1,对烘焙制品的油脂氧化稳定性进行研究

2,含不同油脂类型烘焙制品的配方进行研究,获得更加稳定的配方类型

3,对烘焙制品的保质期进行研究和分析

方案详情

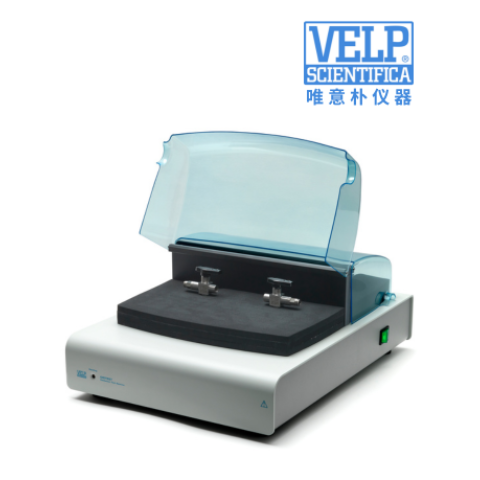

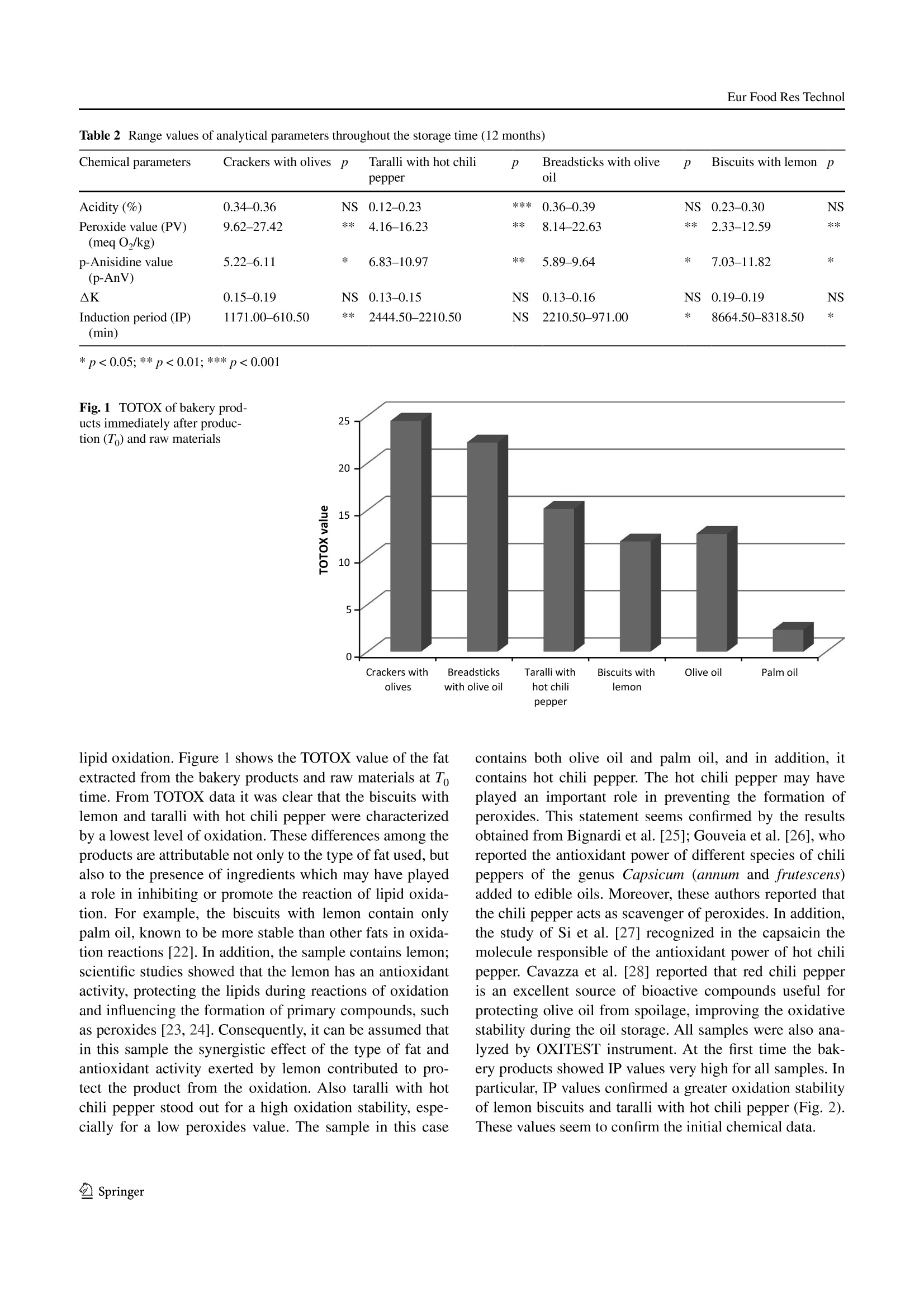

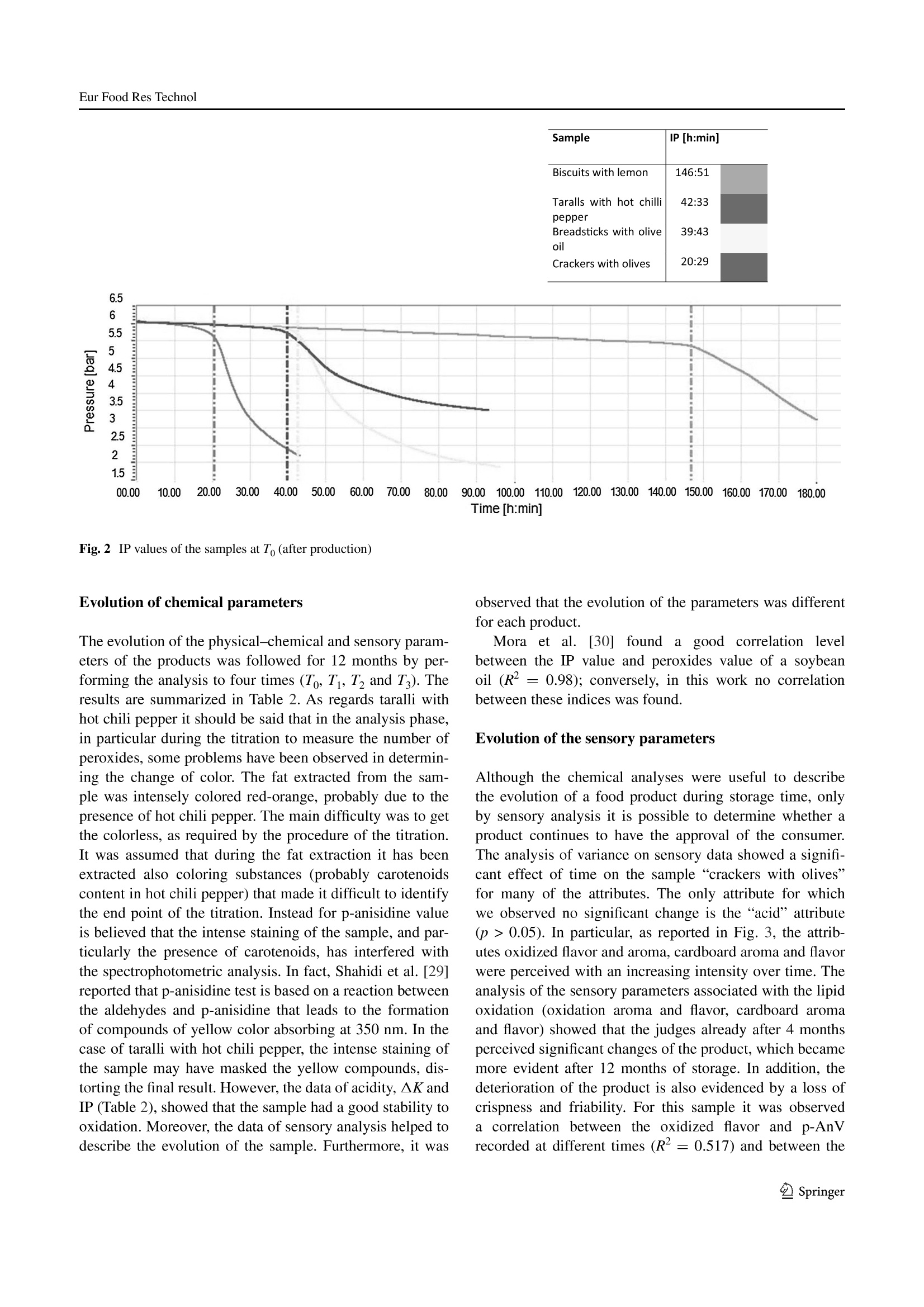

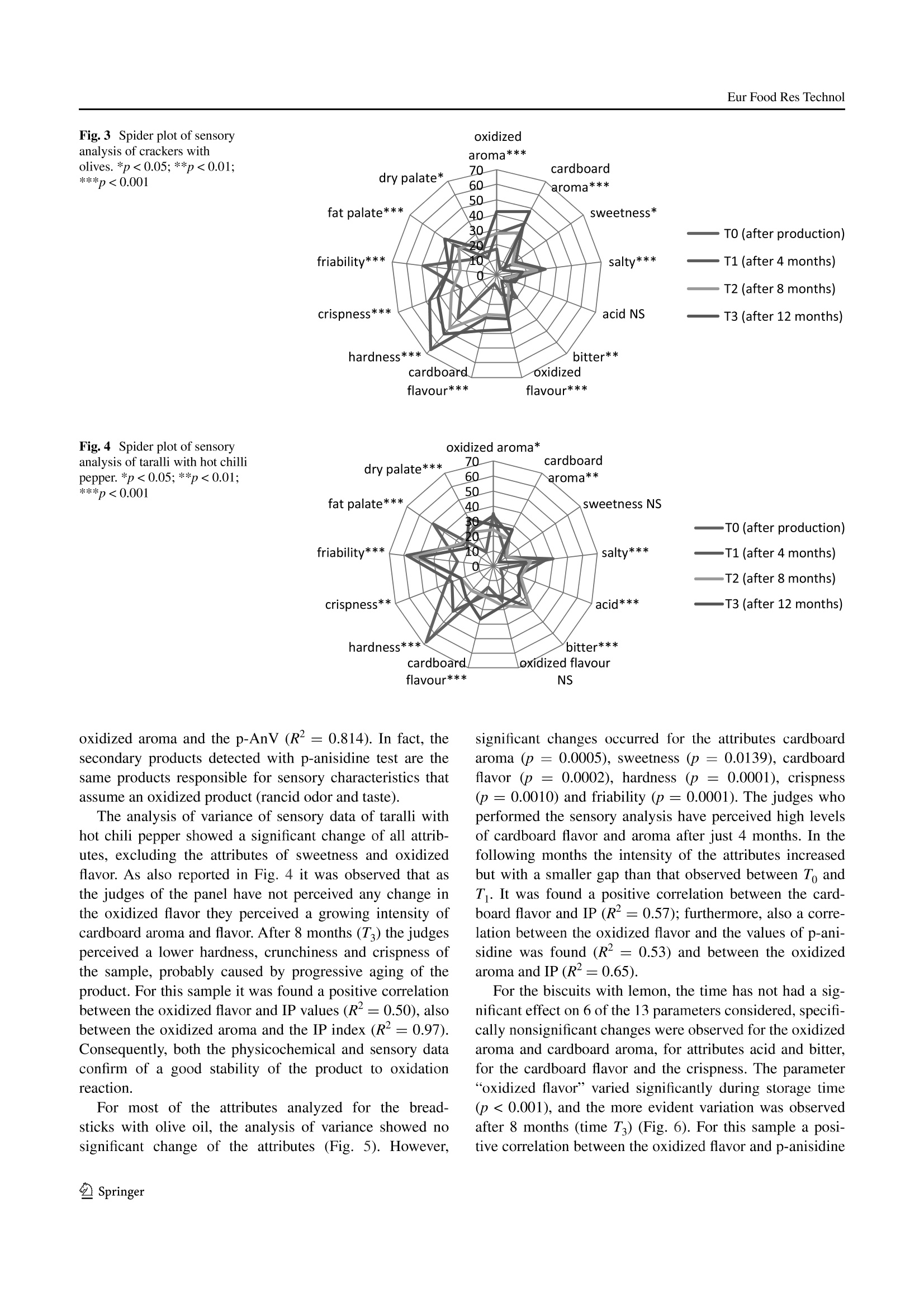

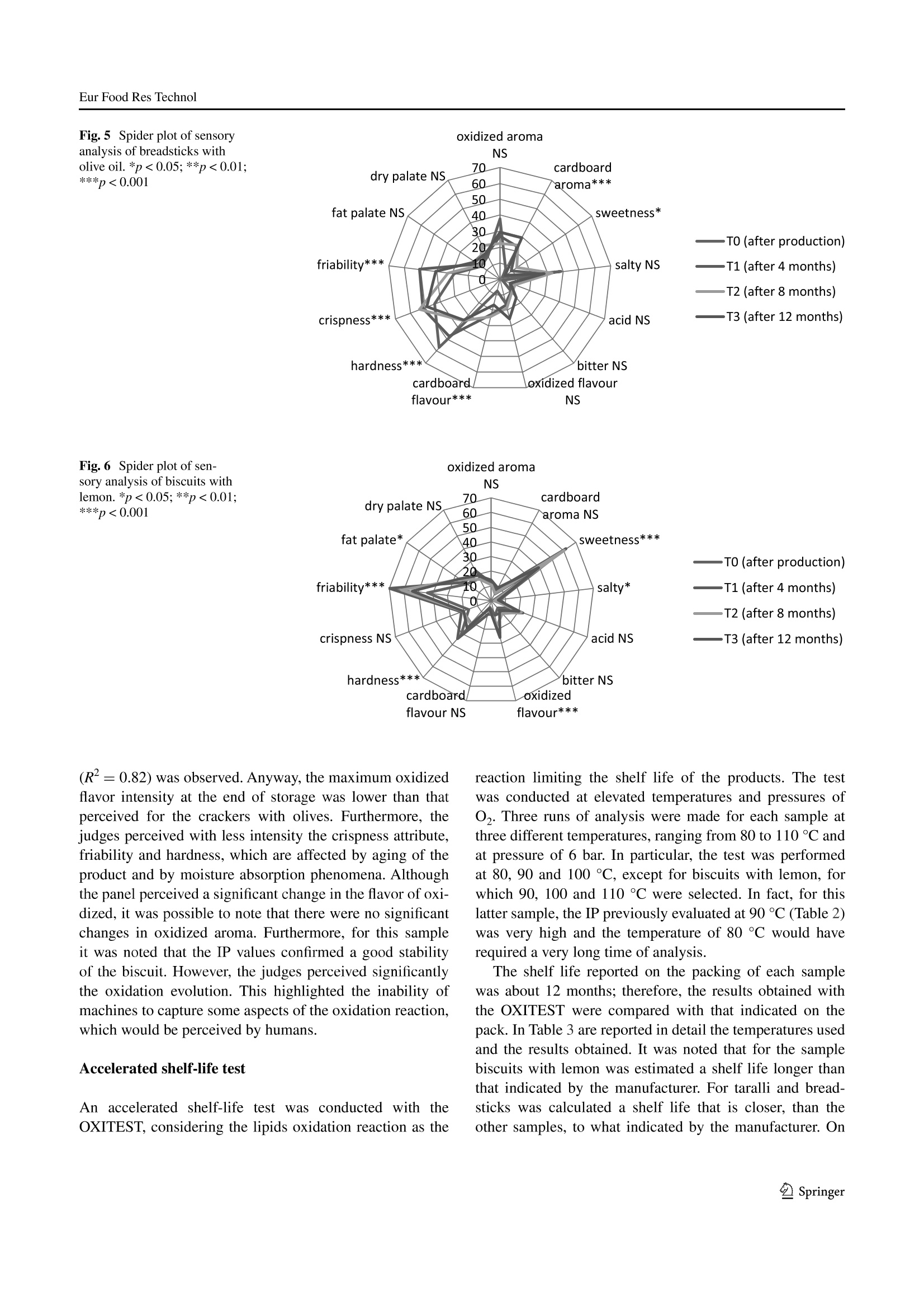

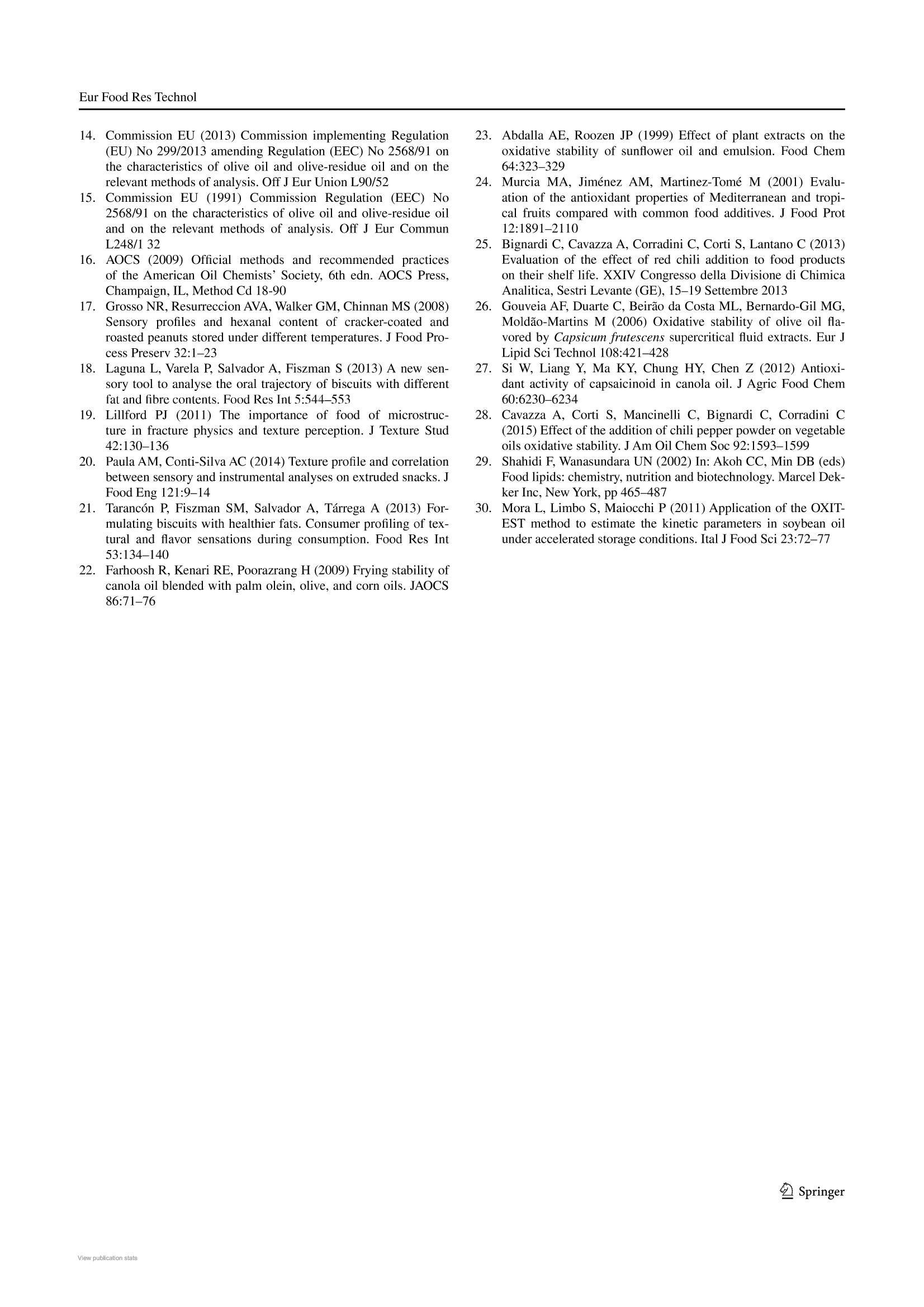

CrossMarkEur Food Res TechnolDOI 10.1007/s00217-016-2831-9ORIGINAL PAPER Eur Food Res Technol Evaluation of the oxidative stability of bakery productsby OXITEST method and sensory analysis Marisa Carmela Carusol·Fernanda Galgano·Maria Antonietta Colangelol· Nicola Condellil·Teresa Scarpal·Roberta Tolvel·Fabio Favati Abstract The lipid oxidation is considered the main causeof the deterioration of the food products with a high fatcontent. Lipid oxidation is associated with the formation ofoff-odor and off-flavor that compromise the acceptability ofthe products; moreover, this reaction affects the nutritionalquality of foods, in particular the fatty acids content. Inthis work the stability of bakery products with a high fatcontent was monitored over a 12 months of storage, con-sidering the lipid oxidation as the limiting factor for theshelf-life products. For this study the OXITEST has beenused as innovative and promising instrument. The OXIT-EST reactor was used to monitor the oxidative stability offour different types of bakery products. The stability of theproducts was also monitored with the sensory and chemi-cal analyses in order to support the instrumental analysis.The sensory analysis was useful to evaluate the perceptiblechanges occurring on the products during storage. Moreo-ver, with the OXITEST an accelerated shelf-life test to pre-dict the shelf life of each product has been performed. Byphysical-chemical data obtained during experimentation itwas found that the products have a different stability to theoxidation reaction, depending on the type of fats used andon the composition of the products. The data obtained fromthe OXITEST were correlated with the sensory data. Fur-thermore,the OXITEST instrument can be utilized as rapid 区 Fernanda Galganofernanda.galgano@unibas.it School of Agricultural, Forestry, Food and EnvironmentalSciences, University of Basilicata, Viale dell'Ateneo Lucano10,85100 Potenza, Italy 2 Department of Biotechnology, University of Verona, StradaLe Grazie 15, 37134 Verona, Italy method for oxidative stability studies; anyway, a furtherresearch will be needed to confirm these results. Keywords Bakery products· Shelf life · Sensory analysisOXITEST·Oxidative stability Introduction The modern food industry tends to satisfy the needs ofconsumers who demand products of high quality also fora long time period. The maintenance of high levels of sen-sory quality associated with the freshness of the producthas also been recommended [1]. For semi-perishable prod-ucts the evaluation of the sensory characteristics is essentialfor monitoring the evolution of the parameters which influ-ence the acceptability; in fact, the sensory characteristics offoods (excluding wine and cheese) change negatively dur-ing storage, causing variations of the product and formation of unwanted aromatic compounds. The use of a panelof tasters is useful to define the shelf life of semi-perishablefoods, but represents an expensive solution for the industry,in terms of both time and money [1]. Regardless of the typeof product analyzed, the shelf life is defined as the periodof time during which slight changes occur in the productwithout compromising the safety and acceptability. Theshelf life of food is influenced by many factors, intrinsicor extrinsic to the product [2]. Among the intrinsic factorsthere are: levels of water activity (aw), pH and total acidity,redox potential, nutrients, endogenous microflora, the pres-ence of substances with antimicrobial action, type of rawmaterials and the formulation of the product. In addition tothese factors, extrinsic factors can trigger and/or acceleratethe reactions of degradation of the food. Among the extrin-sic factors there are: time-temperature combination of treatments during the production process, moisture (RH%)and temperature of the environments of production, storageand distribution, microbiological pollution occurred in oneor more stages of production, type of packaging, handlingby the consumer [3]. Consequently, the shelf life of a prod-uct is the result of a synergistic effect between intrinsic andextrinsic factors which must be taken into account [2]. Bak-ery products belong to the class of semi-perishable prod-ucts. The term"bakery products”is referred to a wide rangeof products used in most countries of the world, includingbread, biscuits, cakes, pies, breadsticks, crackers. The flour,obtained from the Triticum aestivum ssp vulgare L.,is themain ingredient of bakery products. Bakery products con-tain also fat ingredients, often in significant amount. Theaddition of fats in bakery products influences the softness,the flavor, the texture and the alveolation of the product [4].The bakery products undergo phenomena of deteriorationduring their shelf life, and precisely [5]: 1physical deterioration (moisture loss, staling)23 chemical changes (rancidity) microbiological deterioration (growth of yeasts, moldsor bacteria) One of the most serious problems affecting the bakerygoods is the staling. The staling is defined as the processof deterioration, which occurs in bread or other products,during the post baking, negatively affecting the sensorycharacteristics of the product. Literature information indi-cates that properties and molecular modifications of starchare mainly responsible for the development of firmnessand the perception of staling [3]. However, staling evolu-tion is also affected by other factors, such as migration ofmoisture, temperature, gluten and supplemental ingredients[6]. The staling occurs primarily in all bakery goods withhigh humidity (breads and pastries). Also microbiologicaldeterioration is typical of high aw products, while the driedones are not affected by this problem. The products with lower humidity and with a high fatcontent, such as cookies, crackers and breadsticks, are par-ticularly susceptible to lipid oxidation. For these productslipid oxidation is considered the main cause of deterioration[7]. The consequence of lipid oxidation is the formation ofoff-odor and off-flavor that compromise the acceptabilityand also affects the nutritional quality of the products. Infact, one of the main effects of lipid oxidation is the reduc-tion in the content in essential fatty acids. Furthermore, onanimals a toxic effect of primary and secondary products ofoxidation has been observed [8]. Traditional methods detected the oxidation stability offoods by evaluating the quantity of primary and secondaryproducts of oxidation. Accelerated methods are new ana-lytical techniques based on the application of an oxidative stress by increasing one or more oxidative factors. Amongthese latter, OXITEST is an innovative instrument used foroxidative stability studies of fat foods based on the moni-toring of pressure over a period of time in analytical cham-bers where the sample was submitted at high O2 pressureand high temperature. Because the OXITEST is a recentinstrument, at the moment there are still few studies aboutits use [9-12]. In particular, to our knowledge, the literaturefocused on the use of this instrument for analyzing pro-cessed foods, such as bakery products, is scarce [13]. The purpose of this work was to carry out a study of sta-bility of bakery products with a high fat content, consid-ering the lipid oxidation reaction as the limiting factor fortheir shelf life. The evolution of the products was followedby determining chemical parameters notoriously associatedwith fat quality (acidity, peroxides value, p-anisidine value,ultraviolet spectrophotometric analysis). The OXITESTreactor was used to monitor the oxidative stability of fourdifferent types of bakery products. Furthermore, OXITESTinstrument test for accelerated oxidation stability has beenperformed to predict the shelf life of each product, both onraw materials and on finished products, without the needfor any preliminary fat separation. To support the chemi-cal data, sensory analysis of bakery products by a panelof trained judges during 12 months of storage was alsoconducted. Materials and methods Sampling The analyses were conducted on four types of baked prod-ucts, three salty and one sweet, having activity water rang.ing from 0.112 to 0.198, and with a different fat content.The two different fats used for their preparation (palm oiland olive oil) were also analyzed. The samples were packedin small bag by using a OPP-metallized laminated film andprovided by an industry of the district Lucano-Pugliese(Matera, South of Italy). In Table1 is illustrated the com-position of the analyzed products. Chemical analyses The products were analyzed at regular intervals of time,corresponding to the day of production and after 4, 8 and12 months and indicated, respectively, as To, T, T2, T3.During the storage period the bakery products have beenmaintained in the original package in a cool and dry place,at a temperature of 20-25C. Raw materials (olive andpalm oil) from same lot used in bakery production and thefat extracted from the products at each time of analysiswere stored in refrigerator at 14 °C. The fat was extracted Table 1 Composition of the samples Product Ingredients Crackers with olives Wheat flour, palm oil, olive oil, sea salt, yeast. Total fat 15.6%, saturated fat 5.9% Taralli with hot chili pepper r Wheat flour, palm oil, olive oil, sea salt, hot chili pepper, ammonium bicarbonate. Total fat 24.6%, saturated fat 11.9% Breadsticks with olive oil Wheat flour, olive oil,sea salt, yeast. Total fat 13.3%, saturated fat 3.33% Biscuits with lemon Wheat flour, sugar, palm oil, eggs, leavening agents: ammonium bicarbonate, sodium bicarbonate, natural aromas, emulsifier: soy lecithin. Total fat 16.5%, saturated fat 8.2% with Soxhlet method by using petroleum ether as solvent.On the lipid fraction a spectrophotometric analysis in theultraviolet (▲K) was performed [14]; free acidity [15]; per-oxide value (PV) [15]; p-anisidine value (p-AnV), accord-ing to the AOCS Official Method Cd 18-90 [16]. The levelof total oxidation of bakery products and raw materials wasexpressed as TOTOX value (TOTOX=2PV+p-AnV). Allthe analyses were made in triplicate. All the chemical rea-gents were purchased from Sigma-Aldrich (Milan, Italy). Measure of the oxidative stability by OXITEST method The analysis with OXITEST (VELP,Usmate, MB, Italy)was performed on raw materials (olive and palm oil, 10 g)and on bakery products (30 g of grounded product). Theproducts were ground and analyzed by OXITEST foroxidative stability. Each accelerated oxidation test wasrepeated using two different reactors, for a total of fouranalytical replies (each reactor is fitted with two separateoxidation chambers), under over-pressure of pure oxy-gen (0.6 MPa, degree 5.0) and constant high temperature(90 C). The OXITEST response is the induction period(IP), expressed as “stability time”before fat oxidation andcorresponding to a drop of O2 pressure due to the consump-tion of oxygen by the sample. The IP value is automati-cally calculated from oxidation curve by graphical method(two tangent methods) by using the OXISoftTM programincluded in the instrument. In addition, an accelerated shelf-life test for bakeryproducts has been performed at three different temperatures(80, 90 and 100°℃ or 90, 100 and 110C) and the datawere analyzed using the OXISoftTM program. With thisprocedure it is possible to extrapolate and estimate the oxi-dation stability of samples at room temperature, in case oflinear dependence with the temperature. Sensory analysis The sensory evaluation has been conducted on the bakeryproducts. It was used a panel of eight judges (six femalesand two males), aged between 24 and 38 years, recruited inthe University of Basilicata. The judges have been trained to recognize different intensities of 13 sensory attributes(AROMA: oxidized aroma, cardboard aroma; TASTE:sweet, salty, sour, bitter; FLAVOR: oxidized flavor, card-board flavor; TEXTURE: hardness, crispness, friability;TACTILE SENSATIONS: feeling fat palate, feeling drypalate), obtained from the bibliography [17-21]. Moreover,to help judges to recognize the attributes of interest werecreated appropriate reference standards. In particular, asa standard for the crispness were used chips, crackers forfriability, shortbread biscuits for hardness. Wet cardboardhas been used as a standard for the cardboard aroma. Thestandard for oxidized aroma and flavor was obtained bybrushing the cookies with a mixture of olive and palm oilpreviously oxidized with OXITEST (T 90℃, oxygen pres-sure 6 bar) diluted with fresh oil. All the analyses weremade in triplicate and repeated at each time (T,Ti, T2, Ts). Data analysis In order to evaluate the significance of differences betweenthe storage time and the samples, least significance differ-ence (LSD) test was conducted. The analysis of variance(ANOVA) was also performed. Sensory data were acquiredand processed with FIZZ software (ver. 2.47, Biosystemes,Couternon, France). Results and discussion Chemical analyses The measurements made immediately after productionand packaging of the samples allowed to describe the bak-ery products in the initial phase of the trial, highlightingthe differences in terms of physicochemical and sensoryparameters. Peroxide value of the fats extracted was in therange 2.33-27.42 meq O/kg (Table 2). The highest valuewas observed for the fat extracted from the crackers witholives, while the lowest one for cookies with lemon. Per-oxide value of the raw materials was of 6.14 meq O,/kgfor olive oil, whereas a lower value, equal to 0.94 meq O/kg, was observed for palm oil,notoriously more stable to Table 2 Range values of analytical parameters throughout the storage time (12 months) Chemical parameters Crackers with olives p Taralli with hot chili p Breadsticks with olive p Biscuits with lemon p pepper oil Acidity (%) 0.34-0.36 NS 0.12-0.23 *** 0.36-0.39 NS 0.23-0.30 NS Peroxide value (PV) 9.62-27.42 ** 4.16-16.23 ** 8.14-22.63 ** 2.33-12.59 ** (meqO/kg) p-Anisidine value 5.22-6.11 * 6.83-10.97 ** 5.89-9.64 * 7.03-11.82 * (p-AnV) AK 0.15-0.19 NS 0.13-0.15 NS 0.13-0.16 NS 0.19-0.19 NS Induction period (IP) 1171.00-610.50 ** 2444.50-2210.50 NS 2210.50-971.00 * 8664.50-8318.50 * (min) *p<0.05; **p<0.01;***p<0.001 Fig.1 TOTOX of bakery prod-ucts immediately after produc-tion (To) and raw materials pepper lipid oxidation. Figure 1 shows the TOTOX value of the fatextracted from the bakery products and raw materials at Totime. From TOTOX data it was clear that the biscuits withlemon and taralli with hot chili pepper were characterizedby a lowest level of oxidation. These differences among theproducts are attributable not only to the type of fat used, butalso to the presence of ingredients which may have playeda role in inhibiting or promote the reaction of lipid oxida-tion. For example, the biscuits with lemon contain onlypalm oil, known to be more stable than other fats in oxida-tion reactions [22]. In addition, the sample contains lemon;scientific studies showed that the lemon has an antioxidantactivity, protecting the lipids during reactions of oxidationand influencing the formation of primary compounds, suchas peroxides [23,24]. Consequently, it can be assumed thatin this sample the synergistic effect of the type of fat andantioxidant activity exerted by lemon contributed to pro-tect the product from the oxidation. Also taralli with hotchili pepper stood out for a high oxidation stability, espe-cially for a low peroxides value. The sample in this case contains both olive oil and palm oil, and in addition, itcontains hot chili pepper. The hot chili pepper may haveplayed an important role in preventing the formation ofperoxides. This statement seems confirmed by the resultsobtained from Bignardi et al. [25]; Gouveia et al. [26], whoreported the antioxidant power of different species of chilipeppers of the genus Capsicum (annum and frutescens)added to edible oils. Moreover, these authors reported thatthe chili pepper acts as scavenger of peroxides. In addition,the study of Si et al. [27] recognized in the capsaicin themolecule responsible of the antioxidant power of hot chilipepper. Cavazza et al. [28] reported that red chili pepperis an excellent source of bioactive compounds useful forprotecting olive oil from spoilage, improving the oxidativestability during the oil storage. All samples were also ana-lyzed by OXITEST instrument. At the first time the bakery products showed IP values very high for all samples. Irparticular, IP values confirmed a greater oxidation stabilityof lemon biscuits and taralli with hot chili pepper (Fig. 2).These values seem to confirm the initial chemical data. Evolution of chemical parameters The evolution of the physical-chemical and sensory param-eters of the products was followed for 12 months by per-forming the analysis to four times (To, T, T2 and T). Theresults are summarized in Table 2. As regards taralli withhot chili pepper it should be said that in the analysis phase,in particular during the titration to measure the number ofperoxides, some problems have been observed in determin-ing the change of color. The fat extracted from the sam-ple was intensely colored red-orange, probably due to thepresence of hot chili pepper. The main difficulty was to getthe colorless, as required by the procedure of the titration.It was assumed that during the fat extraction it has beenextracted also coloring substances (probably carotenoidscontent in hot chili pepper) that made it difficult to identifythe end point of the titration. Instead for p-anisidine valueis believed that the intense staining of the sample, and par-ticularly the presence of carotenoids, has interfered withthe spectrophotometric analysis. In fact, Shahidi et al. [29]reported that p-anisidine test is based on a reaction betweenthe aldehydes and p-anisidine that leads to the formationof compounds of yellow color absorbing at 350 nm. In thecase of taralli with hot chili pepper, the intense staining ofthe sample may have masked the yellow compounds, dis-torting the final result. However, the data of acidity, AK andIP (Table 2), showed that the sample had a good stability tooxidation. Moreover, the data of sensory analysis helped todescribe the evolution of the sample. Furthermore, it was observed that the evolution of the parameters was differentfor each product. Mora et al. [30] found1 agood correlation levelbetween the IP value and peroxides value of a soybeanoil (R²=0.98); conversely, in this work no correlationbetween these indices was found. Evolution of the sensory parameters Although the chemical analyses were useful to describethe evolution of a food product during storage time, onlyby sensory analysis it is possible to determine whether aproduct continues to have the approval of the consumer.The analysis of variance on sensory data showed a signifi-cant effect of time on the sample “crackers with olives”for many of the attributes. The only attribute for whichwe observed no significant change is the “acid"attribute(p>0.05). In particular, as reported in Fig. 3, the attrib-utes oxidized flavor and aroma, cardboard aroma and flavorwere perceived with an increasing intensity over time. Theanalysis of the sensory parameters associated with the lipidoxidation (oxidation aroma and flavor, cardboard aromaand flavor) showed that the judges already after 4 monthsperceived significant changes of the product, which becamemore evident after 12 months of storage. In addition, thedeterioration of the product is also evidenced by a loss ofcrispness and friability. For this sample it was observeda correlation between the oxidized flavor and p-AnVrecorded at different times (R²=0.517) and between the ***p<0.001 ***p<0.001 oxidized aroma and the p-AnV(R²=0.814). In fact, thesecondary products detected with p-anisidine test are thesame products responsible for sensory characteristics thatassume an oxidized product (rancid odor and taste). The analysis of variance of sensory data of taralli withhot chili pepper showed a significant change of all attrib-utes, excluding the attributes of sweetness and oxidizedflavor. As also reported in Fig.4 it was observed that asthe judges of the panel have not perceived any change inthe oxidized flavor they perceived a growing intensity ofcardboard aroma and flavor. After 8 months (T) the judgesperceived a lower hardness, crunchiness and crispness ofthe sample, probably caused by progressive aging of theproduct. For this sample it was found a positive correlationbetween the oxidized flavor and IP values (R²=0.50), alsobetween the oxidized aroma and the IP index (R²=0.97).Consequently, both the physicochemical and sensory dataconfirm of a good stability of the product to oxidationreaction. For most of the attributes analyzed for the bread-sticks with olive oil, the analysis of variance showed nosignificant change of the attributes (Fig. 5). However, significant changes occurred for the attributes cardboardaroma (p= 0.0005), sweetness (p =0.0139), cardboardflavor(p=0.0002), hardness (p = 0.0001), crispness(p= 0.0010) and friability (p=0.0001). The judges whoperformed the sensory analysis have perceived high levelsof cardboard flavor and aroma after just 4 months. In thefollowing months the intensity of the attributes increasedbut with a smaller gap than that observed between To andT. It was found a positive correlation between the card-board flavor and IP (R’=0.57); furthermore, also a corre-lation between the oxidized flavor and the values of p-ani-sidine was found (R²=0.53) and between the oxidizedaroma and IP (R²=0.65). For the biscuits with lemon, the time has not had a sig-nificant effect on 6 of the 13 parameters considered, specifi-cally nonsignificant changes were observed for the oxidizedaroma and cardboard aroma, for attributes acid and bitter,for the cardboard flavor and the crispness. The parameter“oxidized flavor”varied significantly during storage time(p<0.001), and the more evident variation was observedafter 8 months (time T3) (Fig. 6). For this sample a posi-tive correlation between the oxidized flavor and p-anisidine (R²=0.82) was observed. Anyway, the maximum oxidizedflavor intensity at the end of storage was lower than thatperceived for the crackers with olives. Furthermore, thejudges perceived with less intensity the crispness attribute,friability and hardness, which are affected by aging of theproduct and by moisture absorption phenomena. Althoughthe panel perceived a significant change in the flavor of oxi-dized, it was possible to note that there were no significantchanges in oxidized aroma. Furthermore, for this sampleit was noted that the IP values confirmed a good stabilityof the biscuit. However, the judges perceived significantlythe oxidation evolution. This highlighted the inability ofmachines to capture some aspects of the oxidation reaction,which would be perceived by humans. Accelerated shelf-life test An accelerated shelf-life test was conducted with theOXITEST, considering the lipids oxidation reaction as the reaction limiting the shelf life of the products. The testwas conducted at elevated temperatures and pressures ofO. Three runs of analysis were made for each sample atthree different temperatures, ranging from 80 to 110 ℃ andat pressure of 6 bar. In particular, the test was performedat 80, 90 and 100 °C, except for biscuits with lemon, forwhich 90, 100 and 110 C were selected. In fact, for thislatter sample, the IP previously evaluated at 90°C (Table 2)was very high and the temperature of 80C would haverequired a very long time of analysis. The shelf life reported on the packing of each samplewas about 12 months; therefore, the results obtained withthe OXITEST were compared with that indicated on thepack. In Table 3 are reported in detail the temperatures usedand the results obtained. It was noted that for the samplebiscuits with lemon was estimated a shelf life longer thanthat indicated by the manufacturer. For taralli and bread-sticks was calculated a shelf life that is closer, than theother samples, to what indicated by the manufacturer. On Table 3 Results of accelerated shelf-life test conducted with OXITEST Samples Temperature (C) Estimated shelf life at 20 °C Estimated shelf (months) life at 25°C Biscuits with lemon 90 100 110 22 16 Taralli with hot chili pepper 80 90 100 16 11 Breadsticks with olive oil 80 90 100 15 10 Crackers with olives 80 90 100 5 3 the contrary, for the sample crackers with olives a reducedshelf-life was estimated, compared with the shelf-life indi-cated on the pack. Conclusions The studied bakery products showed a different stabil-ity to oxidation reaction (IP value), depending on the typeof the fat used and on the product composition.“Biscuitswith lemon” were characterized by an initial highest IPvalue with respect to all the other samples. Repeating every4 months the analysis by OXITEST, all the products showeda decrease in the IP value, but at different degree. In particu-lar, for“crackers with olives"and“breadsticks with oliveoil” after 12 months the IP decrease was of about 50%,whereas for “taralli with hot chili pepper"and for “biscuitswith lemon"the IP decrease was more reduced. The higheroxidative stability of these latter could be attributed to theingredients used in the product formulation. For the crackerswith olives it was observed a fast and important deteriorationfrom chemical and sensory point of view, particularly after4 months of storage. This has been confirmed by shelf-lifetest performed with OXISoft program. So, considering theshelf-life test results, the products had an increasing stabil-ity in the following order: crackers with olives, breadstickswith olive oil, taralli with hot chili pepper and biscuits withlemon. Furthermore, the sensory analysis confirmed the dataobtained with the chemical and physical analyses, perceivingthe judges higher oxidation levels in the crackers with olives,followed by breadsticks, taralli and biscuits with lemon. Inparticular, the attributes that have obtained a higher scorewere the oxidized aroma and flavor and the cardboard aromaand flavor. Therefore, this study highlighted that the OXIT-EST instrument could be useful in the food industry in orderto determine the shelf life of bakery foods. However, in orderto confirm the obtained data, it would be desirable to test thisinstrument with other bakery products. Acknowledgements The authors would like to express apprecia-tion to Laurieri s.r.l. industry for supplying the samples. The authorswould also like to thank VELP Scientifica (Usmate, MB, Italy) forlending the OXITEST instrument and Dr. Stefania Corti for the tech-nical assistance. Compliance with ethics requirements This article does not containany studies with human or animal subjects. References ( 1. C alligaris S, Pieve SD, Kravina G, M anzocco L , N i coli C M (2008) Shelf l i fe prediction of bread sticks using oxidation indi-ces: a validation study. J Food Sci 73:51-56 ) ( 2. . K ilcast D , Subramaniam P ( 2 000) The stab i lity and shelf-life of food. Woodhead Publishing, Cambridge ) ( 3. Smith JO, D aifas D P, E l-Khoury W, K o ukoutsis J, E l-Khoury A (2004) S helf life and safet y concern s bakery products-a review.Crit Rev Food Sci Nutr 44:19-55 ) ( 4.Rios RV, Pessanha MDF, Almeida P F , Viana CL, L a nnes S C (2014) A pplications of fats in some foods p roducts. Food S ciTechnol34:3-15 ) ( 5. L egan JD, Voysey PA (1 9 91) Yeast sp o ilage of bakery pr o ductsand ingredients. JAppl Bacteriol 70:361-371 ) ( 6. Hebeda RE, Zobel HF ( 1 996) Baked g o ods f r eshness. MarcelDekker Inc, New York ) ( 7 . Kulp K ( 1 979) S t aling of bread. Am Inst B ak Tech Bull 1:1 ) ( 8. Wasowicz E, Gramza A, Heoe M, Jelen H H, Korczak J, Malecka M, Mildner-Szkudlarz S, R udzinska M , S a motyja U, Za w irska-Wojtasiak R (2004) Oxidation of lipids in food. Pol J Food NutrSci 13:87-100 ) ( 9. Amato M, Caruso M C, Guzzo F , Galgano F , Commisso M , Bochicchio R , L a bella R, Favati F (2 0 15) Nutritional quality of seeds and l eaf m etabolites o f C hia (Salvia hispanica L.) from Southern I taly . Eur Food Res Technol 241:615-625 ) ( 10.(Comandini P , Verardo V, Maiocchi P , Caboni MF (2009) Accel- erated oxidation: c omparative study of a new reactor with oxida- tion stabilit y instrumen t . Eur J Lipid Sc i 111:933-940 ) ( 11 . V erardo V, R iciputi Y, Trivisonn o MC, Marconi E, Caboni MF ( 2010) E f fect of the addition of air-classified ba r ley flours on the lip i dstability of bakery product s . E u r Food Res Technol 231:309-319 ) ( 12 . V erardo V , R iciputi Y , S orrenti G , O rnaghi P , M a rangoni B,Caboni M F (2 0 13) Effect of nitrogen fertilisation rates o n the content o f f atty acids, sterols , tocopherols and phenolic com- pounds, a nd on the oxidative stability of walnut s . LWT Food SciTechnol 50:732-738 ) ( 13. M1aruyama SA, Cla u s T, Chi a velli LUR, Bert o zzi J, Pil a u EJ, deSouza NE, V isentainer JV , Gomes STM, Matsushita M (2014)Analysis of carotenoids, a - tocopherol, sterols and phenolic co m -pounds from white bread enriched wi t h Ch i a (Salvia hi s panicaL.) seeds and c arrot (Daucus c a rota L.) l e aves. J B raz Chem Soc25:1108-1115 ) 14.Commission EU (2013) Commission implementing Regulation(EU) No 299/2013 amending Regulation (EEC) No 2568/91 onthe characteristics of olive oil and olive-residue oil and on therelevant methods of analysis. OffJEur Union L90/52 15.Commission EU (1991) Commission Regulation (EEC) No2568/91 on the characteristics of olive oil and olive-residue oiland on the relevant methods of analysis. Off J Eur CommunL248/1 32 16.AOCS (2009) Official methods and recommended practicesof the American Oil Chemists’ Society, 6th edn. AOCS Press,Champaign, IL, Method Cd 18-90 17.Grosso NR, Resurreccion AVA, Walker GM, Chinnan MS (2008)Sensory profiles and hexanal content of cracker-coated androasted peanuts stored under different temperatures. J Food Pro-cess Preserv 32:1-23 186..Laguna L, Varela P, Salvador A, Fiszman S (2013) A new sen-sory tool to analyse the oral trajectory of biscuits with differentfat and fibre contents. Food Res Int 5:544-553 19.LIillford PJ (2011) The importance of food of microstruc-ture in fracture physics and texture perception. J Texture Stud42:130-136 20.Paula AM, Conti-Silva AC (2014) Texture profile and correlationbetween sensory and instrumental analyses on extruded snacks.JFood Eng 121:9-14 21.T7arancon P, Fiszman SM, Salvador A, Tarrega A (2013) For-mulating biscuits with healthier fats. Consumer profiling of tex-tural and flavor sensations during consumption. Food Res Int53:134-140 22..Farhoosh R, Kenari RE, Poorazrang H (2009) Frying stability ofcanola oil blended with palm olein, olive, and corn oils. JAOCS86:71-76 23.Abdalla AE, Roozen JP (1999) Effect of plant extracts on theoxidative stability of sunflower oil and emulsion. Food Chem64:323-329 24. ]Murcia MA, Jimenez AM, Martinez-Tome M (2001) Evalu-ation of the antioxidant properties of Mediterranean and tropi-cal fruits compared with common food additives. J Food Prot12:1891-2110 25.1Bignardi C, Cavazza A, Corradini C, Corti S, Lantano C (2013)Evaluation of the effect of red chili addition to food productson their shelf life. XXIV Congresso della Divisione di ChimicaAnalitica, Sestri Levante (GE), 15-19 Settembre 2013 26.(Gouveia AF, Duarte C. Beirao da Costa ML, Bernardo-Gil MG,Moldao-Martins M (2006) Oxidative stability of olive oil fla-vored by Capsicum frutescens supercritical fluid extracts. Eur JLipid Sci Technol 108:421-428 27.Si W, Liang Y,Ma KY, Chung HY, Chen Z (2012) Antioxi-dant activity of capsaicinoid in canola oil. J Agric Food Chem60:6230-6234 28..Cavazza A, Corti S, Mancinelli C, Bignardi C, Corradini C(2015) Effect of the addition of chili pepper powder on vegetableoils oxidative stability. J Am Oil Chem Soc 92:1593-1599 29.Shahidi F, Wanasundara UN (2002) In: Akoh CC, Min DB (eds)Food lipids: chemistry, nutrition and biotechnology. Marcel Dek-ker Inc, New York, pp 465-487 30.Mora L, Limbo S, Maiocchi P (2011) Application of the OXIT-EST method to estimate the kinetic parameters in soybean oilunder accelerated storage conditions. Ital J Food Sci 23:72-77 SpringerPublished online: December Springer 本文主要利用Oxitest方法对烘焙类食品的氧化稳定性,配方和货架期进行研究。本研究的样本为4种类型不同成分类型的烘焙类食品。随着生产后的时间推移,四类样本的氧化稳定性和其他多种物理化学性状之间的关系。四类烘焙类食品通过Oxitest方法计算出的保质期和包装上注明的保质期进行比较分析。

确定

还剩7页未读,是否继续阅读?

意大利VELP公司为您提供《烘焙类食品中油脂氧化,保质期,配方,货架期检测方案(氧化分析仪)》,该方案主要用于糕点/月饼/粽子中理化分析检测,参考标准--,《烘焙类食品中油脂氧化,保质期,配方,货架期检测方案(氧化分析仪)》用到的仪器有VELP Oxitest 油脂氧化分析仪

推荐专场

相关方案

更多

该厂商其他方案

更多