方案详情

文

Powder coatings—substances that are protective, decorative, or both—are formed by the application of a coating

powder to a substrate and fusing the coating into a continuous film by the application of heat or radiant energy. Coating

powders are finely divided particles of organic polymer that generally contain pigments, fillers, and additives that

remain finely divided during storage under suitable conditions. In contrast to liquid coatings, which may contain volatile

organic solvents, powder coatings can achieve the same or better characteristics of quality, durability, and corrosion

resistance.

方案详情

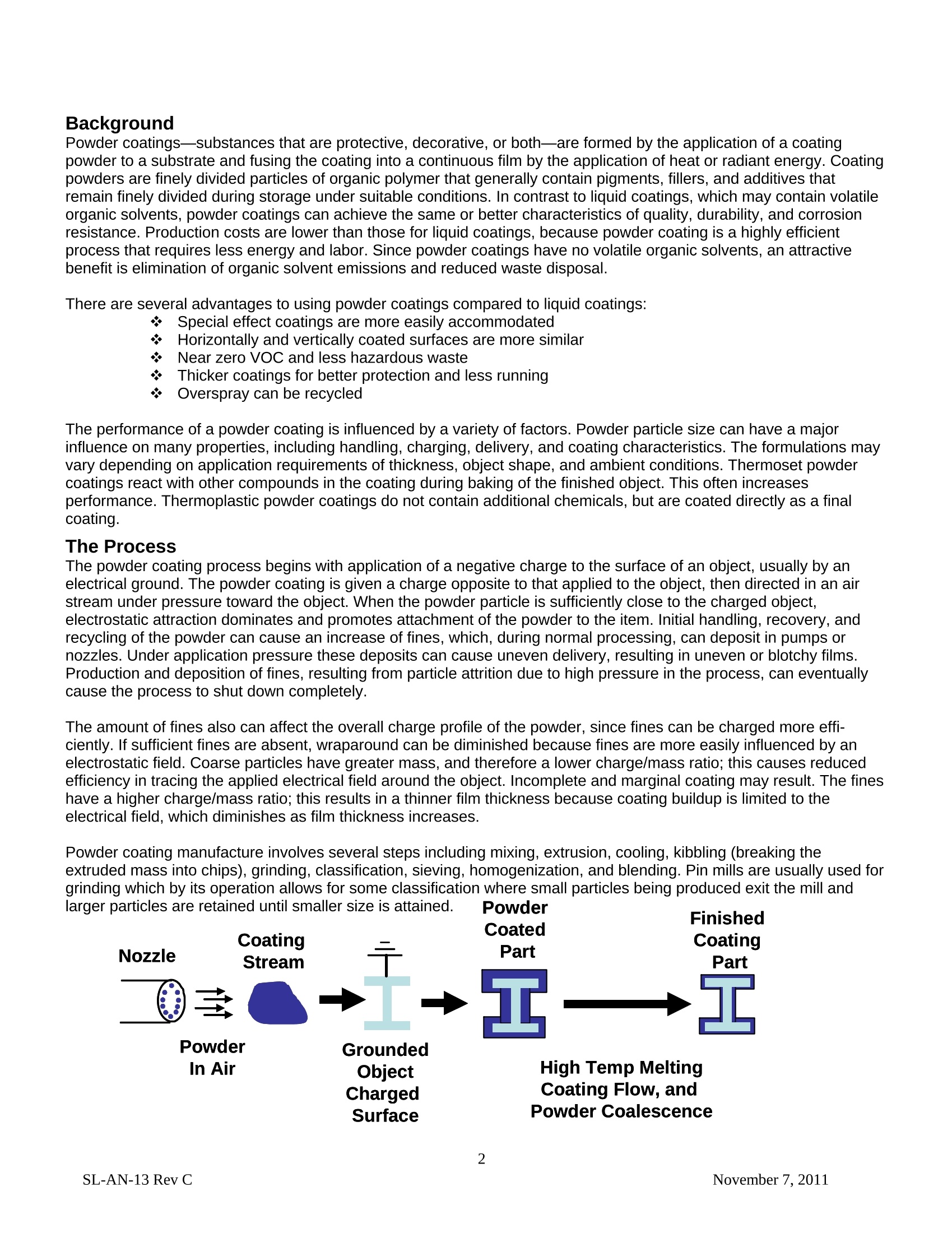

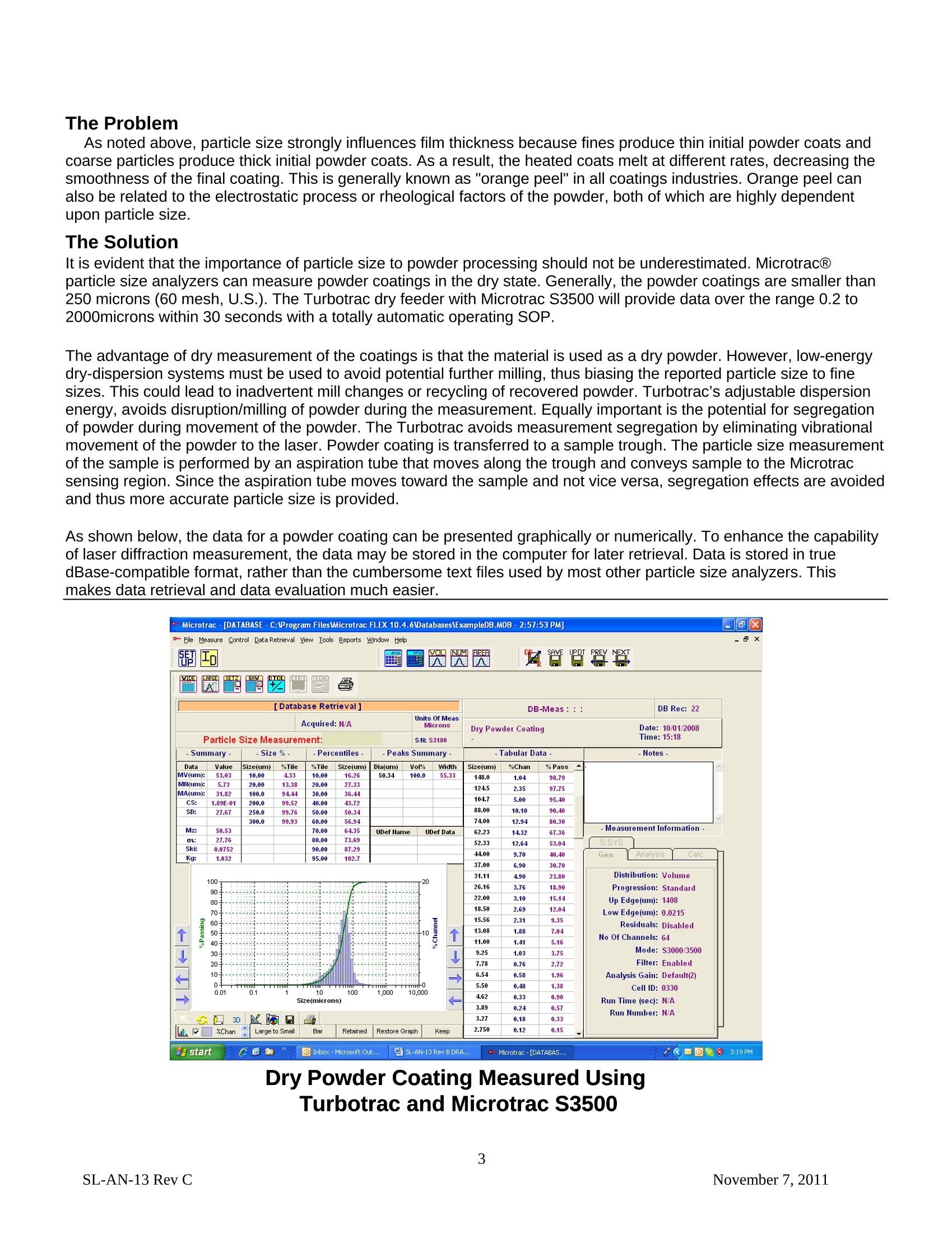

Powder Coatings and Particle SizeMeasurement Philip E. Plantz Application Note SL-AN-13 Rev C Provided By:Microtrac, Inc.Particle Size Measuring Instrumentation Background Powder coatings—substances that are protective, decorative, or both-are formed by the application of a coatingpowder to a substrate and fusing the coating into a continuous film by the application of heat or radiant energy. Coatingpowders are finely divided particles of organic polymer that generally contain pigments, fillers, and additives thatremain finely divided during storage under suitable conditions. In contrast to liquid coatings, which may contain volatileorganic solvents, powder coatings can achieve the same or better characteristics of quality, durability, and corrosionresistance. Production costs are lower than those for liquid coatings, because powder coating is a highly efficientprocess that requires less energy and labor. Since powder coatings have no volatile organic solvents, an attractivebenefit is elimination of organic solvent emissions and reduced waste disposal. There are several advantages to using powder coatings compared to liquid coatings: Special effect coatings are more easily accommodated Horizontally and vertically coated surfaces are more similar Near zero VOC and less hazardous waste Thicker coatings for better protection and less running Overspray can be recycled The performance of a powder coating is influenced Dbyy a variety of factors. Powder particle size can have a majorinfluence on many properties, including handling, charging, delivery, and coating characteristics. The formulations mayvary depending on application requirements of thickness, object shape, and ambient conditions. Thermoset powdercoatings react with other compounds in the coating during baking of the finished object. This often increasesperformance. Thermoplastic powder coatings do not contain additional chemicals, but are coated directly as a finalcoating. The Process The powder coating process begins with application of a negative charge to the surface of an object, usually by anelectrical ground. The powder coating is given a charge opposite to that applied to the object, then directed in an airstream under pressure toward the object. When the powder particle is sufficiently close to the charged object,electrostatic attraction dominates and promotes attachment of the powder to the item. Initial handling, recovery, andrecycling of the powder can cause an increase of fines, which, during normal processing, can deposit in pumps ornozzles. Under application pressure these deposits can cause uneven delivery, resulting in uneven or blotchy films.Production and deposition of fines, resulting from particle attrition due to high pressure in the process, can eventuallycause the process to shut down completely. The amount of fines also can affect the overall charge profile of the powder, since fines can be charged more effi-ciently. If sufficient fines are absent, wraparound can be diminished because fines are more easily influenced by anelectrostatic field. Coarse particles have greater mass, and therefore a lower charge/mass ratio; this causes reducedefficiency in tracing the applied electrical field around the object. Incomplete and marginal coating may result. The fineshave a higher charge/mass ratio; this results in a thinner film thickness because coating buildup is limited to theelectrical field, which diminishes as film thickness increases. Powder coating manufacture involves several steps including mixing, extrusion, cooling, kibbling (breaking theextruded mass into chips), grinding, classification, sieving, homogenization, and blending. Pin mills are usually used forgrinding which by its operation allows for some classification where small particles being produced exit the mill and larger particles are retained until smaller size is attained. Powder The Problem As noted above, particle size strongly influences film thickness because fines produce thin initial powder coats andcoarse particles produce thick initial powder coats. As a result, the heated coats melt at different rates, decreasing thesmoothness of the final coating. This is generally known as "orange peel" in all coatings industries. Orange peel canalso be related to the electrostatic process or rheological factors of the powder, both of which are highly dependentupon particle size. The Solution It is evident that the importance of particle size to powder processing should not be underestimated. Microtrac@particle size analyzers can measure powder coatings in the dry state. Generally, the powder coatings are smaller than250 microns (60 mesh, U.S.). The Turbotrac dry feeder with Microtrac S3500 will provide data over the range 0.2 to2000microns within 30 seconds with a totally automatic operating SOP. The advantage of dry measurement of the coatings is that the material is used as a dry powder. However, low-energydry-dispersion systems must be used to avoid potential further milling, thus biasing the reported particle size to finesizes. This could lead to inadvertent mill changes or recycling of recovered powder. Turbotrac's adjustable dispersionenergy,avoids disruption/milling of powder during the measurement. Equally important is the potential for segregationof powder during movement of the powder. The Turbotrac avoids measurement segregation by eliminating vibrationalmovement of the powder to the laser. Powder coating is transferred to a sample trough. The particle size measurementof the sample is performed by an aspiration tube that moves along the trough and conveys sample to the Microtracsensing region. Since the aspiration tube moves toward the sample and not vice versa, segregation effects are avoidedand thus more accurate particle size is provided. As shown below, the data for a powder coating can be presented graphically or numerically. To enhance the capabilityof laser diffraction measurement, the data may be stored in the computer for later retrieval. Data is stored in truedBase-compatible format, rather than the cumbersome text files used by most other particle size analyzers. Thismakes data retrieval and data evaluation much easier. 区 Dry Powder Coating Measured UsingTurbotrac and Microtrac S3500 Microtrac FLEX software contains all necessary features to allow further data analysis as desired. In addition, data canbe exported automatically to LIMS, LAN systems as well as other standard programs such as FoxPro, dBase, Lotus 1-2-3, or Microsoft Excel. Microtrac particle analyzers use a proprietary algorithm that allows direct conversion of scattered light to a volumedistribution. Measurement is fast, easy, and precise with the customized, patented silicon detector array that ismanufactured by specifically for use in Microtrac analyzers. Production under ISO 9001 certification assures customersof unsurpassed consistency and quality of all components. Expert knowledge and 35 years of laser diffractionexperience in all facets of particle size, electronics, and computer technology assure our customers of the bestpossible technical support and customer value. Microtrac S3500 withTurbotrac Dry Feeder Capabilities ▪Avoids segregation and flowability issues of vibratory feeders. ·Effective with narrow and broad distributions. ▪Measures multi-modal distributions without assumptions or curvefitting ▪Full database management capability exportable/importable to allpopular spreadsheets ▪Modular design provides convenient. portable, small size·Simplicity of operation Please visit the Microtrac website for information on the closest global Microtrac sales representative(www.Microtrac.com) or call Microtrac sales managers in the USA/Canada/Mexico South America at 727 507 9770,Europe+49 (0)2150-705-679-0, Asia/Pacific rim Nikkiso, Ltd 81-3-3443-3732. L-AN-Rev CNovember . L-AN-Rev CNovember .

确定

还剩2页未读,是否继续阅读?

大昌华嘉科学仪器为您提供《粉末涂料中微粒的尺寸检测方案 》,该方案主要用于涂料中微粒的尺寸检测,参考标准--,《粉末涂料中微粒的尺寸检测方案 》用到的仪器有麦奇克激光粒度仪 S3500系列

推荐专场

相关方案

更多

该厂商其他方案

更多