各相温度和热量对预估结果的影响。在相同的条件下对比不同的温控温度,合适的温度控制比设置参数更重要,特比对于UHPLC方法来估计温度。。

方案详情

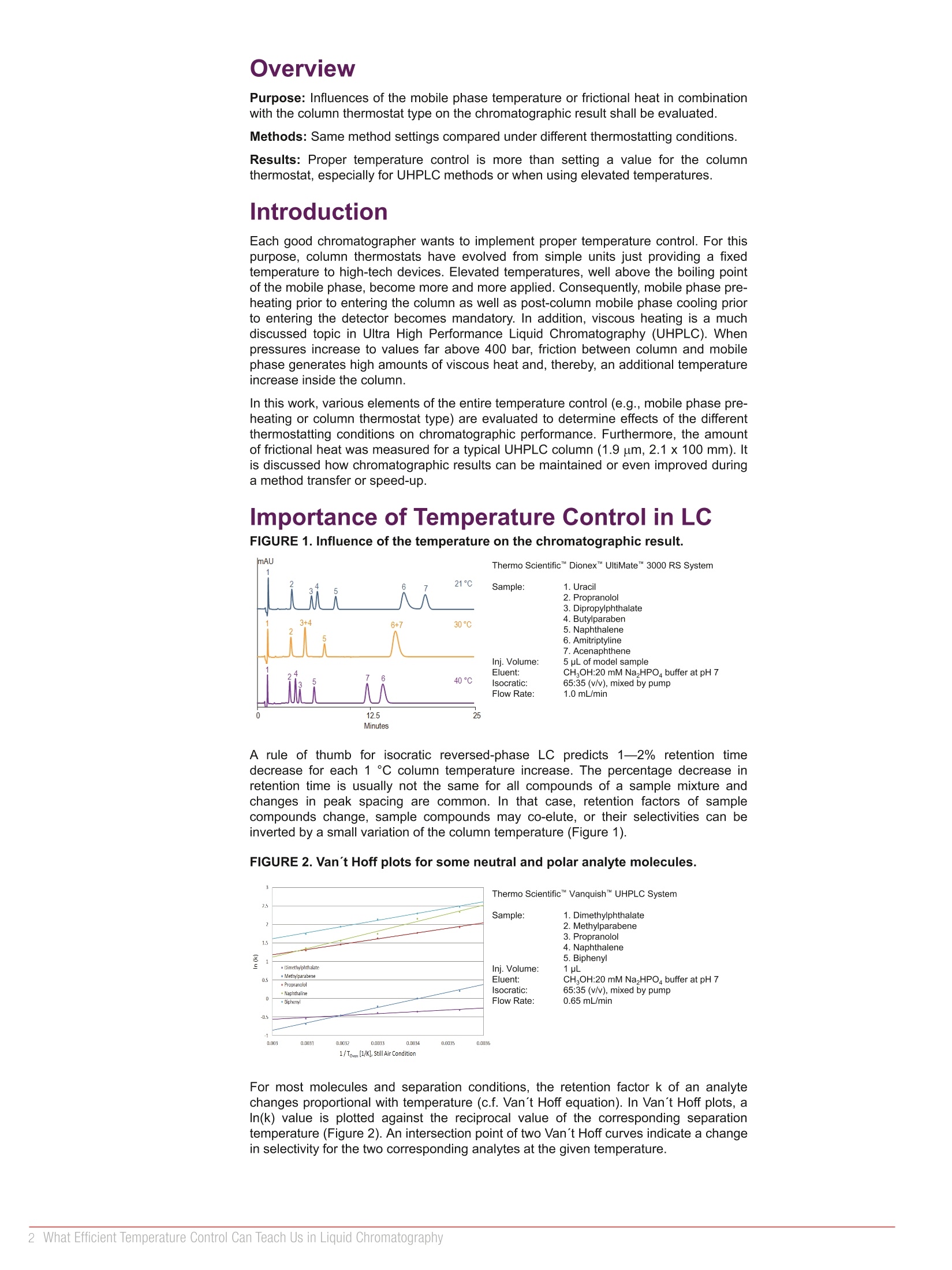

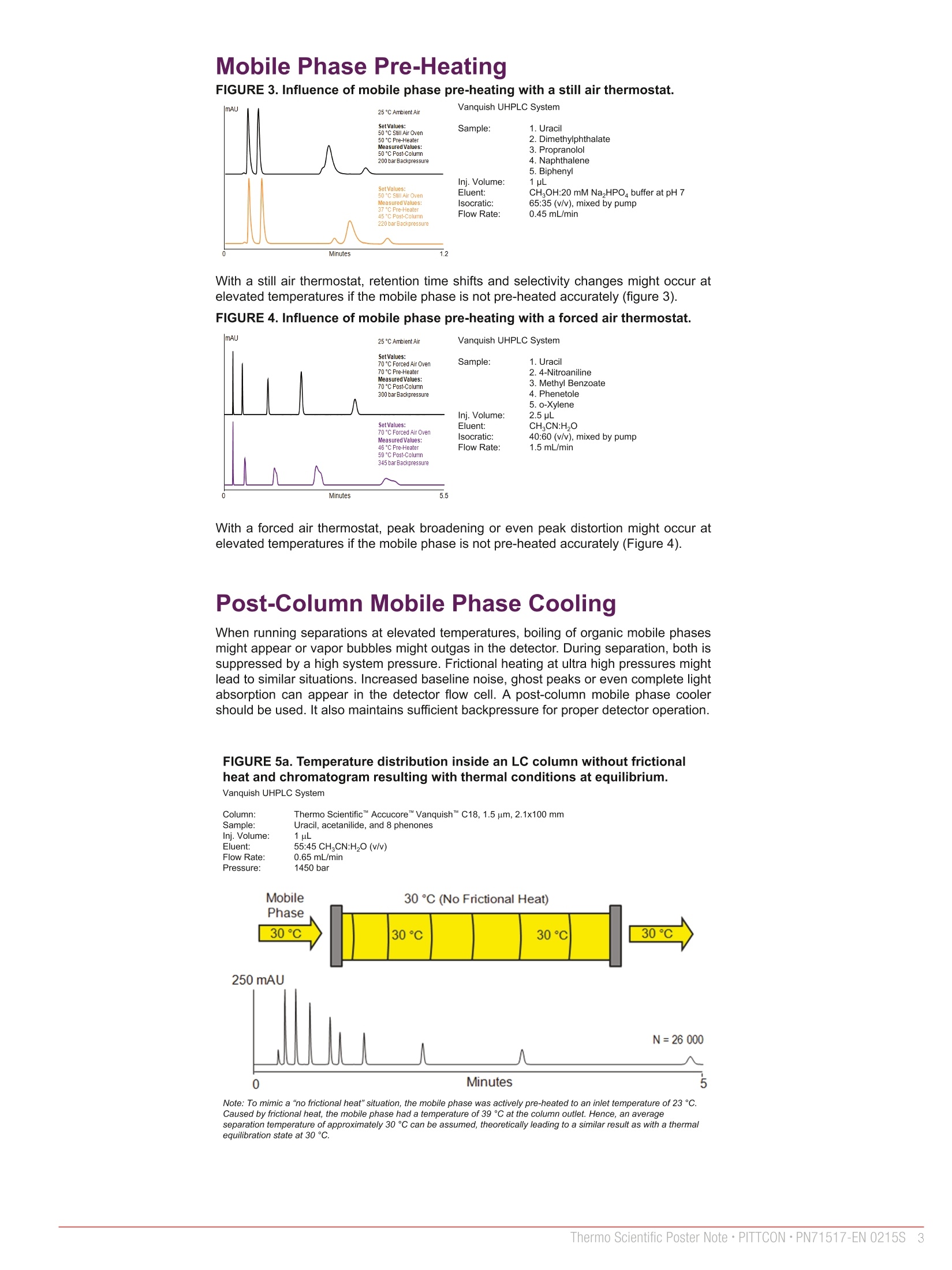

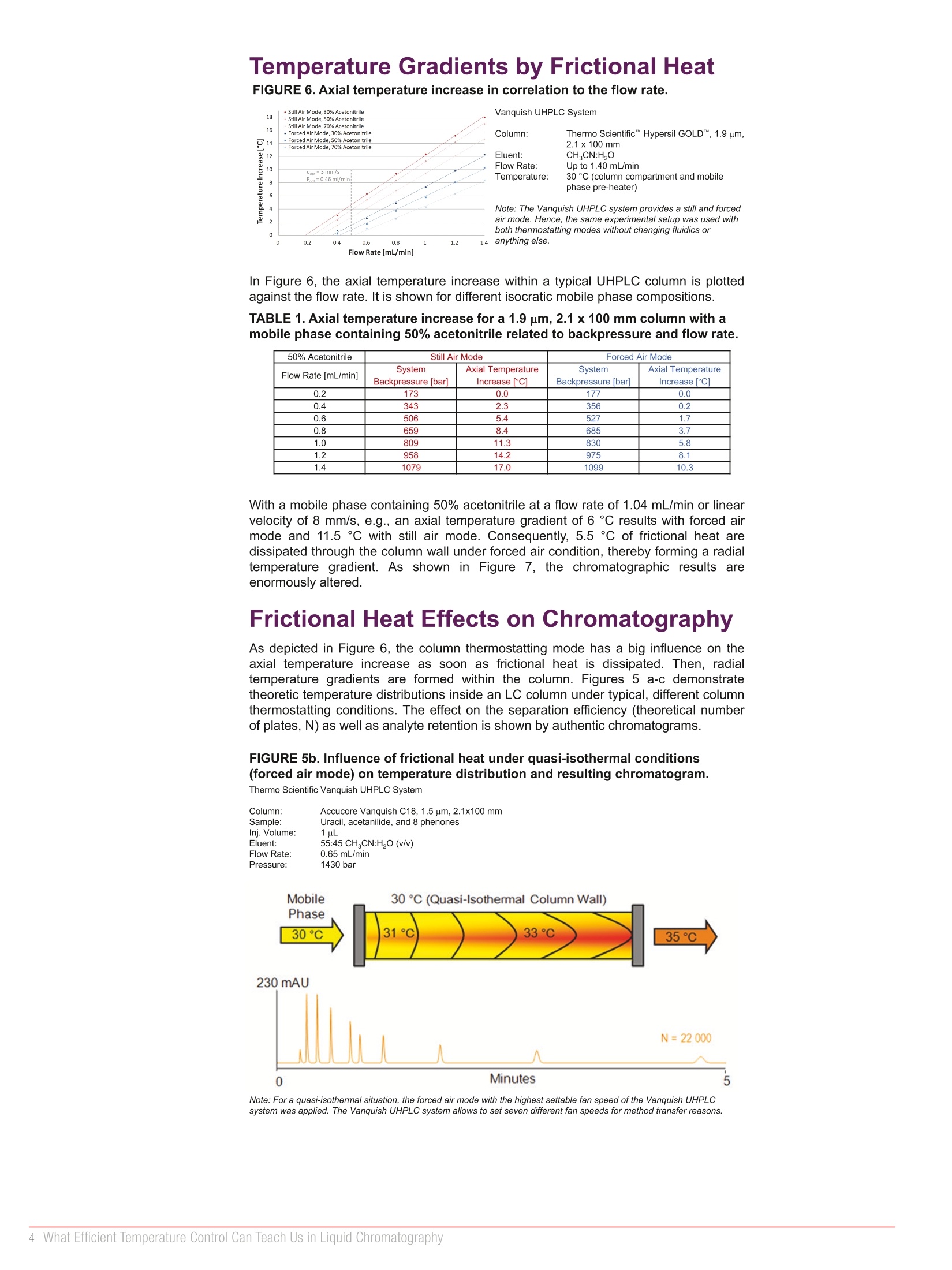

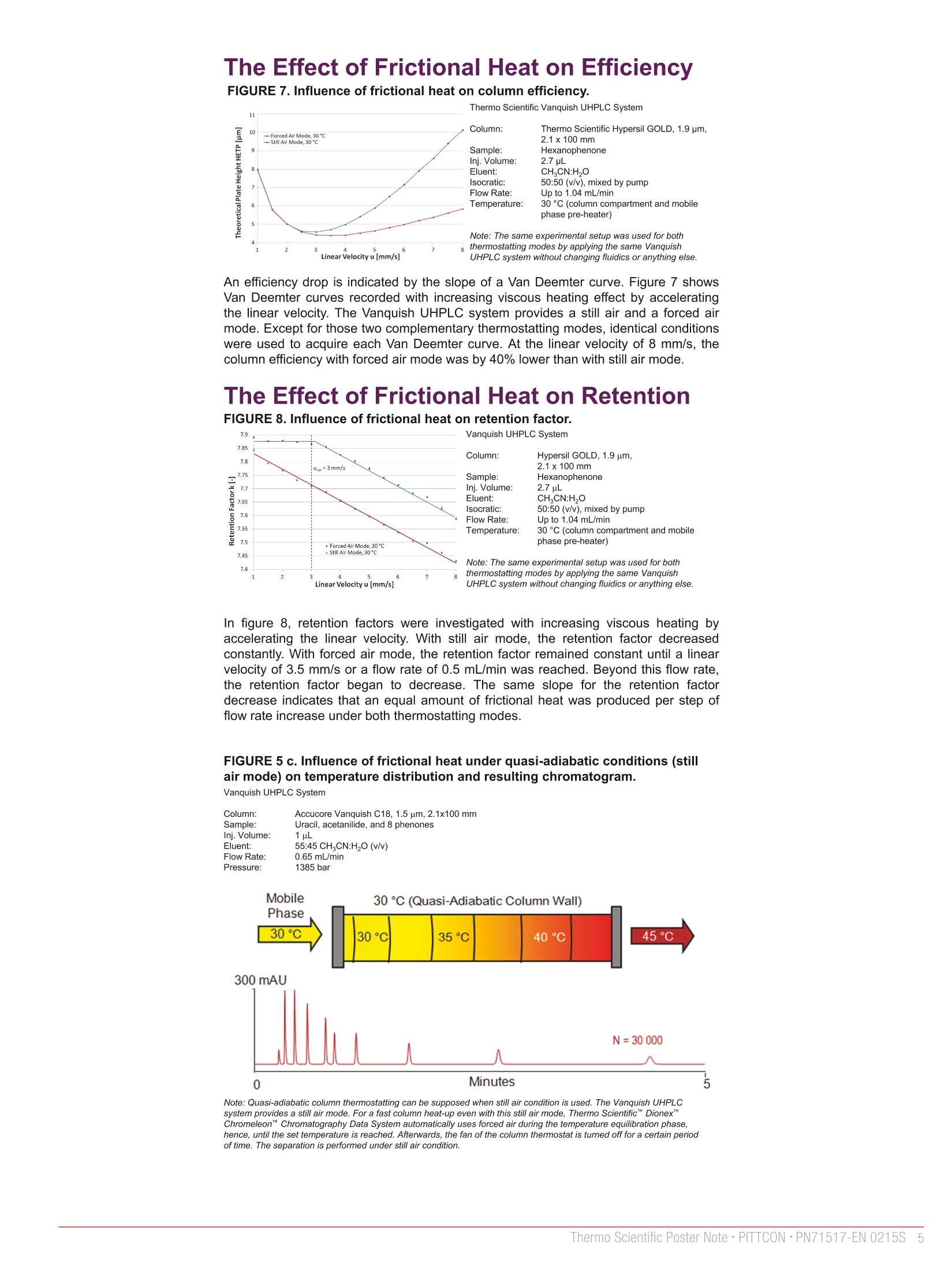

What Efficient Temperature Control CanTeach Us in Liquid Chromatography Frank Steiner,1 David Thomas,’ Evert-Jan Sneekes, and Michael Heidorn 'Thermo Fisher Scientific, Germering, Germany; "Thermo Fisher Scientific, Chelmsford, MA, USA Overview Purpose: Influences of the mobile phase temperature or frictional heat in combinationwith the column thermostat type on the chromatographic result shall be evaluated. Methods: Same method settings compared under different thermostatting conditions. Results: Proper temperature control is more than setting a value for the columnthermostat, especially for UHPLC methods or when using elevated temperatures. Introduction Each good chromatographer wants to implement proper temperature control. For thispurpose, column thermostats have evolved from simple units just providing a fixedtemperature to high-tech devices. Elevated temperatures, well above the boiling pointof the mobile phase, become more and more applied. Consequently, mobile phase pre-heating prior to entering the column as well as post-column mobile phase cooling priorto entering the detector becomes mandatory. In addition, viscous heating is a muchdiscussed topic in Ultra High Performance Liquid Chromatography (UHPLC). Whenpressures increase to values far above 400 bar, friction between column and mobilephase generates high amounts of viscous heat and, thereby,an additional temperatureincrease inside the column. In this work, various elements of the entire temperature control (e.g., mobile phase pre-heating or column thermostat type) are evaluated to determine effects of the differentthermostatting conditions on chromatographic performance. Furthermore, the amountof frictional heat was measured for a typical UHPLC column (1.9 um, 2.1 x 100 mm). Itis discussed how chromatographic results can be maintained or even improved duringa method transfer or speed-up. Importance of Temperature Control in LCFIGURE 1. Influence of the temperature on the chromatographic result. A rule of thumb for isocratic reversed-phase LC predicts 1-2% retention timedecrease for each 1 °C column temperature increase. The percentage decrease inretention time is usually not the same for all compounds of a sample mixture andchanges in peak spacing are common. In that case, retention factors of samplecompounds change, sample compounds may co-elute, or their selectivities can beinverted by a small variation of the column temperature (Figure 1). FIGURE 2. Van’t Hoff plots for some neutral and polar analyte molecules. For most molecules and separation conditions, the retention factor k of an analytechanges proportional with temperature (c.f. Van’t Hoff equation). In Van’t Hoff plots, aIn(k) value is plotted against the reciprocal value of the corresponding separationtemperature (Figure 2). An intersection point of two Van’t Hoff curves indicate a changein selectivity for the two corresponding analytes at the given temperature. Mobile Phase Pre-Heating FIGURE 3. Influence of mobile phase pre-heating with a still air thermostat. Minutes 1.2 With a still air thermostat, retention time shifts and selectivity changes might occur atelevated temperatures if the mobile phase is not pre-heated accurately (figure 3). FIGURE 4. Influence of mobile phase pre-heating with a forced air thermostat. Minutes 5.5 With a forced air thermostat, peak broadening or even peak distortion might occur atelevated temperatures if the mobile phase is not pre-heated accurately (Figure 4). Post-Column Mobile Phase Cooling When running separations at elevated temperatures, boiling of organic mobile phasesmight appear or vapor bubbles might outgas in the detector. During separation, both issuppressed by a high system pressure. Frictional heating at ultra high pressures mightlead to similar situations. Increased baseline noise, ghost peaks or even complete lightabsorption can appear in the detector flow cell. A post-column mobile phase coolershould be used. It also maintains sufficient backpressure for proper detector operation. FIGURE 5a. Temperature distribution inside an LC column without frictionalheat and chromatogram resulting with thermal conditions at equilibrium. Vanquish UHPLC System Column: Thermo Scientific"Accucore"Vanquish"C18, 1.5 um, 2.1x100 mm Sample: Uracil, acetanilide, and 8 phenones Inj. Volume: 1 pLEluent: 55:45 CH,CN:H2O (v/v) Flow Rate: 0.65 mL/min 0 Minutes 5 Note:To mimic a "no frictional heat" situation, the mobile phase was actively pre-heated to an inlet temperature of 23℃.Caused by frictional heat, the mobile phase had a temperature of 39 °℃ at the column outlet. Hence,an averageseparation temperature of approximately 30 ℃ can be assumed, theoretically leading to a similar result as with a thermalequilibration state at 30 ℃. Temperature Gradients by Frictional Heat FIGURE 6. Axial temperature increase in correlation to the flow rate. In Figure 6, the axial temperature increase within a typical UHPLC column is plottedagainst the flow rate. It is shown for different isocratic mobile phase compositions. TABLE 1. Axial temperature increase for a 1.9 um, 2.1 x 100 mm column with amobile phase containing 50% acetonitrile related to backpressure and flow rate. 50% Acetonitrile Still Air Mode Forced Air Mode Flow Rate [mL/min] System Backpressure [bar] Axial TemperatureIncrease[C] System Backpressure [bar] Axial TemperatureIncrease C] 0.2 173 0.0 177 0.0 0.4 343 2.3 356 0.2 0.6 506 5.4 527 1.7 0.8 659 8.4 685 3.7 1.0 809 11.3 830 5.8 1.2 958 14.2 975 8.1 1.4 1079 17.0 1099 10.3 With a mobile phase containing 50% acetonitrile at a flow rate of 1.04 mL/min or linearvelocity of 8 mm/s, e.g., an axial temperature gradient of 6℃ results with forced airmode and 11.5 ℃ with still air mode. Consequently, 5.5℃ of frictional heat aredissipated through the column wall under forced air condition, thereby forming a radialtemperature gradient. As shown in Figure 7, the chromatographic results areenormously altered. Frictional Heat Effects on Chromatography As depicted in Figure 6, the column thermostatting mode has a big influence on theaxial temperature increase as soon as frictional heat is dissipated. Then, radialtemperature gradients are formed within the column. Figures 5 a-c demonstratetheoretic temperature distributions inside an LC column under typical, different columnthermostatting conditions. The effect on the separation efficiency (theoretical numberof plates, N) as well as analyte retention is shown by authentic chromatograms. FIGURE 5b.Influence of frictional heat under quasi-isothermal conditions(forced air mode) on temperature distribution and resulting chromatogram.Thermo Scientific Vanquish UHPLC System Column: Accucore Vanquish C18, 1.5 um, 2.1x100 mm 11rSample: Uracil, acetanilide,and 8 phenones1 uL Inj. Volume: Eluent: 55:45 CH,CN:H2O (v/v)Flow Rate: 0.65 mL/min Pressure: 1430 bar 0 Minutes 5 Note: For a quasi-isothermal situation, the forced air mode with the highest settable fan speed of the Vanquish UHPLCsystem was applied. The Vanquish UHPLC system allows to set seven different fan speeds for method transfer reasons. The Effect of Frictional Heat on Efficiency FIGURE 7.Influence of frictional heat on column efficiencv. 2 8thermostatting modes by applying the same Vanquish Linear Velocity u [mm/s] UHPLC system without changing fluidics or anything else. An efficiency drop is indicated by the slope of a Van Deemter curve. Figure 7 showsVan Deemter curves recorded with increasing viscous heating effect by acceleratingthe linear velocity. The Vanquish UHPLC system provides a still air and a forced airmode. Except for those two complementary thermostatting modes, identical conditionswere used to acquire each Van Deemter curve. At the linear velocity of 8 mm/s, thecolumn efficiency with forced air mode was by 40% lower than with still air mode. The Effect of Frictional Heat on Retention FIGURE 8. Influence of frictional heat on retention factor. ln figure 8, retention factors were investigated with increasing viscous heating byaccelerating the linear velocity. With still air mode, the retention factor decreasedconstantly. With forced air mode, the retention factor remained constant until a linearvelocity of 3.5 mm/s or a flow rate of 0.5 mL/min was reached.Beyond this flow rate,the retention factor began to decrease. The same slope for the retention factordecrease indicates that an equal amount of frictional heat was produced per step offlow rate increase under both thermostatting modes FIGURE 5 c. Influence of frictional heat under quasi-adiabatic conditions (stillair mode) on temperature distribution and resulting chromatogram. Vanquish UHPLC System Column: Accucore Vanquish C18, 1.5 um, 2.1x100 mm Sample: Uracil, acetanilide, and 8 phenones Inj. Volume: 1 pLEluent: 55:45 CH,CN:H2O (v/v) Flow Rate: 0.65 mL/min Pressure: 1385 bar 0 Minutes Note: Quasi-adiabatic column thermostatting can be supposed when still air condition is used. The Vanquish UHPLCsystem provides a still air mode. For a fast column heat-up even with this still air mode, Thermo ScientTMific"Dionex"Chromeleon" Chromatography Data System automatically uses forced air during the temperature equilibration phase,hence, until the set temperature is reached. Afterwards, the fan of the column thermostat is turned off for a certain period. of time. The separation is performed under still air condition. Temperature Control in UHPLC With still air mode, frictional heat is not actively removed from the column. Theseparation temperature inside the column increases axially, depending on the flow rate.Thereby, a retention factor does not stay constant when using different flow rates(Figure 8). Retention factor changes can be critical for certain applications, especiallyfor samples with very polar compounds. For such compound classes, retention factorsoften change irregular to each other which might result in a change of selectivity andresolution (Figure 1). Hence, chromatographic results may change if the frictional heat contribution is notaddressed adequately during a method transfer from HPLC to UHPLC, between twoUHPLC systems with a different column oven, or when a method speed-up is appliedespecially in UHPLC. Retention factors, selectivity, and resolution do not change to thatextent under forced air conditions, if the efficiency loss due to frictional heat does notcompromise chromatographic resolution. Temperature Settings in Method Transfer If a method is transferred from HPLC to UHPLC conditions, the flow rate is adjusted butthe actual linear velocity is kept constant. Ideally, Uopt is used in the HPLC method andmaintained for the UHPLC method. In this case, the use of the forced air mode doesnot significantly compromise the separation efficiency (Figure 7). Retention factors andselectivity are retained while the analysis is generally speeded-up and the resolution isoften improved. The still air mode can also be used but retention control might becomean issue (Figure 8). During a method speed-up, when the flow rate is accelerated beyond Fopt, the frictionalheat contribution to the separation temperature increases. Retention factors cannot bekept constant anymore (Figure 8), even when using the forced air mode. Furthermore,a loss of separation efficiency would occur with the forced air mode. Here, the still airmode is the better choice as the separation efficiency is not affected. To maintain theretention factors and selectivity with the still air mode, frictional heating has to be takeninto account. For this purpose, either the mobile phase or the column compartmenttemperature must be lowered down by half the nominal value of the axial temperatureincrease resulting from frictional heating (Figure 5a, see comment in the note). Conclusion In each case, mobile phase pre-heating is essential for proper temperaturecontrol in LC and to obtain best chromatographic results. .To maintain proper detector operation, a post-column mobile phase cooler needsto be used when elevated temperatures are applied. ■ At column backpressures above 400 bar, frictional heating effects on retentionand column efficiency needs to be addressed. ■ Retention factors, selectivity, and resolution do not change if u and the forcedair mode are applied for a method transfer from HPLC to UHPLC conditions. For a method transfer from HPLC to UHPLC conditions where the linear velocityis above Uoot or when the linear velocity is increased above u ot during a methodspeed-up, the still air mode should be used and either the mobile phase or thecolumn compartment temperature must be lowered down by half the nominalvalue of the axial temperature increase resulting from frictional heating. References 1.Heidorn, Michael. The Role of Temperature and Column Thermostatting in LC.2015. Thermo Scientific White Paper 71499. 2 Heidorn, Michael. A More Flexible Column Thermostatting Technique in LCMethod Transfer. 2015. Thermo Scientific White Paper 71500. www.thermoscientific.com/chromatography ◎2015 Thermo Fisher Scientific Inc. All rights reserved. ISO is a trademark of the International Standards Organization.All other trademarks are the property of Thermo Fisher Scientific and its subsidiaries. This information is presented as anexample of the capabilities of Thermo Fisher Scientific products. It is not intended to encourage use of these products in anymanners that might infringe the intellectual property rights of others. Specifications, terms and pricing are subject to change. SCIENTIFIC What Efficient Temperature Control Can Teach Us in Liquid Chromatography

确定

还剩4页未读,是否继续阅读?

赛默飞色谱与质谱为您提供《中药中理化常数检测方案 》,该方案主要用于化药新药研发中其他检测,参考标准--,《中药中理化常数检测方案 》用到的仪器有赛默飞 Vanquish™ UHPLC超高效液相色谱系统

推荐专场

相关方案

更多

该厂商其他方案

更多