Kidd andWest found that a reduction in respiration rate inapples was correlated to an extension of storagelife (9). Since this time, postharvest scientistshave progressively studied the effect of differentatmospheres on most horticultural produce toobtain optimal concentrations of gases (10-13).Thetaapplication of conventional CA generallyconsists of increasing carbon dioxide levels anddecreasing the oxygen concentration. It has been shown that CA alters the atmosphere surroundingthe product and thus the internal gas composition,reducing the fruit or vegetable metabolic activityanddelaying senescence. Somecontroversyexists around the use of CA. This is because theconsumer may think that CA storage confers acounterfeit freshness to the produce they buy. Thereality is that CA extends the seasonal availabilityof produce, maintains the physicochemical andfunctional quality and can reduce the cost tothe consumer. On top of these advantages, thereduction of storage disorders such as chillinginjury (14-16) help reduce food waste, whichlowers economic, social and environmental impact(17). Furthermore, its potential as an alternativeto using postharvest chemicals is a subject of highinterest(18,19). The effectiveness of CA depends on: cultivar,climacteric nature, storage temperature, selectedconcentration of gases,stageof maturity,commodityquality at harvest and pre-storage treatments. Ifthe conditions are optimal for the chosen crop,senescence will be delayed by: reducing respirationrate and substrate oxidation, delaying ripening ofclimacteric fruit and reducing the rate of ethyleneproduction (20). Also, CA reduces the pathogenrespiration rate, and can maintain natural diseaseresistance. In summary, CA prolongs storage life.However, inappropriate CA storemanagementcan provoke tthee development of)f ooff-odours,off-flavours and physiological disorders. To obtainthe best results, it is essential to have a deepknowledge about the produce physiology and adaptthe technology to each scenario. It is generallyaccepted that applying CA as soon as possible is thebest option to maximise efficacy. Yet this causes adramatic change in the surrounding environmentthat can elicit abiotic stress in the product (21).Recent studies propose CA scheduling as a meansto better adapt to produce metabolism. Chope etal. (22) reported that delaying the start of CA ononions for three weeks was as effective at controllingsprout growth using continuous CA. Alamar et al.(13) applied different CA timings on strawberry,finding that the application of CA for 2.5 days mid-way through storage at 5°C (2.5 days; 15 kPa CO2+5 kPa O2 after 2 days in air) increased shelf-life by 3 days. Likewise, it is recommended to uselow-temperature conditions during pre-storage.The equipment and the methods used are underconstant development. However, the following keycomponents should be installed for an efficient CAfacility: gas tight stores or cabins, a refrigerationsystem, gas control instrumentation and robust monitoring systems (for example oxygen, carbondioxide,eethylene,小temperature aand humiditysensors). The optimal gas concentrations should be adaptedto each commodity. Preferably, fruit and vegetablesmust be stored under low oxygen concentrations,close to the anaerobic compensation point (ACP);taking into account that oxygen levels above theACP quickly increase respiration rate, and whenbelow, fermentation willadversely affect fruitmetabolism (23). In the 1990s, it was demonstratedthat fruit like apples can be stored at oxygen levelsas low as 0.5%(24-26). If the storage is carriedout below 2.5 kPa of oxygen, it is considered ultra-low oxygen (ULO) storage. Although applying ULOis more expensive than conventional CA methods,its use has resulted in better firmness and qualityretention (27). Another option is reducing the initiall oxygenconcentration with the objective of conditioningthe fruit to resist further abiotic stresses.Thistechnique is known as initial low oxygen stress(ILOS) and it has been found to be effective againstsuperficial scald, avoiding the use of chemicaltreatments(28). CA and ULO storage are staticsystems, which means that the atmosphere is setto an optimal level and does not vary accordingto the product response (29). This has severaldisadvantages: the lowest optimal oxygen contentmust be adjusted for each produce and condition(such as cultivar and seasonal variation) and it isdifficult to access fruit within a container withoutdisturbing the atmosphere, which gives no accessto real-time information (30). The CAtechniquehas evolved with the developmentof more accurate control systems, to dynamiccontrolled atmosphere (DCA storage). DCA storageaims for the lowest possible oxygen level, as perULO, but adapts the gas concentrations dynamicallyon the basis of the changing physiological responseof tthe produce ((31). If ithe system detectslow-oxygen stress, it increases the oxygen leveluntil the commodity response is back to the optimalthreshold (23). This method is attractive becauseit uses existing CA technology that is improved bycontrolling parameters in near real-time, extendingthe produce storage life longer than traditional CA.It can also reduce the impact of storage disorderssuch as superficial scald in apples and pears. Untilrecently, superficial scald was prevented by usingthe postharvest antioxidant diphenylamine (DPA)or ethoxyquin (only for pears), but their use is nolonger permitted within the European Union (32). In order to achieve an accurate gas control,CA rooms are continuously monitored to detectthe aforementionedsstress. Ethanolproduction(dynamic controlsystem (DCS)),chlorophyllfluorescence (DCA-CF), and the assessment of therespiratory quotient (RQ) are the main parametersmeasured. DCS uses ethanol, the final product offermentation, as the stress signal for anaerobicconditions. It is determined in the headspace of asample box placed in the storage room with sensorssuch as a quartz crystal microbalance (33, 34). Themain issue with this method is that most of theethanol produced during fermentation remains inthe cells, making its detection difficult (23). DCA-CF is another non-destructive method formeasuring the primary processes of photosynthesissuch as light absorption, excitation energy transferand the photochemical reaction in photosystemII (35). These processes are affected by factorssuch aslight intensity,temperature,:, humidityand gas composition. In this sense, changes in CFmeasurements are indicators to stress, such thatCF can detect cellular injury in advance of symptomdevelopment (36). It has been successfully usedto perceive low oxygen stress in CA environmentsfor storage of apple, avocado, pear and kiwifruit(30, 36, 37). The limitations of this system are:that sensors can only measure a small portion ofan individual fruit, extrapolating the results; theycannot repeatedly measure at the same point;the sensors are still expensive; they need to becalibrated; and peaks in CF can also be causedby other kind of stress, for example abiotic stress(drought, chilling injury). The most popular systemfor DCA-CF is based on fluorescence interactiveresponse monitor (FIRM) sensors, which detectfluoresced light (Isolcell, s.P.a., Italy). Analternative tothese methodssisIStthe RQmeasurement of stored produce, which can beused as a stress signal to adapt gas levels in thestorage facility (23). RQ is the ratio of the carbondioxide production rate to the oxygen consumptionrate of the stored fruit or vegetable (Figure 1).The RQ will remain under one in aerobic conditionsand increase exponentially over unity if oxygenconcentration approaches zero, caused by a shiftfrom aerobic respiration to fermentation, whichimplies low oxygen stress (5,38). In this case,the lilimitation when applied toDCAAsystemsIStheelleakage of the storage 1facility,whichintroduces noise to the results. A new automaticDCA control system based on online real-time RQmeasurements has been recently developed that is integrated into the control system of the CA facility(39). This enables the CA system to adjust thegas concentrations immediately according to RQreadings, avoiding the mentioned noise as it takesinto account the leakage in a predictive model (23). This technology canbe appliedi in individualsample containers that are representative of theconditions of the storage facility. An example ofthis option is the LabPod (Storage Control Inc,USA), a hermetically water-sealed container witha stainless steel base and a transparent plasticcover (Figure 2). Each pod has oxygen, carbondioxide andtemperature:sensors wit:hh dcigital Fig.2. LabPod (Storage Control Inc, USA) storingGala apples communication to a central operating panel. In it,RQ is periodically and automatically measured andused to set the gas concentrations in the storageroom. It is recommended for products that arekept in long-term storage, such as apples, kiwifruitand pear, as, at this moment, it requires a capitalinvestment and is expensive to operate (40). Novelbiosensors and photonics are now being developedto better understand physiologically-targeted CAinterventions to control ripening. They will alsoallow real-time phenotyping, which offers newinsight into fruit and vegetable quality and safetyaspects(41). Apart from the factors already mentioned, theaction of ethylene (C2H4) hass to be carefullyconsidered. Ethylene is a natural plant hormonewhich works at trace levels stimulating or regulatingfruit ripeningg((especiallyin (climacteric fruit)(42). CA storage implies the increase of carbondioxide and the reduction of oxygen. Low oxygenand/or elevated carbon dioxidee concentrationsinhibit the ethylene production rate by suppressing1-aminocyclopropane-1-carboxylic acid synthasetranscripts, the key enzyme innthe ssynthesispathway of iethylene (43). Another effectiveoption to inhibit ethylene is the application of1-methylcyclopropene (1-MCP) (Figure 3). 1-MCPis a gaseous cyclic olefin which binds irreversiblyto ethylene receptors avoiding ethylene-dependentresponses (44-46). 1-MCP is very efficientbecause its affinity for the receptor is around ten Fig. 3. Diagram showing the sequence of ethyleneaction and 1-MCP interaction in one of the possiblesites times greater than that of ethylene (44). Somerecent studies show that the effects of 1-MCP arecomparable to CA in maintaining fresh producequality (47). However, DCA is the solution that canallow optimal results during postharvest storage(48). Research has been focused on inhibiting ethyleneaction in the last decade. However, scrubbingtechnologies are also available and their efficiencyhas been widely proven. These techniques includehigh-temperature catalytic degradation, oxidationof ethyleneuthroughpotassiumpermanganate(KMnO4)-based mechanisms, activated carbonand impregnated zeolite (42). The mostcommercially used technique to remove ethyleneis simple ventilation but it is not compatible withenvironments which require sealing such as CAor some MAP solutions and ethylene adsorptionmaterials. Modified Atmosphere Packaging Packaging should be designed according to themarketing and distribution needs of the product.It should do the following: protect the productfrom mechanicaldamage, avoidjmoisture lossand modify the internal atmosphere to prolongshelf-life. Physical injuries (vibration andcompression bruises or abrasion damage) can bereduced by proper package design which acts as ashock-absorber. Packages must also allow the productto reach the optimal storage temperature quickly. MAP is a technology that alters the atmospherewithin the package according to the interactionbetween tthe product respiration rate and thetransfer ofgases through the package (49).Diffusion through the package depends on thefilm characteristics (permeability, area and thickness) and the temperature of the surroundingenvironment (50). When the packaging technologyis adapted to the produce respiration rate, anequilibrium modified atmosphere (EMA) can beestablished in the package, leading to a reductionin the respiration rate and metabolic processes,and with it, increased product shelf-life. The mostused gases in MAP are oxygen, carbon dioxide andnitrogen. As previously mentioned, whilst oxygenis consumed during storage life, carbon dioxidegenerated through respiration. This process,as well as the interchange with the surroundingenvironment, will help to achieve EMA. Packaging systems delay senescence bydecreasing respiration rate, metabolic activity andmicrobial growth (51). There are two types of MAPbased on gaseous transmission rates: passive andactive. The former uses the natural permeabilityand thickness of the packaging film to establish thedesired atmosphere for the product as a result of itsrespiration (52). Despite the promise of MAP, it isnot yet used ubiquitously in the food industry (53)for the following reasons: the cost of the technologypackaging machinery and materials, the analyticalequipment necessary to ensure the correct gasmixture, and the fact that some benefits of MAPare lost once the package is opened or where thereare leaks. The most common polymers used arepolyamide (PA), polypropylene (PP, oriented ornot), polyethylene (PE), low density polyethylene(LDPE), linear low density polyethylene (LLDPE),polystyrene (PS), polyester (PES), polyethyleneterephthalate (PET), ethylene vinyl alcohol (EVOH)and polyvinylchloride (PVC)(54, 55). The technique has been successfully applied towhole and fresh-cut products such as artichokes(56), lettuce (57) and strawberry (58). In orderfor the produce to create the optimal atmospherethe [packagingj materiall mustbee permeable.These packaging films can be microperforated toenable gas interchange between the inside andthe outside of the packaging. Xtend@ packaging(Johnson Matthey, UK)helps equilibrate the packedproduce atmosphere within the optimal range ofoxygen and carbon dioxide for a specific fruit orvegetable. It is also able to retain humidity withinthe package, reducing weight loss during storage.Another example is PerfoTec@(PerfoTec BV, TheNetherlands). The film permeability for a particularproduct is determined and the PerfoTec@ lasersystem carries out the required microperforations.New structural polymers are now available to improve packaging materials towards bio-basedandjtbio-degradable, non-petroleum sustainable packaging materials such as polylactic acid (PLA; forexample, NATIVIA@, UAE) made from corn or otherstarch or sugar sources(59), polylactide aliphaticcopolymer (CPLA)) (60) and polymers derivedfrom high proportions of recycled plastics (61). Atthis point, these new materials have limitationsin terms of their cost and technical performance.MAP ilsshighlydependent on respiration andtemperature. To overcome this, membranes likeBreatheWay@ contain thermoresponsive crystallinepolymers that allow high gas transmission rates athigh temperatures (62). One of the current challenges of MAP is the controlof transpiration rate (TR) in fresh produce storage(63). TR is related to the mass transfer process fromthe stored product to the surrounding atmosphere(64) and is affected by fresh produce factors suchasmmaturity sstage, andenvironmentalfactorssuch as water vapour pressure deficit gradient(65). Water loss after harvest leads to weightloss and quality reduction of the produce while anaccumulation of water at the product surface willhelp the growth of spoilage microorganisms (63).Nowadays macroperforations are used to diminishthe impact of this problem, yet their presenceprecludes the creation of a modified atmosphere. Microbial growth within the package is one of thechallenges for MAP. Nanotechnology can enhancepackaging functionality by adding antimicrobial,structuraland barrier properties(66).Thistechnology can also improve mechanical propertiesof films and reduce oxygen transmission rates(61).Other gases have also enriched MAP: helium,argon, xenon and nitrous oxide (N20). They arealso reported to reduce microbial growth andmaintain quality (67-69), but are yet to be widelyused commercially. Active MAP is based on the alteration of gaseswithinn the package toachieve the idealgasequilibrium earlier than passive MAP. Thetechniquesused include flushing pre-set gas mixtures intothe package; introducing gas scavengers, such asoxygen and carbon dioxide scavengers, moistureabsorbers, and ethylene scrubbers; and insertinggas emitters, such as carbon dioxide emitters (70).In the case of flushing gas mixtures, it is proventhat high initial concentrations of oxygen (above70 kPa) have an antimicrobial effect on aerobic andanaerobic microorganisms (71-73). This is alsoeffective for helping inhibit enzymatic browning(74, 75) and avoiding loss of firmness (74, 76).However, operating in high oxygen environmentscarriesthe riskof fire. Highcarbon dioxideconcentrations inhibit severalenzymess of the Krebs' cycle (77), slowing down ripening processesand decay. However, their efficacy will depend oncultivar, maturity stage and storage conditions.With respect to active inserts, oxygen scavengersare traditionally based on a metal powder (generallyiron,fiferrous carbonate or metallic platinum),ascorbic acid and enzymes (glucose oxidase andalcohol oxidase). Active inserts are defined according to theirscavenging reaction (such as enzyme mediatedoxidation and oxidation speed), and theirscavenging capacity (millilitres offoxygenremoved). They can lower oxygen concentrationswithin the sealedpacks, slowing deteriorationcaused by oxidation (78). The use of sulfites, suchaspotassium sulfite,yaand naturalantioxidants,including tocopherols, lecithin, organic acids andplant extracts, are currently being explored (79)to reduce the oxidation of the fresh produce anddelaydenaturation of proteins(80). Currentlythey are applied to breadsl,rnluts, candies andconfectioneries,coffee and teaaandprocessed,smokeda1nd curedrmeats,aamong others,toimprovestorageconditions. Generally thesescavengers are designed for oxygen removal fromsealed food packaging and not semi-permeablefresh produce EMA packaging. More research isneeded as existing oxygen scavenger formats aretypically cumbersome and not appropriate for freshproduce storage conditions. Carbon dioxide scavengers (chemical absorberssuch as calcium hydroxide, sodium carbonate,calcium oxide; physicalabsorbersssuch aszeolite and activated carbon) can similarly delaysenescence and reduce browning and mould decay(81). This is particularly interesting for climactericproducts,which produceenhighconcentrationsof carbon dioxideceaffectinggtheir organolepticcharacteristics. Another optionn is thee rremovalal ofethylenefrom the package. Ethylene scrubbers, such aspotassium permanganate pellets (Ryan Co, USA)and clay mineral coated strips (It's Fresh, UK)(42), can slow down senescence and reduce decayby neutralising the effect of the plant hormone.Carbon dioxide emitters increase carbon dioxideconcentration within the package,helping achievethe optimal gas mixture for each product (70). A recent trend, known as smart or intelligentpackaging,is tofitpackaging withsensorsable to monitor quality, microbiological growthor temperaturee aalong the supply chailn(82,83). Intelligent packaging components includeradio frequency identification sensors (84), time-temperature andd ripenesssindicators (forexample,ripeSense@, New Zealand),and biosensors(85). Also, carbon dioxide and oxygen gas sensorsare being developed for real-time monitoring ofproduce quality (86). Some low cost intelligentpackaging options are available to provide visualinformation on freshness: fluorescent dyes ormolybdenum ions (87, 88). These can inform notonly about food quality, but also food safety (89). It is possible to create physical barriers on thefruit surface which provide protection againstmoisture loss and can help control oxygen andcarbon dioxide concentrations, in a similar wayto MAP as they are able to change the internalatmosphere of the produce.This technique isknown as edible coating (90). The ideal ediblecoating should be able to extend storage lifewithout causing anaerobiosis and reduce decayand water loss (90), acting also as antimicrobialagents. The development of this technique beganwith the application of wax coatings on fruit usingdipping methods. The material used to formulatethemirhastto begenerallyrregardeddassafe(GRAS) and has evolved with time. According toArvanitoyannis and Gorris (91), the edible coatingmust: be water resistant and cover the productcompletely when applied, reduce water vapourpermeability, generate the optimal atmosphere,improve the produce appearance, melt over 40°Cwithout decomposition, dry with high efficiencyperformance,一I have lowvviscosity, be easilyemulsifiable, be economical, be translucent andnot interfere with produce quality. The compositionof edible coatings has advanced to be based onnatural compounds. Some of the latest examplesare: Aloe vera gel (92), alginate-based ediblecoatings (93), shellac (94) or silk fibroin (95). At a commercial level, AgriCoat NatureSeal Ltd,UK, provides a sucrose ester based edible coatingfor whole fruit, mainly melon(Semperfresh@,UK) and fresh-cut produce (NatureSeal@, UK),which are sulfite-free (GRAS) and delay ripeningeffects. Edible coatings are able to extend theshelf-life of perishable products, maintain initialappearance,including colour and gloss, and delaydecay. The correct formulation should not affectflavour or appearance. To maintain safety withinthe packaging an application of solutions such asnatural antimicrobial like cinnamon or vanillin (93),and essential oils (96) can be used within the ediblecoating or on their own. Films can also be coatedwith inhibitors such as titanium dioxide (TiO2), whichis able to inactivate pathogens like Escherichia coli(97, 98). These packaging options are required to respond to consumers'demand for ready to eat fruitand vegetables. The fresh-cut industry has to facenot only physiological issues that lead to ripeningand senescence of fresh produce, but also the likelymicrobial growth caused by the exposure of tissuesto the environment. Mechanical wounding, due tominimal processing, damages cells making it easierfor pathogens to contaminate the produce and forenzymes to catalyse non-desirable processes suchas browning. Hence, the application of the correctgas mixture environment, edible coatings andnatural antimicrobials are critical in this case (99). Other postharvest technologies can complementMAP. In ordertto controlmicrobial growth,non-ionising, germicidal and artificial ultraviolet C(UV-C) light (100) can be applied. Some studiesshow an enhancement of bioactive compoundswhen this technique is used (100, 101). There areno residues left in the fruit or vegetable after UV-Ctreatment, which is an advantage in meeting newconsumer requirements. A promising techniqueto improve food safety is cold plasma technology(NSW Department of Primary Industries,Australia).It is created by applying an electric current tonormal air or a gas to generate reactive gaseousspecies with antimicrobial activity. It involves nochemicals, and therefore, no residues. Future Prospects The growing demand to decrease postharvest useof chemicals and the need for more sustainabletechnologieshasled totheddevelopment ofimproved CA andMAP storage methods. Moreresearch is needed to understand the dynamicphysiological responses of fresh produce to CA andMAP in order to determine the optimal conditionsfor each cultivar and scenario. Critically, a betterunderstanding of how flavour can be extended isrequired; one of the most repeated consumers'complaints is the lack of fresh fruit and vegetableflavour. With respect to MAP, the structure andfunctionality of film polymers should be improved,and newsustainable materials developed anddeployed. Moreover, a reduction of cost will makethese technologies accessible to a wider numberof companies within the sector, improving theadoption of MAP and reducing food waste. Research should focuso optimising gasconcentrations by selection ofappropriatelypermeable packaging materials, and on improvingtheir interaction with active materials such asscavengers, emitters, and nanoparticles. In thiscase,a modelling approach taking into account different materials, gas compositions andtemperatures will enhance results in the short term.Studies on consumer response to active materialsandtheeirinformationpresentedby intelligentpackaging is needed. Finally, these advances willdrive the development of microbiologically safeproducts, with high functional and sensory quality. Concluding Remarks In conclusion, CA storage and MAPserve asimportant tools to maintain fruit and vegetablequality along the supply chain, reducing food wasteand extending fresh produce availability all yearround. They need however to be adapted to thenew requirements of consumers, being innocuousand applicable to 'residue free' produce. Thanks torecent technological developments, it is possibleto create storage environments that adjust theirsettings tothephysiological response of tthecommodity,further extendinggpostharvestlifewhile maintaining quality. The advances in CA andMAP will drive the development of more sustainablematerials and more efficient gas control, which areessential instruments for postharvest management.However, these technologies have the followingmain limitations: imprecise monitoring of fruit andvegetable response, high energy requirements,high cost of materials and reduced retention ofinitial quality (such as flavour-life). These problemscan be overcome through physiologically-targetedCA and MAP. Acknowledgements The authors would like to thank Professor RandyBeaudry,/, MichigansStateUniversity, USA,forhis valuable contribution, providing some of theinformation included in this manuscript. References 1. S. Sim, M. Barry, R. Clift and S. J. Cowell, Int. J.Life Cycle Assess., 2007,12,(6),422 ( 2. R. E . P aull, Postharvest Biol. T echnol., 1 999, 1 5 ,(3), 263 ) 3. I. Dincer, "Refrigeration Systems and Applications",3rd Edn., John Wiley & Sons Ltd, Chichester, UK,2017, 752 pp 4. M. C. Sanchez-Mata, M. Camara and C. Diez-Marques, Food Chem., 2003, 80, (3), 309 5. S. C. Fonseca, F. A.R. Oliveira and J. K. Brecht,J.Food Eng., 2002,52, (2), 99 6. A. Valls, F. Garcia, M. Ramirez and J. Benlloch, ( Tunn. Undergr. Sp. Technol. , 201 5 , 50, 178 ) ( 7. R. M . B eaudry, Postharvest Biol. T e chnol., 1 999,15, (3), 2 93 ) ( 8 . D . G. Dalrympl e, Tec h nol. Cult., 1969, 10,(1 ) , 3 5 ) 9. F. Kidd and C. West, A Relation Between theRespiratory Activity and the Keeping Quality ofApples", Report of the Food Investigation BoardLondon for 1925 and 1926, pp. 37-41 ( 1 0 . R . M . S m oc k , `Controlled Atm o sph er e S t orage o f F r uits', i n "Ho rt icu l t ur al Rev i ews", ed.J . J an i ck , Vol.1, T h e AVI Publis h i n g Company In c , Con n ecticut , USA, 1 979, pp. 3 01 - 33 6 ) 11. K. P. Wright and A. A. Kader, Postharvest Biol.Technol., 1997, 10, (1), 89 ( 12. L. A. A b ayomi a nd L. A . T err y ,J . S ci. F ood Agric., 2 009,89, (4), 683 ) ( 1 3 . M. C a r m en Alama r , E. Co l ling s , K. C o o l s an d L. A . T e rry , P ostharvest Biol . Technol.,2017, 134, 7 6 ) ( 1 4. E. Pesi s , D. Aha r o n i , Z. A haro n , R . B e n-Ar i e , N . Aharon i a n d Y . F uch s , Postharvest B i ol. T ec h nol., 2 000,19, (1), 93 ) ( 1 5. S. Lur i e an d C. H . C ris o s t o , P ostharv e st B i ol.Technol. , 2005, 3 7, ( 3), 195 ) ( 1 6. S. P . Si ng h a nd Z . Singh, I nt. J. F ood S c i. Tec h nol.,201 2, 48,( 2 ) , 3 63 ) ( 1 7 . M . d e l Car m en Alamar, N. F al a g a n, E . A k tas a n d L.A. Terry, J . Sc i . Food Agri c ., 20 1 7 , 98, (1), 8 ) 18. L. G. Neven and L. Rehfield-ray,J. Econ. Entomol.2006,99, (3),658 ( 1 9 . W. Li, K . Wan g , L. Ch en , J . A. Jo h n s on and S .Wang, J . Stored Prod. Res. , 2015 , 62, 5 2 ) 20. A. K. Thompson, "Controlled Atmosphere Storageof Fruits and Vegetables", CABI International,London, UK, 2010,288 pp 21. "Crop Post-Harvest: Science and Technology:Perishables". eds.D. Rees,, G. Farrelll and .J.Orchard, Vol. 3, Blackwell Publishing Ltd, Chicester,UK, 2012, 464 pp 22. G. A. Chope, L. A. Terry and P. J. White, PostharvestBiol. Technol.,2007,44,(3),228 23. N. Bessemans, P. Verboven, B. E. Verlinden andB. M. Nicolai, Postharvest Biol. Technol., 2016,115,91 ( 24. J. Grael l, C. L ar r igaud i ere and M . V endrell , FoodSci. Te ch nol. I nt. , 1997, 3, (3), 2 03 ) 25. M. L. Lopez, M. T. Lavilla, I. Recasens, J. Graelland M. Vendrell,J. Sci. Food Agric.,2000,80,(3),311 26. C. D. Gran and R. M. Beaudry, Postharvest Biol.Technol., 1993,3, (3), 259 27. P. G. Levesque, J. R. DeEll2and D. P..NMurr,HortScience, 2006, 41,(5), 1322 28. Z. Wang and D. R. Dilley, Acta Hortic., 2001,553, 261 ( 29. M . E . S alt v ei t, Postharvest Biol . T echnol., 2003,27, ( 1), 3 ) ( 30. D. T. T r an, B. E . Ver li nden, M . Hertog a n d B. M . Nico l a i , Sc i . Ho r tic. Amsterda m, 201 5, 184, 1 8 ) ( 3 1. A. Zan e l l a, Post h arvest B iol. T echnol., 2003, 2 7,(1),69 ) ( 32. R. K . Pra n ge , A. H. Wright, J. M . D e L o ng and A .Zan el l a , Ac ta Ho r tic . , 2 0 13 , 1012, 9 05 ) ( 3 3. S. P . Sc h oute n , R. K. Pra n ge, J. V e rs c ho o r, T . R . La m mers a n d J . O osterhav e n, IFAC P roc. Vol. 1 998 , 31,(9) ,2 5 ) ( 3 4. H. J un c ai, H . Yao hu a a n d G . K ang q uan, I nt . J. A g ric . Biol . Eng.,201 4, 7 , (5) , 7 1 ) ( 35. J . R. DeEl l , O. va n Kooten, R . K. P r a nge a n d D. P . M urr, H orti c. R ev. , 1999,23,(2 ) , 69 ) 36. R. K. Prange, J. M. DeLong and A. H. Wright, ActaHortic., 2012,945,89 37. J. P. Mattheis and D. Rudell,Postharvest Biol.Technol.,2011,60,(2), 125 ( 3 8. P. V . M a ha j a n, A. Luca and M . E delen b os, Comput.Electron. Ag r ., 2016,121, 347 ) 39. N. Bessemans, P. Verboven, B. E. Verlinden and B.M. Nicolai, Postharvest Biol. Technol., 2018, 136,31 40. "Eco-Friendly Technology for Postharvest ProduceQuality", ed. M. W. Siddiqui, Elsevier Inc, Boston,USA, 2016 ( 4 1 . W. Y an g , L. Duan , G . C h e n, L . X i o ng and Q. L iu,Curr. Opin. P la n t B iol., 20 1 3, 16,( 2 ), 1 80 ) ( 4 2. L . A . T erry, T . I lke n h an s, S. P o u l s t on , L . Ro wsella n d A . W . J . S m i t h, P o stharvest B i ol. Tec hnol.,2007, 45, ( 2),214 ) 43. H. P. J. deWild, E. J.1. Woltering and H. W.Peppelenbos, J. Exp. Botany, 1999, 50, (335),837 44. S. M. Blankenship and J. M. Dole, Postharvest Biol.Technol., 2003, 28,(1), ( 45 . L. L i , A. L i c h te r, D . C h al up owi c z, D. G a m r a sn i , T . Goldberg, O. N erya, R. B en-Ari e a n d R. Porat,Po s th a rvest Biol. T e chnol . ,2016,111 ,3 22 ) ( 4 6 . C . B . Watki n s,Bi o tech n o l. Adv . , 2 2006 , 224. ( 4 ) , 389 ) 47.N.Falagan,Artes, .F.Artes-Hernandez,P.A.Gomez,-rAPerez-Pastor and E.AAguayo,Postharvest Biol. Technol.,2015, 110, 24 ( 4 8 . N . Bessemans, P. Verboven , B. Verlinden a nd B . N ico l a i ,Comparative Stu d y of RQ-DCA a n d DCA-C F T echno l ogy f o r St o rage of G olden D elicio u sApple Fru i t', XII Inter n at i onal C ont r o l led & Mo d ifiedAtmosphe re Re s e a rch Con f er e n c e (Ca M a2 0 17),Wa r saw, P ola nd , 1 8 th - 22n d J u ne, 2 017 ) ( 49 . M . Olivei r a, M . Abadias, J . Usal l , R. T orres, N. T eixido an d I. Vi n as, Trends Food S ci. T e c hnol., 2 01 5 ,46,( 1 ), 13 ) 50. R. Beaudry,`MAP as a Basis for Active Packaging',in "Intelligent and Active Packaging for Fruitsand Vegetables", ed. C. L. Wilson, Taylor andFrancis Group LLC, Boca Raton, USA, 2007, pp.31-56 ( 51. M. d el Carmen Vil la l obos, M . J. S err a dilla, A. M artin , A. Her n andez - Leon, S. R u iz-Moyano and M . de G. Cord o ba, F ood Microbiol., 2 017, 63, 35 ) ( 52. N. Somboon k aew a nd L. A . T e r r y , Postharv e st Biol. Te c hnol. , 2010,56,(3), 246 ) ( 53. N . Peelman, P. Ragaert, A. Vandem o ortele, E .Ve rg u ldt , B. De Meu l en a er a n d F . Dev li eg h e r e ,I n nov. Food Sci. E m erg. T echnol., 2014 , 2 6, 319 ) ( 54. M. Zh a ng, X . M eng, B. B h and a ri a n d Z. F a n g, Cr i t.Rev. F o od S ci . N u t r ., 201 5 ,56 , (13),2 1 7 4 ) ( 5 5 . C. Gh i d e lli a nd M. B. Pe r ez-G a go, C r i t. Rev. FoodSci. Nutr ., 2016 ,1 ) ( 5 6. M. G i me n ez, C . O l ar t e , S . S a nz , C. Lo mas , J. F . Ech a varri a n d F . A yala , F o o d M i crobiol . , 2003, 2 0 ,( 2) , 231 ) 57. G. D. Posada-Izquierdo, F. Perez-Rodriguez, F.Lopez-Galvez, A. Allende, M. I. Gil and G. Zurera,Int. J. Food Microbiol., 2014, 177, 1 ( 58. I. Siro, F. D e vl i e ghe r e , L . Jacxse n s, M . Uytte n d ael e an d J . D ebevere, Int. J. F o o d S c i. T echnol., 2006,41,(1),93 ) ( 5 9. A. M istriot i s, D . B ri asso u l is , A . Gi a nno u l i s an d S.D'Aquin o , Postharvest Biol. Technol. , 2016, 1 11, 380 ) ( 60. V. Si r acusa, P. Roccul i , S . Romani a nd M. D . R o sa,Tr e nds Food Sci . T echnol.,2008 , 19,( 1 2 ) , 634 ) ( 61. M. D . W ilson, R. A . S tanley, A . Eyles a nd T. R oss,Cri t. Rev . Food Sc i. Nut r .,2017, 1 ) 62. R. Clarke, Breatheway@ Membrane Technologyand Modified Atmosphere Packaging', in "ModifiedAtmosphere Packaging for Fresh-Cut Fruits andVegetables", eds. A. L. Brody, H. Zhuang and J.H. Han, Blackwell Publishing Ltd, Chichester, UK,2011, pp. 185-208 ( 63. O. J . Caleb , P . V. M ahaja n , F. A. A l-Said a nd U . L . Opara, CyTA J. Food, 2 013, 1 1 , (3), 199 ) ( 64 . Z. A. Belay, O. J . Ca l e b and U . L. Opara, FoodPackag. Shelf Life , 2 016, 10, 1 ) ( 65. M. J . Sousa- G allagher and P. V . M ahajan, F ood C ontrol, 2 01 3 , 29, (2 ) , 4 4 4 ) ( 66. M .Eleftheri a dou, G . Pyrgiotaki s and P . D e mokrit o u,Curr. Opin. Biotech n ol., 2017, 44, 8 7 ) ( 67. X. Meng, M . Zh a ng and B. Ad h ik a r i , P o stharvestBiol. Techno l ., 2012, 71, 1 3 ) ( 68. A . Tomas- C alle j as, M . Bolu d a,P. A. Robles, F. A r tes and F . Ar tes -He rn ande z , L WT- Food Sci . T echnol.,2011, 44, (6), 1 4 22 ) ( 6 9 . M . Z h a ng , Z . G . Zhan, S . J . W a ng a nd J. M . T a ng , LWT - F ood Sci. Technol., 2008 , 41, (4), 686 ) 70. "Modified and Controlled Atmospheres for theStorage, Transportation,and Packaging ofHorticultural Commodities", ed. E.M. Yahia, Taylorand Francis Group LLC, Boca Raton, USA, 2009,608 pp 71. A. L. Brown, J. C. Brooks, E. Karunasena, A.Echeverry, A. Laury and M. M. Brashears, J. FoodSci., 2011,76, (6), M427 ( 72. M. M aghoum i , P. A . G omez, F. A rte s -He r nan d ez , Y. M ostofi, Z. Za m an i an d F. A r tes, J. Sci. Food Agric . ,201 2, 93, (5), 1 162 ) ( 7 3 . T . Ji ang, Post h arvest B iol. T echnol., 2013, 7 6, 9 1 ) ( 74. G. O ms-Oli u , R. M . R a ybaudi- Ma ssil i a M a rtinez,R. So l i va- F or t u n y an d O . Ma r tin-Bell o so, Foo d Control, 2008, 1 9, (2 ), 19 1 ) ( 75. F. L opez-Galve z , P . Ragaert, M . A. Haq u e, M . Er i ksson, M . C. van Labeke and F. D e v liegh e re,Posth a rvest Biol. Techn o l., 20 1 5, 1 00, 16 8 ) ( 7 6 . A . A mana t idou, R . A. S l ump , L. G. M. G o r r is a n d E.J. Smi d , J . Fo o d Sci. , 2000, 6 5, (1) , 61 ) ( 77. R. C . Soliva - Fortuny a n d O. Martin - Be l loso , T rendsFood Sci. T echnol., 2003, 1 4, (9), 341 ) ( 78. G . T e wari , D . S . J a yas, L. E . J ere m iah a nd R . A . Holley, Int. J . Food Sci. Technol., 2002, 3 7,(2), 209 ) 79. R. S. Cruz, G. P. Camilloto and A. C. dos SantosPires, 'Oxygen Scavengers: An Approach on FoodPreservation’, in "Structure and Function of FoodEngineering", ed. A. A.Eissa, InTech, Rijeka,Croatia, 2012, pp. 21-42 ( 80. D . A. Pe r e i ra de Abreu , P. Pas e iro Losad a , J . Marotoand J . M . Cr u z, Innov. F o od S ci. E m erg. T e chnol., 2 01 1 ,12,(1),50 ) ( 81 . D. S. Lee , T rends F o od S ci . T echn ol . , 2016 , 57,PartA, 1 46 ) ( 82 . B. Ku s wandi, Y . Wicak s ono, Ja y us , A . A bdu l la h ,L. Y . Heng and M. Ahmad, Sens. Instrum. FoodQual ., 2 01 1 ,5, ( 3-4), 13 7 ) ( 83. R. J e d e rmann , M. N icometo, I . U ysal a n d W . L a ng,Philos . Trans . Roy . So c . A , 20 1 4,372, (2 0 17), 20130302 ) ( 84. J. K . Brech t , F. E . L oaza, M . C. N . Nunes , J . P .Emond, I . U y s al, F . B adi a , J . W ells a nd J. S aenz , Acta Ho r ti c . , 2016 , 1120,2 5 3 ) ( 85. J . G. B or d on ab a a n d L . A. T err y , J. Agric . Food ) ( Chem., 2009, 5 7, ( 1 8), 8220 ) ( 86. X . M eng , S. Kim , P. P u lig u ndla a n d S. Ko , J. Ko reanSoc. Appl. Biol . Chem., 2014 , 5 7, ( 6), 723 ) ( 87 . A. W. H empel, R. N. Gill a nders, D. B. Pa p kovskyand J . P. Ke r ry, Int. J . Dairy Technol., 2012, 65,(3),456 ) ( 88. C. Lang a nd T. Huber t , F ood Bioprocess T e c h nol., 2 01 2 , 5,(8),32 4 4 ) 89. P. M. A. Toivonen, E. J. Mitcham and L. A. Terry,Postharvest Care and the Treatment of Fruits andVegetables', in "Horticulture: Plants for Peopleand Places", eds. G. Dixon and D. Aldous, Vol.1, Springer Science+Business Media, Dordrecht,Netherlands, 2014, pp. 465-483 90. R. K. Dhall, Crit. Rev. Food Sci. Nutr., 2013, 53,(5),435 ( 91. I. Arvan it oyann i s a n d L. G o rris, E di b l e a n dBiodegrad a b l e F P ol y m er i c Materials i t for Foo d Packagi n g o r C oatin g' , i n h "Processing Foods:Qu a l ity Opt i m i za t io n and Process Assessment", eds. F . A. R. O li v e ir aa c a n d J. C . Oli ve i ra , CRCPress L L C, B oca R ato n, U SA, 1999, pp. 35 7 -3 7 2 ) ( 92. J. M. Va l verde, D. Vale r o , D . Mart i nez - Rom e ro, F .Gui l len, S. Castill o and M. Ser r ano, J . Agric . FoodChem., 2 005,53, (2 0 ) , 7807 ) ( 93. N . Fa l agan , F. Artes a n d E . Agua y o, F o od S c i.Te c hnol. I n t . , 20 1 6,22, ( 5), 42 9 ) ( 94. K. C h i t ravathi, O. P. Chau h an a n d P. S. R a ju , J . F o od Sc i . Tech n ol. , 201 6 ,53, (8 ) , 3320 ) 95. B. Marelli, M. A. Brenckle, D. L. Kaplan and F. G.Omenetto, Sci.Rep., 2016,6, 25263 96. S. Burt, Int. J. Food Microbiol.,2004, 94,(3),223 97. C. Chawengkijwanich and Y. Hayata, Int. J. FoodMicrobiol., 2008,123, (3), 288 98. S. H. Othman, N. R. Abd Salam, N. Zainal, R. K.Basha and R. A. Talib, Int. J. Photoenergy, 2014,945930 ( 99. A. B. Cabezas-Se rr ano,M. L. Amodio a nd G.Col e l li , Postharvest Biol. Te c hnol., 2 013 , 75, 1 7 ) ( 100. F. Nig r o and A . Ippo l ito,Acta Horti c ., 2016 , 1144, 293 ) ( 101 . D. L i , Z. L uo, W. Mou, Y . W an g , T . Ying and L. M ao, P ost h arvest Biol . Tech n ol. , 2 0 14 , 90 , 56 ) The Authors Natalia Falagan graduated as an Agricultural Engineer at the Technical University ofValencia, Spain, and obtained her PhD in Food Engineering in 2015 at the TechnicalUniversity of Cartagena, Spain. She conducted her research work at the Universityof California, Davis, USA, and Institut National de la Recherche Agronomique (INRA),Bordeaux, France. She was awarded the PhD extraordinary award. During this period,Falagan gained extended experience in both controlled atmosphere storage andmodified atmosphere packaging, analytical methods for the targeted and untargetedanalysis of secondary metabolites as well as vitamins and sugars in numerous matrices.Falagan was appointed as a Research Fellow in 2016 by Cranfield University, UK. Professor Leon A. Terry is Director of Environment and Agrifood at Cranfield University.He is an appointed member of the UK Government's Agriculture and Food SecurityStrategy Advisory Panel (AFS SAP) 2015-2018, and a long-standing member of thePostharvest Biology and Technology Editorial Board. He is a Fellow of the Royal Societyof Biology, the Higher Education Academy and the Institute of Agricultural Engineers.Terry has been heavily involved with two of the UK Government's Agritech Centres asa current Director of the Agri-EPI Centre and former interim Director of Crop Healthand Protection. Johnson Matthey 在过去的几十年里,食品零售的本质已经被全球贸易所改变。整个供应链的基础设施,设施和技术的发展,加上全球经济的自由化,推动了消费者对全年供应新鲜水果和蔬菜的期望(1))。保持新鲜度需要高度易腐烂的园艺产品的有效运输和储存。收获后,水果和蔬菜保持其生理系统并继续其代谢活动。呼吸和蒸腾导致基质(例如糖和有机酸)的消耗以及伴随成熟和衰老的水分的损失,最终使得产品不可销售。食物浪费是一个全球问题,在过去十年中有所增加。在发达国家,获得先进的采后技术对于减少损失和浪费至关重要,同时保持食品安全和质量。从历史上看,冷藏库如地窖,地下室,洞穴和冰屋都被用来保存新鲜农产品(2)。自18世纪认识到微生物食物腐败以来,该技术已经取得了进展。水果和蔬菜必须冷却以除去热量:在加工,运输和储存之前(3)。如今,制冷设备更具成本效益,可持续发展并消耗更少的能源。它们可用作集中系统,可在各种温度下运行,并可快速响应工作温度的变化。降低储存温度会降低酶活性,呼吸和代谢过程,从而延长保质期。然而,目前的市场需求要求更高,采后期越长,必须保持高质量和食品安全标准。因此,其他技术(如CA存储和MAP)用于增强和增强冷存储。这些主动或被动改变了产品周围和内部的气氛组成,以影响细胞代谢,导致成熟后期水果和蔬菜中的分解代谢减少(4),和酶促反应的抑制(5)。每种商品都有自己的最佳CA和MAP条件,这些条件与对储存时间,相对湿度和乙烯浓度的控制一起可能影响保质期和风味寿命。这些技术的一个重要特征是它们是无害的,可以应用于有机水果和蔬菜。由于新技术的发展和对新鲜农产品生理学的改进知识,CA和MAP技术一直在发展。本综述概述了CA和MAP技术中最新的方法,突出了它们的优点,缺点和主要应用。动态气调保鲜技术CA技术是20世纪采后产业发展起来最成功的技术之一。但是,约 在密封的地下凹坑100 BC已经存储罗马人粒(6,7)。Jacques Etienne Berard在19世纪早期在法国观察到水果在低氧气氛中没有成熟(8)。1927年,Kidd和West发现苹果呼吸率的降低与储存寿命的延长相关(9)。由于此时,采后科学家已经逐步研究不同气氛的上最园艺产品的影响,以获得气体的最佳浓度(10 -13)。常规CA的应用通常包括增加二氧化碳水平和降低氧浓度。已经表明,CA改变了产品周围的气氛,从而改变了内部气体成分,降低了水果或蔬菜的代谢活性并延缓了衰老。关于CA的使用存在一些争议。这是因为消费者可能认为CA存储为他们购买的产品赋予了假冒新鲜感。现实情况是,CA扩大了产品的季节性可用性,保持了物理化学和功能质量,并且可以降低消费者的成本。上的这些优点,贮积症的减少顶部如冷害(14 - 16)帮助减少食物浪费,从而降低经济,社会和环境影响(17)。此外,其作为替代使用采后化学品的潜在是高息(的受试者18,19)。CA的有效性取决于:品种,成熟期性质,储存温度,选定的气体浓度,成熟阶段,收获时的商品质量和储存前处理。如果条件对于所选作物是最佳的,则衰老将通过以下方式延迟:降低呼吸速率和底物氧化,延迟成熟期果实成熟并降低乙烯产量(20))。此外,CA降低病原体呼吸速率,并且可以维持天然疾病抗性。总之,CA可延长存储寿命。然而,不适当的CA商店管理可能会引起异味,异味和生理障碍的发展。为了获得最佳结果,必须深入了解产品生理学并使技术适应每种情况。人们普遍认为,尽快应用CA是最大化疗效的最佳选择。然而,这会导致周围环境发生巨大变化,从而引发产品中的非生物胁迫(21)。最近的研究提出CA调度作为更好地适应产生新陈代谢的手段。Chope 等人。(22据报道,将洋葱上的CA开始延迟三周对于使用连续CA控制芽苗生长同样有效。Alamar 等人。(13)在草莓上应用不同的CA时间,发现在5°C(2.5天; 15 kPa CO 2 + 5 kPa O 2)中途应用CA 2.5天中途在空气中2天后,保质期增加3天。同样,建议在预存储期间使用低温条件。所使用的设备和方法正在不断发展。但是,应为有效的CA设施安装以下关键部件:气密储存室或舱室,制冷系统,气体控制仪器和强大的监测系统(例如氧气,二氧化碳,乙烯,温度和湿度传感器)。应根据每种商品调整最佳气体浓度。优选地,水果和蔬菜必须在低氧浓度下储存,接近无氧补偿点(ACP); 考虑到ACP以上的氧气水平会迅速提高呼吸率,而在低于此值时,发酵会对水果代谢产生不利影响(23)。在20世纪90年代,人们证明了像苹果这样的水果可以在低至0.5%(24 - 26)的氧气水平下储存。如果储存在低于2.5kPa的氧气下进行,则认为是超低氧(ULO)储存。虽然应用ULO比传统CA方法更昂贵,但其使用导致更好的坚固性和质量保持性(27)。

确定

还剩9页未读,是否继续阅读?

图拉扬科技有限公司为您提供《农产品,园艺产品中二氧化碳,氧气检测方案(气调保鲜)》,该方案主要用于其他中理化分析检测,参考标准--,《农产品,园艺产品中二氧化碳,氧气检测方案(气调保鲜)》用到的仪器有Labpod Mini气调保鲜试验系统

推荐专场

相关方案

更多