传统分析方法如筛析法、比表面积法有一定的局限,只能提供特征值的大小,无法给出详细的粒度分布,且测试时间长、人工成本高。

激光粒度仪,检测速度快、重复性高,并能够给出详细的粒度分布,指导水泥厂家提升水泥质量的同时,减少能耗!

方案详情

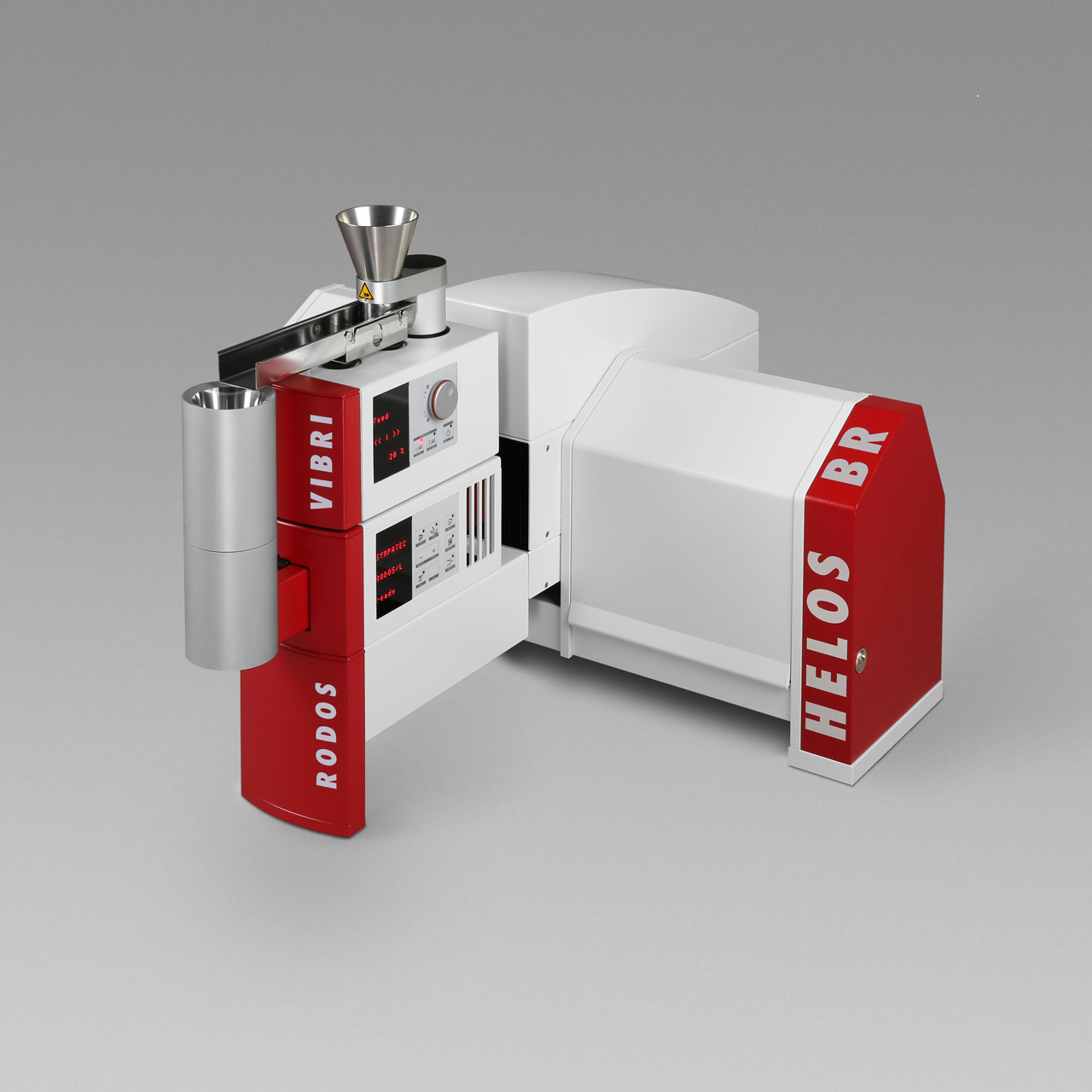

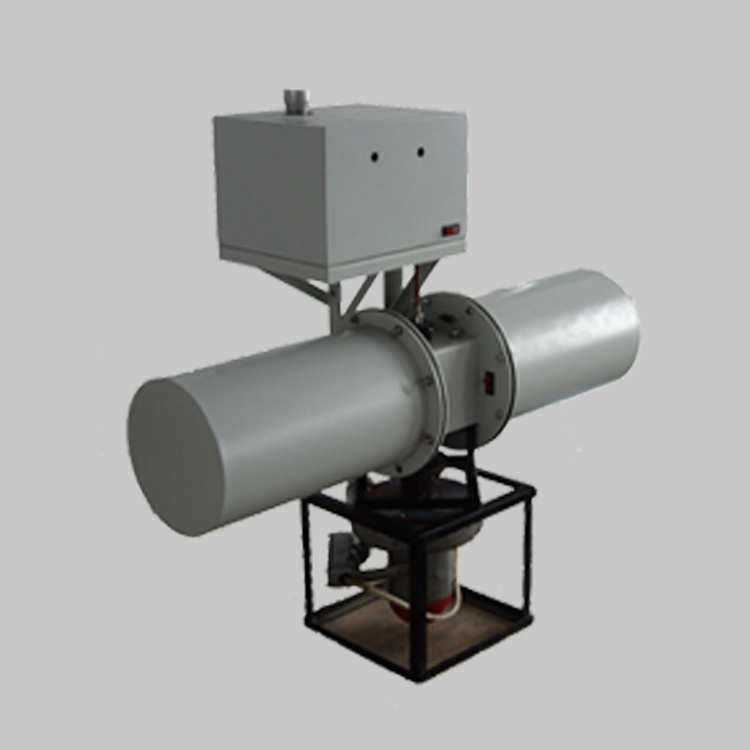

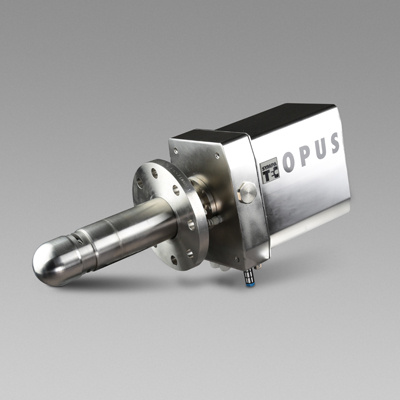

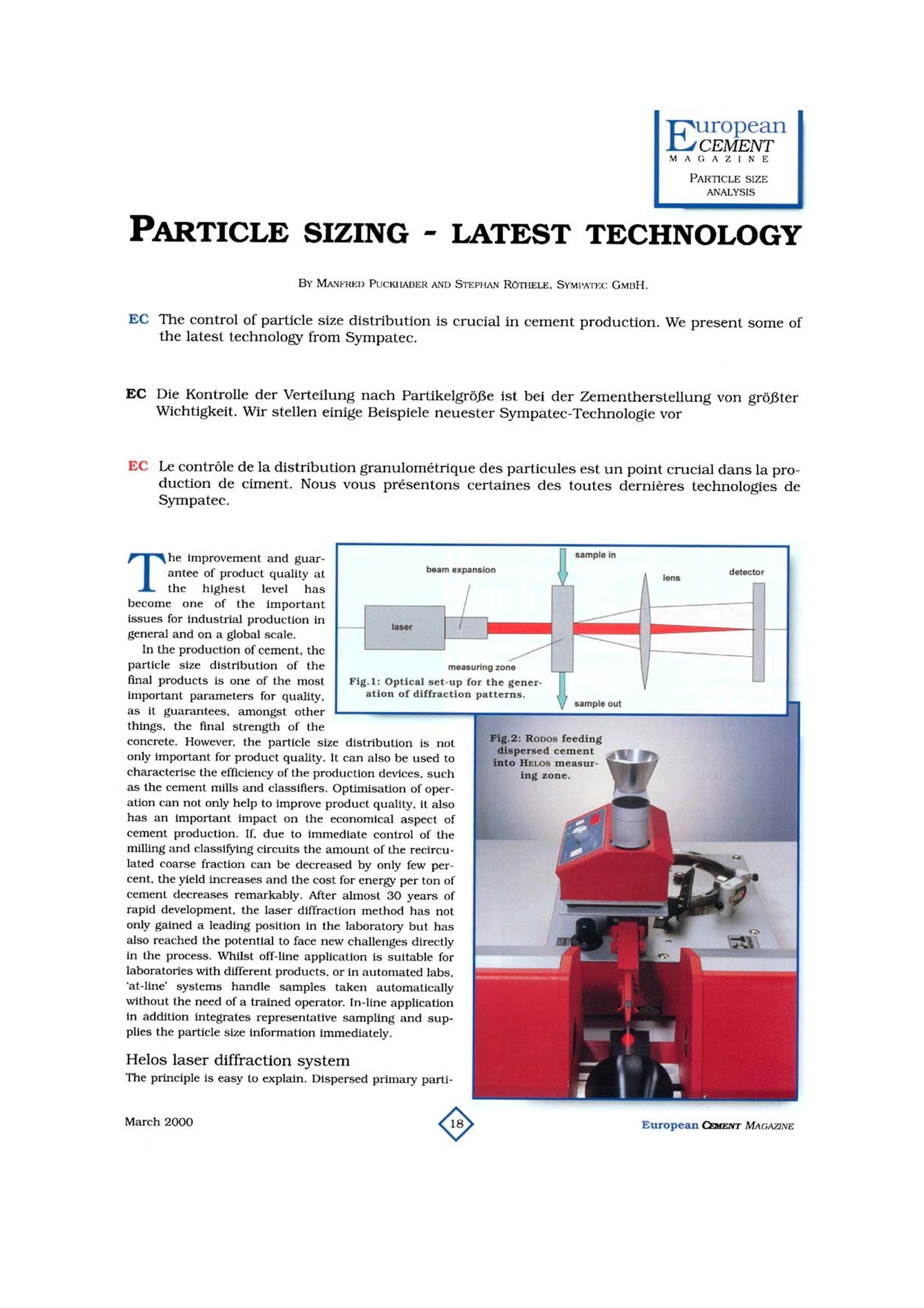

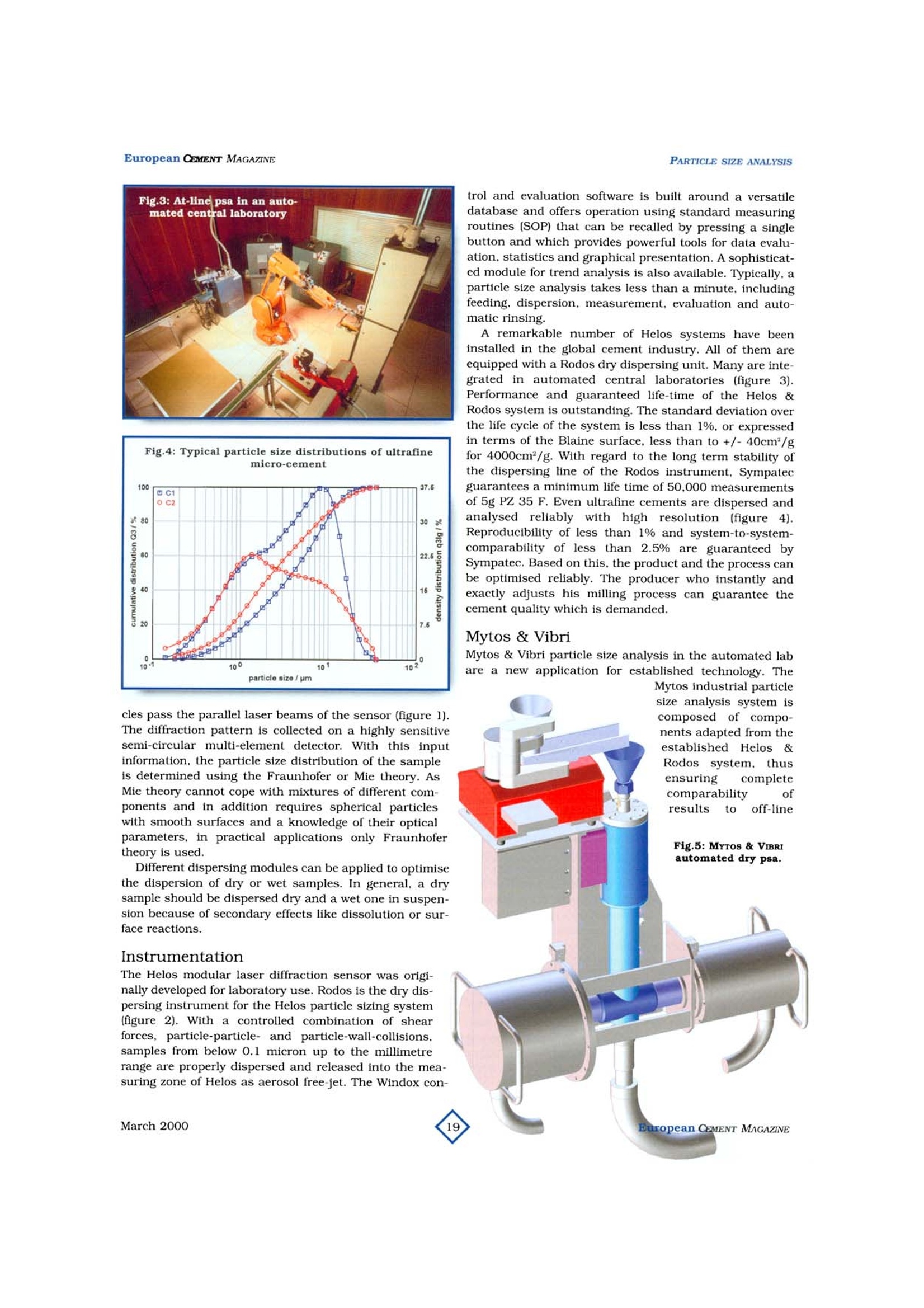

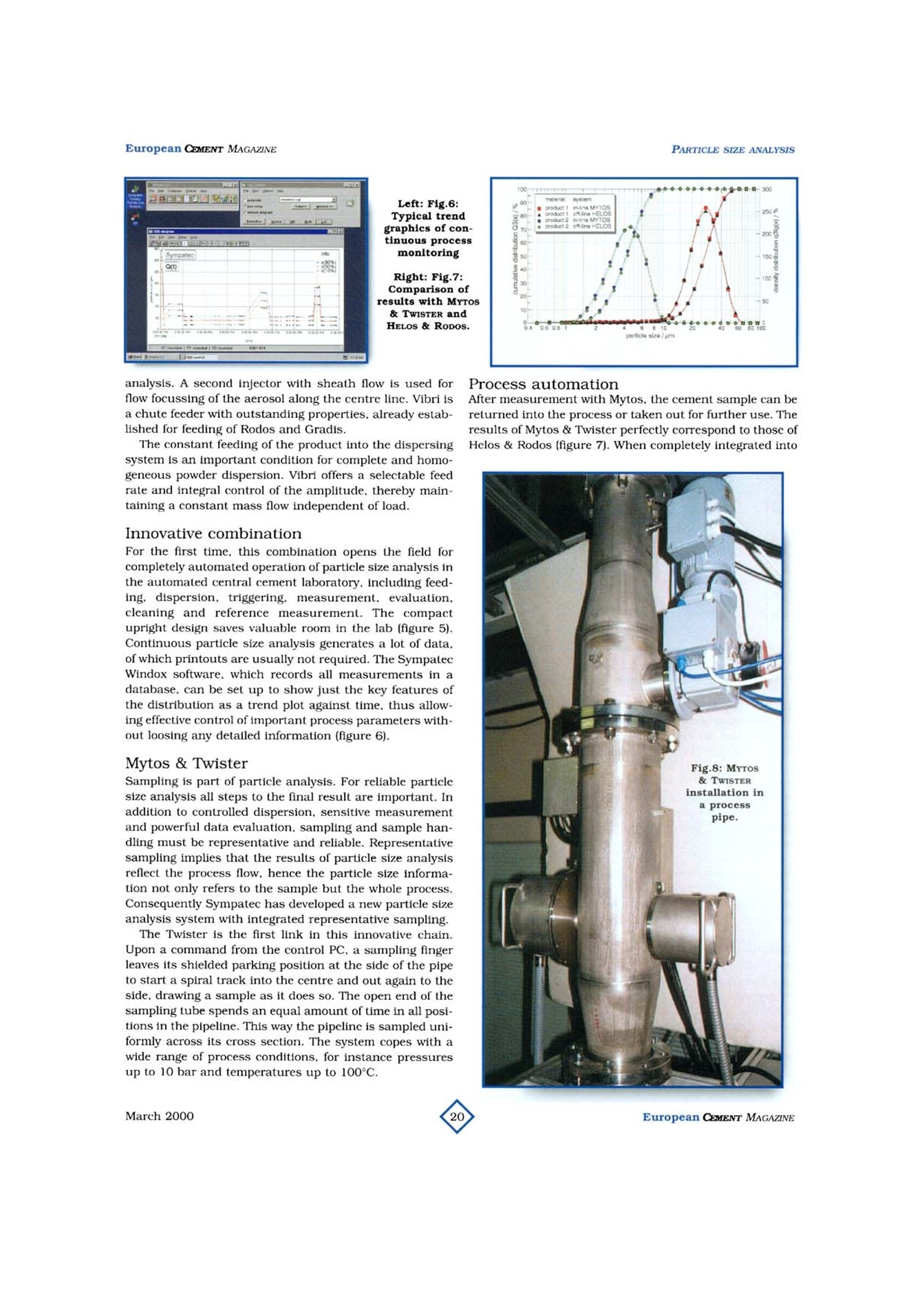

European CEMENT MAGAZINEPARTICLE SIZE ANALYSIS PARTICLE SIZING- LATEST TECHNOLOGY BY MANFRED PUCKHABER AND STEPHAN ROTHELE, SYMPATEC GMBH. EC The control of particle size distribution is crucial in cement production. We present some ofthe latest technology from Sympatec. EC Die Kontrolle der Verteilung nach PartikelgroBe ist bei der Zementherstellung von groBterWichtigkeit. Wir stellen einige Beispiele neuester Sympatec-Technologie vor EC Le controle de la distribution granulometrique des particules est un point crucial dans la pro-duction de ciment. Nous vous presentons certaines des toutes dernieres technologies deSympatec. he improvement and guar-Tantee of product quality atthe highest level hasbecoiome one of the importantissues for industrial production ingeneral and on a global scale. In the production of cement, theparticle size distribution of thefinal products is one of the mostimportant parameters for quality,as it guarantees, amongst otherthings, the final strength of the concrete. However, the particle size distribution is notonly important for product quality. It can also be used tocharacterise the efficiency of the production devices, suchas the cement mills and classifiers. Optimisation of oper-ation can not only help to improve product quality, it alsohas an important impact on the economical aspect ofcement production. If, due to immediate control of themilling and classifying circuits the amount of the recircu-lated coarse fraction can be decreased by only few per-cent, the yield increases and the cost for energy per ton ofcement decreases remarkably. After almost 30 years ofrapid development, the laser diffraction method has notonly gained a leading position in the laboratory but hasalso reached the potential to face new challenges directlyin the process. Whilst off-line application is suitable forlaboratories with different products. or in automated labs,at-line’ systems handle samples taken automaticallywithout the need of a trained operator. In-line applicationin addition integrates representative sampling and sup-plies the particle size information immediately. Helos laser diffraction system The principle is easy to explain. Dispersed primary parti- cles pass the parallel laser beams of the sensor (figure 1).The diffraction pattern is collected on a highly sensitivesemi-circular multi-element detector. With this inputinformation, the particle size distribution of the sampleis determined using the Fraunhofer or Mie theory. AsMie theory cannot cope with mixtures of different com-ponents and in addition requires spherical particleswith smooth surfaces and a knowledge of their opticalparameters, in practical applications only Fraunhofertheory is used. Different dispersing modules can be applied to optimisethe dispersion of dry or wet samples. In general. a drysample should be dispersed dry and a wet one in suspen-sion because of secondary effects like dissolution or sur-face reactions. Instrumentation The Helos modular laser diffraction sensor was origi-nally developed for laboratory use. Rodos is the dry dis-persing instrument for the Helos particle sizing system(figure 2). With a controlled combination of shearforces, particle-particle- and particle-wall-collisions,samples from below 0.1 micron up to the millimetrerange are properly dispersed and released into the mea-suring zone of Helos as aerosol free-jet. The Windox con- trol and evaluation software is built around a versatiledatabase and offers operation using standard measuringroutines (SOP) that can be recalled by pressing a singlebutton and which provides powerful tools for data evalu-ation. statistics and graphical presentation. A sophisticat-ed module for trend analysis is also available. Typically, aparticle size analysis takes less than a minute, includingfeeding. dispersion, measurement, evaluation and auto-matic rinsing. A remarkable number of Helos systems have beeninstalled in the global cement industry. All of them areequipped with a Rodos dry dispersing unit. Many are inte-grated in automated central laboratories (figure 3).Performance and guaranteed life-time of the Helos &Rodos system is outstanding. The standard deviation overthe life cycle of the system is less than 1%. or expressedin terms of the Blaine surface, less than to +/-40cm/gfor 4000cm²/g. With regard to the long term stability ofthe dispersing line of the Rodos instrument. Sympatecguarantees a minimum life time of 50,000 measurementsof 5g PZ 35 F. Even ultrafine cements are dispersed andanalysed reliably with high resolution(figuree 4).Reproducibility of less than 1% and system-to-system-comparability of less than 2.5% are guaranteed bySympatec. Based on this. the product and the process canbe optimised reliably. The producer who instantly andexactly adjusts his milling process can guarantee thecement quality which is demanded. Mvtos & Vibri Mytos & Vibri particle size analysis in the automated labare a new application for established technology. The analysis. A second injector with sheath flow is used forflow focussing of the aerosol along the centre line. Vibri isa chute feeder with outstanding properties. already estab-lished for feeding of Rodos and Gradis. The constant feeding of the product into the dispersingsystem is an important condition for complete and homo-geneous powder dispersion. Vibri offers a selectable feedrate and integral control of the amplitude. thereby main-taining a constant mass flow independent of load. Innovative combination For the first time. this combination opens the field forcompletely automated operation of particle size analysis inthe automated central cement laboratory. including feed-ing. dispersion, triggering. measurement. evaluation,cleaning and reference measurement. The compactupright design saves valuable room in the lab (figure 5).Continuous particle size analysis generates a lot of data,of which printouts are usually not required. The SympatecWindox software. which records all measurements in adatabase. can be set up to show just the key features ofthe distribution as a trend plot against time. thus allow-ing effective control of important process parameters with-out loosing any detailed information (figure 6). Mytos & Twister Sampling is part of particle analysis. For reliable particlesize analysis all steps to the final result are important. Inaddition to controlled dispersion,sensitive measurementand powerful data evaluation. sampling and sample han-dling must be representative and reliable. Representativesampling implies that the results of particle size analysisreflect the process flow, hence the particle size informa-tion not only refers to the sample but the whole process.Consequently Sympatec has developed a new particle sizeanalysis system with integrated representative sampling. The Twister is the first link in this innovative chain.Upon a command from the control PC, a sampling fingerleaves its shielded parking position at the side of the pipeto start a spiral track into the centre and out again to theside. drawing a sample as it does so. The open end of thesampling tube spends an equal amount of time in all posi-tions in the pipeline. This way the pipeline is sampled uni-formly across its cross section. The system copes with awide range of process conditions. for instance pressuresup to 10 bar and temperatures up to 100℃. Process automation After measurement with Mytos, the cement sample can bereturned into the process or taken out for further use. Theresults of Mytos & Twister perfectly correspond to those ofHelos & Rodos (figure 7). When completely integrated into a process pipeline, the system usesabout 1.2m of space (figure 8). buteven with only half a metre available,it can be installed with Twister in-lineand Mytos on-line outside the processpipeline. If necessary. several Twisterunits can be connected to one on-lineMytos. In addition to the advanced datahandling. Windox allows the fullyautomated control of process parame-ters via programmable logic control.Investment costs for in-line analysershave proven to pay off in the shortesttime because of better product qualityand money saved through reducedenergy consumption. Summary As dry products -like cement-tendto react or interact with liquids,Sympatec offers reliable particle sizeanalysis with dry dispersion. TheHelos & Rodos system with guaran-teed life-time performance, superiorreproducibilty and system-to-system-comparability are best suited for thischallenging task. Mytos & Twister come as in-lineversion of this successful particle sizeanalyser with integrated representa-tive sampling. Because of completecomparabilityand reliability ofresults, product and process areimproved and the investment pays off in the shortest time. References [1] K. LESCHONSKI, S. ROTHELE, U.MENZEL::ASpecial Feeder : :forDiffraction Pattern Analysis of DryPowders. Part. Charact. 1, 7-13 (1984)[2] I. KESTEN: U. Control andOptimisation of Cement guality withLaser Diffraction Particle Size Analysisand DryDispersion. FifthNCBInternational Seminar on Cement andBuilding Materials, New Delhi, (26-29November 1996] ( [3] M. PUCKHABER, S. ROTHELE, W. WITT: I n-line Laser Diffractio n Proven P article Size A nalysis i nIndustria lE nvironment. PowderHandling & Processing V o l. 10, N o . 4,416-421[1998] E C ) arch uropean CMENT MAGAZINE arch

确定

还剩2页未读,是否继续阅读?

德国新帕泰克有限公司苏州代表处为您提供《激光粒度仪(干法测试)在水泥质量控制中的应用(英文)》,该方案主要用于其他中--检测,参考标准--,《激光粒度仪(干法测试)在水泥质量控制中的应用(英文)》用到的仪器有气流干法激光粒度仪HELOS&RODOS/L、德国工业在线干法激光粒度分析和过程控制系统

推荐专场

相关方案

更多