方案详情

文

利用德国LaVision公司的ParticleMaster-Shadow阴影法粒径测量分析系统,对细水雾的喷雾特性进行了实验测量和分析。

方案详情

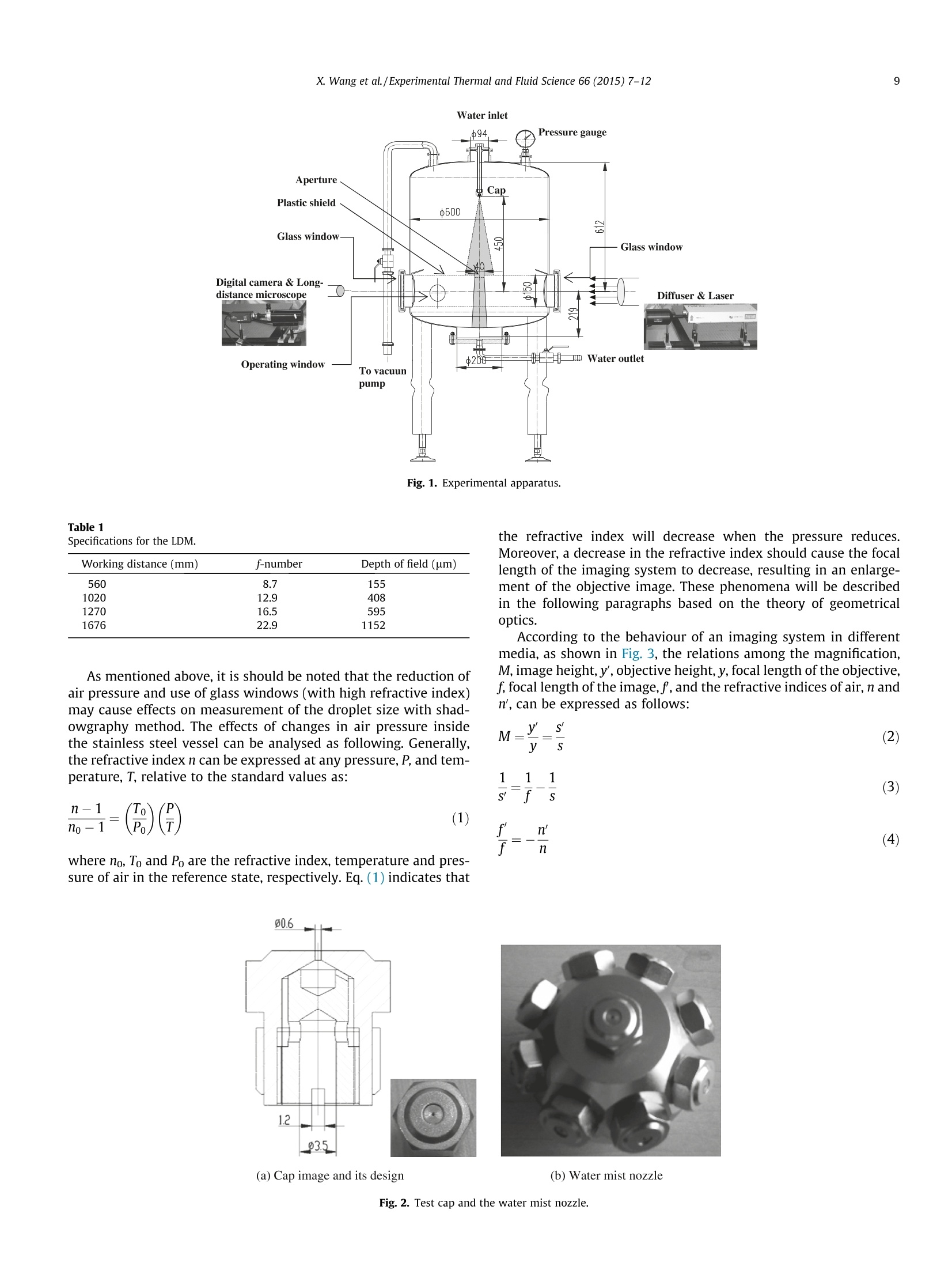

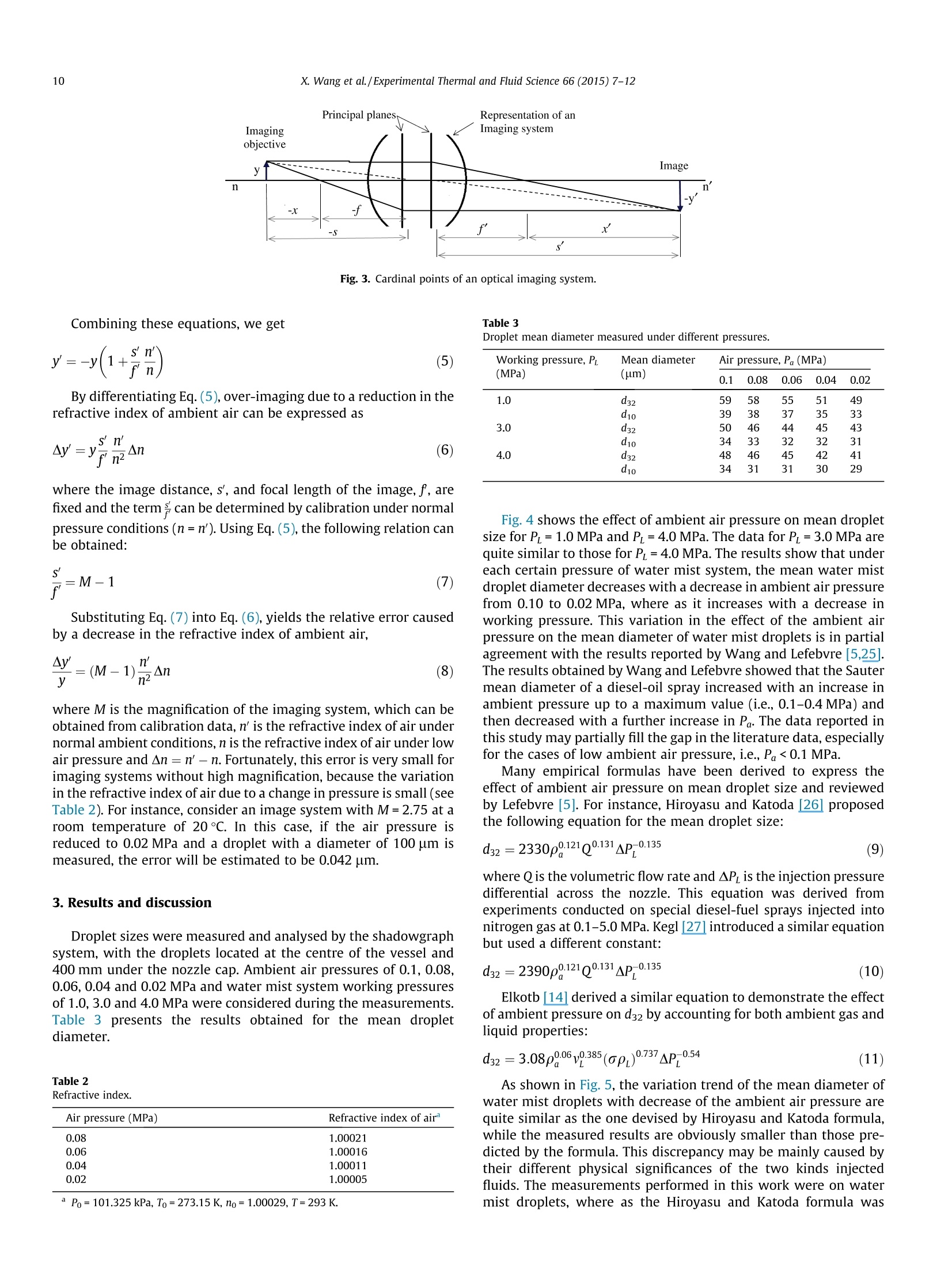

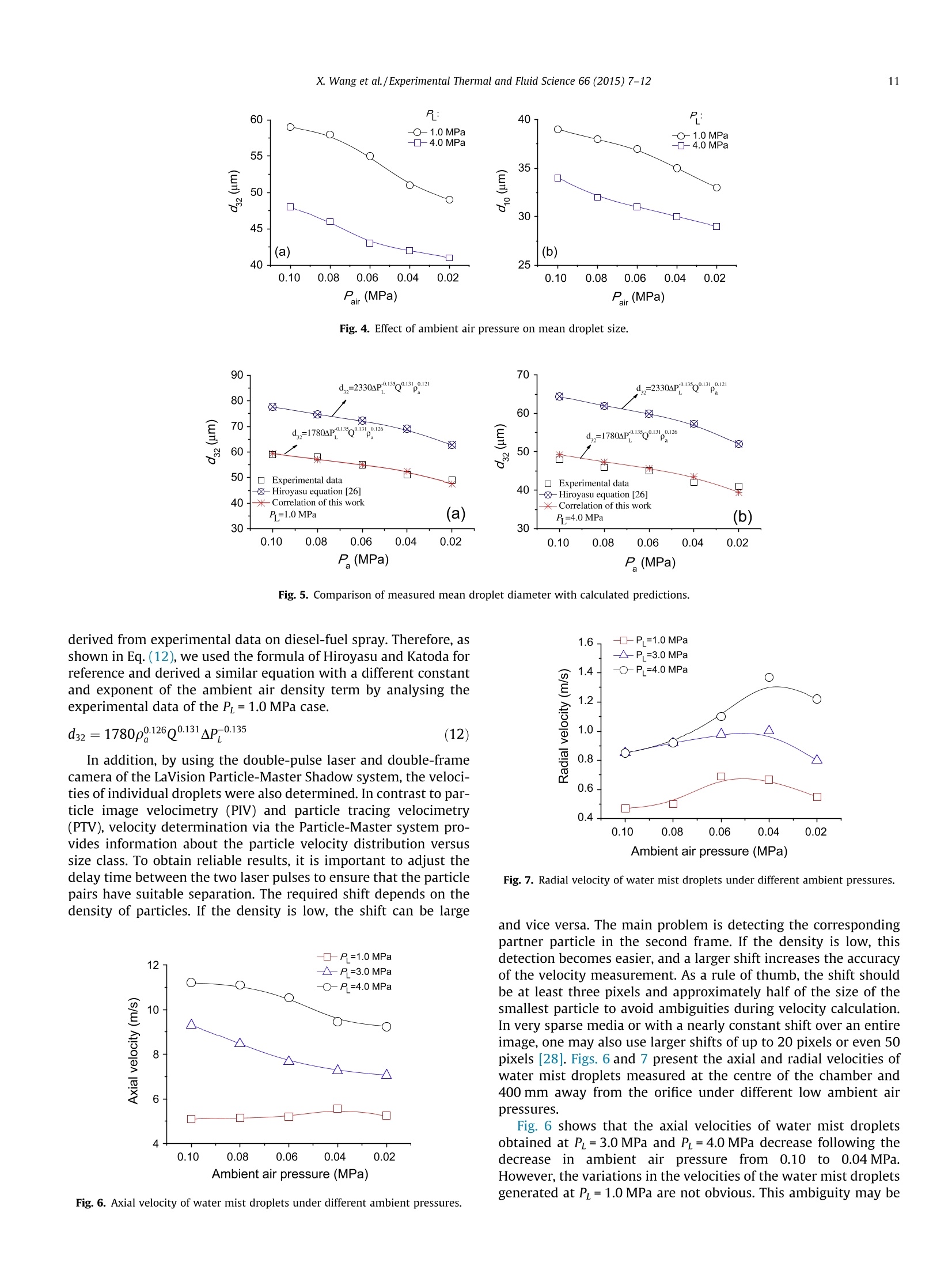

Experimental Thermal and Fluid Science 66 (2015)7-12 Contents lists available at ScienceDirect Experimental Thermal and Fluid Sciencejournalhomepage:www.elsevier.com/locate/etfs Effect of low ambient air pressure on spray characteristics of water mist CrossMark (ishi Wang a.b.*, Pei Zhu, Yuan Li, Xiaomin Ni, Minghao Fan State Key Lab. of Fire Science, University of Science 8 Technology of China, Hefei 230026, China "Collaborative Innovation Center for Urban Public Safety, Anhui Province, Hefei 230026, China Anhui Province Key Laboratory of Electric Fire and Safety Protection, Hefei 230022, China ARTICLEIN F O ABSTRACT Article history:Received 10 May 2014Received in revised form 14 March 2015Accepted 17 March 2015 Available online 26 March 2015 To investigate the effect of low ambient air pressure on the characteristics of water mist which wasinjected into a low pressure (<0.1 MPa) environment, the sizes and velocities of the water droplets weremeasured using Shadowgraph technique. A stainless steel vessel with a diameter of 600 mm and heightof 800 mm was designed for simulating low ambient air pressure conditions using a vacuum pump.Ambient air pressures of 0.1, 0.08, 0.06, 0.04, 0.02 MPa, and working pressures of the water mist systemof 1.0, 3.0, 4.0 MPa were considered. The results show that, under each certain pressure of water mist sys-Keywords: tem, both of the Sauter mean diameSter (d32) and thepray characteristic arithmetic mean diameter (d1o) of water mist dro-Spauter mean diameterlets decrease with decrease of the ambient air pressure from 0.10 to 0.02 MPa. An empirical formula hasAmbient air pressurebeen developed to express the influence of ambient air pressure on Sauter mean diameter of water mist.ShadowgraphyIn addition, the axial velocities of water mist droplets generated with working pressure of 3.0 MPa andWater mist 4.0 MPa decrease following a decrease in ambient air pressure, while there is no obvious variation tothe tested results of the cases with 1.0 MPa working pressure. 2015 Elsevier Inc. All rights reserved. 1. Introduction The transformation of bulk liquid into sprays and other physicaldispersions of small droplets in a gaseous atmosphere is importantin several industrial processes and has many practical applicationsin the spray combustion of liquid fuels and fire suppression withwater mist/spray, etc. Studies of the effect of ambient pressure or temperature on fuelspray combustion have received much attention in past years[1-7]. However, most of the studies focused on the effects of highambient air pressures (>0.1 MPa). For instance, Hiroyasu et al. [8]studied the effects of high ambient pressure (3.0 MPa) and jetvelocity on the breakup of high-velocity water jets under condi-tions similar to those encountered in diesel engines. Similar testsusing diesel-type nozzles with water as the test fluid were alsoconducted by Arai et al. [9]. These studies reported that an increasein ambient pressure causes the breakup length to diminish andindicated that ambient pressures in the range of 0.1-3 MPa havea strong effect on breakup length and spray angle of the high speedjet. DeCorso [10] was among the first to investigate the effect ofambient air pressure on the spray characteristics of simplex swirl ( * C orresponding author at: State Key Lab. of Fire Science, Un i versity of Science & T echnology of China, Hefei 2 30026, China. Tel.: +86 5 51 63606437; fax: +86 551 63601669. ) ( E -mail a ddress: w xs@ustc.ed u .cn ( X . Wang). ) atomisers. That measured an increase in drop size when the ambi-ent pressure was increased from 0.1 to 0.79 MPa and attributedthis increase in drop size to increased coalescence of the spraydrops as the ambient pressure increased. Lee and Reitz [11] inves-tigated the effects of gas density and velocity on the breakupmechanisms of liquid drops injected into a transverse high-velocitygas flow at four spray chamber pressures (1, 3.7, 6.4 and 9.2 atm).Over a pressure range of 0.1-0.5 MPa, a marked rise in the Sautermean diameter (d32) was observed with an increase in ambientair pressure (Pa) (d32 oP27). For a given nozzle, known as thepressure-swirl atomizers, many equations have been proposedfor d32 via correlation of available experimental data where bothambient air and liquid properties were taken account [12-141. Nomenclature focal length of the objective (m) s' image distance (m) focal length of the image (m) T air temperature (K) ma mass of air (kg) To air temperature in the reference state (K) M magnification of the imaging system y objective height (m) n refractive index of air y' image height (m) na the amount of substance of air p density (kg/m) no refractive index of air in the reference state V kinematic viscosity (m/s) n' refractive index of air on the image side surface tension (kg/s-) P pressure (Pa) Po air pressure in the reference state (Pa) Subscripts AP injection pressure differential across the nozzle (Pa) a air Q volumetric flow rate (m’/s) L liquid R the ideal gas constant(mPa mol-1K-1) S objective distance (m) 0.1 MPa. But the properties of water are different from those of fueland the ambient pressure of water mist applications is mostlylower than the spray combustion field. So the study on the effectof low ambient air pressure on water mist droplet size and velocityis still essential. The object of this paper is to investigate the effect of low ambi-ent pressure on water mist characteristics, so the droplet sizes andvelocities of water mist ejected into the environment at ambientpressures of 0.1, 0.08, 0.06, 0.04 and 0.02 MPa were measuredand analysed. The results should be helpful for optimising thewater mist fire suppression systems and valuable for consideringthe effect of low ambient air pressure on spray combustion in somehigh-altitude areas, known as Tibet of China, where the ambient airpressures of many areas are lower than 0.06 MPa. 2. Experimental description 2.1. Experimental apparatus As shown in Fig. 1, the experimental apparatus includes threeparts: a stainless steel vessel, a LaVision Particle-Master Shadowsystem and a water mist system. A KAWAKE JP-140V vacuumpump was connected to the vessel for generating low air pressureinside the vessel. Two glass windows with 150 mm diameter werealigned approximately 612 mm under the nozzle cap for conveni-ent of using shadowgraph technology. Only one cap (with one ori-fice and 30° cone angle) of the water mist nozzle was placed at thecentre of the vessel top to avoid wall effect and dense spraysbecause the dimensions of the vessel are not large enough to con-sider a practical used water mist nozzle. In fact, even under generalpressure conditions, water mist nozzle is usually characterizedwith one of its caps as described in some standard codes, such asGBT 26785-2011 of China, to avoid over-attenuation of light bydense spray. In addition, a barrel like plastic shield was lied flatbetween the two glass windows to reduce the droplets numberalong the laser light, and at its top centre (just under the nozzlecap), opened a square aperture with 40 mm side. Thus only someof the droplets which were ejected inside the shield through theaperture could be measured. The imaging sample area was about5 mm×5 mm. Nominally, about 5-30 droplets were collectedand analysed, the cases with less than 5 droplets were neglected. The LaVision Particle-Master Shadow system features a double-pulsed 532 nm Nd-YAG laser, a programmable timing unit (PTU), aLaVision diffuser with a 120 mm output aperture, a mirror-basedlong distance microscope (LDM) that has 560 mm to 1520 mmworking range and 70 mm back focal length, a CMOS camera and a LaVision computer with DaVis 8.0 software. The laser pulseenergy was adjusted to 100 mJ (maximum is 200 mJ) to avoid dam-age to the CMOS camera by incidence of high optical density. Thepulse width (5-10ns) and the interval between pulses were pro-grammed by the DaVis software according to the desired applica-tion. A LaVision diffuser was used for strobe backgroundillumination for shadowgraph imaging. Table 1 presents informa-tion regarding the fnumbers and the field of view (FOV) of the sys-tem for a chosen working distance. A self-contained water mist system was used to generate waterdroplets. Only one cap of a nine-cap water mist nozzle was used forexperimental tests to avoid wall effects and dense sprays. Fig. 2presents an image of the cap and the nozzle. The diameter of thecap orifice and its K-factor were 0.6 mm and 0.12L/min/MPa05,respectively. The droplets were imaged at the centre of the vesseland approximately 400 mm away from the cap orifice. 2.2. Experimental methodology Water mist droplet sizes and velocities were measured usingshadowgraphy technique. This technique is based on high-res-olution imaging with pulsed backlight illumination. The techniqueis independent of the shape and opacity of the particles and allowsfor the investigation of particles as small as 5 um using an appro-priate imaging system and light illuminating source. The details ofthe basic principles of shadowgraphy can be seen elsewhere [21-24]. A double-pulse laser combined with a double-frame camerawere used by LaVision Particle-Master Shadow system, whichallows the system to evaluate the velocities of individual particles. Since the calibration and focus adjustment are difficult to per-form after the air pressure inside the vessel was previouslypumped to a low level (less than 0.1 MPa), so the Particle-MasterShadow system was calibrated and focused prior to data collectionunder normal ambient air pressure conditions. The calibrationplate was put inside the vessel and adjusted for well calibratingthrough an operating window which was sealed after the calibra-tion, while the two glass windows were well assembled duringthe calibrating, because the droplet image size should be reduceddue to its large refractive index of 1.57 if they were not consideredin calibration. Measurements at normal air pressure of 0.1 MPawere performed immediately following the calibration, thenconducted other tests by reducing the air pressure inside thevessel and adjusting the working pressure of the water mistsystem, respectively. In each test, an average value of the dropletsize and velocity wasdetermined basedon at 1least threemeasurements. Fig. 1. Experimental apparatus. Specifications for the LDM. Working distance (mm) f-number Depth of field (um) 560 8.7 155 1020 12.9 408 1270 16.5 595 1676 22.9 1152 As mentioned above, it is should be noted that the reduction ofair pressure and use of glass windows (with high refractive index)may cause effects on measurement of the droplet size with shad-owgraphy method. The effects of changes in air pressure insidethe stainless steel vessel can be analysed as following. Generally,the refractive index n can be expressed at any pressure, P, and tem-perature, T, relative to the standard values as: where no, To and Po are the refractive index, temperature and pres-sure of air in the reference state, respectively. Eq.(1) indicates that (a) Cap image and its design the refractive index will decrease when the pressure reduces.Moreover, a decrease in the refractive index should cause the focallength of the imaging system to decrease, resulting in an enlarge-ment of the objective image. These phenomena will be describedin the following paragraphs based on the theory of geometricaloptics. According to the behaviour of an imaging system in differentmedia, as shown in Fig. 3, the relations among the magnification,M, image height,y', objective height, y, focal length of the objective,f, focal length of the image,f, and the refractive indices of air, n andn', can be expressed as follows: Fig. 3. Cardinal points of an optical imaging system. Combining these equations, we get By differentiating Eq.(5), over-imaging due to a reduction in therefractive index of ambient air can be expressed as where the image distance,s', and focal length of the image, j, arefixed and the term,can be determined by calibration under normalpressure conditions (n=n'). Using Eq. (5), the following relation canbe obtained: Substituting Eq.(7) into Eq. (6), yields the relative error causedby a decrease in the refractive index of ambient air, where M is the magnification of the imaging system, which can beobtained from calibration data, n’ is the refractive index of air undernormal ambient conditions, n is therefractive index of air under lowair pressure and An = n’-n. Fortunately, this error is very small forimaging systems without high magnification, because the variationin the refractive index of air due to a change in pressure is small (seeTable 2). For instance, consider an image system with M=2.75 at aroom temperature of 20℃. In this case, if the air pressure isreduced to 0.02 MPa and a droplet with a diameter of 100 um ismeasured, the error will be estimated to be 0.042 um. 3. Results and discussion Droplet sizes were measured and analysed by the shadowgraphsystem, with the droplets located at the centre of the vessel and400 mm under the nozzle cap. Ambient air pressures of 0.1, 0.08,0.06, 0.04 and 0.02 MPa and water mist system working pressuresof 1.0, 3.0 and 4.0 MPa were considered during the measurements.Table 3 presents the results obtained for the mean dropletdiameter. Table 2Refractive index. Air pressure (MPa) Refractive index of air 0.08 1.00021 0.06 1.00016 0.04 1.00011 0.02 1.00005 Po=101.325kPa, To=273.15 K, no=1.00029,T=293 K. Table 3Droplet mean diameter measured under different pressures. Working pressure, P Mean diameter Air pressure, Pa (MPa) (MPa) (um) 0.1 0.08 0.06 0.04 0.02 1.0 3.0 4.0 Fig. 4 shows the effect of ambient air pressure on mean dropletsize for PL=1.0 MPa and PL=4.0 MPa. The data for PL=3.0 MPa arequite similar to those for PL=4.0 MPa. The results show that undereach certain pressure of water mist system, the mean water mistdroplet diameter decreases with a decrease in ambient air pressurefrom 0.10 to 0.02 MPa, where as it increases with a decrease inworking pressure. This variation in the effect of the ambient airpressure on the mean diameter of water mist droplets is in partialagreement with the results reported by Wang and Lefebvre [5,25].The results obtained by Wang and Lefebvre showed that the Sautermean diameter of a diesel-oil spray increased with an increase inambient pressure up to a maximum value (i.e., 0.1-0.4MPa) andthen decreased with a further increase in Pa. The data reported inthis study may partially fill the gap in the literature data, especiallyfor the cases of low ambient air pressure, i.e.,Pa<0.1 MPa. Many empirical formulas have been derived to express theeffect of ambient air pressure on mean droplet size and reviewedby Lefebvre [5]. For instance, Hiroyasu and Katoda [26] proposedthe following equation for the mean droplet size: where Q is the volumetric flow rate andAP is the injection pressuredifferential across the nozzle. This equation was derived fromexperiments conducted on special diesel-fuel sprays injected intonitrogen gas at 0.1-5.0 MPa. Kegl[27]introduced a similar equationbut used a different constant: Elkotb [14]derived a similar equation to demonstrate the effectof ambient pressure on d32 by accounting for both ambient gas andliquid properties: As shown in Fig. 5, the variation trend of the mean diameter ofwater mist droplets with decrease of the ambient air pressure arequite similar as the one devised by Hiroyasu and Katoda formula,while the measured results are obviously smaller than those pre-dicted by the formula. This discrepancy may be mainly caused bytheir different physical significances of the two kinds injectedfluids. The measurements performed in this work were on watermist droplets, where as the Hiroyasu and Katoda formula was Fig. 4. Effect of ambient air pressure on mean droplet size. derived from experimental data on diesel-fuel spray. Therefore, asshown in Eq.(12), we used the formula of Hiroyasu and Katoda forreference and derived a similar equation with a different constantand exponent of the ambient air density term by analysing theexperimental data of the PL=1.0 MPa case. In addition, by using the double-pulse laser and double-framecamera of the LaVision Particle-Master Shadow system, the veloci-ties of individual droplets were also determined. In contrast to par-ticle image velocimetry (PIV) and particle tracing velocimetry(PTV), velocity determination via the Particle-Master system pro-vides information about the particle velocity distribution versussize class. To obtain reliable results, it is important to adjust thedelay time between the two laser pulses to ensure that the particlepairs have suitable separation. The required shift depends on thedensity of particles. If the density is low, the shift can be large Fig. 6. Axial velocity of water mist droplets under different ambient pressures. Fig.7. Radial velocity of water mist droplets under different ambient pressures. and vice versa. The main problem is detecting the correspondingpartner particle in the second frame. If the density is low, thisdetection becomes easier, and a larger shift increases the accuracyof the velocity measurement. As a rule of thumb,the shift shouldbe at least three pixels and approximately half of the size of thesmallest particle to avoid ambiguities during velocity calculation.In very sparse media or with a nearly constant shift over an entireimage, one may also use larger shifts of up to 20 pixels or even 50pixels [28]. Figs. 6 and 7 present the axial and radial velocities ofwater mist droplets measured at the centre of the chamber and400 mm away from the orifice under different low ambient airpressures. Fig. 6 shows that the axial velocities of water mist dropletsobtained at Pz=3.0MPa and P=4.0 MPa decrease following thedecrease in1 ambient air pressure from 0.10 to 0.04 MPa.However, the variations in the velocities of the water mist dropletsgenerated at PL=1.0 MPa are not obvious. This ambiguity may be attributed to the fact that higher working pressures lead to the pro-duction of finer droplets that can easily disperse radially due toflow field fluctuations. As shown in Fig.7, it can be observed thatthe radial velocity of the water mist droplets increases up to amaximum value with a decrease in ambient pressure and thendecreases with a further decrease in ambient air pressure. Whenthe ambient air pressure is reduced to 0.02 MPa, the radial veloci-ties of the water mist droplets decrease in all of the test cases.Fig.7 also shows that the radial velocity of the water mist dropletsincreases with a decrease in ambient pressure up to a maximumvalue and then decreases with a further decrease in ambient airpressure. The maximum value occurs slightlyearlier atPL=1.0 MPa than at the other two working pressures. From the results as shown in Figs. 6 and 7, it can be inferred thatunder each certain pressure of water mist system, the axial pene-tration of water mist droplets decreases with a decrease in ambientair pressure. A study on how to quantitatively determine theeffects of low ambient pressure on water mist penetration willbe conducted in the near future. 4. Conclusions The sizes and velocities of water mist droplets ejected into alow-pressure (<0.1MPa) environment were measured usingShadowgraphy technology. Ambient air pressures of 0.1, 0.08,0.06,0.04 and 0.02 MPa and water mist system working pressuresof 1.0, 3.0 and 4.0 MPa were tested. The following conclusions canbe drawn from the experimental results. (1) Under each certainpressure of water mist system, both of the Sauter mean diameterand the arithmetic mean diameter of water mist droplets decreasewith decrease of ambient air pressure from 0.10 to 0.02 MPa. (2)An empirical formula was derived to express the effects of ambientair pressure on the Sauter mean diameter of water mist dropletswith d32 x P0.126.(3)The axial velocities of water mist droplets gen-erated with working pressure of 3.0 MPa and 4.0 MPa decrease fol-lowing a decrease in ambient air pressure, while there is noobvious variation to the tested results of the cases with 1.0 MPaworking pressure. Acknowledgements The authors appreciate the support of the Natural ScienceFoundation of China (Grant No. 51323010), the Anhui ProvincialNatural Science Foundation (Grant No. 1408085MKL95) and theFundamental Research Funds for the Central Universities. ( References ) [4] S. Kook, L.M. Pickett, Liquid length and vapor penetration of conventional,Fischer-Tropsch,coal-derived, and surrogate fuel sprays at high-temperatureand high-pressure ambient conditions, Fuel 93(2012) 539-548, http://dx.doi.org/10.1016/j.fuel.2011.10.004. [5]A.H. Lefebvre, Atomization and Sprays, Hemisphere, Washington,D.C., 1989. [6]L. Postrioti, F. Mariani, M. Battistoni, Experimental and numerical momentumflux evaluation of high pressure diesel spray, Fuel 98 (2012) 149-163, http://dx.doi.org/10.1016/j.fuel.2012.03.043. [7]:S.H. Park, H.J. Kim, H.K. Suh, C.S. Lee, Experimental and numerical analysis ofspray-atomization characteristics of biodiesel fuel in various fuel and ambienttemperatures conditions, J. Heat Fluid Flow 30 (2009) 960-970, http://dx.doi.org/10.1016/j.ijheat fluidflow.2009.04.003. ( [8] 1 H. Hiroyasu, M . S h imiz u, M. Arai, The breakup of a h i g h s p e ed jet i n a highpressure gaseous a tmosphere, i n : Proc. of t he 2 nd Int. Conference on LiquidAtomization and Spray Sys te ms, Madison, Wi s ., 1982, pp. 6 9-7 4. ) [9]M. Arai, M. Shimizu, H. Hiroyasu, Break-up length and spray angle of highspeed jet, in: Proc. of the 3rd Int. Conference on Liquid Atomization and SpraySystems, London, UK, 1985,1B/4,pp. 1-10. [10]S.M. DeCorso, Effect of ambient and fuel pressure on spray drop size, Trans.ASME J. Eng. Power 82 (1960) 10-18. ( [11] C .H. L ee, R.D. Reitz, An experimental s t udy of the effect o f gas density on thedistortion and breakup m echanism of drops in high speed gas stream, Int. J.Multiphase F low 2 6 (20 0 0)22 9 -244, http: / /dx .do i. o r g /1 0 . 1 016/ S 0 301 - 9322(99)00020-8. ) ( 1121 A. H . Le f ebvre, Gas Turbine Combustion, H emisphere, Washingt o n D. C., 1983. ) ( [13 ] A.R. Jones, Design optimization o f a l arge p ressure-jet atomizer for p ower plant, in: Proc. of th e 2nd Int. Conference on Liquid Atomization and S praySystems, M adison, W is., 1982, pp. 181-185. ) ( [14 ] M.M.Elkotb, Fuel atomization for spray modeling, Prog. Energy Com bust. Sci.8(1982)61-91, h ttp://dx.doi.org / 10.1016/0360-1285(82)90009-0 . ) ( [15] P.E . Santangelo, C haracterization o f h igh-pressure wa ter-mist s pr ays: experimental a n alysis o f droplet size and dispersion, Exp. Thermal Flu i d Sci . 34 (2010) 1353-1366. h tt p : //d x. d oi.o rg/ 1 0.10 1 6 /j.expthermflusci.2010.0 6 . 008 . ) ( [16] Meenakshi Gupta, Amit Pasi, Anjan Ray, Kale S R, An exp eri m e ntal study o f th eeffe cts of water m ist chara cte ristic s on pool fi r e suppression , Exp . Thermal Fluid Sci. 44 (2013) 768-778, h ttp: // dx. d o i .or g / 10. 10 1 6 / j.expthermflusci.2012.09 . 020 . ) ( 171 X . Huang, X.S. Wang, G . X. Liao, C haracterization of an effervescent atomizationwater mist nozzle a n d it s fire s up pression tests, Proc. Co mbust . Inst. 33 ( 20 11 ) 2573-2579,ht t p:/ /dx.doi.org/10.1 0 16/j.pr o ci.2010.06.0 0 1. ) [18]B.P. Husted, P. Petersson, I. Lund, G. Holmstedt, Comparison of PIV and PDAdroplet velocity measurement techniques on two high-pressure water mistnozzles, Fire Saf. J.44 (2009)1030-1045, http://dx.doi.org/10.1016/j.firesaf.2009.07.003. ( [19 ] X. Cai,X.S. Wang, T.S. Liang,G.X. Liao, Experimental study on the e ffects of lowambient pressure conditions at h igh alt i tu de on f ire suppression with water mist , J . F Fire Sci. 28 ( 2 010 ) 441-4 5 8. 0 , h t tp: / /dx .d oi . or g /1 0. 1 17 7/ 07349041 1 036131 1 . ) ( [20] C.F. Tao, X. Cai , X. S . Wang, Experimental study o n th e ef f ects of ambientpressure conditions on spray ch a ra cteristics o f water mist, in: Proc.of the nd Int. Conference on Mechanic A utomation and Co n trol En g ineering, InnerMongolia, C h ina, 2011, pp.7363 -7366. ) [21]F.J. Weinberg, The shadowgraph of a flat flame, Proc.R. Soc. Lond.A 235(1956)510-517,http:/dx.doi.org/10.1098/rspa.1956.0101. ( [22] W. Schopf . J .C. P a t terson , A.M.H . Br o ok e r , Evaluati o n o f t h e s hadowgrap h method for the conv e ctive flow in a side-heated ca v ity, E x p. Fluids 21 (1 9 9 6) 331-340. ) ( [23] G .S. Settl e s , S chlie r e n and Shadowgraph T e ch n ique s , S p ringer , Ber l in, 2001, p. 376 . ) [24]M.J. Hargather, G.S. Settles, Retroreflective shadowgraph technique for large-scale flow visualization, Appl. Opt.48 (2009) 4449-4457, http://dx.doi.org/10.1364/AO.48.004449. [25]X.F. Wang, A.H. Lefebvre, Influence of ambient air pressure on pressure-swirlatomization, Atomization Spray Technol.3 (1987)209-226. [26]H. Hiroyasu, T. Katoda, Fuel droplet size distribution in a diesel combustionchamber.SAE Trans., 1974; Paper 74017, http://dx.doi.org/10.4271/740715. [27]Breda Kegl, Injection system design optimization by considering fuel spraycharacteristics, I. Mech. Des. 126 (2004) 703-710, http://dx.doi.org/10.1115/1.1758248. ( [28] 1 P articleMaster Shadow, P roduct-Manual f o r D a Vis 8 . 0, Item-Number(s): 1105032.LaVision G m bH, Gottingen, 26th January, 2011. ) http://dx.doi.org/j.expthermflusci.@Elsevier Inc. All rights reserved. The author has requested enhancement of the downloaded file. All in-text references underlined in blue are linked to publications on ResearchGate. To investigate the effect of low ambient air pressure on the characteristics of water mist which wasinjected into a low pressure (<0.1 MPa) environment, the sizes and velocities of the water droplets weremeasured using Shadowgraph technique. A stainless steel vessel with a diameter of 600 mm and heightof 800 mm was designed for simulating low ambient air pressure conditions using a vacuum pump.Ambient air pressures of 0.1, 0.08, 0.06, 0.04, 0.02 MPa, and working pressures of the water mist systemof 1.0, 3.0, 4.0 MPa were considered. The results show that, under each certain pressure of water mist system,both of the Sauter mean diameter (d32) and the arithmetic mean diameter (d10) of water mist dropletsdecrease with decrease of the ambient air pressure from 0.10 to 0.02 MPa. An empirical formula hasbeen developed to express the influence of ambient air pressure on Sauter mean diameter of water mist.In addition, the axial velocities of water mist droplets generated with working pressure of 3.0 MPa and4.0 MPa decrease following a decrease in ambient air pressure, while there is no obvious variation tothe tested results of the cases with 1.0 MPa working pressure.

确定

还剩4页未读,是否继续阅读?

北京欧兰科技发展有限公司为您提供《细水雾中低周围空气压力对其喷雾特性的影响检测方案(激光粒度仪)》,该方案主要用于其他中低周围空气压力对其喷雾特性的影响检测,参考标准--,《细水雾中低周围空气压力对其喷雾特性的影响检测方案(激光粒度仪)》用到的仪器有LaVision ParticleMaster-Shadow 粒径测量系统、PLIF平面激光诱导荧光火焰燃烧检测系统

推荐专场

相关方案

更多

该厂商其他方案

更多