卡尔·费休库仑法测定液化石油气中微量水分

使用日本京都电子公司(KEM)- 库仑法卡尔·费休水分测定仪,测定液化石油气(LPG)中水分含量的应用资料。

符合下列标准规范:

GB/T 18619.1-2002 天然气中水含量的测定卡尔费休-库仑法

SN/T 2382-2009 液化石油气中微量水分的测定卡尔•费休法

ISO 10101-3:1993 Natural gas -- Determination of water by the Karl Fischer method -- Part 3: Coulometric procedure.(天然气中水含量的测定 卡尔•费休法 第3部分:库仑法)

GB/T 3727-2003 工业用乙烯、丙烯中微量水的测定(卡尔·费休库仑法)

GB/T 6023-2008 工业用丁二烯中微量水的测定卡尔-费休库仑法

方案详情

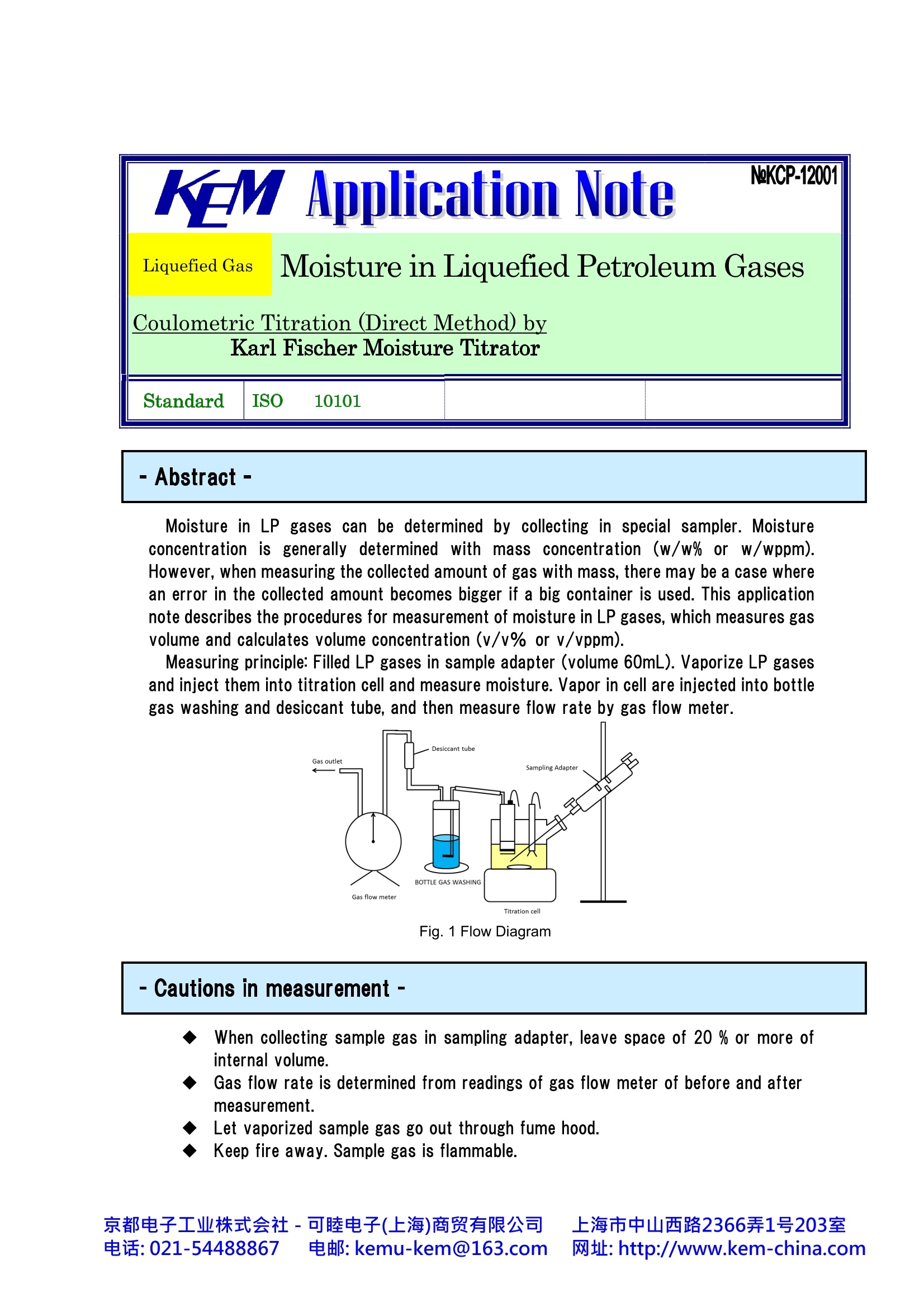

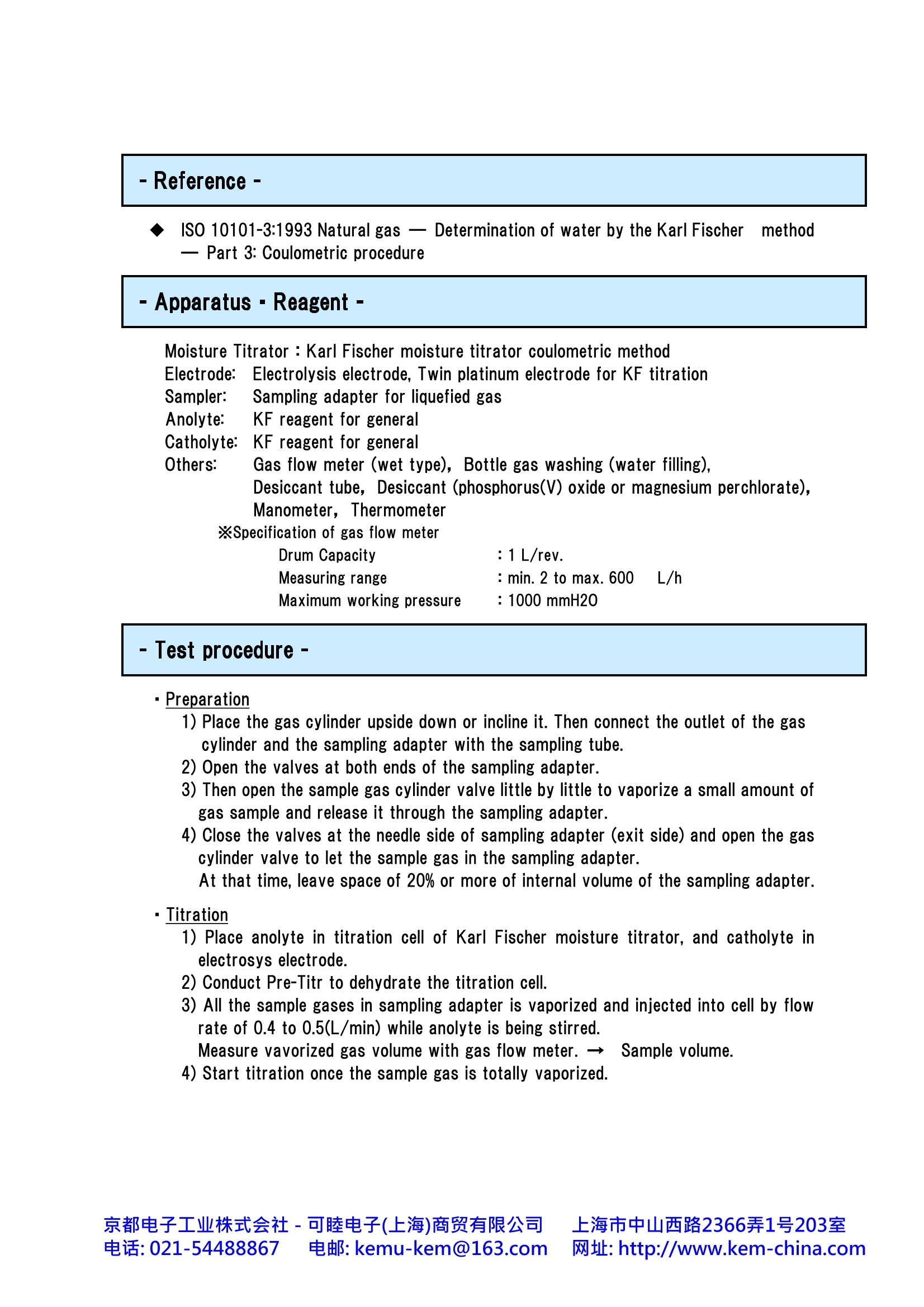

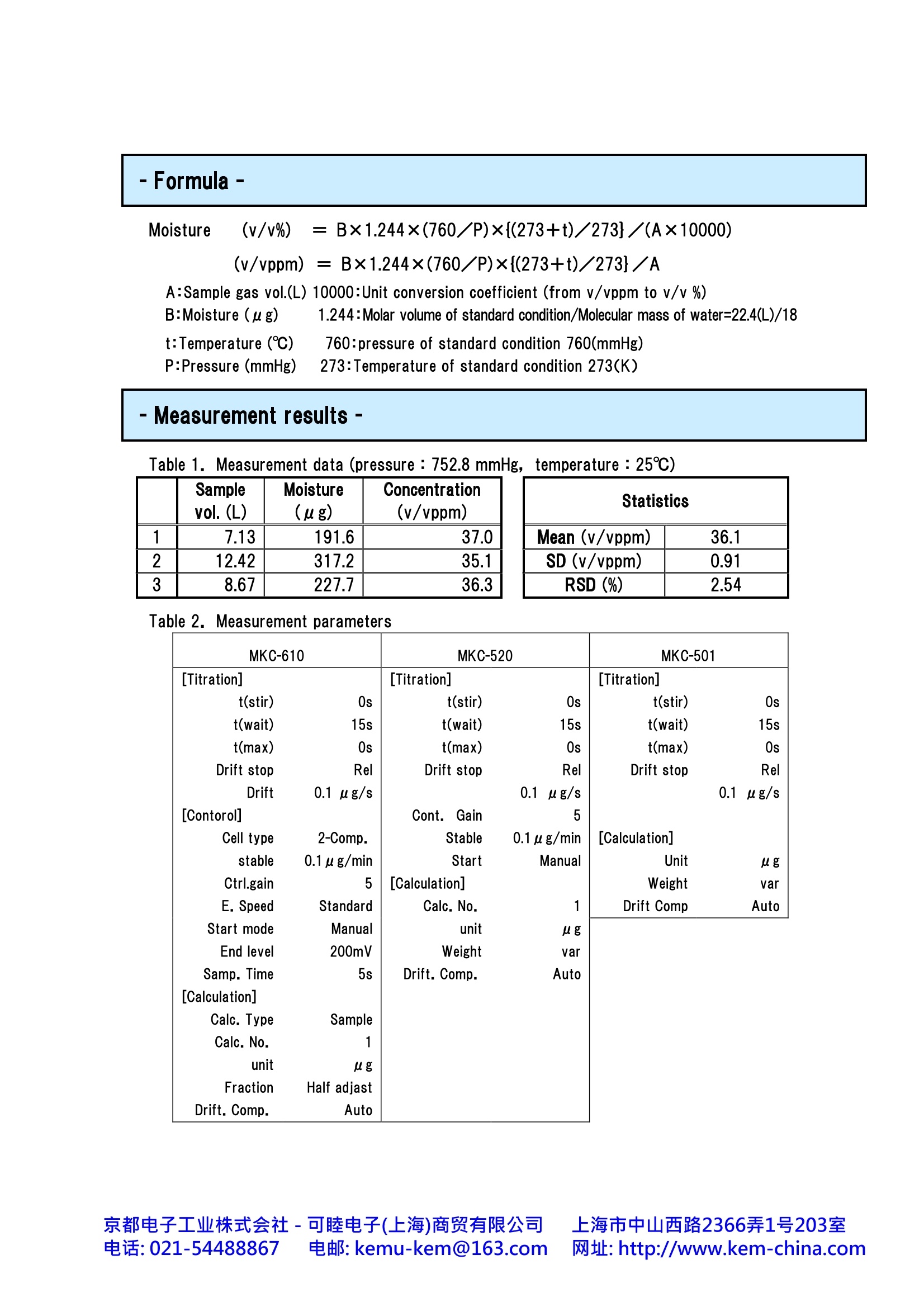

NoKCP-12001 KcM Application Note Liquefied Gas Moisture in Liquefied Petroleum Gases Coulometric Titration (Direct Method) by Karl Fischer Moisture Titrator Standard ISO 10101 -Abstract- Moisture in LPgases can be determined by collecting in special sampler. Moistureconcentration is generally determined with mass concentration (w/w% or w/wppm).However,when measuring the collected amount of gas with mass, there may be a case wherean error in the collected amount becomes bigger if a big container is used. This applicationnote describes the procedures for measurement of moisture in LP gases, which measures gasvolume and calculates volume concentration (v/v% or v/vppm). Measuring principle: Filled LP gases in sample adapter (volume 60mL). Vaporize LP gasesand inject them into titration cell and measure moisture. Vapor in cell are injected into bottlegas washing and desiccant tube, and then measure flow rate by gas flow meter. Fig. 1 Flow Diagram -Cautions in measurement - When collecting sample gas in sampling adapter, leave space of 20 % or more ofinternal volume. Gas flow rate is determined from readings of gas flow meter of before and aftermeasurement. Let vaporized sample gas go out through fume hood. Keep fire away. Sample gas is flammable. -Reference - ISO 10101-3:1993 Natural gas -Determination of water by the Karl Fischermethod- Part 3: Coulometric procedure -Apparatus·Reagent - Moisture Titrator : Karl Fischer moisture titrator coulometric method Electrode:: Electrolysis electrode, Twin platinum electrode for KF titration Sampler: Sampling adapter for liquefied gas Anolyte: KF reagent for general Catholyte: KF reagent for general Others: Gas flow meter (wet type), Bottle gas washing (water filling), Desiccant tube, Desiccant (phosphorus(V) oxide or magnesium perchlorate), Manometer, Thermometer ※Specification of gas flow meter Drum Capacity :1 L/rev. Maximum working pressure : 1000 mmH20 -Test procedure- · Preparation 1) Place the gas cylinder upside down or incline it. Then connect the outlet of the gascylinder and the sampling adapter with the sampling tube. 2) Open the valves at both ends of the sampling adapter. 3) Then open the sample gas cylinder valve little by little to vaporize a small amount ofgas sample and release it through the sampling adapter. 4) Close the valves at the needle side of sampling adapter (exit side) and open the gascylinder valve to let the sample gas in the sampling adapter. At that time, leave space of 20% or more of internal volume of the sampling adapter. ·Titration 1) Place anolyte in titration cell of Karl Fischer moisture titrator, and catholyte inelectrosys electrode. 2) Conduct Pre-Titr to dehydrate the titration cell. 3) All the sample gases in sampling adapter is vaporized and injected into cell by flowrate of 0.4 to 0.5(L/min) while anolyte is being stirred. Measure vavorized gas volume with gas flow meter. →Sample volume. 4) Start titration once the sample gas is totally vaporized. -Formula - Moisture (v/v%) = B×1.244×(760/P)×{(273+t)/273}/(A×10000)(v/vppm)=B×1.244×(760/P)×{(273+t)/273}/A A:Sample gas vol.(L) 10000:Unit conversion coefficient (from v/vppm to v/v %) B:Moisture(u g) 1.244 :Molar volume of standard condition/Molecular mass of water=22.4(L)/18 t:Temperature (℃) 760:pressure of standard condition 760(mmHg) P:Pressure (mmHg) 273:Temperature of standard condition 273(K) - Measurement results - Table 1. Measurement data (pressure : 752.8 mmHg, temperature:25C) Statistics Samplevol. (L) Moisture( g) Concentration(v/vppm) Mean (v/vppm) 36.1 191.6 37.0 SD (v/vppm) 0.91 317.2 35.1 RSD (%) 2.54 227.7 36.3 Table 2. Measurement parameters MKC-610 MKC-520 MKC-501 [Titration] t(stir) Os t(wait) t(max) 15s0s Drift stop Rel Drift 0.1 ug/s [Contorol] Cell type 2-Comp. stable 0.1 u g/min Ctrl.gain 5 E. Speed Standard Start mode Manual End level 200mV Samp.Time 5s [Calculation] Calc. Type Sample Calc.No. 1unit u gFraction Half adjast Drift. Comp. Auto [Titration] t(stir) Os t(wait) 15s t(max) Os Drift stop Rel 0.1 ug/s Cont. Gain 5 Stable 0.1ug/min Start Manual [Calculation] Calc. No. 1 unit u g Weight var Drift. Comp. Auto Titrationl t(stir) Os t(wait) 15s t(max) 0s Drift stop Rel 0.1 ug/s Calculation] Unit ug Weight var Drift Comp Auto 电话: 电邮:kemu-kem@com 网址: http://www.kem-china.com

确定

还剩1页未读,是否继续阅读?

可睦电子(上海)商贸有限公司-日本京都电子(KEM)为您提供《液化石油气中微量水分检测方案(卡氏水分测定)》,该方案主要用于天然气/燃气中微量水分检测,参考标准--,《液化石油气中微量水分检测方案(卡氏水分测定)》用到的仪器有MKH-710M容量法库仑法混合型卡尔费休水分仪、MKC-710B卡尔费休库仑法微量水分测定仪、MKC-710S豪华型库仑法卡尔费休水分仪、MKC-710M四通道旗舰型库仑法卡尔费休水分仪

推荐专场

相关方案

更多