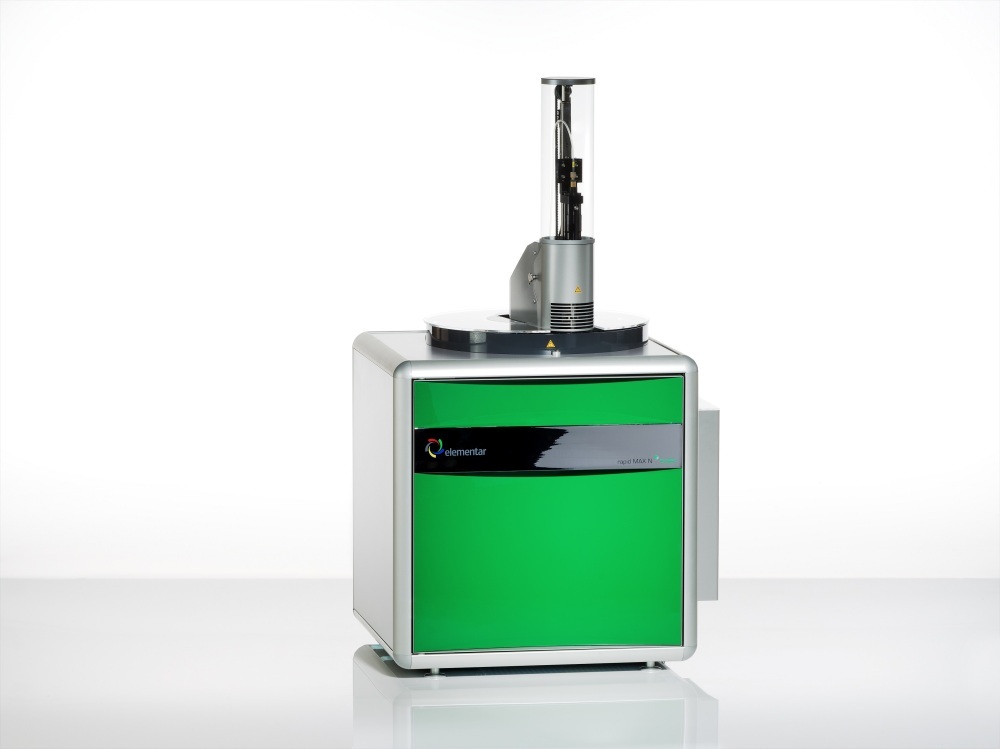

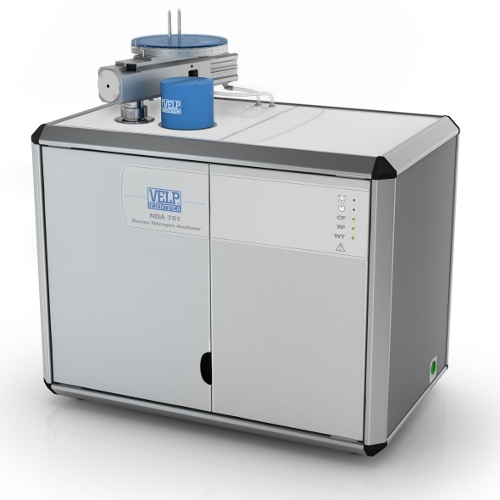

CEM SPRINT——目前世界上唯一的真蛋白质快速测仪,诞生于2007年, 2008年获IFT创新奖。该仪器采用了生命科学领域的iTAG“蛋白质分子标签”技术,这项技术可以给蛋白质贴上“标签”,提供一种在样品中直接测量真蛋白质含量的手段。

方案详情

Strategic Directions International, Inc. Strategic Information for the Analytical & Life Science Instrument Industry Volume 17, Number 13October 15, 2008 REPRINT Food Analysis Protein Testing in theWake of Melamine 1 Business Climate Survev Economic Crisis DepressesGrowth Prospects Executive BriefingQIAGEN Adds AnotherInstrument Line 2 Sales Index Strong Sales for Equipment/Consumables in Q2 3 Industry WatchFinancial Crisis CouldImpact Biomed Charities 5 Region WatchChina Is Tops for PharmaOutsourcing in Asia 5 US FY09 BudgetContinuing ResolutionResults in Few Increases .7 News Market Profile Cell-Cell Electrofusion i12 Bottom Line 12 Protein and Melamine Testing in Food The addition of the chemical melamine toChinese dairy products has caused morethan 10 infant deaths worldwide and over50,000 children in China to be hospital-ized. Melamine in itself is not harmful,but when levels are high enough, it cancause crystals to form in the liver, lead-ing to renal failure.This scandal comeson the heels of last year's discovery of theaddition of melamine to wheat gluten inpet food imported from China, which ledto thousands of animal deaths (see IBO11/15/07). Melamine is added to foodproducts to fake a higher protein level ina sample that has been diluted. Currently, testing for protein con-tent in food is done using methods thatdo not directly test protein, and insteadobtain protein readings by measuringnitrogen levels, which the addition ofmelamine will increase. In food testing,protein analysis is used for determiningproperties of proteins, such as chemicalcomposition, type and concentration,which are important in quality controland labeling. This article will primarily in-vestigate the current state of direct proteindetection methods, their advantages anddisadvantages, and their possible future.In the absence of a standard direct proteintest, melamine testing is the solution tothe current crisis The Kjeldahl and Dumas methodsare the standard methods for proteintesting of foods. Both methods rely onthe measurement of nitrogen, which isreleased in the Kjeldahl method after anacid, such as sulfuric acid, digests thesample. Using the Dumas method, whichis a faster variation of the Kjeldahl meth-od, nitrogen is measured after a sampleof a known mass is combusted.These methods are easy to run, recognized byregulatory agencies, low cost and repro-ducible."Currently, Kjeldahl and Dumasare the classical methods important inmodern food protein analysis and arethe approved methods by internationalorganizations,"stated Dr. Anthony Fon-tana, technical director of Chemistry atthe independent food testing companySilliker."Kjeldahl is applied as a referencemethod for the evaluation of alternativeprotein determination techniques," heexplained to IBO. The downsides of the Kjeldahlmethod include the use of hazardoussubstances and that it is relatively slow.For Dumas, the protein contained in theactual sample may be misrepresentedbecause a small sample size is requiredfor the reaction. But,currently, the mostpertinent drawback is that these methodscannot detect some forms of adulterationsince they do not directly measure protein.“If a regulatory agency, such as the FDA,determines that an alternative analyticalmethod is superior to Kjeldahl or Dumas,then they may require this technique. Ifor how soon this may occur is anyone’sguess,"commented Dr. Fontana. Two direct methods for protein test-ing in food that do not rely on testingnitrogen levels are UV-Visible and in-frared spectroscopy (IR). UV-Vis can de-termine low concentrations of proteinsin a sample, and thus is mainly usedfor pure protein analysis in laboratoriesrather than for quality control. WithUV-Vis, certain chemical groups, suchas peptide bonds, aromatic side-groupsand aggregate proteins, can be targetedfor protein determination, allowing fora clear verification of results. The run- ning time of the whole process isrelatively short, but sample prepa-ration can be time consuming andlabor intensive due to the necessityof obtaining a transparent sample.In addition, amino acid sequencesdiffer in some proteins, which occa-sionally leads to a misinterpretationof absorbance readings. In contrast, IR is good for qualitycontrol purposes. Because it requiresless sample preparation and is non-destructive, it is used for on-lineanalysis. It is widely used for proteinanalysis of wheat, grain and dairyproducts. However, equipment cali-bration is a necessary but sometimestime-consuming step in IR analysisof food samples. Another drawbackis the high cost of instruments. AsDr. Fontana explained, IR also has“accuracy, reproducibility, interfer-ence and quantification issues. Thesespectrophotometric methods...haveresponses that vary with the aminoacid composition of the proteins, havepossible interferences from nonproteincompounds, like carbohydrates, saltsand lipids, that have to be taken intoaccount, [and] may have instabilityof the reagents and may have a timedependency of the response based onreagent mixing, color developmentand so on."He added, "for a specificmatrix these spectrometric techniquesmay be applied, but as a generalmethod for direct protein detection ina wide variety of food matrices, theyhave limitations." A recently introduced techniquefor direct protein analysis in food isCEM's SPRINT Rapid Protein Ana-lyzer, which began shipping in thefirst quarter of this year. The SPRINTuses protein-tagging technology to de-termine protein levels in two minutes.According to CEM, it is less expensive,safer and easier to use than Kjeldahland can be used in labs and on theproduction floor because it does notrequire the use of an acid. Accordingto John Urh, CEM’s SPRINT productmanager, the company developed theproduct based on customer requests.As he told IBO, "our tagging tech-nology allows us to bind to proteinsdirectly and measure that binding,and that gives us the protein measure- ments. We settled on this technologytwo years ago. We said we’d go aheadand build a product on this technol-ogy, one that would be automatedand easy to use." With the SPRINT, the companywanted to circumvent the weaknessesof indirect protein detection methods,such as the requirement of supple-mental adulterant testing.“There arestill other sources of nitrogen suchas urea, so just testing for melaminewill help reduce the incentive to add “There are still other sourc-es of nitrogen such as urea,so just testing for melaminewill help reduce the incen-tive to add melamine to aproduct, but there are stillways to fool the tests byadding different sourcesof nitrogen to the material.To me, it seems that a testthat measures protein di-rectly will always win outin a situation when peopleare adding adulterants to amaterial.” melamine to a product, but there arestill ways to fool the tests by addingdifferent sources of nitrogen to thematerial," said Mr. Urh. “To me, itseems that a test that measures pro-tein directly will always win out ina situation when people are addingadulterants to a material." The company also shied awayfrom the use of spectroscopy tech-niques such as IR in the developmentof the SPRINT because, as Mr. Urhtold IBO,"[it] measures the vibrationsof the different molecular bonds. Theproblem with this is that it measuresthe similar types of bonds that arenot in protein."He continued,"Whenyou’re looking at a signal for proteinin IR, you’re looking at a signal thatincludes a lot of other components.And there's a lot of mathematics and a deconvolution of data that has to beperformed to get that protein number,so it is not a direct measurement." According to Mr. Urh, the onlybarrier to adoption of CEM’s technol-ogy is that it is new to the food indus-try,and that it will take time for CEM’scustomer base to learn about it. TheSPRINT conforms to the Associationof Analytical Communities'(AOAC)standards for dairy analysis and theAmerican Association of Cereal Chem-ists'standards for grain analysis. Stud-ies for it conformity to AOAC's meatstandards are underway. However, direct melamine test-ing is the current the way in whichthe melamine crisis is being handled.According to the World HealthOrganization (WHO), more currentmethods for melamine testing areLC-MS/MS and LC-MS. LC-MS/MS,with a melamine detection limit of50 pg/mL, is both reliable and cov-ers a wide range of samples. Thedownside is that the process is themost expensive and complicatedof these techniques and, includingsample preparation, analysis can takeup to two days. LC-MS is similar toLC-MS/MS in detection limit andsample range, but its sensitivity issuch that sample interference is pos-sible. GC-MS,which was extensivelyused during the pet food scandal, ismore sensitive than LC-MS with asensitivity of 0.01 mg/kg. It differsfrom LC-MS/MS and LC-MS in thatit requires the melamine to be reactedinto trimethylsilyl derivatives beforeanalysis. This step is labor intensiveand sensitive enough to add a largemargin of error if mishandled. The nature of these tests has ledChina to seek faster and easier testingmethods for melamine. At the start ofOctober, China's Ministry of Scienceand Technology released an appealto members of the public to developa way to detect melamine in only 30minutes,according to Xinhuanet.com. That same month, the WHOannounced that it was developinga test kit that would rapidly deter-mine melamine levels, according toChina Daily. ELISA test kits have alsobeen quite effective, according to theWHO, in quickly detecting melamine in milk, wheat gluten and pet food samples, but until re-cently they have not been capable of detecting melamine atthe limits set by governments. The most stringent limit is0.05 ppm, set by Taiwan at the end of September. However,Hong Kong's limit for pregnant or breast-feeding womenand children under three years of age is 1 ppm, while forall everyone else, it is 2.5 ppm, which is the limit in the USand the EU. Romer Labs' AgraQuant Melamine ELISA canmeet government requirements as it detects melamine at0.50-25 mg/kg for milk powder and 0.10-0.50 mg/kg formilk, yogurt and yogurt drinks. Nevertheless, such adulterant-specific solutions areunlikely to be the answer. "There are other nonproteinnitrogen-containing adulterants that would interfere withthe conversion of nitrogen into protein and not be detectedby melamine analysis,"explained Dr. Fontana."Accurateconversion of nitrogen into protein only occurs if the ni-trogen content of the protein fraction is known and othernonprotein nitrogen-containing compounds are accountedfor. Separation of nonprotein nitrogen from true proteincan be accounted for by the addition of protein precipita-tion testing. nstrument Business Outlook · October

确定

还剩1页未读,是否继续阅读?

培安有限公司为您提供《食品中蛋白质和三聚氰胺检测方案(蛋白测定仪)》,该方案主要用于液体乳中非法添加检测,参考标准--,《食品中蛋白质和三聚氰胺检测方案(蛋白测定仪)》用到的仪器有CEM Sprint 生物标签真蛋白测试仪

推荐专场

相关方案

更多

该厂商其他方案

更多