方案详情

文

文中采用Pyris 1 TGA在自动递进模式下对口香糖进行了定量分析研究。结果表明采用Pyris 1 TGA,可实现省时、高分辨率及更准确的定量分析。

方案详情

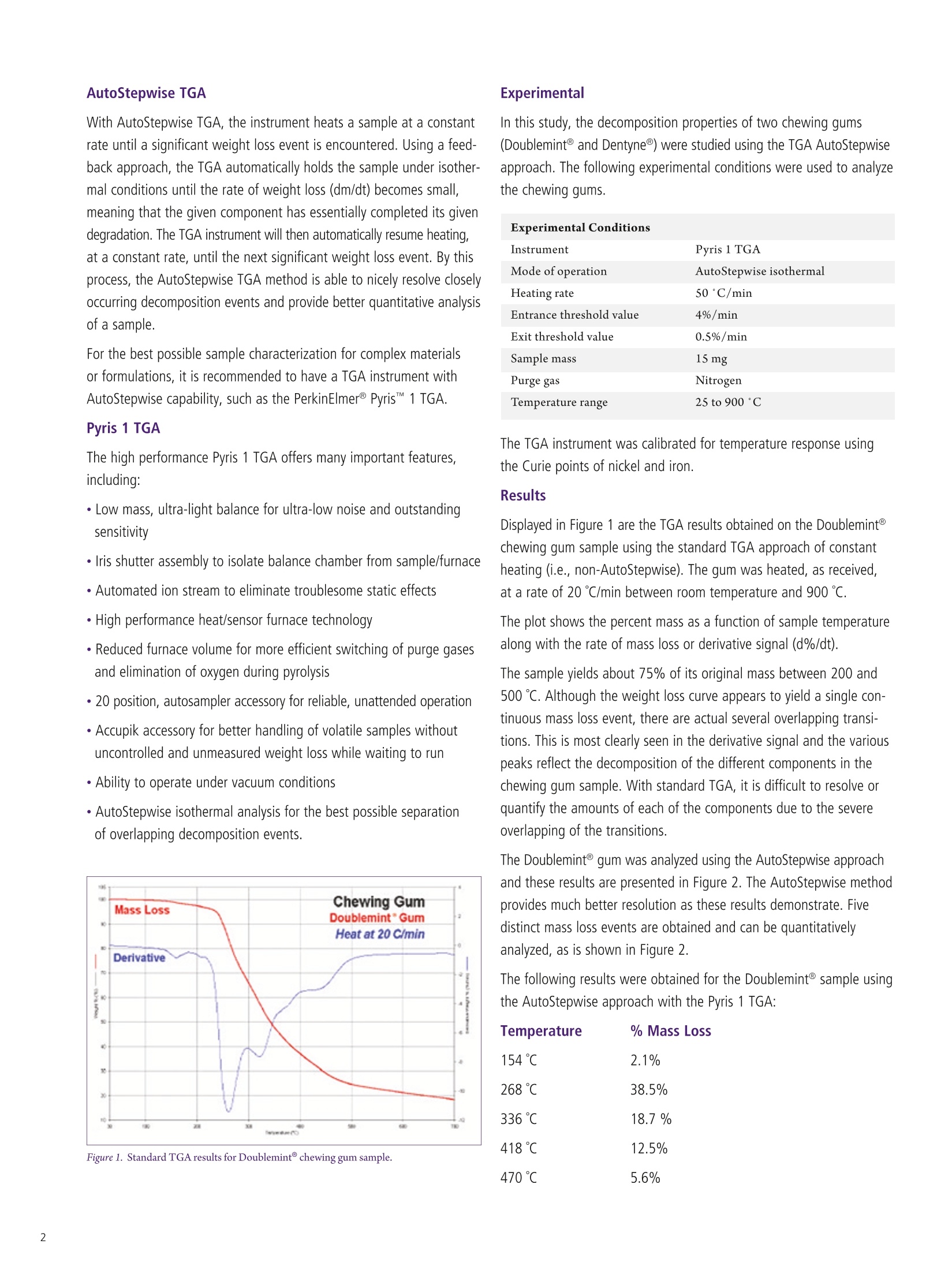

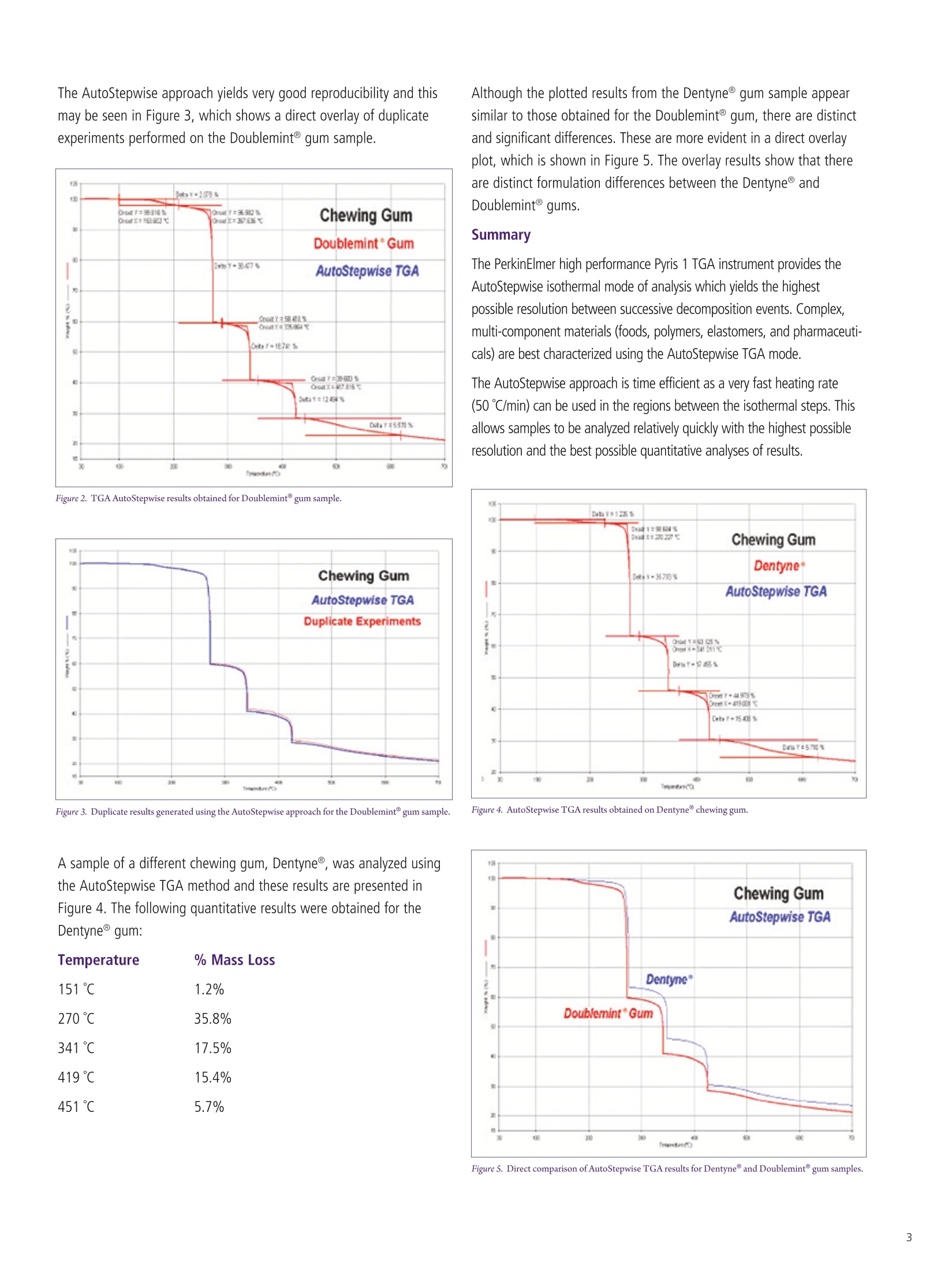

AutoStepwise TGACopyright C2009-2010, PerkinElmer, Inc. All rights reserved. PerkinElmer is a registered trademark of PerkinElmer, Inc. All other trademarks are the property of their respective owners. Better Quantitative Analysisof Chewing Gum withAutoStepwise TGA The gum base of chewing gums is a complex mixture of a number ofcomponents, including: PVAC (poly vinyl acetate), natural elastomers,glycerin, softening agents, and carbonates. In addition, chewing gumcontains flavoring agents, sucrose or other sweeteners and colorants.These various components provide the desired textural and viscoelasticproperties to the chewing gum. The correct combination of the gumformulation provides the end characteristics to the chewing gum,including: stickiness, softness and chewability. It is desired to have a means of characterizing the composition of chewing gum for quality assurance purposes. One of the best means ofdetecting components in a complex formulation, such as chewing gum and other foods, is with thermogravimetric analysis (TGA). TGA is a well-established method for the characterization of materials. The technique measures sample mass as a function of temperature ortime and provides useful decomposition temperature information. However, for complex formulations or multi-component materials, standard (constant heating) TGA may not possess the necessary resolution forseparating out the weight losses associated with the various components. What is required is a TGA, which can provide enhanced resolution orseparation using AutoStepwise isothermal methods. With AutoStepwise TGA, the instrument heats a sample at a constantrate until a significant weight loss event is encountered. Using a feed-back approach, the TGA automatically holds the sample under isother-mal conditions until the rate of weight loss (dm/dt) becomes small,meaning that the given component has essentially completed its givendegradation. The TGA instrument will then automatically resume heating,at a constant rate, until the next significant weight loss event. By thisprocess, the AutoStepwise TGA method is able to nicely resolve closelyoccurring decomposition events and provide better quantitative analysisof a sample. For the best possible sample characterization for complex materialsor formulations, it is recommended to have a TGA instrument withAutoStepwise capability, such as the PerkinElmer@ Pyris" 1 TGA. Pyris 1 TGA The high performance Pyris 1 TGA offers many important features,including: ·Low mass, ultra-light balance for ultra-low noise and outstandingsensitivity · Iris shutter assembly to isolate balance chamber from sample/furnace ·Automated ion stream to eliminate troublesome static effects · High performance heat/sensor furnace technology · Reduced furnace volume for more efficient switching of purge gasesand elimination of oxygen during pyrolysis ·20 position, autosampler accessory for reliable, unattended operation ·Accupik accessory for better handling of volatile samples withoutuncontrolled and unmeasured weight loss while waiting to run · Ability to operate under vacuum conditions ·AutoStepwise isothermal analysis for the best possible separationof overlapping decomposition events. Figure 1. Standard TGA results for Doublemint chewing gum sample. Experimental In this study, the decomposition properties of two chewing gums(Doublemint and Dentyne@) were studied using the TGA AutoStepwiseapproach. The following experimental conditions were used to analyzethe chewing gums. Experimental Conditions Instrument Pyris 1 TGA Mode of operation AutoStepwise isothermal Heating rate 50°C/min Entrance threshold value 4%/min Exit threshold value 0.5%/min Sample mass 15 mg Purge gas Nitrogen Temperature range 25 to 900°C The TGA instrument was calibrated for temperature response usingthe Curie points of nickel and iron. Results Displayed in Figure 1 are the TGA results obtained on the Doublemintchewing gum sample using the standard TGA approach of constantheating (i.e., non-AutoStepwise). The gum was heated, as received,at a rate of 20℃/min between room temperature and 900℃. The plot shows the percent mass as a function of sample temperaturealong with the rate of mass loss or derivative signal (d%/dt). The sample yields about 75% of its original mass between 200 and500℃. Although the weight loss curve appears to yield a single con-tinuous mass loss event, there are actual several overlapping transi-tions. This is most clearly seen in the derivative signal and the variouspeaks reflect the decomposition of the different components in thechewing gum sample. With standard TGA, it is difficult to resolve orquantify the amounts of each of the components due to the severeoverlapping of the transitions. The Doublemint@ gum was analyzed using the AutoStepwise approachand these results are presented in Figure 2. The AutoStepwise methodprovides much better resolution as these results demonstrate. Fivedistinct mass loss events are obtained and can be quantitativelyanalyzed, as is shown in Figure 2. The following results were obtained for the Doublemint@ sample usingthe AutoStepwise approach with the Pyris 1 TGA: The AutoStepwise approach yields very good reproducibility and thismay be seen in Figure 3, which shows a direct overlay of duplicateexperiments performed on the Doublemint@ gum sample. Figure2. TGA AutoStepwise results obtained for Doublemint gum sample. Figure 3. Duplicate results generated using the AutoStepwise approach for the Doublemint"gum sample. A sample of a different chewing gum, Dentyne@, was analyzed usingthe AutoStepwise TGA method and these results are presented inFigure 4. The following quantitative results were obtained for theDentyne@gum: Although the plotted results from the Dentyne@ gum sample appearsimilar to those obtained for the Doublemint@ gum, there are distinctand significant differences. These are more evident in a direct overlayplot, which is shown in Figure 5. The overlay results show that thereare distinct formulation differences between the Dentyne@ andDoublemint gums. Summary The PerkinElmer high performance Pyris 1 TGA instrument provides theAutoStepwise isothermal mode of analysis which yields the highestpossible resolution between successive decomposition events. Complex,nulti-component materials (foods, polymers, elastomers, and pharmaceuti-cals) are best characterized using the AutoStepwise TGA mode. The AutoStepwise approach is time efficient as a very fast heating rate(50℃C/min) can be used in the regions between the isothermal steps. Thisallows samples to be analyzed relatively quickly with the highest possibleresolution and the best possible quantitative analyses of results. Figure 4. AutoStepwise TGA results obtained on Dentyne" chewing gum. PerkinElmer, Inc. 940 Winter StreetWaltham, MA 02451 USAP: (800) 762-4000 or(+1) 203-925-460 www.perkinelmer.com For a complete listing of our global offices, visit www.perkinelmer.com/ContactUs

确定

还剩2页未读,是否继续阅读?

珀金埃尔默企业管理(上海)有限公司为您提供《口香糖中产品品质检测方案 》,该方案主要用于糖果中营养成分检测,参考标准--,《口香糖中产品品质检测方案 》用到的仪器有

相关方案

更多

该厂商其他方案

更多