方案详情

文

铜由于其高导电性在电子设备和布线中得到广泛应用,已成为现代世界中普遍存在的一种元件。因此,铜在全球范围内需求量很大,而且以其99.999999%的纯度日益成为超高规格元件最纯粹的商业形式。要证明这些低水平的微量元素超出了XRF和Arc/Spark OES等技术的能力,因此需要更灵敏的仪器来分析ppb水平的污染物,且不需要大量的样品制备或消化。激光烧蚀电感耦合等离子体质谱法(LA-ICP-MS)满足了这些要求,而来自ESI的NWR系列激光烧蚀系统在系统和样品室技术方面的新进展使用户能够在一种不干涉的、全自动采样器的模式下操作。近来高质量、经过认证的参考材料的可靠性不断提高,使LA-ICP-MS成为工业测定铜中污染物的可行技术。

方案详情

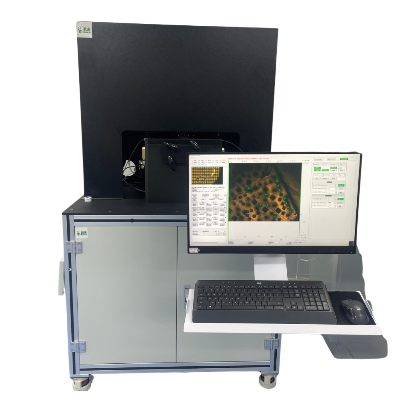

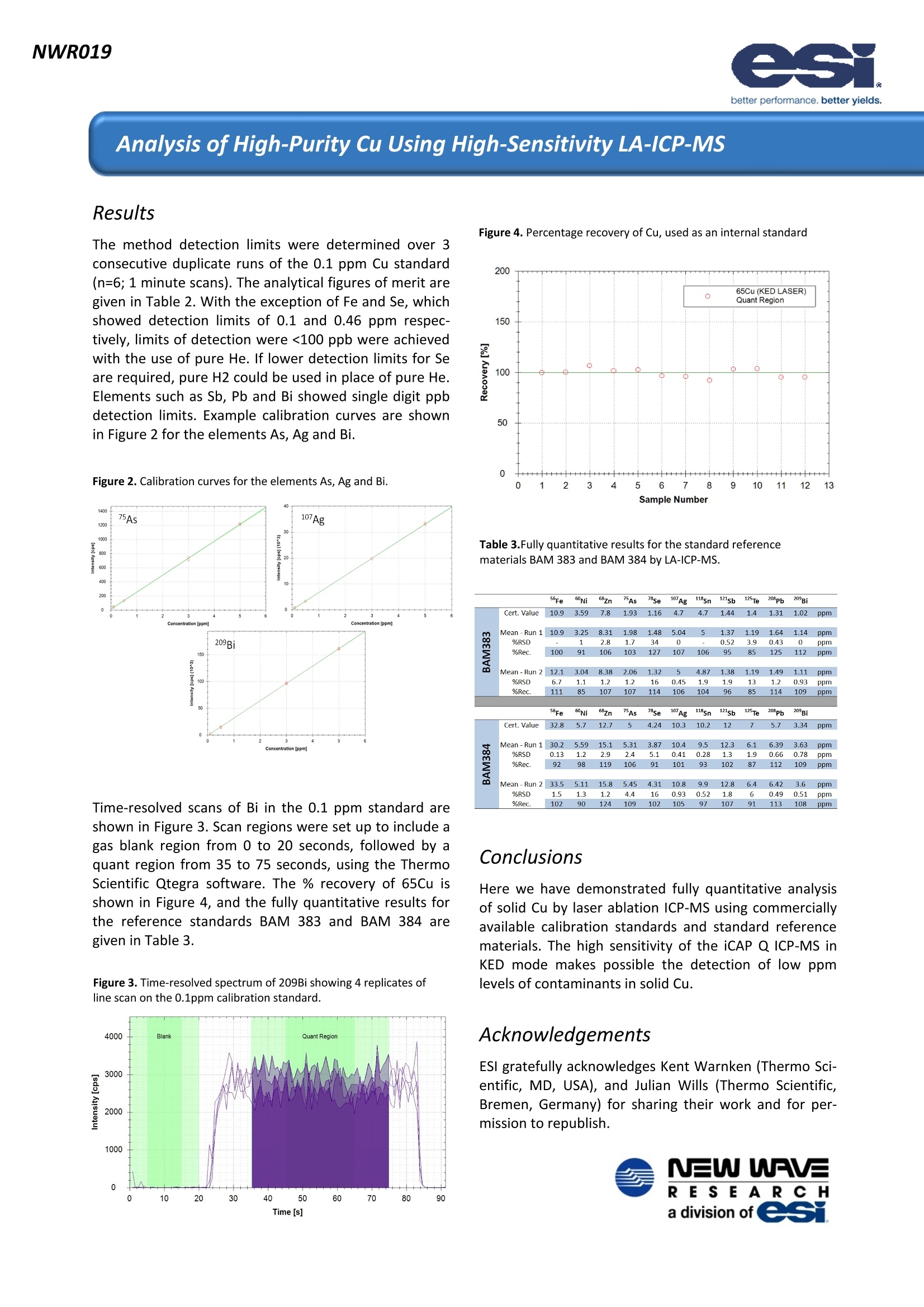

NWR019 NEW WVERESEARCHa sion ofeSi Analysis of High-Purity Cu Using High-Sensitivity LA-ICP-MS Copper has become a ubiquitous component of themodern world as a result of its extensive use in elec-tronic devices and wiring thanks to its high electricalconductivity. Consequently, copper is in high demandglobally, and increasingly in its purest commercial format 99.999999% purity for ultra-high specification com-ponents. The requirement to certify traceelements atthese low levels is beyond the capabilities of tech-niques such as XRF and Arc/Spark OES, hence moresensitive instrumentation is required to analyse con-taminants at ppb levels, preferably without the needfor extensive sample preparation/digestion. Laser Ablation Inductively-Coupled Plasma Mass Spec-trometry (LA-ICP-MS) meets these requirements, whilenew advances in system and sample chamber tech-nologies on the NWR-series laser ablation systemsfrom ESI enable the user to operate in a hands-off,autosampler-like mode. The availability of high-quality,certified reference materials has increased recently,making LA-ICP-MS a viable technique for the industrialdetermination of contaminants in copper. Methods A series of 4 calibration standards (0.1, 0.5, 3.0 and 5.0ppm) from CopperSpec Inc. (www.copperspec.com)were placed in the sample chamber (2 Volume Cell) ofa NWR213 laser ablation system connected to an iCAPQ ICP-MS (Thermo Scientific). The method was vali-dated by measuring the European Reference Materials(ERM) EB383 and EB384. Each standard and referencestandard was measured in duplicate using a 1 minutescan line, after first pre-ablating the surface, on con-secutive days to determine experimental robustness(Table 1). Figure 1. The NWR213 laser ablation system Table 1. Instrumental parameters for the analysis of solid Cu. Parameter Value Forward Power (W) 1550 Nebuliser Ar Flow (mL/min) 790 Ablation Cell He Flow (mL/min) 800 Q-Cell He Flow (mL/min) 5.2 Wavelength(nm) 213 Fluence(J/cm2) 7.5 Repetition Rate (Hz) 20 Spot Size (um) 250 Scan Rate (um/s) 15 The NWR213laser ablation system from ESl is a213nm system suitable for use in a broad range of ap-plications. The standard sample chamber is a two vol-ume large format cell (100mm x 100mm) cell that canhold many samples at one time. Helium was introduced into the laser cell using thestandard on-board mass flow controller at a rate of800 mL/min and mixed with Argon just prior to thetorch. A 900 um (60 second) scan line was positionedon each of the four standards and the two referencematerials. Pre-ablation of the surface was carried out,due to severe contamination of Fe and Zn. After pre-ablation, two additional passes were made and theresults averaged and compared to the certified values.The ICP-MS was operated in kinetic energy discrimina-tion (KED) mode with He collision gas and instrumentsetup was performed using the Autotune wizard onNIST 612 glass with a limit of ThO+ of <0.3% (STDmode). The instrument was configured with a 2.0 mmquartz injector and a 2.8 mm skimmer cone insert.Samples were analysed for 11 isotopes:56Fe, 60Ni, 68zn,75As,78Se,:,107Ag,118Sn,121Sb,125Te,208Pband209Bi. 65cuwas used as an internal standard (Table 2). Table 2. Analytical figures of merit for the analysis of pure Cu bylaser ablation ICP-MS. The IDL is calculated as three times thestandard deviation of two runs conducted on consecutive days. (amu) Time (s) (cps/ppb) (ppb) Fe 56 0.05 KED(He) Normal 1.7 0.9983 170 100 Cu 65 0.05 KED(He) High - Ni 60 0.05 KED (He) Normal 1.1 0.9999 36 26 Zn 68 0.05 KED(He) Normal 0.26 0.9983 74 43 As 75 0.05 KED (He) Normal 0.22 0.9998 92 69 Se 78 0.05 KED (He) Normal 0.014 0.9947 300 460 Ag 107 0.05 KED(He) Normal 6.2 0.9999 0 13 Sn 118 0.05 KED(He) Normal 1.8 0.9999 40 40 Sb 121 0.05 KED(He) Normal 1.7 0.9998 0 6 Te 125 0.05 KED (He) Normal 0.037 0.9992 23 78 Pb 208 0.05 KED(He) Normal 24 0.9994 0 4 Bi 209 0.05 KED (He) Normal 31 0.9998 0 7 Analysis of High-Purity Cu Using High-Sensitivity LA-ICP-MS Results The method detection limits were determined over 3consecutive duplicate runs of the 0.1 ppm Cu standard(n=6; 1 minute scans). The analytical figures of merit aregiven in Table 2. With the exception of Fe and Se, whichshowed detection limits of 0.1 and 0.46 ppm respec-tively, limits of detection were <100 ppb were achievedwith the use of pure He. If lower detection limits for Seare required, pure H2 could be used in place of pure He.Elements such as Sb, Pb and Bi showed single digit ppbdetection limits. Example calibration curves are shownin Figure 2 for the elements As, Ag and Bi. Figure 2. Calibration curves for the elements As, Ag and Bi. Time-resolved scans of Bi in the 0.1 ppm standard areshown in Figure 3. Scan regions were set up to include agas blank region from 0 to 20 seconds, followed by aquant region from 35 to 75 seconds, using the ThermoScientific Qtegra software. The % recovery of 65Cu isshown in Figure 4, and the fully quantitative results forthe reference standards BAM 383 and BAM 384 aregiven in Table 3. Figure 3. Time-resolved spectrum of 209Bi showing 4 replicates ofline scan on the 0.1ppm calibration standard. Figure 4. Percentage recovery of Cu, used as an internal standard Table 3.Fully quantitative results for the standard referencematerials BAM 383 and BAM 384 by LA-ICP-MS. 5Fe 60Ni 58Zn As 78Se10Ag 118Sn 1121sb1125Te 208Pb 209Bi Cert. Value 10.9 3.59 7.8 1.93 1.16 4.7 4.7 1.44 1.4 1.31 1.02 ppm Mean-Run 1 10.9 3.25 8.31 1.98 1.48 5.04 5 1.37 11.19 1.64 1.14 ppm %RSD 1 2.8 1.7 34 0 0.52 3.9 0.43 0 ppm %Rec. 100 91 106 103 127 107 106 95 85 125 112 ppm Mean-Run 2 12.1 3.044 8.38 2.06 1.32 5 4.87 1.38 1.19 1.49 1.11 ppm %RSD 6.7 1.1 1.2 1.2 16 0.45 1.9 1.9 13 1.2 0.93 ppm %Rec. 111 85 107 107 114 106 104 96 85 114 109 ppm Fe 60Ni 68Zn As "Se 107Ag 118sn 121sb 125Te 208Pb 209Bi Cert. Value 32.8 5.7 12.7 5 4.24 10.3 10.2 12 5.7 3.34 ppm Mean-Run 1 30.2 5.59 15.1 5.31 3.87 10.4 9.5 12.3 1 6.39 3.63 ppm %RSD 0.13 1.2 2.9 2.4 5.1 0.41 0.28 1.3 1.9 0.66 0.78 ppm %Rec. 92 98 119 106 91 101 93 102 87 112 109 ppm Mean-Run 2 33.5 5.11 15.8 5.45 4.31 10.8 9.9 12.8 6.4 6.42 3.6 ppm %RSD 1.5 1.3 1.2 4.4 16 0.93 0.52 1.8 6 0.49 0.51 ppm %Rec. 102 90 124 109 102 105 97 107 91 113 108 ppm Conclusions Here we have demonstrated fully quantitative analysisof solid Cu by laser ablation ICP-MS using commerciallyavailable calibration standards and standard referencematerials. The high sensitivity of the iCAP Q ICP-MS inKED mode makes possible the detection of low ppmlevels of contaminants in solid Cu. Acknowledgements ESl gratefully acknowledges Kent Warnken (Thermo Sci-entific, MD, USA), and Julian Wills (Thermo Scientific,Bremen, Germany) for sharing their work and for per-mission to republish. 铜由于其高导电性在电子设备和布线中得到广泛应用,已成为现代世界中普遍存在的一种元件。因此,铜在全球范围内需求量很大,而且以其99.999999%的纯度日益成为超高规格元件最纯粹的商业形式。要证明这些低水平的微量元素超出了XRF和Arc/Spark OES等技术的能力,因此需要更灵敏的仪器来分析ppb水平的污染物,且不需要大量的样品制备或消化。激光烧蚀电感耦合等离子体质谱法(LA-ICP-MS)满足了这些要求,而来自ESI的NWR系列激光烧蚀系统在系统和样品室技术方面的新进展使用户能够在一种不干涉的、全自动采样器的模式下操作。近来高质量、经过认证的参考材料的可靠性不断提高,使LA-ICP-MS成为工业测定铜中污染物的可行技术。

确定

还剩1页未读,是否继续阅读?

上海凯来仪器有限公司为您提供《金属中高纯铜检测方案(激光剥蚀进样)》,该方案主要用于铜中含量分析检测,参考标准--,《金属中高纯铜检测方案(激光剥蚀进样)》用到的仪器有ESL213 灵活的激光剥蚀系统

推荐专场

相关方案

更多