本文报道了针对激光干涉法热膨胀仪在日本国家计量研究实验室(NRLM)和英国国家物理实验室(NPL)之间所进行的比对测试工作。比对测试采用多晶硅、低膨胀陶瓷和熔融石英标准参考材料(SRM 739)三种材料,两个实验室采用各自的激光干涉法热膨胀对三种材料分别在250~375K和290~800K温度范围内进行了比对测试,比对结果显示每种材料热膨胀系数测试结果都与相应的合成不确定度内相吻合。

方案详情

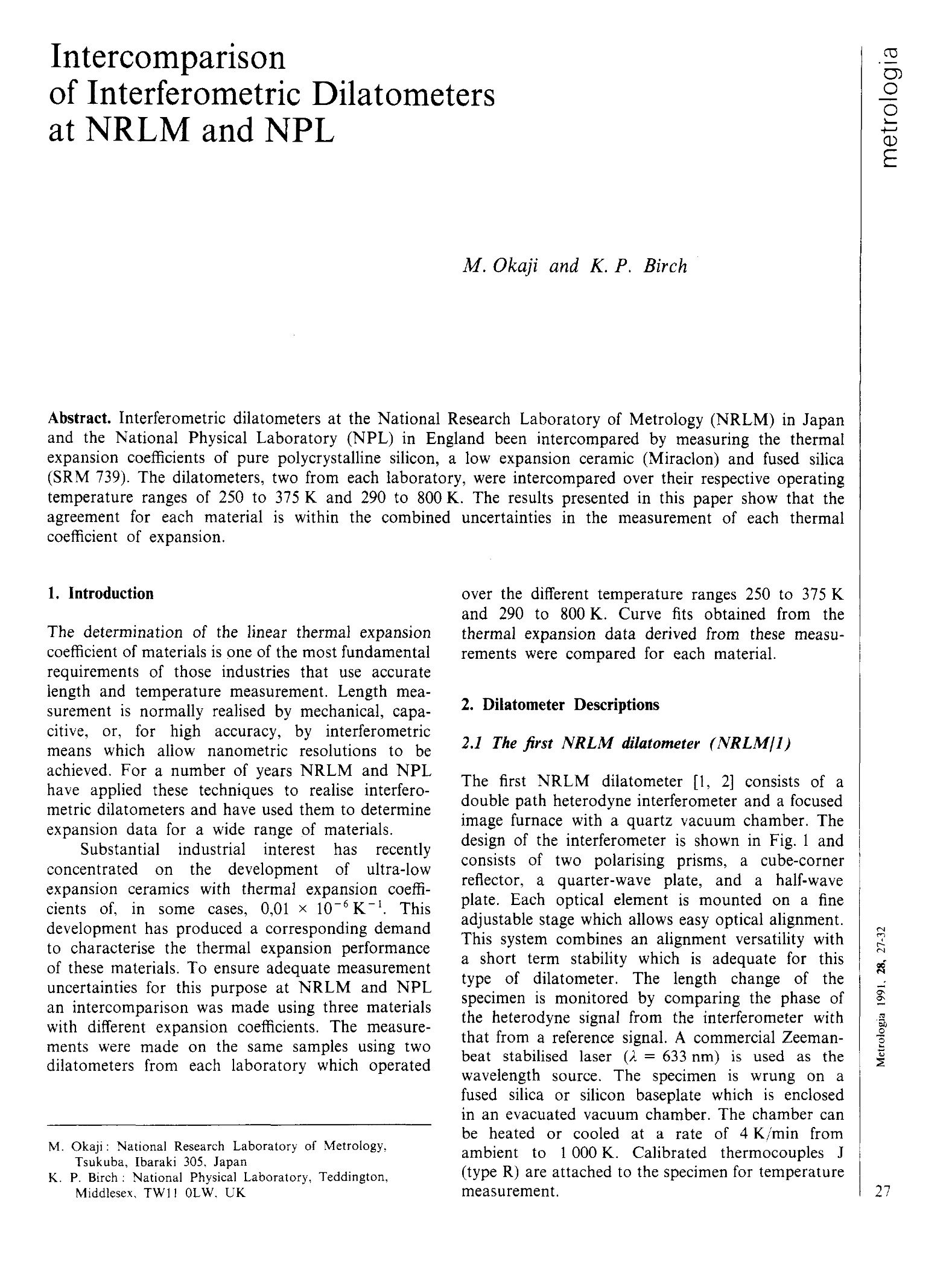

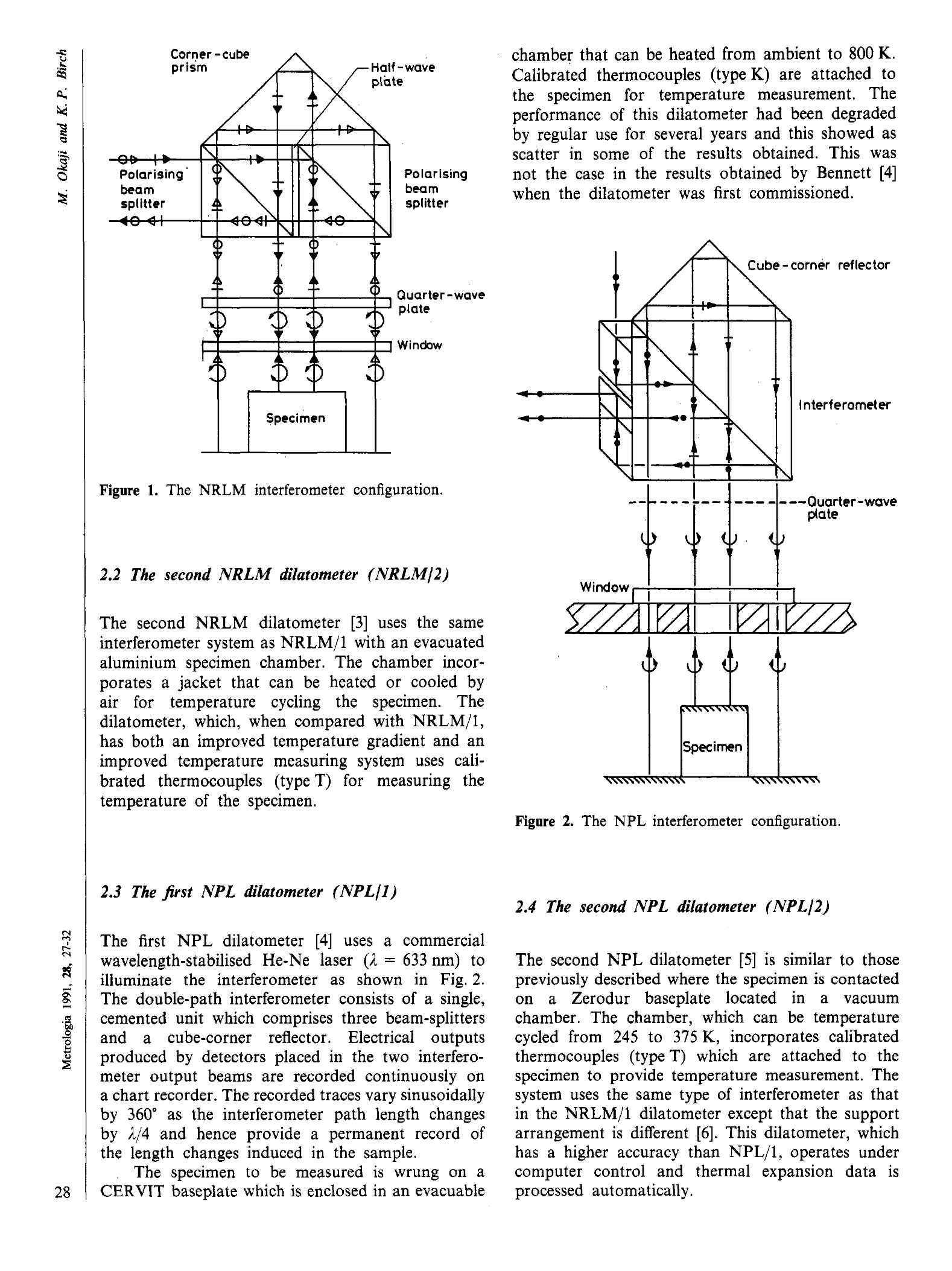

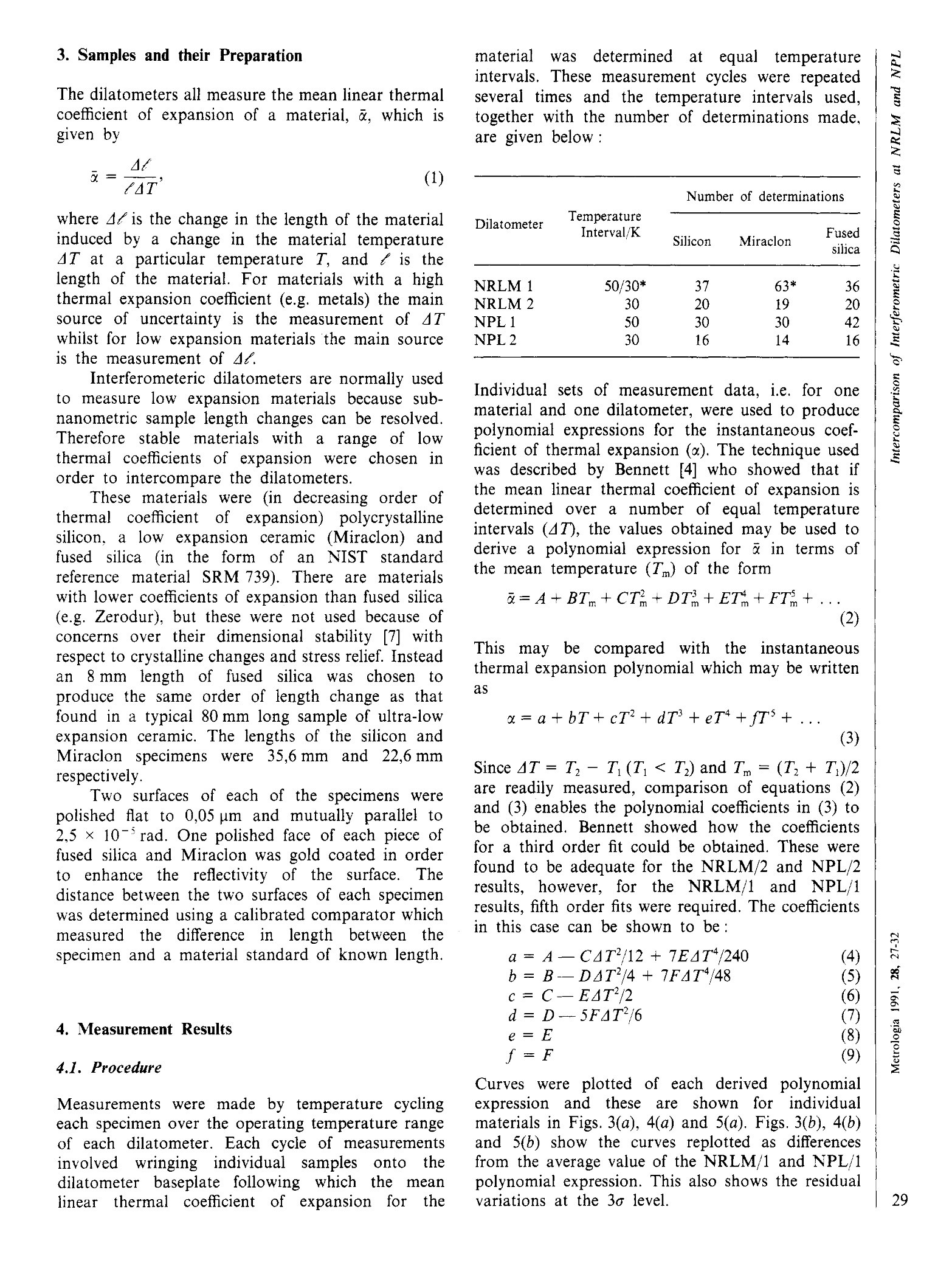

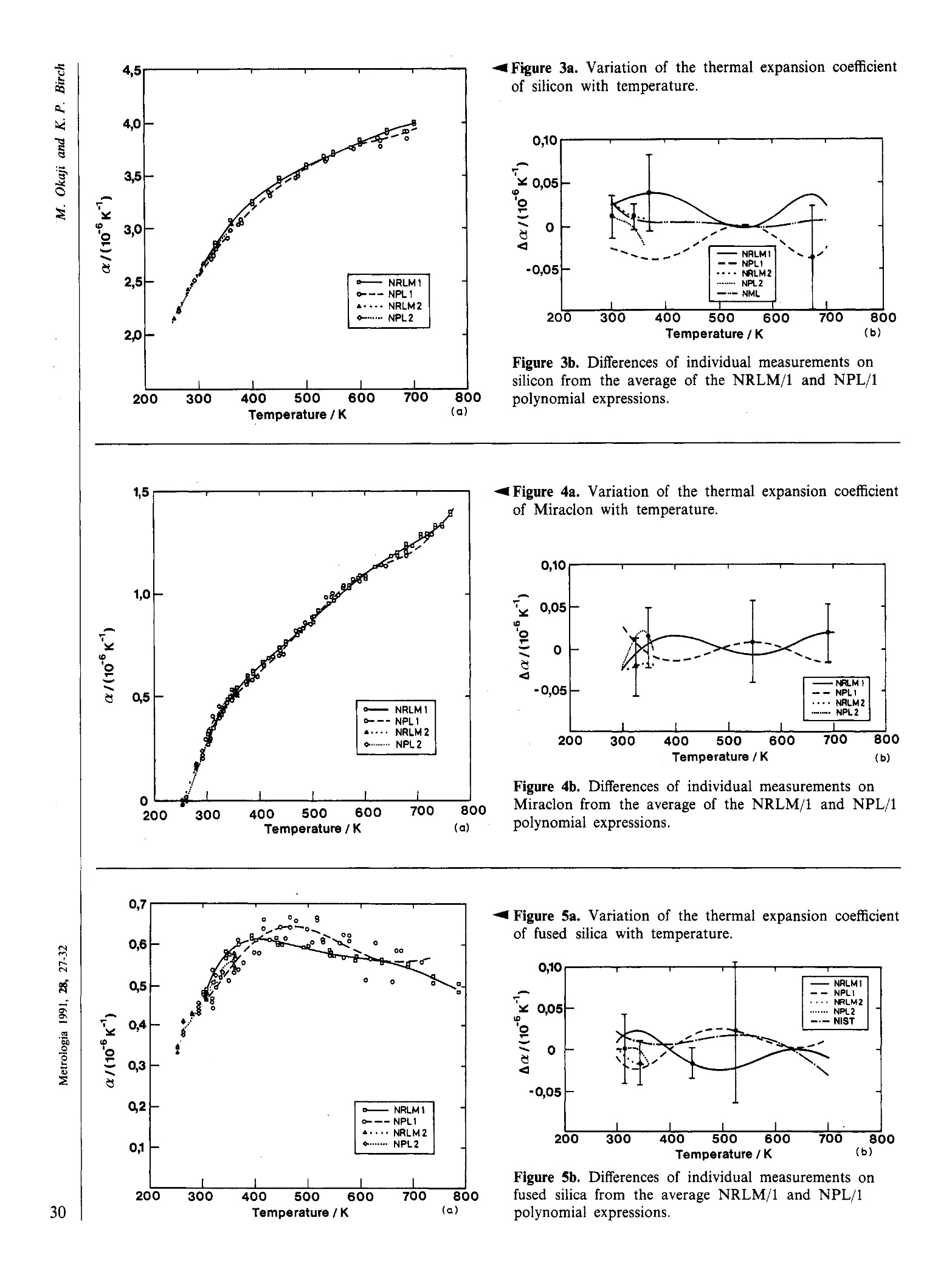

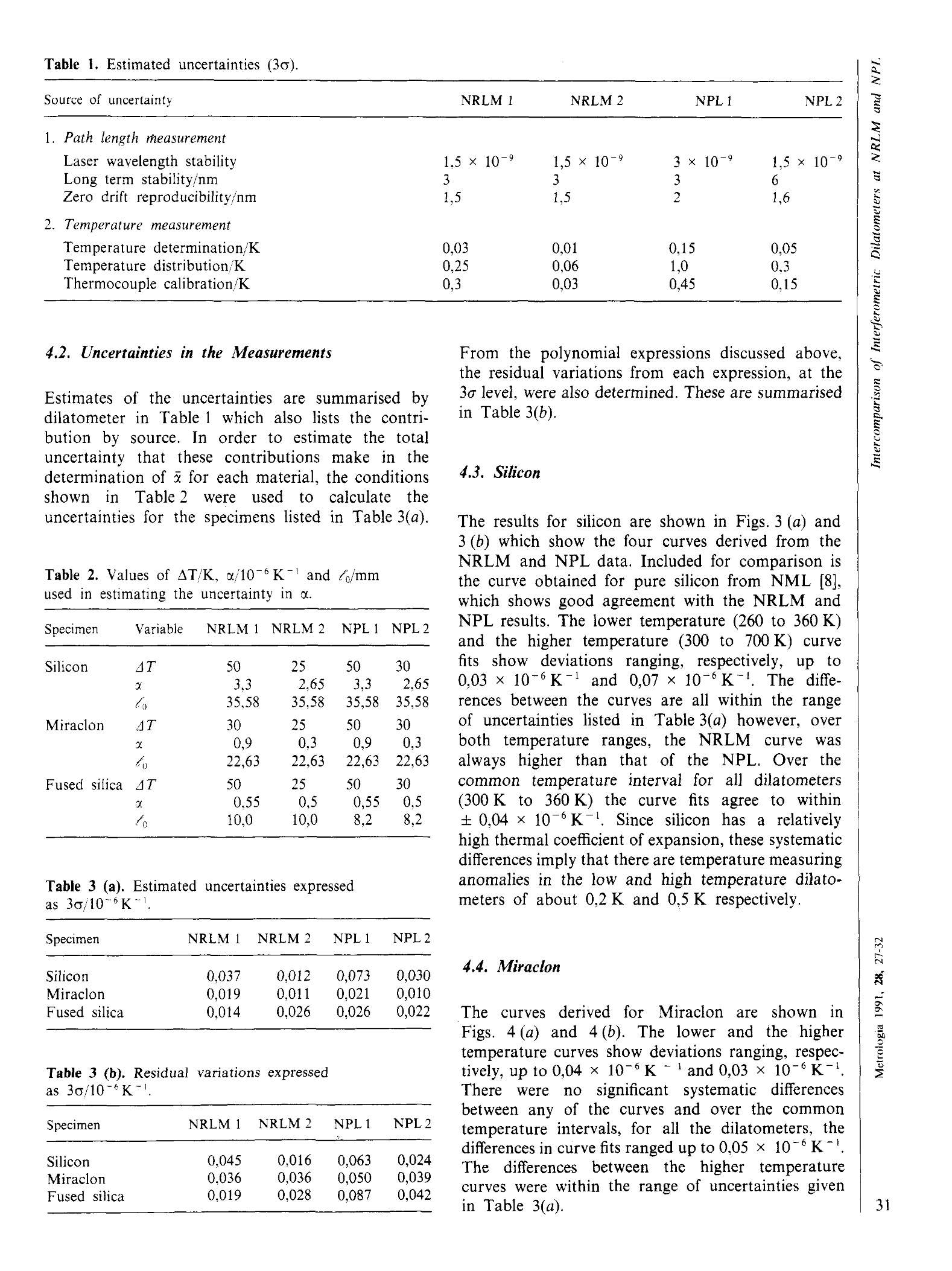

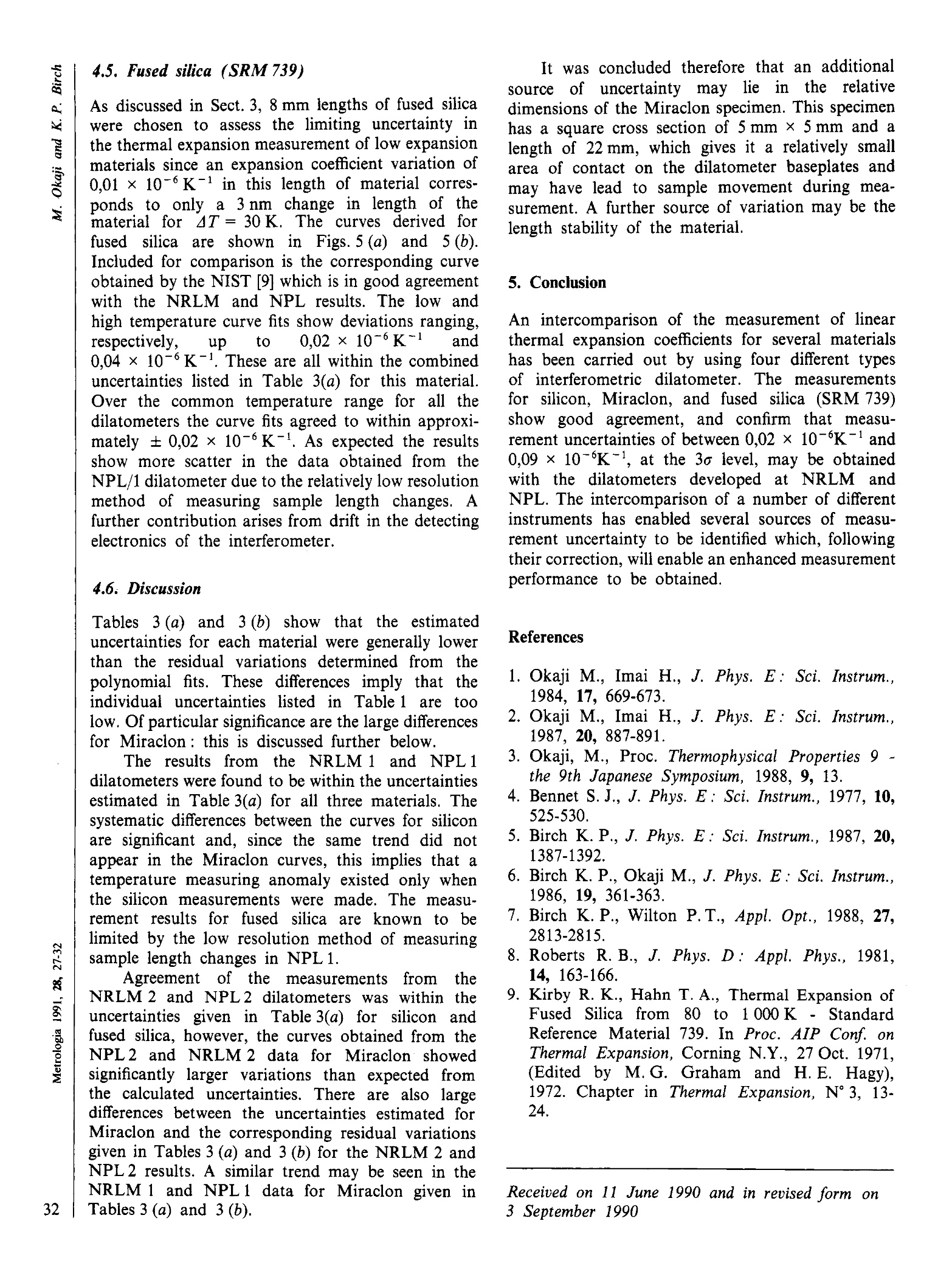

Intercomparisonof Interferometric Dilatometersat NRLM and NPL 4.5. Fused silica (SRM 739) M. Okaji and K. P. Birch Abstract. Interferometric dilatometers at the National Research Laboratory of Metrology (NRLM) in Japanand the National Physical Laboratory (NPL) in England been intercompared by measuring the thermalexpansion coefficients of pure polycrystalline silicon, a low expansion ceramic (Miraclon) and fused silica(SRM 739). The dilatometers, two from each laboratory, were intercompared over their respective operatingtemperature ranges of 250 to 375 K and 290 to 800 K. The results presented in this paper show that theagreement for each material is within the combined uncertainties in the measurement of each thermalcoefficient of expansion. The determination of the linear thermal expansioncoefficient of materials is one of the most fundamentalrequirements of those industries that use accuratelength and temperature measurement. Length mea-surement is normally realised by mechanical, capa-citive.or, for high accuracy, by int metmeanswhich allow nanometric resolutions to beachieved. For a number of years NRLM and NPLhave applied these techniques to realise interfero-metric dilatometers and have used them to determineexpansion data for a wide range of materials. Substantialindustrialinterest hasrrecentlyconcentratedonnttheedevelopmentcofultra-lowexpansion ceramics with thermal expansion coeffi-cients of.innsome cases.0,01×10-6K-1. Thisdevelopment has produced a corresponding demandto characterise the thermal expansion performanceof these materials. To ensure adequate measurementuncertainties for this purpose at NRLM and NPLan intercomparison was made using three materialswith different expansion coefficients. The measure-ments were made on the same samples using twodilatometers from each laboratory which operated ( M. Okaji: N ational R esearch L aboratory of M etrology,Tsukuba, I baraki 305, Japan ) ( K. P . B irch: N ational Physical Laboratory, Teddington,Middlesex、 TW1 1 0LW, UK ) over the different temperature ranges 250 to 375 Kand 290 to 800 K. Curve fits obtained from thethermal expansion data derived from these measu-rements were compared for each material. 2. Dilatometer Descriptions 2.1 The first NRLM dilatometer (NRLM|1) The first NRLM dilatometer [1, 2] consists of adouble path heterodyne interferometer and a focusedimage furnace with a quartz vacuum chamber. Thedesign of the interferometer is shown in Fig. 1 andconsists oftwo polarising prisms, a cube-cornerreflector, aquarter-wave plate, and.2ahalf-waveplate. Each optical element is mounted on a fineadjustable stage which allows easy optical alignment.This system combines an alignment versatility witha short term stability which is adequate for thistype ofddilatometer..The length change of tthespecimen is monitored by comparing the phase ofthe heterodyne signal from the interferometer withthat from a reference signal. A commercial Zeeman-beat stabilised laser (二=633 nm)isBiuused astthewavelength source. The specimen is.wrung on afused silica or silicon baseplate which is enclosedin an evacuated vacuum chamber. The chamber canbe heated or cooledatarate of 4 K/min fromambient to 1000 K. Calibrated thermocouples J(type R) are attached to the specimen for temperaturemeasurement. Figure 1. The NRLM interferometer configuration. 2.2 The second NRLM dilatometer (NRLM/2) The second NRLM dilatometer [3] uses the sameinterferometer system as NRLM/1 with an evacuatedaluminium specimen chamber. The chamber incor-porates a jacket that can be heated or cooled byairfor temperature cyclinggthespecimen.1.Thedilatometer, which, when compared with NRLM/1,has both an improved temperature gradient and animproved temperature measuring system uses cali-brated thermocouples (type T) for measuring thetemperature of the specimen. 2.3 The first NPL dilatometer (NPL/1) The first NPL dilatometer [4] usesis aa commercialwavelength-stabilised He-Ne laser (a=633 nm) toilluminate the interferometerr as shown in Fig.2.The double-path interferometer consists of a single,cemented unit which comprises three beam-splittersand agcube-cornerrireflector..Electrical outputsproduced by detectors placed in the two interfero-meter output beams are recorded continuously ona chart recorder. The recorded traces vary sinusoidallyby 360° as the interferometer path length changesby a/4 and hence providee a permanent record of.the length changes induced in the sample. The specimen to be measured is wrung on aCERVIT baseplate which is enclosed in an evacuable chamber that can be heated from ambient to 800 K.Calibrated thermocouples (type K) are attached tothe specimen for temperature measurement. Theperformance of this dilatometer had been degradedby regular use for several years and this showed asscatter in some of the results obtained. This wasnot the case in the results obtained by Bennett [4]when the dilatometer was first commissioned. Figure 2. The NPL interferometer configuration 2.4 The second NPL dilatometer (NPL/2) The second NPL dilatometer [5] is similar to thosepreviously described where the specimen is contactedon aa Zerodur baseplateielocatedin a vacuumchamber. The chamber, which can be temperaturecycled from 245 to 375K, incorporates calibratedthermocouples (type T) which are attached to thespecimen to provide temperature measurement. Thesystem uses the same type of interferometer as thatin the NRLM/1 dilatometer except that the supportarrangement is different [6]. This dilatometer, whichhas a higher accuracy than NPL/1, operates undercomputer control and thermal expansion data isprocessed automatically. 3. Samples and their Preparation The dilatometers all measure the mean linear thermalcoefficient of expansion of a material, a, which isgiven by where dt is the change in the length of the materialinduced by a change in the material temperature4T at a particular temperature T, and {is thelength of the material. For materials with a highthermal expansion coefficient (e.g. metals) the mainsource of uncertainty is the measurement of ATwhilst for low expansion materials the main sourceis the measurement of A. Interferometeric dilatometers are normally usedto measure low expansion materials because sub-nanometric sample length changes can be resolved.Therefore stable materialswithh a range of lowthermal coefficients of expansion were chosen inorder to intercompare the dilatometers. These materials were (in decreasing order ofthermal coefficientt of expansion)polycrystallinesilicon, a low expansion ceramic (Miraclon) andfused silica (in the form ofaan NISTstandard+...reference material SRM 739). There are materialswith lower coefficients of expansion than fused silica(e.g. Zerodur), but these were not used because ofconcerns over their dimensional stability[7] withrespect to crystalline changes and stress relief. Insteadan8 mm length of fused silicawwas chosen toproduce the same order of length change as thatfound in a typical 80 mm long sample of ultra-lowexpansion ceramic. The lengths of the silicon andMiraclon specimenswere35,6 mm and22,6 mmrespectively. Two surfaces of each of the specimens werepolished flat to 0,05 um and mutually parallel to2,5 × 10-rad. One polished face of each piece offused silica and Miraclon was gold coated in orderrefectivity of the curto)enhance tlace.Thedistance between the two surfaces of each specimenwas determined using a calibrated comparator whichmeasureddtheedifferenceiinlength tbetweenthespecimen and a material standard of known length. 4. Measurement Results 4.1. Procedure Measurementsswere madeleby temperature cyclingeach specimen over the operating temperature rangeof eachddilatometer. Each cycle of measurementsinvolvedwringingindividualsamples onto thedilatometerrbaseplate following which the meanlinear:thermalcoefficient (of expansionn ffor the material was determined at equal temperatureintervals..These measurement cycles were repeatedseveral times and the temperature intervalsused.together with the number of determinations made,are given below : Dilatometer Number of determinations Temperature Fused silica Interval/K Silicon Miraclon NRLM 1 50/30* 63* NRLM 2 NPL 1 NPL 2 I Individual sets of measurement data, i.e. for onematerial and one dilatometer, were used to producepolynomial expressions for the instantaneous coef-ficient of thermal expansion (a). The technique usedwas described by Bennett [4] who showed that ifthe mean linear thermal coefficient of expansion isdetermined over a number of equal temperatureintervals (4T), the values obtained may be used toderive a polynomial expression for & in terms ofthe mean temperature (Tm) of the form This mayybe compared with the instantaneousthermal expansion polynomial which may be writtenas Since 4T= T2-T(T

确定

还剩4页未读,是否继续阅读?

上海依阳实业有限公司为您提供《NRLM和NPL实验室间激光干涉膨胀仪的相互比较》,该方案主要用于其他中检测,参考标准--,《NRLM和NPL实验室间激光干涉膨胀仪的相互比较》用到的仪器有激光干涉法热膨胀测试系统

推荐专场

相关方案

更多

该厂商其他方案

更多