德国FRITSCH(飞驰)公司的激光粒度仪Analysette 22为干/湿两用,单独的分散单元实现了即插即用。同时,宽的测量范围不仅可以在研磨前准确的检测合金的粒径情况,而且在研磨后,对其颗粒粒径的变化,也能准确的检测出,为后续试验分析提供可靠的实验数据。

方案详情

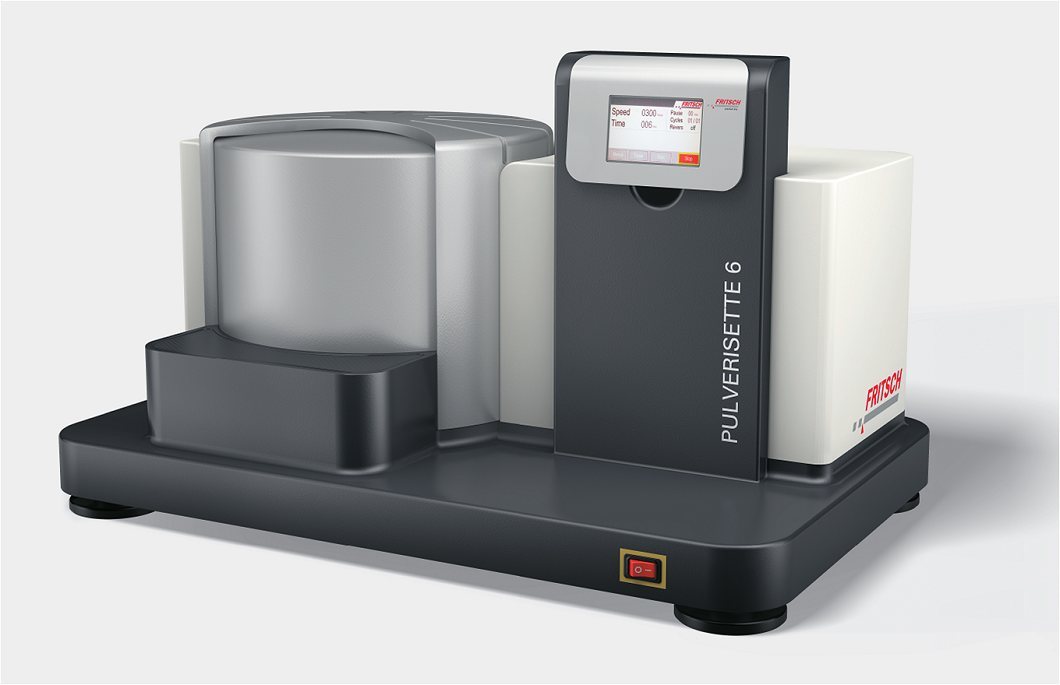

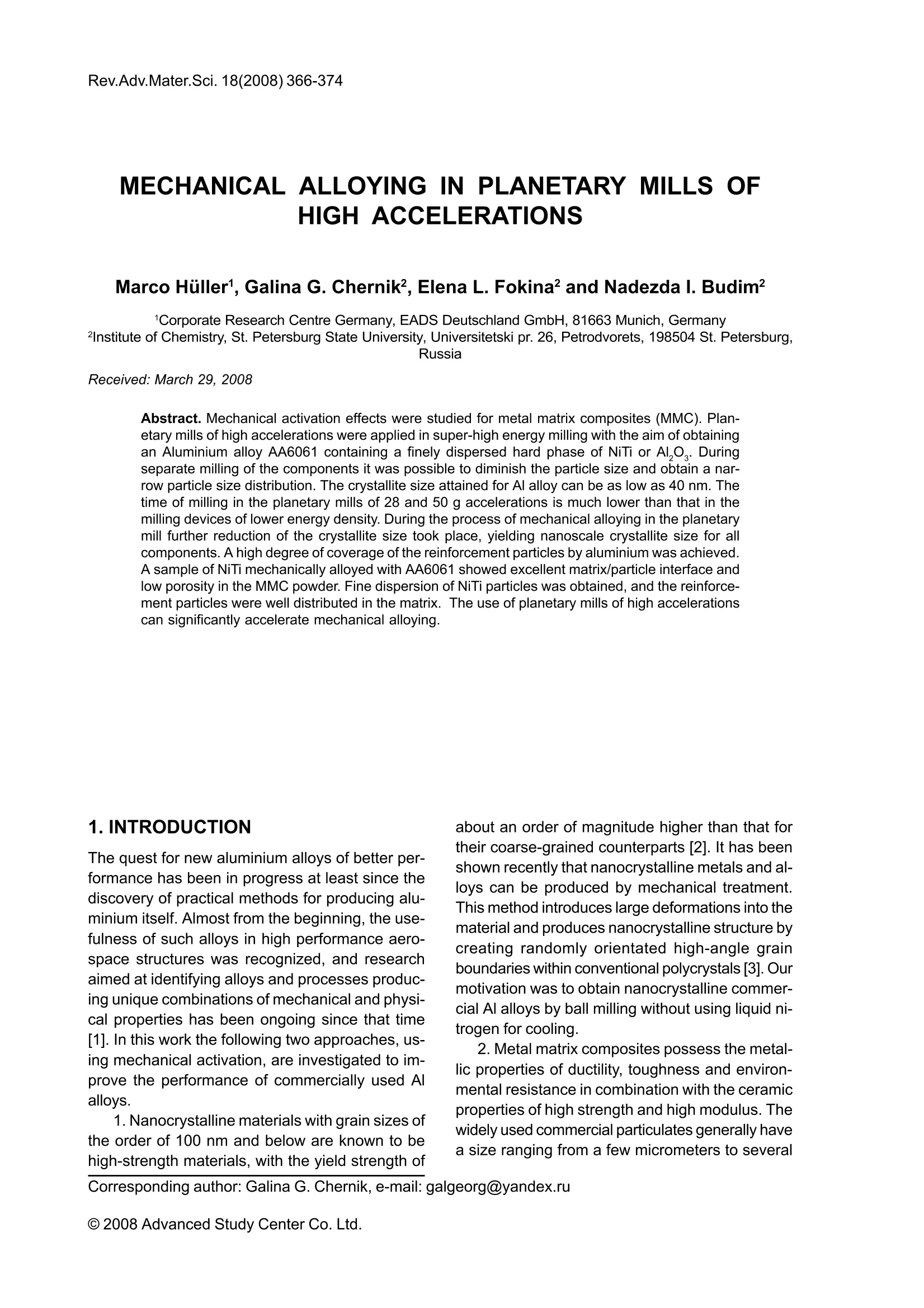

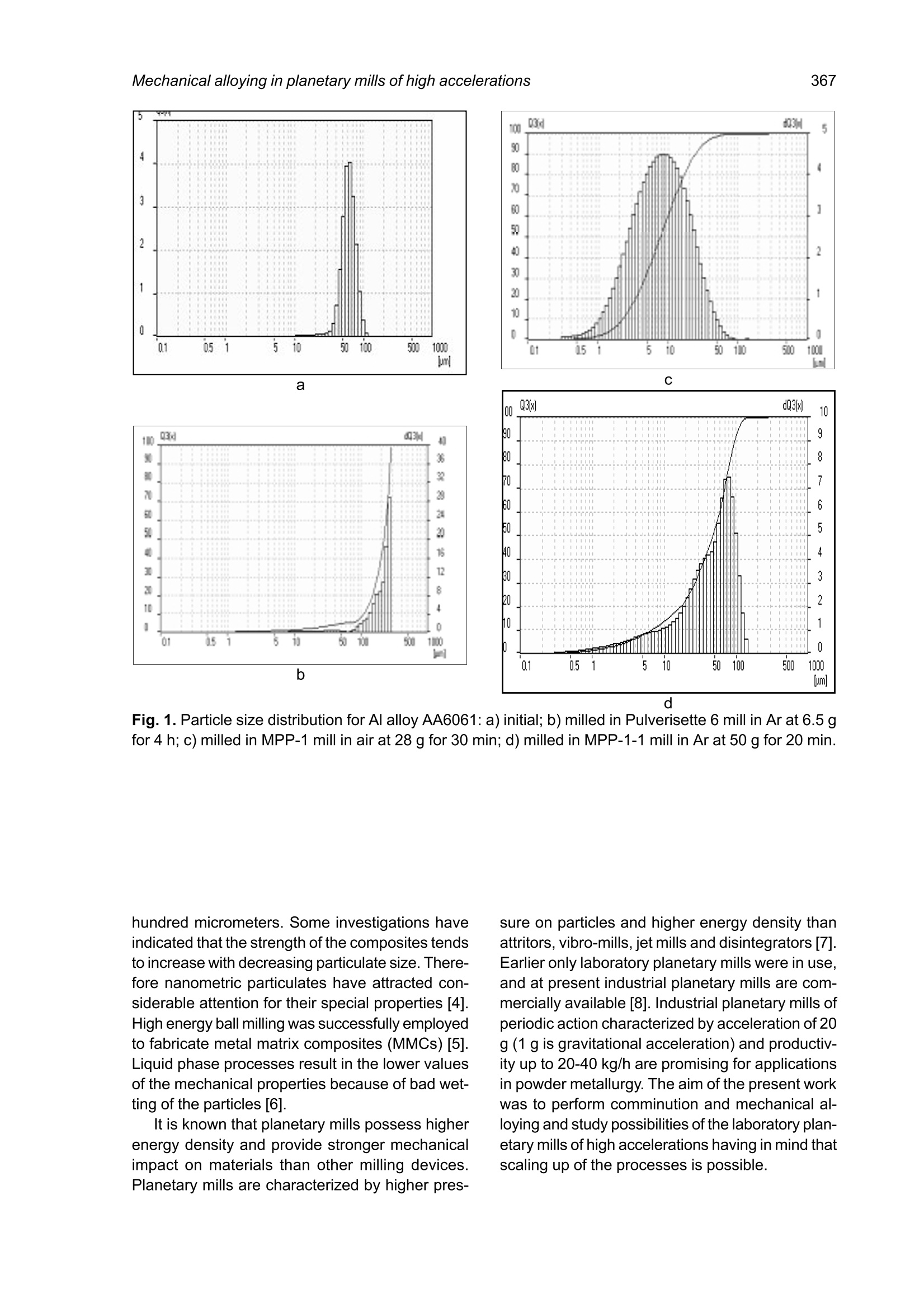

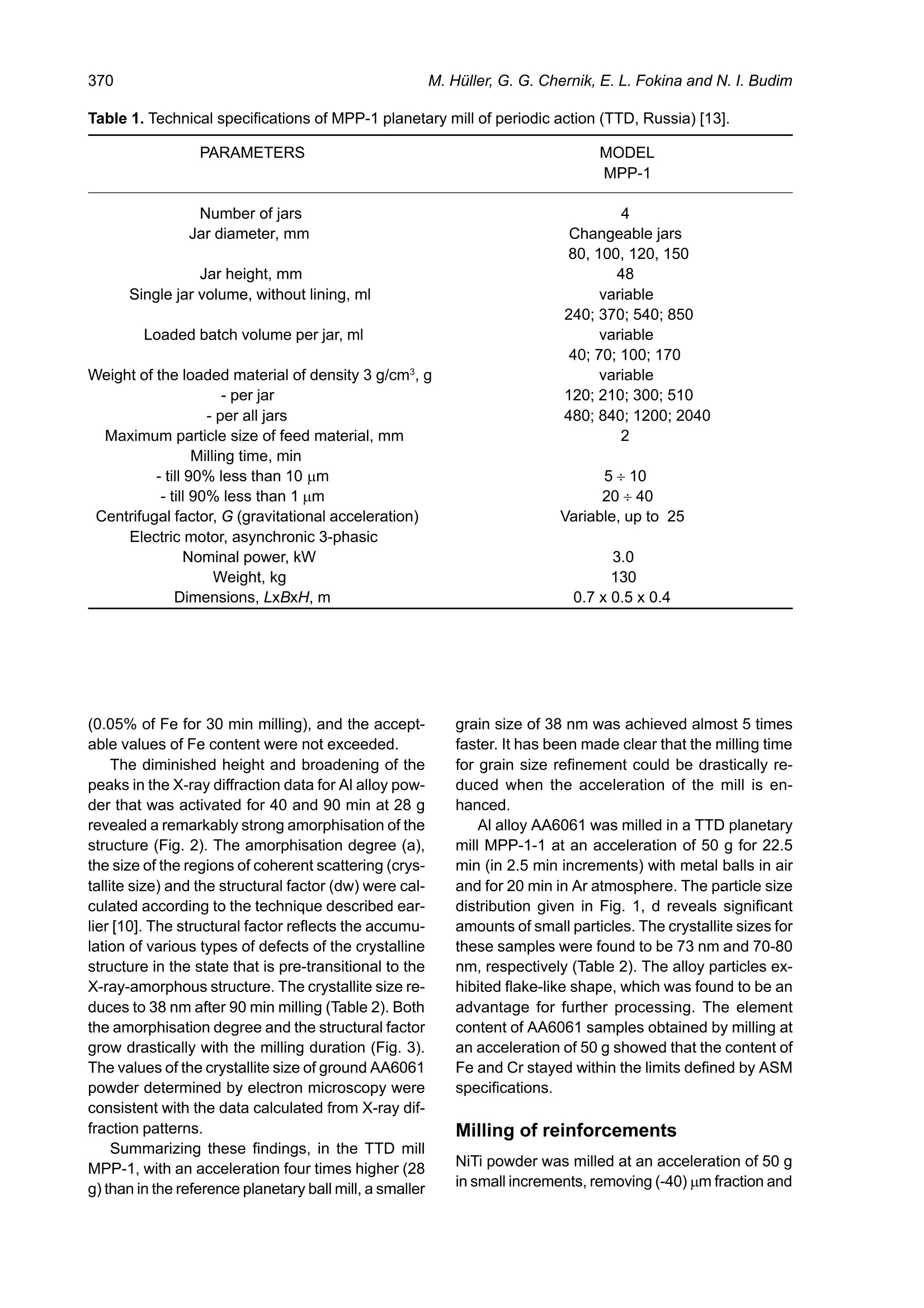

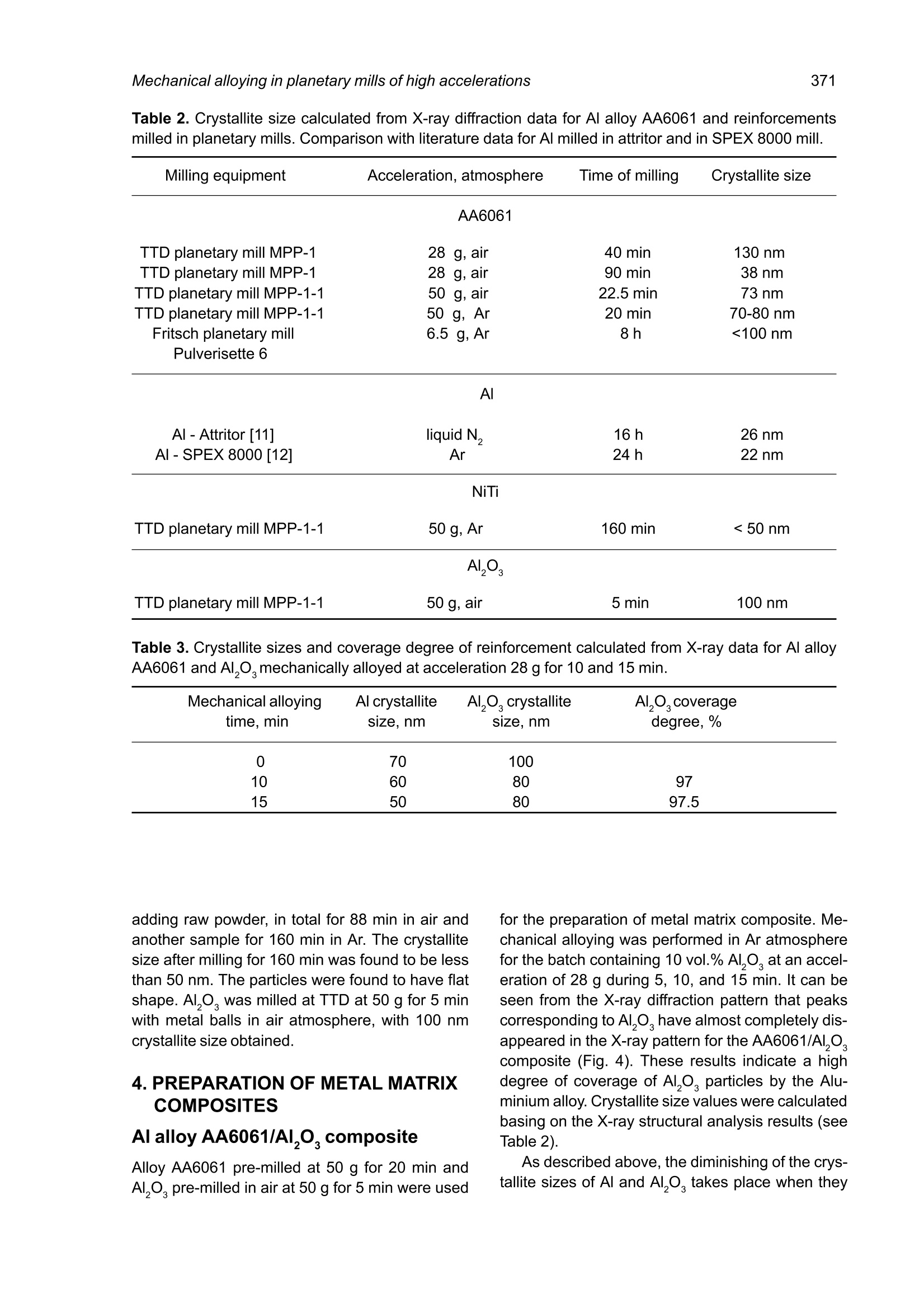

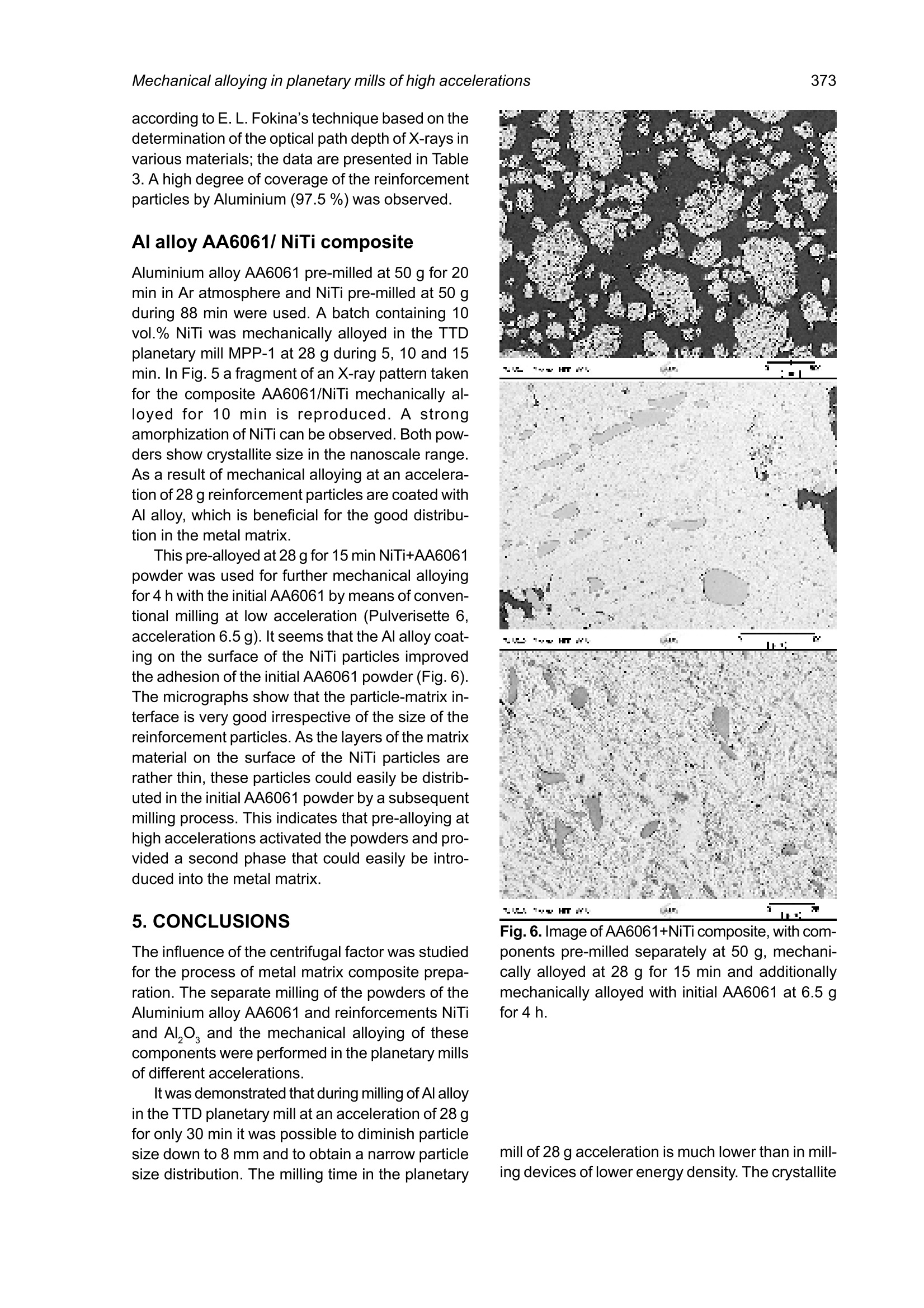

Rev.Adv.Mater.Sci.18(2008)366-374 Mechanical alloying in planetary mills of high accelerationsi367 MECHANICAL ALLOYING IN PLANETARY MILLS OFHIGH ACCELERATIONS Marco Huller, Galina G. Chernik²,Elena L. Fokina² and Nadezda I. Budim² 1Corporate Research Centre Germany, EADS Deutschland GmbH, 81663 Munich, Germany 2Institute of Chemistry, St. Petersburg State University, Universitetski pr. 26, Petrodvorets, 198504 St. Petersburg,Russia Received: March 29, 2008 Abstract. Mechanical activation effects were studied for metal matrix composites (MMC). Plan-etary mills of high accelerations were applied in super-high energy milling with the aim of obtainingan Aluminium alloy AA6061 containing a finely dispersed hard phase of NiTi or Al,O. Duringseparate milling of the components it was possible to diminish the particle size and obtain a nar-row particle size distribution. The crystallite size attained for Al alloy can be as low as 40 nm. Thetime of milling in the planetary mills of 28 and 50 g accelerations is much lower than that in themilling devices of lower energy density. During the process of mechanical alloying in the planetarymill further reduction of the crystallite size took place, yielding nanoscale crystallite size for allcomponents. A high degree of coverage of the reinforcement particles by aluminium was achieved.A sample of NiTi mechanically alloyed with AA6061 showed excellent matrix/particle interface andlow porosity in the MMC powder. Fine dispersion of NiTi particles was obtained, and the reinforce-ment particles were well distributed in the matrix. The use of planetary mills of high accelerationscan significantly accelerate mechanical alloying. 1.INTRODUCTION The quest for new aluminium alloys of better per-formance has been in progress at least since thediscovery of practical methods for producing alu-minium itself. Almost from the beginning, the use-fulness of such alloys in high performance aero-space structures was recognized, and researchaimed at identifying alloys and processes produc-ing unique combinations of mechanical and physi-cal properties has been ongoing since that time[1]. In this work the following two approaches,us-ing mechanical activation, are investigated to im-prove the performance of commercially used Alalloys. 1.Nanocrystalline materials with grain sizes ofthe order of 100 nm and below are known to behigh-strength materials, with the yield strength of about an order of magnitude higher than that fortheir coarse-grained counterparts [2]. It has beenshown recently that nanocrystalline metals and al-loys can be produced by mechanical treatment.This method introduces large deformations into thematerial and produces nanocrystalline structure bycreating randomly orientated high-angle grainboundaries within conventional polycrystals [3]. Ourmotivation was to obtain nanocrystalline commer-cial Al alloys by ball milling without using liquid ni-trogen for cooling. 2. Metal matrix composites possess the metal-lic properties of ductility, toughness and environ-mental resistance in combination with the ceramicproperties of high strength and high modulus. Thewidely used commercial particulates generally havea size ranging from a few micrometers to several ( O 2008 Advanced Study Center Co. Ltd. ) C a b d Fig. 1. Particle size distribution for Al alloy AA6061: a) initial; b) milled in Pulverisette 6 mill in Ar at 6.5 gfor 4 h; c) milled in MPP-1 mill in air at 28 g for 30 min; d) milled in MPP-1-1 mill in Ar at 50 g for 20 min. hundred micrometers. Some investigations haveindicated that the strength of the composites tendsto increase with decreasing particulate size. There-fore nanometric particulates have attracted con-siderable attention for their special properties [4].High energy ball milling was successfully employedto fabricate metal matrix composites (MMCs) [5].Liquid phase processes result in the lower valuesof the mechanical properties because of bad wet-ting of the particles [6]. It is known that planetary mills possess higherenergy density and provide stronger mechanicalimpact on materials than other milling devices.Planetary mills are characterized by higher pres- sure on particles and higher energy density thanattritors, vibro-mills, jet mills and disintegrators [7].Earlier only laboratory planetary mills were in use,and at present industrial planetary mills are com-mercially available [8]. Industrial planetary mills ofperiodic action characterized by acceleration of 20g (1 g is gravitational acceleration) and productiv-ity up to 20-40 kg/h are promising for applicationsin powder metallurgy. The aim of the present workwas to perform comminution and mechanical al-loying and study possibilities of the laboratory plan-etary mills of high accelerations having in mind thatscaling up of the processes is possible. 20, deg 20, deg Fig. 2. Comparison of X-ray diffraction [111] maximum of Al alloy AA6061 samples -powder milled atacceleration 28 g for 90 min (a), powder milled for 40 min (b) and initial powder (c). 2. EXPERIMENTAL Materials Aluminium powder AA6061 was produced byintergas spray-atomization at ECKART-WERKE(Furth, Germany). ASM specifications allow thefollowing content of elements: Al - balance, Mg0.8-1.2%, Si 0.4-0.8%, Cu 0.15-1.4%, Cr 0.04-0.35%,Fe 0.7%. The particle size of the initial pow-der was reported to be 50-100 um. Al,O, micro-powder, particle size 100-400 um, was manufac-tured by Abler (Germany) and NiTi powder wassupplied by NANOVAL (Berlin, Germany), Ni:Tiratio = 50:50, particle size 45-350 mm. Milling conditions Mechanical milling was performed at the Corpo-rate Research Centre of the European AeronauticDefence and Space Company (EADS) in the fol- lowing milling device: planetary ball mill Pulverisette6 (Fritsch, Germany). The vial and the balls (10mm diameter) are made up of hardened steel. Theball-to-powder ratio was 5:1. A rotational speed of250 rpm results in an acceleration of about 6.5 g.Milling with the use of Pulverisette 6 planetary millwas accomplished inside an Ar filled glove box. Toavoid temperatures >60 C the process wasstopped for 45 min after 15 min milling. Milling wasperformed for 1, 4, 8, 16, and 64h. The possibilities of the planetary ball mills [8]produced by Technics and Technology of Disinte-gration Ltd. (TTD, Russia) were investigated. Theplanetary mills of periodic action (MPP) of thismanufacturer are characterized by high accelera-tion of 25 g and higher [9].Laboratory planetarymills MPP-1 (at acceleration 28 g) and MPP-1-1(acceleration 50 g)with steel jars and milling bod-ies were exploited. Milling experiments at high ac-celerations were performed at the TTD company. 100 Time ofmilling, min Fig.3. Dependence of the degree of amorphisation (a) and structural factor (dw) calculated from X-raydata for AA6061 upon time of milling in air at acceleration 28 g. The technical specifications of MPP-1 mill are givenin Table 1. The milling of NiTi was performed at 50g, with removing of the finest fraction and addingof the initial powder after 5 min milling. The totaltime of the milling experiments was 88 min for mill-ing in air and 160 min for milling in jars filled withargon. Al,O, was milled in air at 50 g for 5 min. Methods Scanning electron microscope(SEM) observationswere performed by means of JEOL JSM-6320F.X-ray diffraction analysiswas performed at St.Petersburg State University using DRON 4 M(Burevestnik, Russia) X-ray diffractometer, CuKradiation, Ni filter. Emission spectroscopy analysiswas done by means of a DFS-13 spectrophotom-eter (Russia) in order to estimate the contents ofelements in the subject matter. TEM observationswere carried out with a Philips CM20 microscopeoperated at 200 kV at the University of Erlangen.The determination of the particle size was carriedout by means of laser diffraction using“Analysette22” (Fritsch, Germany). 3. RESULTS AND DISCUSSIONMilling of Al alloy AA6061 Milling of AA6061 in planetary mills of different ac-celerations was undertaken with the aim to dimin-ish the crystallite size. Particle size distribution forthe initial and milled powders is reproduced in Fig.1. Milling at acceleration of 6.5 g induced particlegrowth because of strong cold welding tendencies(Fig.1b). The particle size increased from 50 umto about 1500 um in the milling time of more than 4h. Particles milled for a duration longer than 4 hexhibited an almost spherical morphology. Theaverage crystallite size was found to be less than100 nm. After milling in TTD planetary mill MPP-1 at anacceleration of 28 g the diminishing of the particlesize was achieved. The average particle size dobserved after 30 min milling was 7.5 um. The sizedistribution curve of a sample ground for 30 minwas rather narrow (Fig. 1c). For that sample 10%of the particles had sizes less than 2 um. Contami-nation as a result of grinding was rather small (0.05% of Fe for 30 min milling), and the accept-able values of Fe content were not exceeded. The diminished height and broadening of thepeaks in the X-ray diffraction data for Al alloy pow-der that was activated for 40 and 90 min at 28 qrevealed a remarkably strong amorphisation of thestructure (Fig. 2). The amorphisation degree (a),the size of the regions of coherent scattering (crys-tallite size) and the structural factor (dw) were cal-culated according to the technique described ear-lier [10]. The structural factor reflects the accumu-lation of various types of defects of the crystallinestructure in the state that is pre-transitional to theX-ray-amorphous structure. The crystallite size re-duces to 38 nm after 90 min milling (Table 2). Boththe amorphisation degree and the structural factorgrow drastically with the milling duration (Fig. 3).The values of the crystallite size of ground AA6061powder determined by electron microscopy wereconsistent with the data calculated from X-ray dif-fraction patterns. Summarizing these findings, in the TTD millMPP-1, with an acceleration four times higher (28g) than in the reference planetary ball mill, a smaller Table 1. Technical specifications of MPP-1 planetary mill of periodic action (TTD,Russia)[13]. PARAMETERS MODEL MPP-1 Number of jars 4 Jar diameter, mm Changeable jars 80, 100, 120, 150 Jar height, mm 48 Single jar volume, without lining, ml variable 240; 370;540;850 Loaded batch volume per jar, ml variable 40;70; 100; 170 Weight of the loaded material of density 3 g/cm, g variable -perjar 120;210;300;510 -per all jars 480; 840;1200;2040 Maximum particle size of feed material, mm 2 Milling time, min - till 90% less than 10 pm 510 - till 90% less than 1 um 20:40 Centrifugal factor, G (gravitational acceleration) Variable, up to 25 Electric motor, asynchronic 3-phasic Nominal power, kW 3.0 Weight, kg 130 Dimensions,LxBxH, m 0.7 x0.5 x 0.4 grain size of 38 nm was achieved almost 5 timesfaster. It has been made clear that the milling timefor grain size refinement could be drastically re-duced when the acceleration of the mill is en-hanced. Al alloy AA6061 was milled in a TTD planetarymill MPP-1-1 at an acceleration of 50 g for 22.5min (in 2.5 min increments) with metal balls in airand for 20 min in Ar atmosphere. The particle sizedistribution given in Fig. 1, d reveals significantamounts of small particles. The crystallite sizes forthese samples were found to be 73 nm and 70-80nm, respectively (Table 2). The alloy particles ex-hibited flake-like shape, which was found to be anadvantage for further processing. The elementcontent of AA6061 samples obtained by milling atan acceleration of 50 g showed that the content ofFe and Cr stayed within the limits defined by ASMspecifications. Milling of reinforcements NiTi powder was milled at an acceleration of 50 gin small increments, removing (-40) um fraction and Table 2. Crystallite size calculated from X-ray diffraction data for Al alloy AA6061 and reinforcementsmilled in planetary mills. Comparison with literature data for Al milled in attritor and in SPEX 8000 mill. Milling equipment Acceleration, atmosphere Time of milling Crystallite size AA6061 TTD planetary mill MPP-1 28 g, air 40 min 130 nm TTD planetary mill MPP-1 28 g, air 90 min 38 nm TTD planetary mill MPP-1-1 50 g, air 22.5 min 73 nm TTD planetary mill MPP-1-1 50 g, Ar 20 min 70-80 nm Fritsch planetary mill 6.5 g,Ar 8 h <100 nm Pulverisette 6 AI Al - Attritor [11] liquid N, 16 h 26 nm Al-SPEX 8000 [12] Ar 24 h 22 nm NiTi TTD planetary mill MPP-1-1 50 g,Ar 160 min <50 nm A,0: TTD planetary mill MPP-1-1 50 g, air 5 min 100 nm Table 3. Crystallite sizes and coverage degree of reinforcement calculated from X-ray data for Al alloy AA6061 and Al,O,mechanically alloyed at acceleration 28 g for 10 and 15 min. Mechanical alloying Al crystallite Al,O,crystallite Al,O, coverage time, min size, nm size, nm degree,% 70 100 10 60 80 97 15 50 80 97.5 adding raw powder, in total for 88 min in air andanother sample for 160 min in Ar. The crystallitesize after milling for 160 min was found to be lessthan 50 nm. The particles were found to have flatshape. Al,O, was milled at TTD at 50 g for 5 minwith metal balls in air atmosphere, with 100 nmcrystallite size obtained. 4. PREPARATION OF METAL MATRIXCOMPOSITES Al alloy AA6061/AI,O,composite Alloy AA6061 pre-milled at 50 g for 20 min andAl,, pre-milled in air at 50 g for 5 min were used for the preparation of metal matrix composite. Me-chanical alloying was performed in Ar atmospherefor the batch containing 10 vol.% Al,O, at an accel-eration of 28 g during 5, 10, and 15 min. It can beseen from the X-ray diffraction pattern that peakscorresponding to Al,O, have almost completely dis-appeared in the X-ray pattern for the AA6061/AI,O,composite (Fig. 4). These results indicate a highdegree of coverage of Al particles by the Alu-minium alloy. Crystallite size values were calculatedbasing on the X-ray structural analysis results (seeTable 2) As described above, the diminishing of the crys-tallite sizes of Al and Al,O, takes place when they Fig. 4. X-ray diffraction pattern for Al milled in air at 50 g for 5 min (curve 1) and composite AA6061/AL,O mechanically alloyed in Ar atmosphere at acceleration 28 g for 15 min (curve 2). 2000 Fig. 5. X-ray diffraction pattern for AA6061/NiTi composite (components pre-milled separately at accel-eration 50 g)mechanically alloyed in Ar at acceleration 28 g for 10 min. are milled separately (at 50 g). Furthermore, dur-ing the process of mechanical alloying in the plan-etary mill at an acceleration of 28 g further reduc- tion of crystallite size is going on, as well as theencapsulation of AI,O, particles with Al alloy. Thecoverage degree of Al,O, particles was determined according to E.L. Fokina’s technique based on thedetermination of the optical path depth of X-rays invarious materials; the data are presented in Table3. A high degree of coverage of the reinforcementparticles by Aluminium (97.5%) was observed. Al alloy AA6061/ NiTi composite Aluminium alloy AA6061 pre-milled at 50 g for 20min in Ar atmosphere and NiTi pre-milled at 50 gduring 88 min were used. A batch containing 10vol.% NiTi was mechanically alloyed in the TTDplanetary mill MPP-1 at 28 g during 5, 10 and 15min. In Fig. 5 a fragment of an X-ray pattern takenfor the composite AA6061/NiTi mechanically al-loyed for 10 min is reproduced. A strongamorphization of NiTi can be observed. Both pow-ders show crystallite size in the nanoscale range.As a result of mechanical alloying at an accelera-tion of 28 g reinforcement particles are coated withAl alloy, which is beneficial for the good distribu-tion in the metal matrix. This pre-alloyed at 28 g for 15 min NiTi+AA6061powder was used for further mechanical alloyingfor 4 h with the initial AA6061 by means of conven-tional milling at low acceleration (Pulverisette 6,acceleration 6.5 g). It seems that the Al alloy coat-ing on the surface of the NiTi particles improvedthe adhesion of the initial AA6061 powder (Fig.6).The micrographs show that the particle-matrix in-terface is very good irrespective of the size of thereinforcement particles. As the layers of the matrixmaterial on the surface of the NiTi particles arerather thin, these particles could easily be distrib-uted in the initial AA6061 powder by a subsequentmilling process. This indicates that pre-alloying athigh accelerations activated the powders and pro-vided a second phase that could easily be intro-duced into the metal matrix. 5.CONCLUSIONS The influence of the centrifugal factor was studiedfor the process of metal matrix composite prepa-ration. The separate milling of the powders of theAluminium alloy AA6061 and reinforcements NiTiand Al,O, and the mechanical alloying of thesecomponents were performed in the planetary millsof different accelerations. Itwas demonstrated that during milling of Al alloyin the TTD planetary mill at an acceleration of 28 gfor only 30 min it was possible to diminish particlesize down to 8 mm and to obtain a narrow particlesize distribution. The milling time in the planetary Fig. 6. Image ofAA6061+NiTi composite, with com-ponents pre-milled separately at 50 g, mechani-cally alloyed at 28 g for 15 min and additionallymechanically alloyed with initial AA6061 at 6.5 gfor4h. size attained can be as low as 40 nm. The millingtime needed to achieve a crystallite size of the na-nometer scale in planetary mills of high accelera-tions is significantly lower compared to the valuesreported in the literature for milling in an attritor andin a SPEX mill (Table 2). The milling of Al alloy in the TTD planetary millof 50 g acceleration in Ar atmosphere resulted inobtaining a crystallite size in the nanoscale regionin only 20 min. The milling of reinforcement par-ticles of NiTi required 88-160 min; flat flake-likeshape of the particles was beneficial for embed-ding of the reinforcements in the metal matrix. The mechanical alloying of AA6061/NiTi andAA6061/AI,O, metal matrix composites (with pre-milled components) was performed in the planetarymill at 28 g for only 15 min. During the process ofmechanical alloying the further reduction of crys-tallite size took place, yielding nanoscale crystal-lite size for all the components. The encapsulationof reinforcement particles with Al alloy was re-vealed. A high degree of coverage (97.5%) of thereinforcement particles by the Aluminium alloy wasachieved. Subsequent mechanical alloying at lowacceleration (6.5g) for 4 h resulted in homoge-neous distribution of NiTi reinforcements in thematrix and in a good connection to the matrix. Thus, fast mechanical alloying at an accelera-tion of 28 g of the components activated at a higheracceleration provided metal-coated particles whichcould be easily distributed in the metal matrix by asubsequent milling process. Therefore, planetarymills of high accelerations can substantially reducethe time of production of nanocrystalline metalmatrix composites. ACKNOWLEDGEMENTS The grant of the 6 Framework Program NMP2-CT-2004-505885 is gratefully acknowledged. We are indebted to Dr. V.G. Kochnev and his co-work-ers at the TTD company (Technics and Technol-ogy of Disintegration, Russia) for milling of thesamples in the TTD planetary mills. ( REFERENCES ) ( [1]R. R. Sawtell and C.L. Jensen // MetallurgicalTransactions. A 21A (1990)421. ) ( [2] E. Hellstern , H.J. Fecht, Z . Fu and W.L. Johnson // J.Appl Phys. 65 (1989)305 ) ( [3] H.J. Fecht, E. Hellstern, Z. Fu and W.L.Johnson // Adv. Powder Metall. 1 (1989) 11. ) ( [4] Z.Y. Ma, Y.L. Li, Y. Liang, F. Zheng, J. Bi andS.C. Tjong // Mater. Sci. Engineering A 219(1996)229. ) ( [5] M.S. EI-Eskandarany // J. Alloys Compounds279(1998)263. ) ( [6] A. Malchere,M. Grosbras,D.L. Demenet,L. Bresson and E. Gaffet// Materials ScienceForum225-227(1996)763. ) ( [7] M.V. Chaikina, Mechanochemistry of Naturaland Synthetic Apatites (Novosibirsk,2002), In Russian. ) ( [8]V.G. Kochnev, Planetary mill, RU Patent1358990(1992). ) ( [9] E. L . Fokina, N.l. Budim, V.G. Kochnev andG.G. C hernik //J. Mater. Sci.39 (2004)5217. ) ( [10] A.N. Streletskii, V.I. Lapshin and E.L. Fokina . // Kinetika i kataliz 30 (1989) 1064, In Russian. ) ( [11]F. Zhou, J. Lee, S. Dallek and E.J. Lavernia // J. Mater.Res. 16(2001)3451. ) ( [12] J. Eckert, J.C. Holzer, C.E. Krill and W.L. Johnson // Materials Science Forum 88-90 (1992)505. ) ( [13]www.ttd.spb.ru )

确定

还剩7页未读,是否继续阅读?

北京飞驰科学仪器有限公司为您提供《铝合金中铝合金粉的粒径分布检测方案(激光粒度仪)》,该方案主要用于合金中铝合金粉的粒径分布检测,参考标准--,《铝合金中铝合金粉的粒径分布检测方案(激光粒度仪)》用到的仪器有德国FRITSCH(飞驰)A22大量程纳米激光粒度仪、德国FRITSCH P6 单罐行星式高能球磨机/仪

推荐专场

相关方案

更多

该厂商其他方案

更多