方案详情

文

QUV 和Q-SUN的工作原理、主要参数

QUV和Q-SUN如何分别执行相关耐候试验标准(ISO,ASTM,SAE,AATCC,IEC,国标,行标等)

结合不同产品的QUV/Q-SUN试验结果和大气曝晒结果,说明如何根据产品特性、应用场合选用试验设备

方案详情

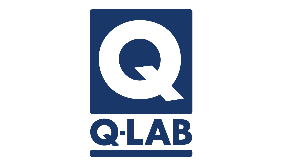

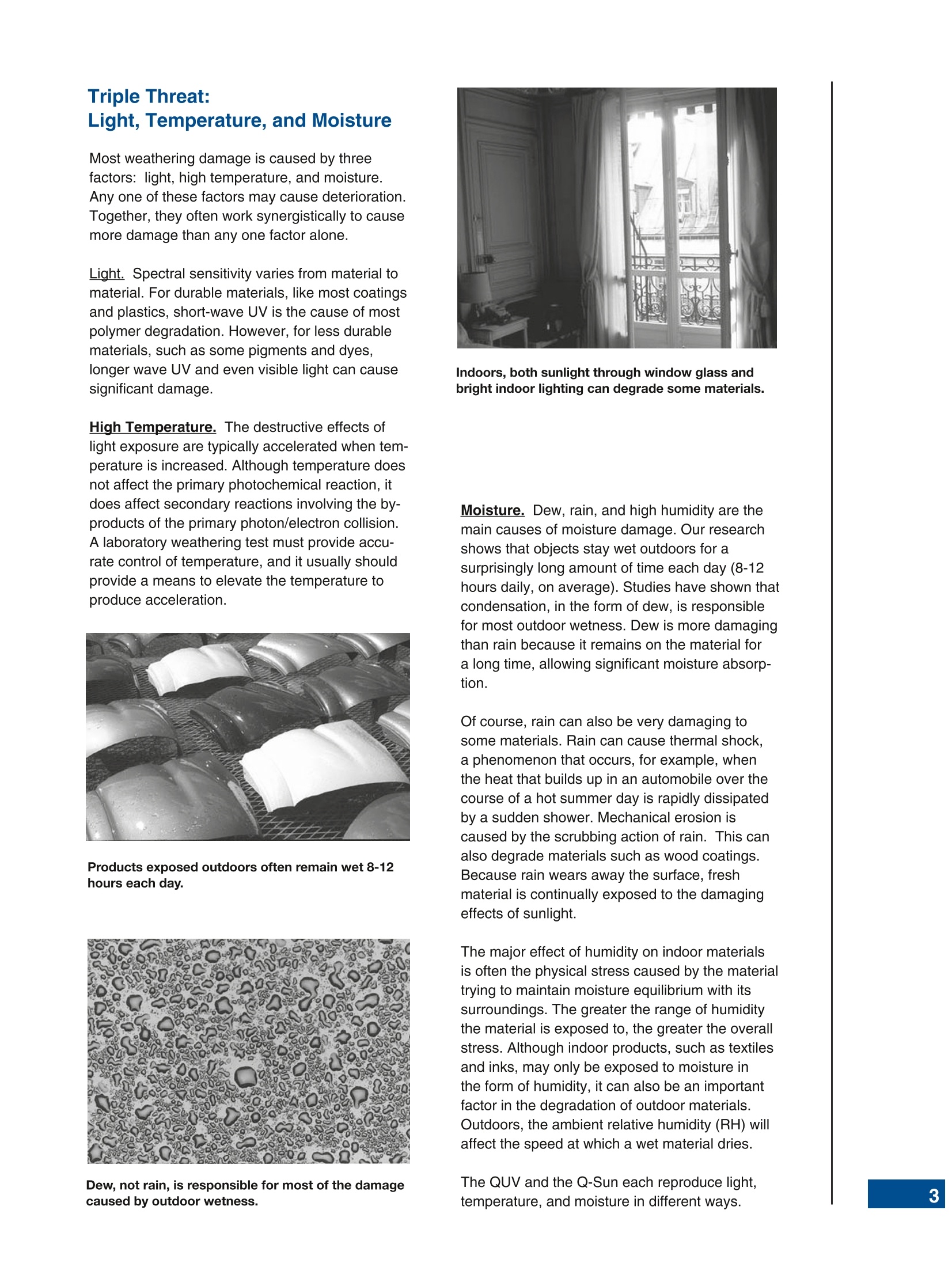

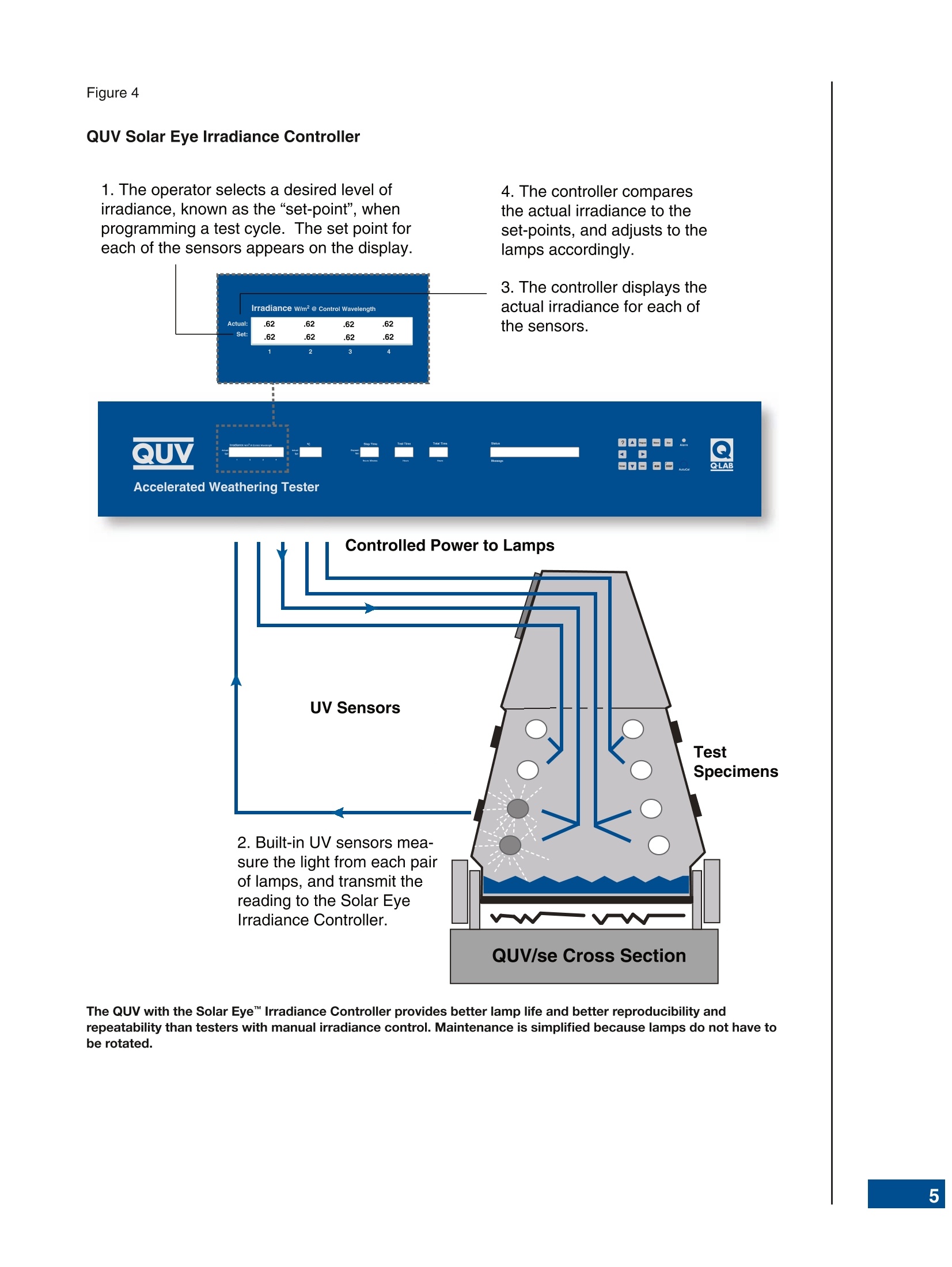

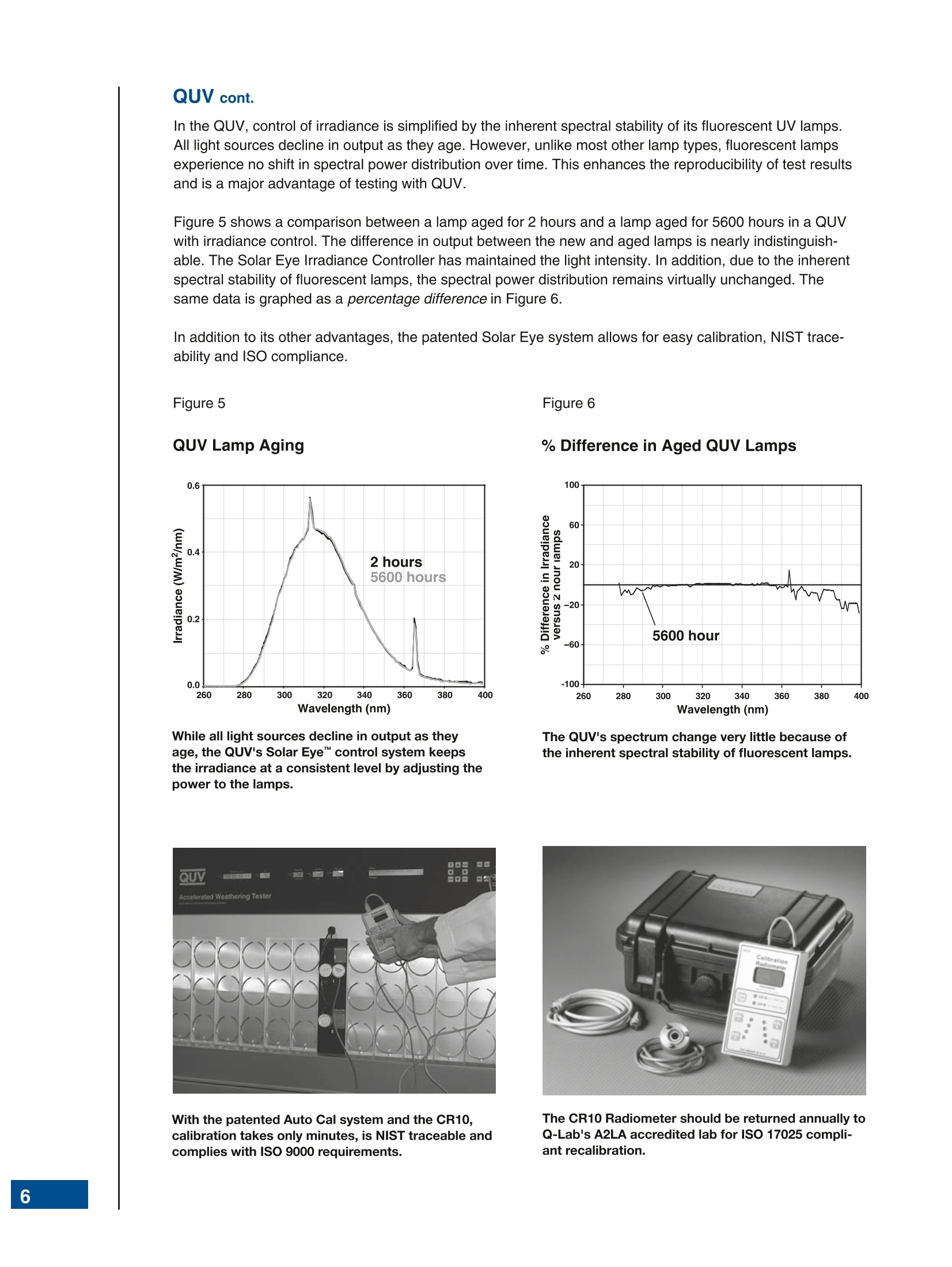

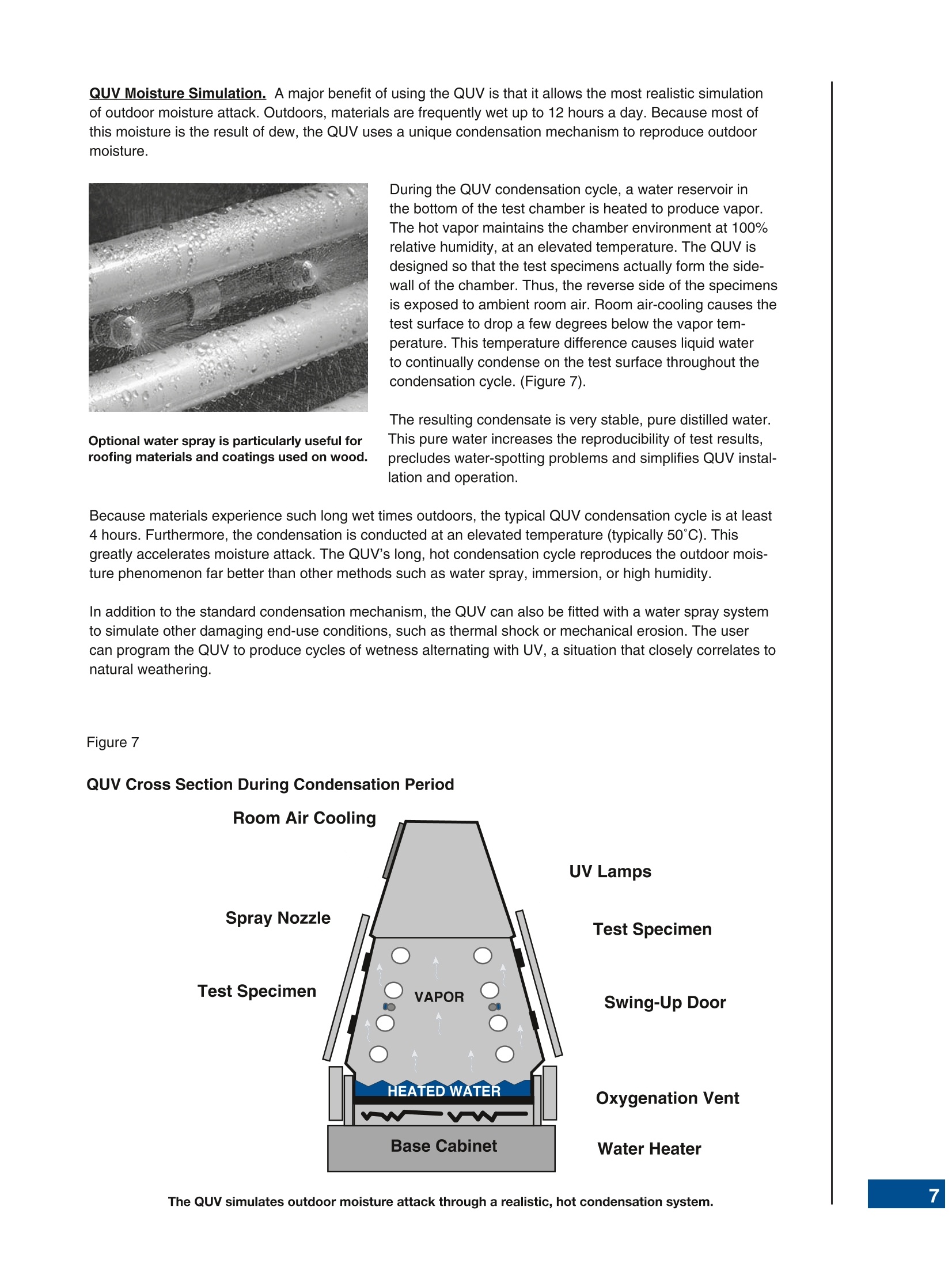

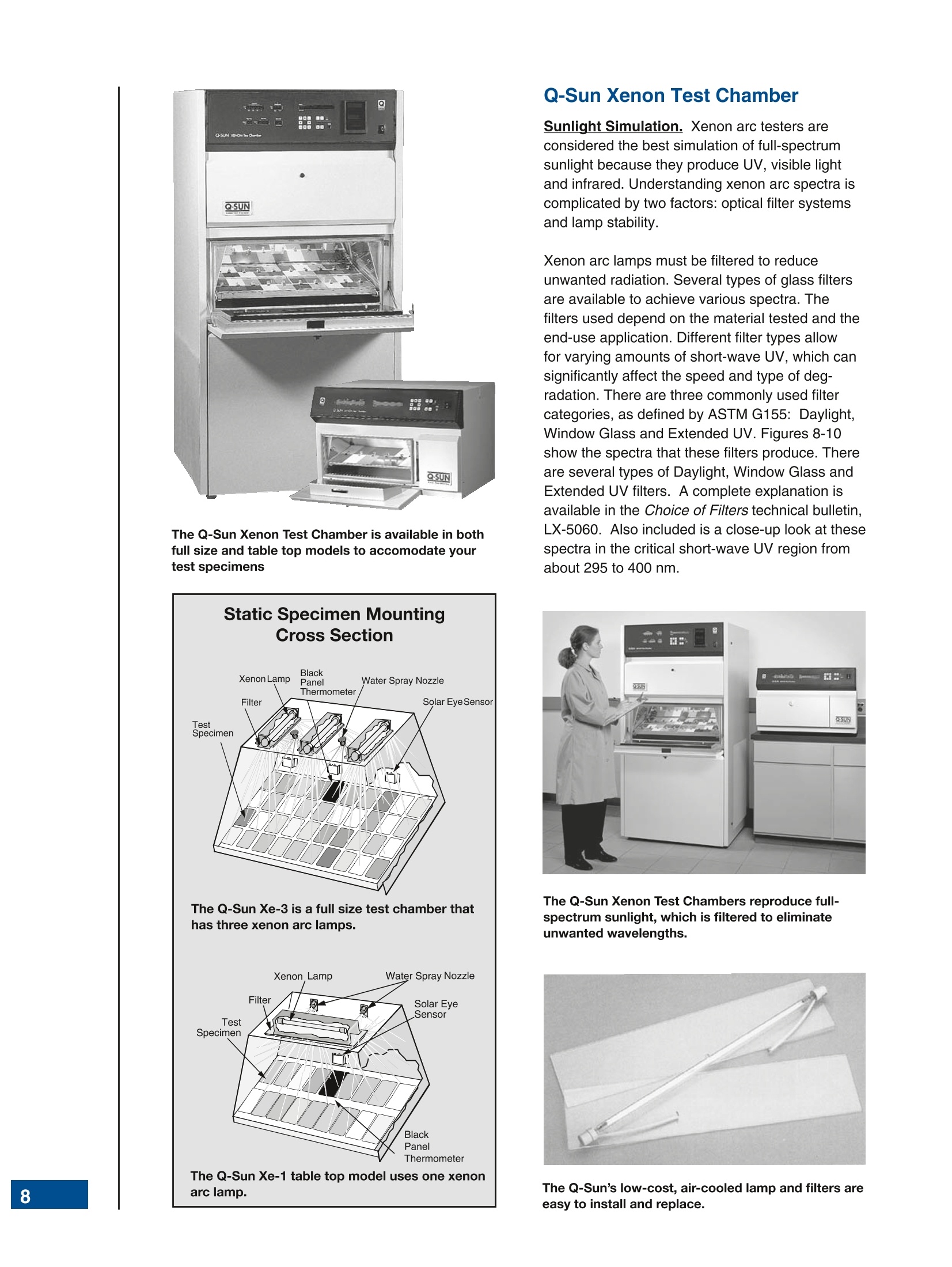

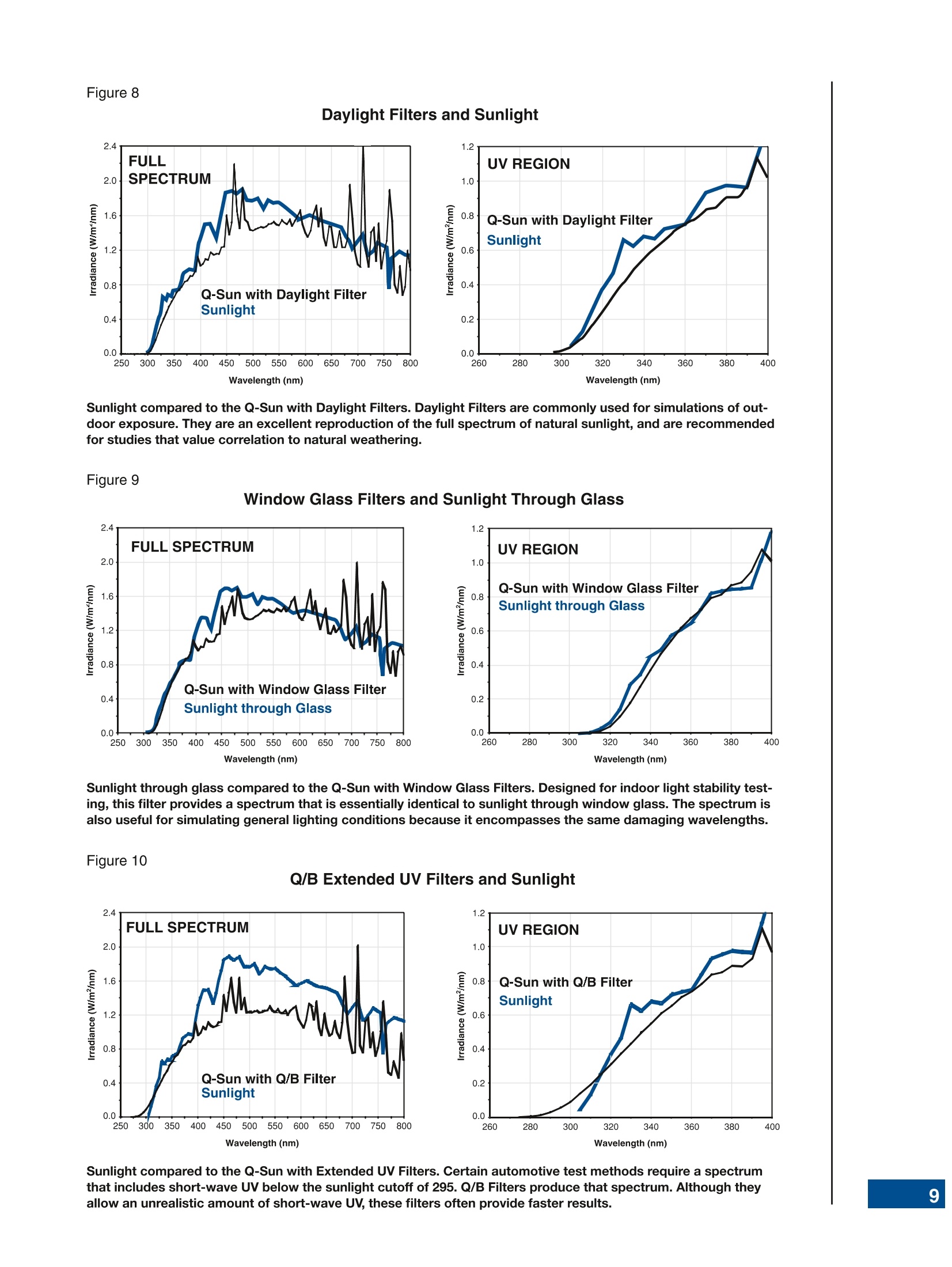

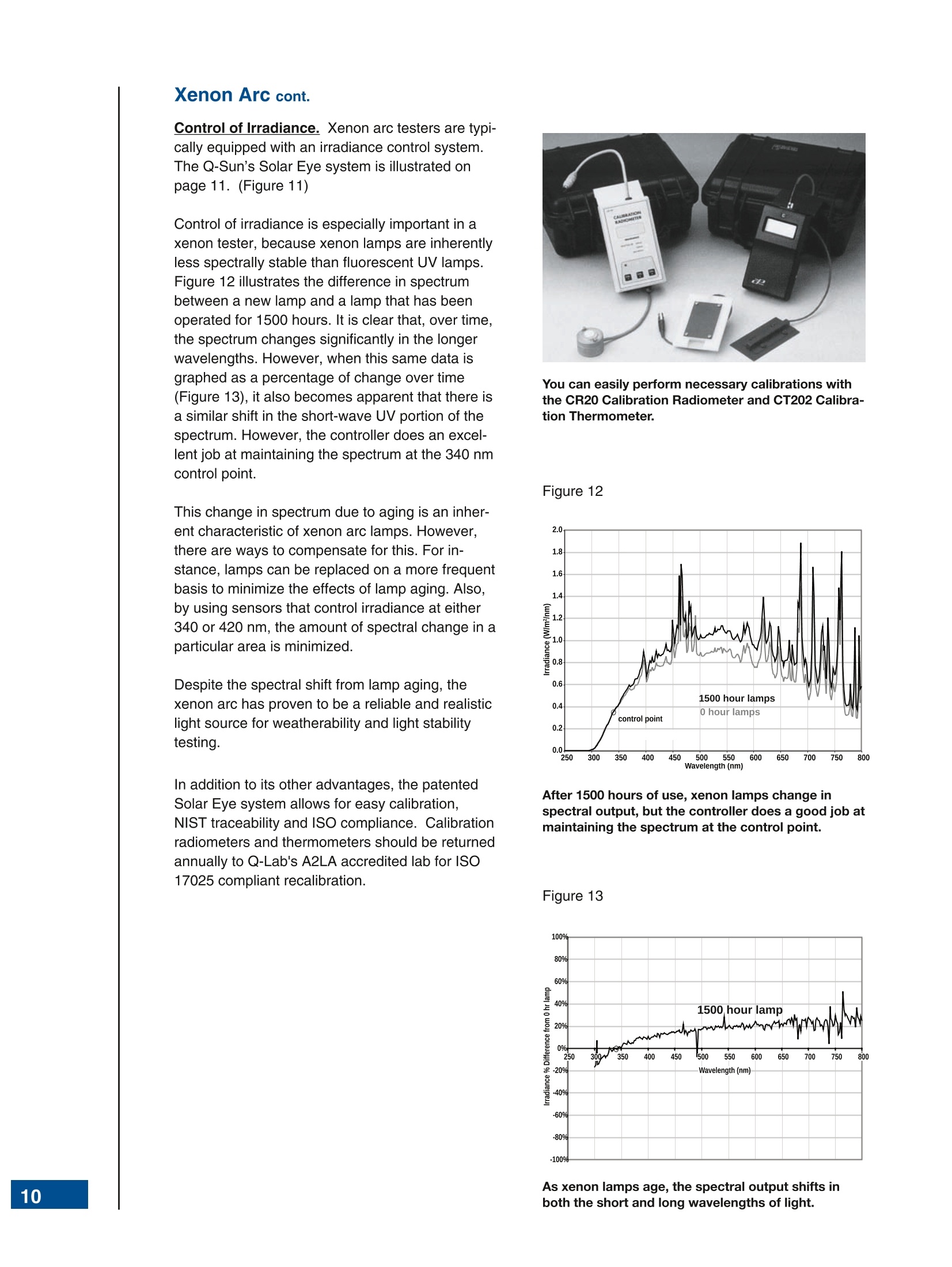

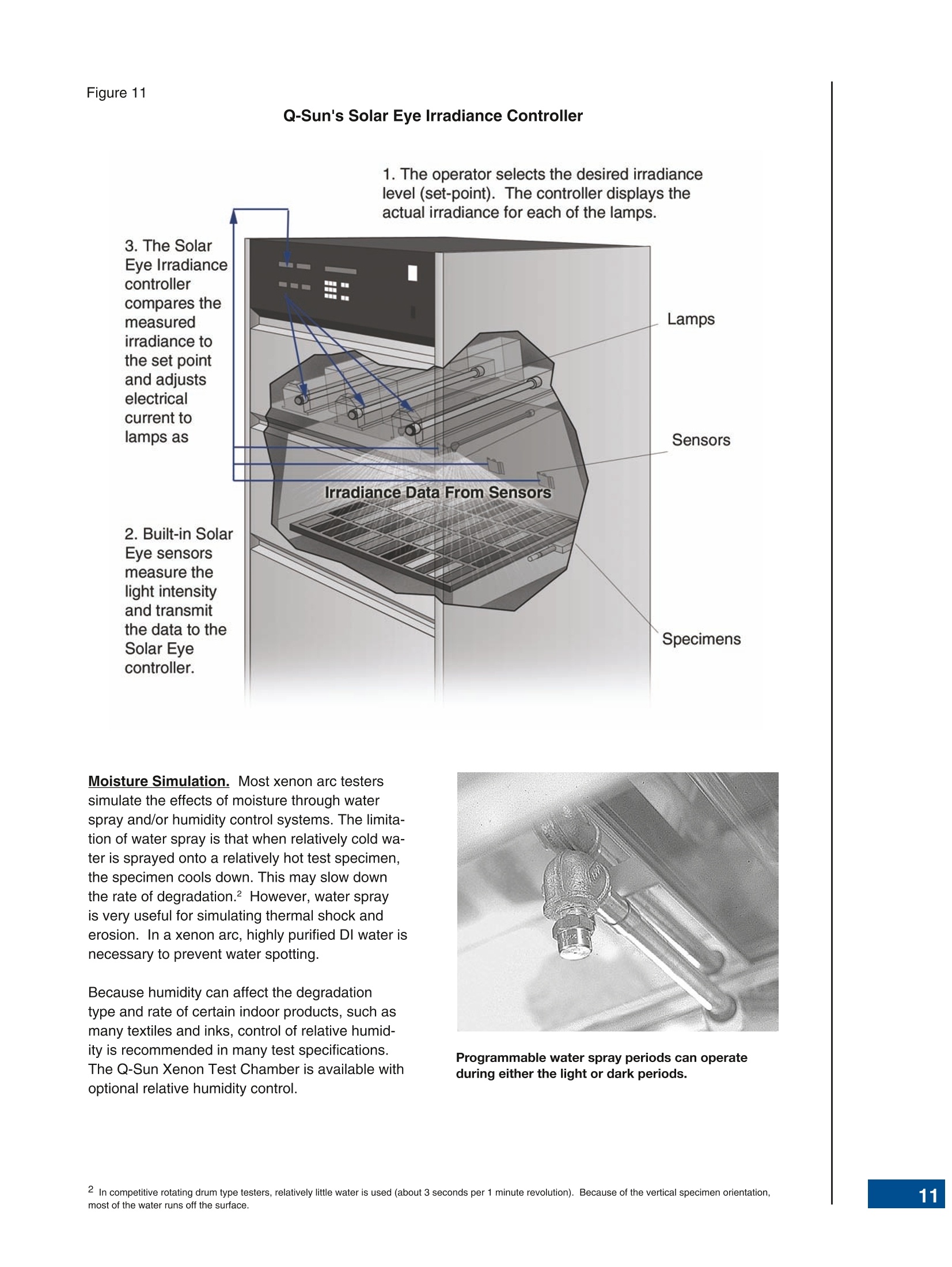

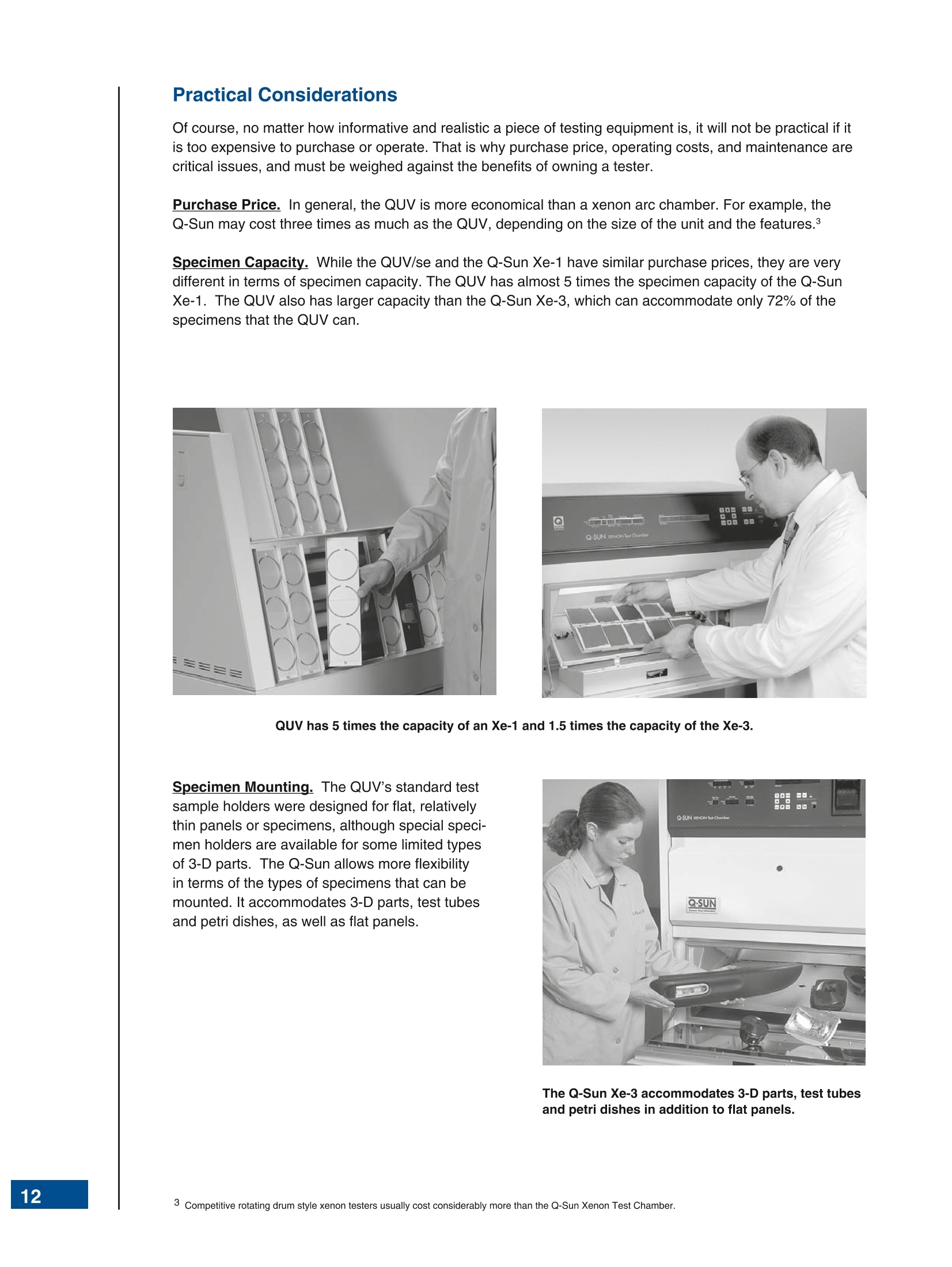

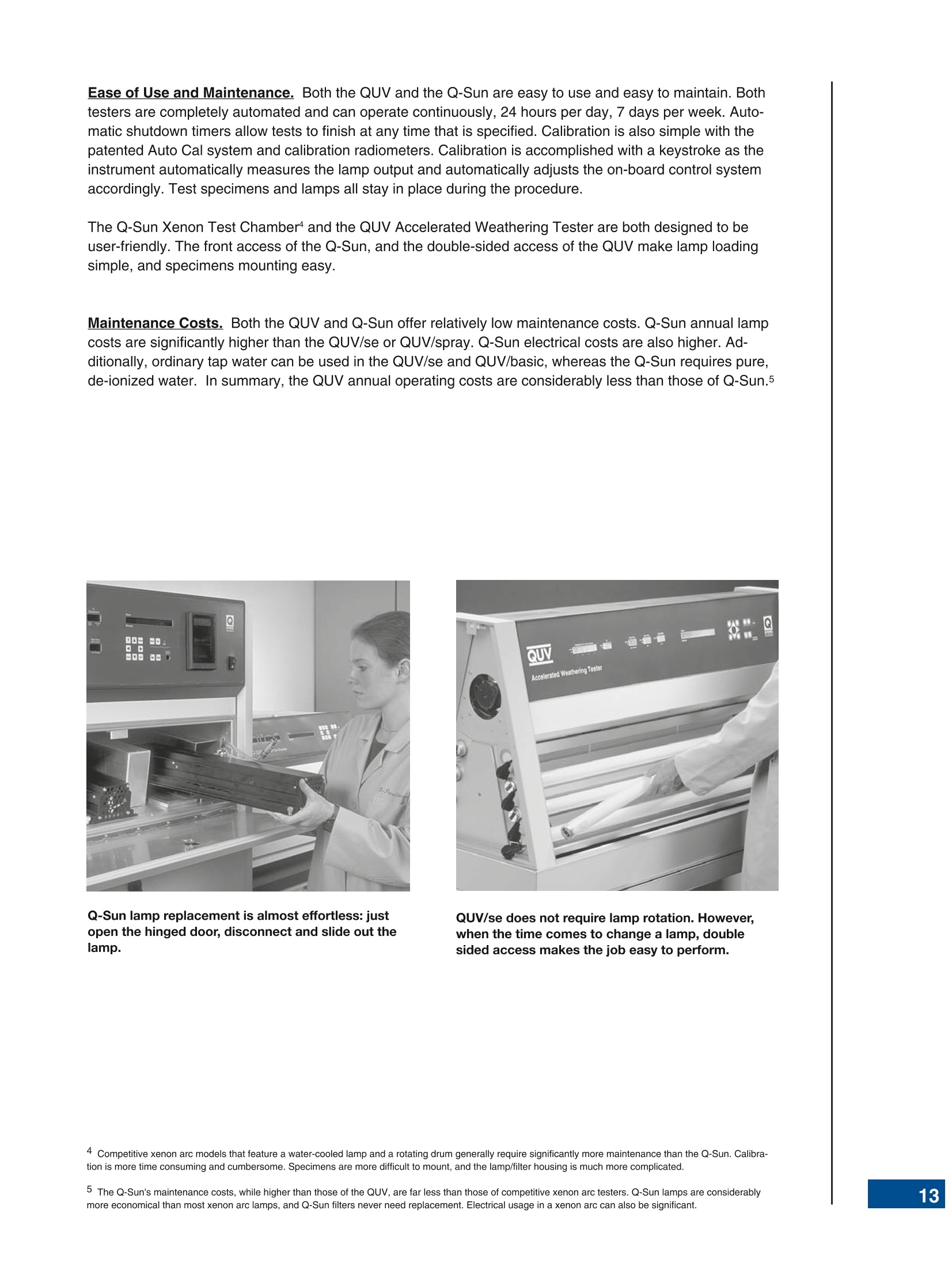

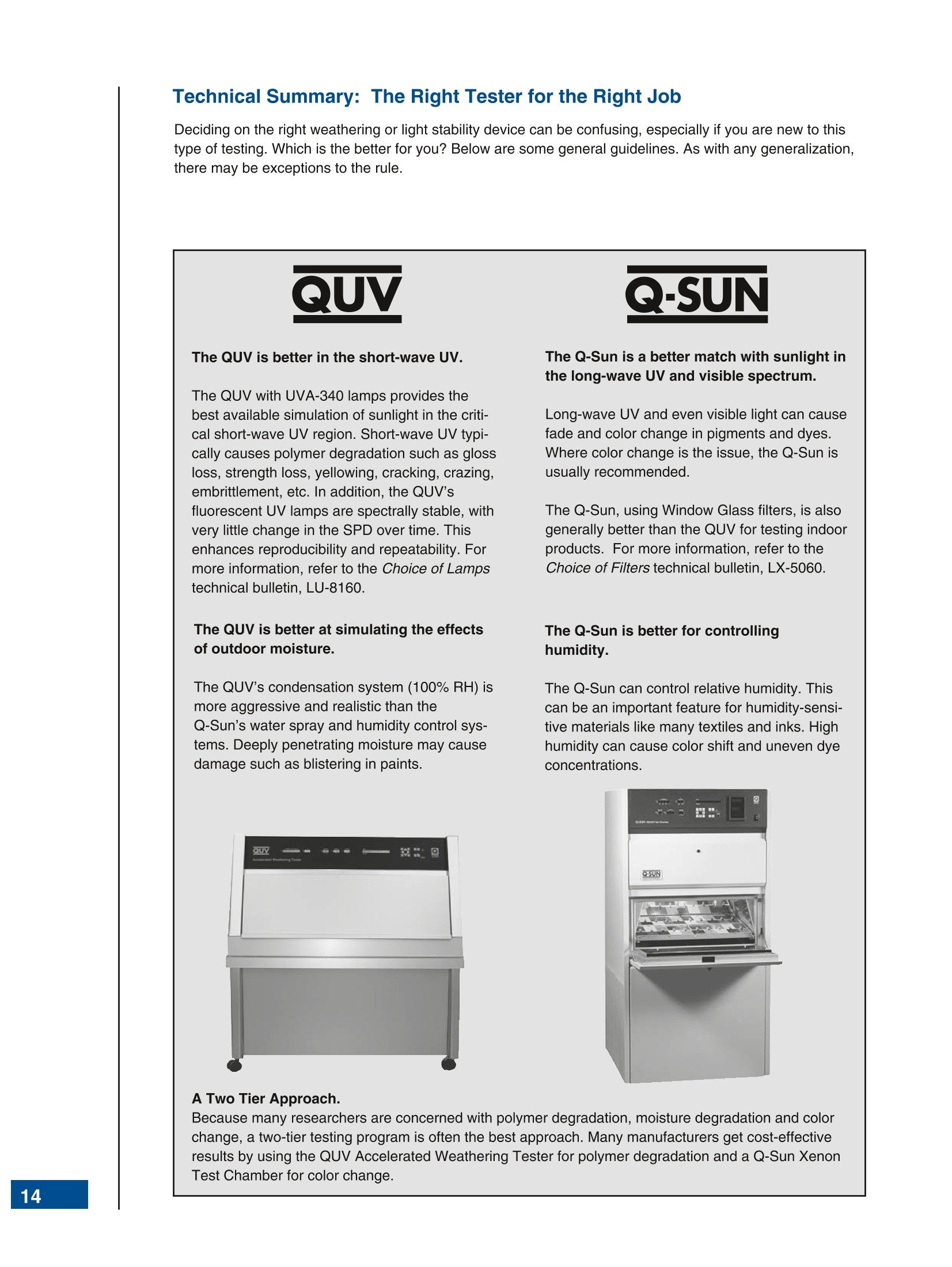

Figure 4 Figure 8 QUV & Q-Sun A Comparison of Two Effective Approachesto Accelerated Weathering & Light Stability Testing 60The Need For Testing Light, high temperature, and moisture, can cause damage to coatings, plastics, inks, and otherorganic materials. This damage includes gloss loss, fading, yellowing, cracking, peeling, embrittle-ment, loss of tensile strength, and delamination. Even indoor lighting and sunlight through windowglass can degrade some materials such as pigments and dyes, causing fade and color change. Zw For many manufacturers, it is crucial to formulate products that can withstand weathering andlight exposure. Accelerated weathering and light stability testers are widely used for research anddevelopment, quality control and material certification. These testers provide fast and reproducibleresults. Two Different Approaches In recent years, low-cost and easy to use laboratory testers have been developed, including theQUV Accelerated Weathering Tester (ASTM G154) and the Q-Sun Xenon Test Chamber (ASTMG155). This paper will explore the ways in which these two testers differ, including emission spectra andmethod of moisture simulation. The inherent strengths and weaknesses of each tester will bediscussed, including purchase price and operating costs. Guidelines will be given for which testeris generally recommended for a particular material or application. The QUV is the world's most widely usedweathering tester. It is based on the concept that,for durable materials,short-wave UV causes mostweathering damage. Q-Sun Xenon Test Chambers reproduce the fullspectrum of sunlight, including ultraviolet, visiblelight and infrared. Historical Perspective While it is clear that weatherability and lightstability are important for many products, the bestway to test is sometimes controversial. Variousmethods have been used over the years. Mostresearchers now use natural exposure testing, theQUV Weathering Tester, or a xenon arc chamber,such as the Q-Sun. Natural exposure testing has many advantages:it is realistic, inexpensive and easy to perform.However, many manufacturers do not have sev-eral years to wait and see if a“new and improved”product formulation is truly an improvement. The Q-Sun (xenon arc) and QUV (fluorescentUV) are the most commonly used acceleratedweathering testers. The two testers are basedon completely different approaches. The xenontest chamber reproduces the entire spectrum ofsunlight, including ultraviolet (UV), visible light,and infrared (IR). The xenon arc is essentially anattempt to simulate sunlight itself, from 295 nm-800 nm (see Figure 1 below). The sunlight spectrum consists of various wave-lengths, which determine a material's mode ofdegradation in an outdoor environment. Figure 1 Sunlight compared to the QUV and the Q-Sun. The QUV provides the best available simulation of sunlight in theshort-wave UV region from 365 nm down to the solar cut-off. However, it is deficient in longer wavelengths. TheQ-Sun reproduces sunlight's full spectrum, which is critical for testing many products that are sensitive to long-wave UV, visible light, and infrared. The QUV, on the other hand, does not attempt to reproduce sunlight, just the damaging effects of sunlightthat can occur from 300 nm - 400 nm. It is based on the concept that, for durable materials exposed out-doors, short-wave UV causes the most weathering damage (Figure 1). Which is the better way to test? There is no simple answer to this question. Depending on your application,either approach can be quite effective. Your choice of tester should depend on the product or material youare testing, the end-use application, the degradation mode with which you are concerned, and your budget-ary restrictions. To understand the differences between the Q-Sun and the QUV, it is necessary to first look more closely atwhy materials degrade. Triple Threat:Light, Temperature, and Moisture Most weathering damage is caused by threefactors: light,high temperature, and moistureAny one of these factors may cause deterioration.Together, they often work synergistically to causemore damage than any one factor alone. Light. Spectral sensitivity varies from material tomaterial. For durable materials, like most coatingsand plastics, short-wave UV is the cause of mostpolymer degradation. However, for less durablematerials, such as some pigments and dyes,longer wave UV and even visible light can causesignificant damage. High Temperature. The destructive effects of light exposure are typically accelerated when tem-perature is increased. Although temperature doesnot affect the primary photochemical reaction, itdoes affect secondary reactions involving the by-products of the primary photon/electron collision.A laboratory weathering test must provide accu-rate control of temperature, and it usually shouldprovide a means to elevate the temperature toproduce acceleration. Products exposed outdoors often remain wet 8-12hours each day. Dew, not rain, is responsible for most of the damagecaused by outdoor wetness. Indoors, both sunlight through window glass andbright indoor lighting can degrade some materials. Moisture. Dew, rain,and high humidity are themain causes of moisture damage. Our researchshows that objects stay wet outdoors for asurprisingly long amount of time each day (8-12hours daily, on average). Studies have shown thatcondensation, in the form of dew, is responsiblefor most outdoor wetness. Dew is more damagingthan rain because it remains on the material fora long time, allowing significant moisture absorp-tion. Of course, rain can also be very damaging tosome materials. Rain can cause thermal shock.a phenomenon that occurs, for example, whenthe heat that builds up in an automobile over thecourse of a hot summer day is rapidly dissipatedby a sudden shower. Mechanical erosion iscaused by the scrubbing action of rain. This canalso degrade materials such as wood coatings.Because rain wears away the surface, freshmaterial is continually exposed to the damagingeffects of sunlight. The major effect of humidityon indoor materialsis often the physical stress caused by the materialtrying to maintain moisture equilibrium with itssurroundings. The greater the range of humiditythe material is exposed to, the greater the overallstress. Although indoor products, such as textilesand inks, may only be exposed to moisture inthe form of humidity, it can also be an important. factor in the degradation of outdoor materials.Outdoors, the ambient relative humidity (RH) willaffect the speed at which a wet material dries. The QUV and the Q-Sun each reproduce light,temperature, and moisture in different ways. The QUV uses fluorescent UV lamps to reproduce thedamaging effects of sunlight on durable materials. Figure 2 UVA-340 lamps provide the best available simulationof sunlight in the critical short-wave UV region. Figure 3 Wavelength (nanometers) UV-B lamps utilize short-wave UV for maximumacceleration and are most useful for testing verydurable materials, or for quality control. Sunlight Simulation. The QUV is designed toreproduce the damaging effects of sunlight ondurable materials using fluorescent UV lamps.These lamps are electrically similar to the com-mon cool white lamps used in general lighting, butare designed to produce mainly UV rather thanvisible light or infrared. There are different types of lamps with differentspectra. The type of lamp should best resemblethe light conditions found in your end use environ-ment. UVA-340 lamps provide the best availablesimulation of sunlight in the critical short-wave UVregion. The spectral power distribution (SPD) ofthe UVA-340 matches sunlight very closely fromthe solar cut-off to about 360 nm (Figure2). UV-Blamps (Figure 3) are also commonly used in theQUV. They typically cause faster degradation thanUV-A lamps, but their short wavelength output be-low the solar cut-off can cause unrealistic resultsfor many materials. In just a few days or weeks, the QUV can reproducethe damage that occurs over months or yearsoutdoors. Control of Irradiance. Control of irradiance (lightintensity) is necessary to achieve accurate andreproducible test results.Most QUV models are.equipped with the Solar Eye Irradiance Control-ler.1 This precision light control system allows theuser to choose the level of irradiance. With theSolar Eye feedback-loop system, the irradianceis continuously and automatically monitored andprecisely maintained. The Solar Eye automaticallycompensates for lamp aging or any other vari-ability by adjusting power to the lamps. Figure 4shows how the irradiance control system works 4. The controller comparesthe actual irradiance to theset-points, and adjusts to thelamps accordingly. 3. The controller displays theactual irradiance for each ofthe sensors. .62 Specimens reading to the Solar EyeIrradiance Controller. QUV/se Cross Section The QUV with the Solar Eye"Irradiance Controller provides better lamp life and better reproducibility andrepeatability than testers with manual irradiance control. Maintenance is simplified because lamps do not have tobe rotated. QUV cont. In the QUV, control of irradiance is simplified by the inherent spectral stability of its fluorescent UV lamps.All light sources decline in output as they age. However, unlike most other lamp types, fluorescent lampsexperience no shift in spectral power distribution over time. This enhances the reproducibility of test resultsand is a major advantage of testing with QUV. Figure 5 shows a comparison between a lamp aged for 2 hours and a lamp aged for 5600 hours in a QUVwith irradiance control. The difference in output between the new and aged lamps is nearly indistinguish-able. The Solar Eye Irradiance Controller has maintained the lightintensity. In addition, due to the inherentspectral stability of fluorescent lamps, the spectral power distribution remains virtually unchanged. Thesame data is graphed as a percentage difference in Figure 6. In addition to its other advantages, the patented Solar Eye system allows for easy calibration, NIST trace-ability and ISO compliance. Figure 5 QUV Lamp Aging While all light sources decline in output as theyage, the QUV's Solar Eye" control system keepsthe irradiance at a consistent level by adjusting thepower to the lamps. With the patented Auto Cal system and the CR10,calibration takes only minutes, is NIST traceable andcomplies with ISO 9000 requirements. % Difference in Aged QUV Lamps The QUV's spectrum change very little because ofthe inherent spectral stability of fluorescent lamps. The CR10 Radiometer should be returned annually toQ-Lab's A2LA accredited lab for ISO 17025 compli-ant recalibration. QUV Moisture Simulation. A major benefit of using the QUV is that it allows the most realistic simulationof outdoor moisture attack. Outdoors, materials are frequently wet up to 12 hours a day. Because most ofthis moisture is the result of dew, the QUV uses a unique condensation mechanism to reproduce outdoormoisture. Optional water spray is particularly useful forroofing materials and coatings used on wood. During the QUV condensation cycle, a water reservoir inthe bottom of the test chamber is heated to produce vapor.The hot vapor maintains the chamber environment at 100%relative humidity, at an elevated temperature. The QUV isdesigned so that the test specimens actually form the side-wall of the chamber. Thus, the reverse side of the specimensis exposed to ambient room air. Room air-cooling causes thetest surface to drop a few degrees below the vapor tem-perature. This temperature difference causes liquid waterto continually condense on the test surface throughout thecondensation cycle.(Figure 7). The resulting condensate is very stable, pure distilled water.This pure water increases the reproducibility of test results,precludes water-spotting problems and simplifies QUV instal-lation and operation. Because materials experience such long wet times outdoors, the typical QUV condensation cycle is at least4 hours. Furthermore, the condensation is conducted at an elevated temperature (typically 50℃). Thisgreatly accelerates moisture attack. The QUV's long, hot condensation cycle reproduces the outdoor mois-ture phenomenon far better than other methods such as water spray, immersion, or high humidity. In addition to the standard condensation mechanism, the QUV can also be fitted with a water spray systemto simulate other damaging end-use conditions, such as thermal shock or mechanical erosion. The usercan program the QUV to produce cycles of wetness alternating with UV, a situation that closely correlates tonatural weathering. Figure7 QUV Cross Section During Condensation Period The Q-Sun Xenon Test Chamber is available in bothfull size and table top models to accomodate yourtest specimens Q-Sun Xenon Test Chamber Sunlight Simulation. Xenon arc testers areconsidered the best simulation of full-spectrumsunlight because they produce UV, visible lightand infrared. Understanding xenon arc spectra iscomplicated by two factors: optical filter systemsand lamp stability. Xenon arc lamps must be filtered to reduceunwanted radiation. Several types of glass filtersare available to achieve various spectra. Thefilters used depend on the material tested and theend-use application. Different filter types allowfor varying amounts of short-wave UV, which cansignificantly affect the speed and type of deg-radation. There are three commonly used filtercategories, as defined by ASTM G155: Daylight,Window Glass and Extended UV. Figures 8-10show the spectra that these filters produce. Thereare several types of Daylight, Window Glass andExtended UV filters. A complete explanation isavailable in the Choice of Filters technical bulletin,LX-5060. Also included is a close-up look at thesespectra in the critical short-wave UV region fromabout 295 to 400 nm. The Q-Sun Xenon Test Chambers reproduce full·spectrum sunlight, which is filtered to eliminateunwanted wavelengths. The Q-Sun’s low-cost, air-cooled lamp and filters areeasy to install and replace. Daylight Filters and Sunlight Sunlight compared to the Q-Sun with Daylight Filters. Daylight Filters are commonly used for simulations of out-door exposure. They are an excellent reproduction of the full spectrum of natural sunlight, and are recommendedfor studies that value correlation to natural weathering. Figure 9 Window Glass Filters and Sunlight Through Glass Sunlight through glass compared to the Q-Sun with Window Glass Filters. Designed for indoor light stability test-ing, this filter provides a spectrum that is essentially identical to sunlight through window glass. The spectrum isalso useful for simulating general lighting conditions because it encompasses the same damaging wavelengths. Figure 10Q/B Extended UV Filters and Sunlight Sunlight compared to the Q-Sun with Extended UV Filters. Certain automotive test methods require a spectrumthat includes short-wave UV below the sunlight cutoff of 295. Q/B Filters produce that spectrum. Although theyallow an unrealistic amount of short-wave UV, these filters often provide faster results. Control of Irradiance. Xenon arc testers are typi-cally equipped with an irradiance control system.The Q-Sun’s Solar Eye system is illustrated onpage 11. (Figure 11) Control of irradiance is especially important in axenon tester, because xenon lamps are inherentlyless spectrally stable than fluorescent UV lamps.Figure 12 illustrates the difference in spectrumbetween a new lamp and a lamp that has beenoperated for 1500 hours. It is clear that, over time,the spectrum changes significantly in the longerwavelengths. However, when this same data isgraphed as a percentage of change over time(Figure 13), it also becomes apparent that there isa similar shift in the short-wave UV portion of thespectrum.However, the controller does an excel-lent job at maintaining the spectrum at the 340 nmcontrol point. This change in spectrum due to aging is an inher-ent characteristic of xenon arc lamps. However,there are ways to compensate for this. For in-stance, lamps can be replaced on a more frequentbasis to minimize the effects of lamp aging.Also,by using sensors that control irradiance at either340 or 420 nm, the amount of spectral change in aparticular area is minimized. Despite the spectral shift from lamp aging, thexenon arc has proven to be a reliable and realisticlight source for weatherability and light stabilitytesting. In addition to its other advantages, the patentedSolar Eye system allows for easy calibration,NIST traceability and ISO compliance. Calibrationradiometers and thermometers should be returnedannually to Q-Lab's A2LA accredited lab for ISO17025 compliant recalibration. You can easily perform necessary calibrations withthe CR20 Calibration Radiometer and CT202 Calibra-tion Thermometer. Figure 12 After 1500 hours of use, xenon lamps change inspectral output, but the controller does a good job atmaintaining the spectrum at the control point. Figure 13 250 350 400 450 500 550 600 650 700 750 Wavelength (nm) As xenon lamps age, the spectral output shifts inboth the short and long wavelengths of light. 1. The operator selects the desired irradiancelevel (set-point). The controller displays the Solar Eye controller. Moisture Simulation. Most xenon arc testerssimulate the effects of moisture through waterspray and/or humidity control systems.The limita-tion of water spray is that when relatively cold wa-ter is sprayed onto a relatively hot test specimen,the specimen cools down. This may slow downthe rate of degradation.2However, water sprayis very useful for simulating thermal shock anderosion. In a xenon arc, highly purified DI water isnecessary to prevent water spotting. Because humidity can affect the degradationtype and rate of certain indoor products, such asmany textiles and inks, control of relative humid-ity is recommended in many test specifications.The Q-Sun Xenon Test Chamber is available withoptional relative humidity control. Programmable water spray periods can operateduring either the light or dark periods. Practical Considerations Of course, no matter how informative and realistic a piece of testing equipment is, it will not be practical if itis too expensive to purchase or operate. That is why purchase price, operating costs, and maintenance arecritical issues, and must be weighed against the benefits of owning a tester. Purchase Price. In general, the QUV is more economical than a xenon arc chamber. For example, theQ-Sun may cost three times as much as the QUV,depending on the size of the unit and the features.3 Specimen Capacity. While the QUV/se and the Q-Sun Xe-1 have similar purchase prices, they are verydifferent in terms of specimen capacity. The QUV has almost 5 times the specimen capacity of the Q-SunXe-1. The QUV also has larger capacity than the Q-Sun Xe-3, which can accommodate only 72% of thespecimens that the QUV can. 三三三=QUV has 5 times the capacity of an Xe-1 and 1.5 times the capacity of the Xe-3. Specimen Mounting. The QUV's standard testsample holders were designed for flat, relativelythin panels or specimens, although special speci-men holders are available for some limited typesof 3-D parts. The Q-Sun allows more flexibilityin terms of the types of specimens that can bemounted. It accommodates 3-D parts, test tubesand petri dishes, as well as flat panels. The Q-Sun Xe-3 accommodates 3-D parts, test tubesand petri dishes in addition to flat panels. Ease of Use and Maintenance. Both the QUV and the Q-Sun are easy to use and easy to maintain. Bothtesters are completely automated and can operate continuously, 24 hours per day, 7 days per week. Auto-matic shutdown timers allow tests to finish at any time that is specified. Calibration is also simple with thepatented Auto Cal system and calibration radiometers. Calibration is accomplished with a keystroke as theinstrument automatically measures the lamp output and automatically adjusts the on-board control systemaccordingly. Test specimens and lamps all stay in place during the procedure. The Q-Sun Xenon Test Chamber and the QUV Accelerated Weathering Tester are both designed to beuser-friendly. The front access of the Q-Sun, and the double-sided access of the QUV make lamp loadingsimple, and specimens mounting easy. Maintenance Costs. Both the QUV and Q-Sun offer relatively low maintenance costs. Q-Sun annual lampcosts are significantly higher than the QUV/se or QUV/spray. Q-Sun electrical costs are also higher. Ad-ditionally, ordinary tap water can be used in the QUV/se and QUV/basic, whereas the Q-Sun requires pure,de-ionized water. In summary, the QUV annual operating costs are considerably less than those of Q-Sun.5 Q-Sun lamp replacement is almost effortless:justopen the hinged door, disconnect and slide out thelamp. ( 4 C ompetitive x e non arc models that fe a ture a water-cooled la m p and a r o tating dr u m gen e rally require significantly more maintenance tha n the Q-S u n. Calibra- tion is more time consuming and cumbersome. Sp e cimens are m ore difficult to mount, an d the la m p/filter housing is much more complicated. ) Technical Summary: The Right Tester for the Right Job Deciding on the right weathering or light stability device can be confusing,especially if you are new to thistype of testing. Which is the better for you? Below are some general guidelines. As with any generalization,there may be exceptions to the rule. The QUV is better in the short-wave UV. The QUV with UVA-340 lamps provides thebest available simulation of sunlight in the criti-cal short-wave UV region. Short-wave UV typi-cally causes polymer degradation such as glossloss, strength loss, yellowing, cracking,crazing,embrittlement, etc. In addition, the QUV'sfluorescent UV lamps are spectrally stable,withvery little change in the SPD over time. Thisenhances reproducibility and repeatability. Formore information, refer to the Choice of Lampstechnical bulletin, LU-8160. The QUV is better at simulating the effectsof outdoor moisture. The QUV's condensation system (100% RH) ismore aggressive and realistic than theQ-Sun’s water spray and humidity control sys-tems. Deeply penetrating moisture may causedamage such as blistering in paints. A Two Tier Approach. The Q-Sun is a better match with sunlight inthe long-wave UV and visible spectrum. Long-wave UV and even visible light can causefade and color change in pigments and dyes.Where color change is the issue, the Q-Sun isusually recommended. The Q-Sun, using Window Glass filters, is alsogenerally better than the QUV for testing indoorproducts. For more information, refer to theChoice of Filters technical bulletin,LX-5060. The Q-Sun is better for controllinghumidity. The Q-Sun can control relative humidity. Thiscan be an important feature for humidity-sensi-tive materials like many textiles and inks. Highhumidity can cause color shift and uneven dyeconcentrations. SUN Because many researchers are concerned with polymer degradation, moisture degradation and colorchange, a two-tier testing program is often the best approach. Many manufacturers get cost-effectiveresults by using the QUV Accelerated Weathering Tester for polymer degradation and a Q-Sun XenonTest Chamber for color change. Test Methods (partial list) QUV Accelerated Weathering Tester Q-Sun Xenon Test Chamber General General InkS Textiles Plastics Roofing Cosmetics Packaging Foodstuffs Pharmaceuticals Building Materials Paints and Coatings Sealants and Adhesives Automotive Components Q-Lab Corporation Q-Lab Headquarters Q-Lab Europe Q-Lab China & Instruments Division Express Trading Estate Room 1809/1810, Liangyou Bld. 800 Canterbury Road Stonehill Road, Farnworth 618 Shangcheng Road Cleveland, OH 44145 USA Bolton, BL4 9TP England Pudong District Phone: 440-835-8700 Phone: 00-44-(0) 1204-861616 Shanghai, China 200120 Fax: 4 4 0 - 8 3 5 - 8 7 3 8 Fax: 00-44-(0) 1204-861617 Phone:0-86-21-5879-7970 Fax: 0-86-21-5879-7960 www.q-lab.com C 2006 Q-Lab Corporation. info@q-lab.com All Rights Reserved.

确定

还剩14页未读,是否继续阅读?

美国Q-Lab公司中国代表处为您提供《材料,成品中耐候老化性能检测方案(其它试验箱)》,该方案主要用于其他中耐候老化性能检测,参考标准--,《材料,成品中耐候老化性能检测方案(其它试验箱)》用到的仪器有Q-Lab 老化测试研究服务

相关方案

更多