本文章详细介绍了牛奶中钾离子的测定,包括校准液、水样的准备,校准和测量过程,以及电极和仪表的维护等内容。

方案详情

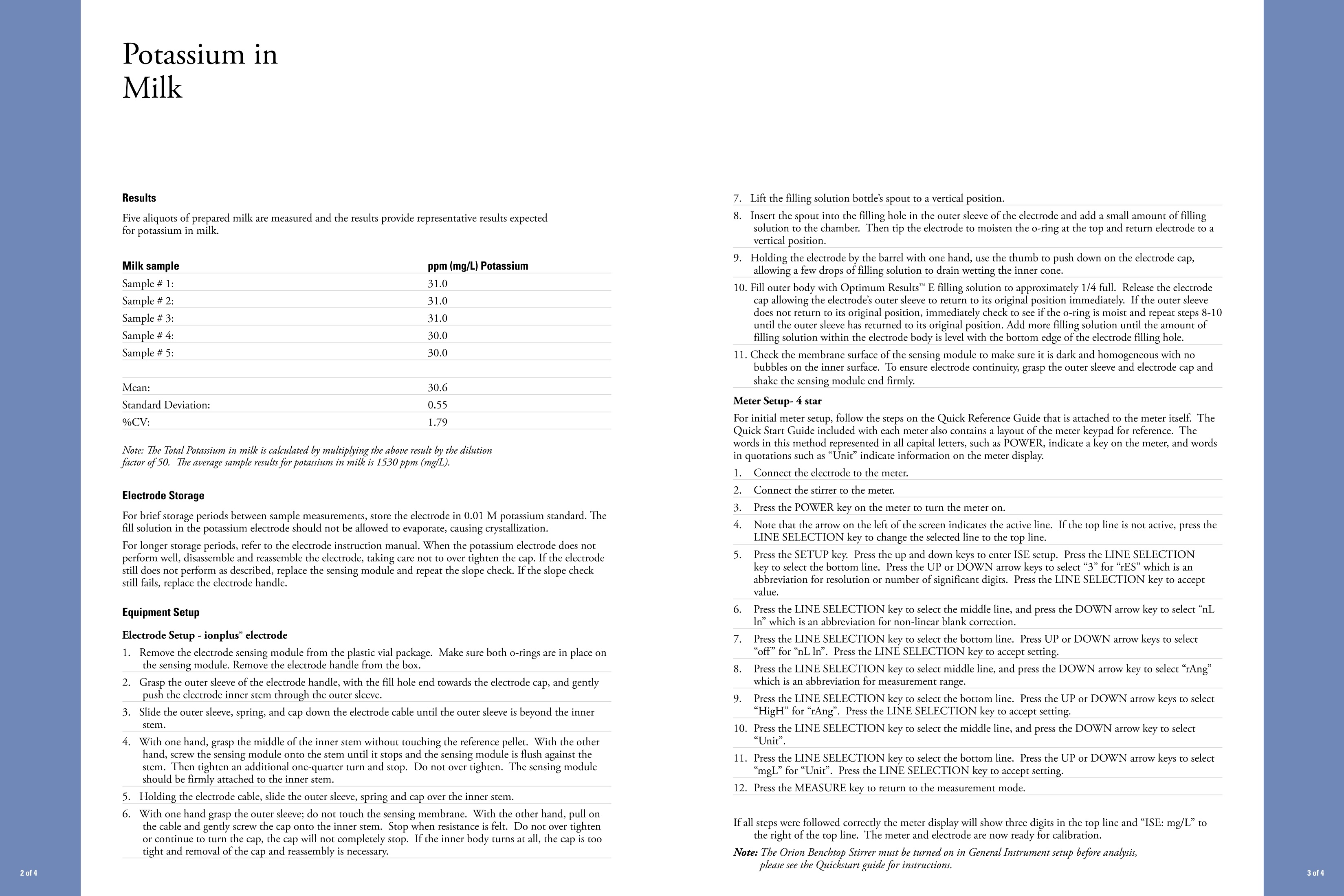

Potassium inMilk Calibration and Analysis 1. Allow all the standards and the samples to attain room temperature for precise measurementssince the measurement is temperature sensitive. 2.Calibrate the meter using the 10 ppm followed by the 100 ppm standard, stirring the standardsat a gentle and uniform rate. 3P.lace the electrode and stirrer into the beaker with the 10 ppm standard with the electrode tip fullyimmersed in the solution. The stirrer should be positioned slightly below the tip of the electrode.Press the STIRRER key on the meter to turn the stirrer on. Press the CALIBRATE key. 4.Wait for a stable reading (1-2 minutes). Enter the standard value of“10”using the UP and DOWNarrow keys and the DECIMAL/DIGIT key. 5. Press the CALIBRATE key to accept the 10 ppm standard and press the STIRRER key toturn the stirrer off. 6.Rinse electrode and stirrer thoroughly with deionized water. Gently remove excess solution from theouter sleeve of the electrode by dabbing with a clean paper tissue. Do not wipe or rub the sensingelement of the electrode. 7. Place the probe and stirrer into the beaker with the 10 ppm standard with the electrode tip fullyimmersed in the solution. The stirrer should be positioned slightly below the tip of the electrode.Press the STIRRER key on the meter to turn the stirrer on. 8.Wait for a stable reading (1-2 minutes). Enter the standard value of“100” using the UP and DOWNarrow keys and the DECIMAL/DIGIT key. 9.Press the MEASURE key to accept the 100 ppm standard and to move to the measure mode of themeter. Press the STIRRER key to turn the stirrer off. 10. Rinse electrode and stirrer thoroughly with deionized water. Gently remove excess solution from theouter sleeve of the electrode by dabbing with a clean paper tissue. Do not wipe or rub the sensingelement of the electrode. 11. Place the probe and stirrer in a prepared sample with the electrode tip fully immersed in the solution.Press the MEASURE key on the meter; the stirrer will turn on. The ISE: mg/L icon will flash as themeasurement is being made. The ISE:mg/L icon will become solid and the display value will freezewhen a stable reading is achieved. This value is logged and printed automatically and the stirrer turnsoff automatically. 12. Repeat steps 10 and 11 for additional samples. Upon completion of samples, rinse electrode withdeionized water and store the electrode according to instructions in the Electrode Storage section ofthis method note. Potassium inMilk Introduction This method measures the potassium ion in milk. The Orion 9719 Potassium Combination Electrodemeasures potassium in aqueous solutions simply, accurately and economically. The Potassium Ionplus°electrode is capable of measuring potassium concentration from 0.04 to 39,000 ppm potassium. Thefree-flowing Sure-Flowjunction assures stable, drift-free potentials. Recommended Equipment Cat. No. Potassium Application Package (includes all items with a catalog no) 1010135 1. 4-Star benchtop pH/ISE meter 1115000 2. Ionplus° potassium electrode 9719BNWP 3. Orion benchtop stirrer (or magnetic stir plate and bar) 096019 4. Orion benchtop electrode stand 1110001 5. Beakers (50mL) 6. Graduated cylinders (5 mL and 50mL) 7. Pipettes (10 mL) and a digital pipette 8.Volumetric flasks (100 mL and 500 mL) Required Solutions Cat. No 1. 0.1M potassium as KCl 921906 2. ISA-Ionic strength Adjuster for Potassium Electrode 93191 3. Reference Filling Solution, Optimum Results"E 900065 4. Deionized water Calibration Standard Preparation 1. To prepare a 100 ppm potassium standard: pipette 2.56 mL of the 3900 ppm (0.1 M) potassiumstandard and 2 mL of the potassium ISA solution into a 100 mL volumetric flask. Dilute to the markwith deionized water. Mix well. 2.To prepare a 10 ppm potassium standard: pipette 10 mL of the 100 ppm potassium standard preparedabove, and 2 mL of the potassium ISA solution into a 100 mL volumetric flask. Dilute to the markwith deionized water. Mix well. 3. Using a graduated cylinder, transfer 30 mL of the 10 ppm standard into a 50 mL beaker. .44. Using a graduated cylinder, transfer 30 mL of the 100 ppm standard into a 50 mL beaker. Sample Preparation 1.Pipette 10 mL of the milk sample into a 500 mL volumetric flask. Add 10 mL potassium ISA to thesame flask. Dilute to the mark with deionized water. Mix well. 2.Using a graduated cylinder, measure 30 mL of the sample into a 50 mL beaker. 3. Repeat this procedure for additional measurements. Five aliquots of prepared milk are measured and the results provide representative results expectedfor potassium in milk Milk sample ppm (mg/L) Potassium Sample #1: 31.0Sample # 2: 31.0Sample #3: 31.0Sample # 4: 30.0Sample # 5: 30.0 %CV: Mean: 30.6. Standard Deviation: 0.551.79 Note: The Total Potassium in milk is calculated by multiplying the above result by the dilutionfactor of50. The average sample results for potassium in milk is 1530 ppm (mg/L). Electrode Storage For brief storage periods between sample measurements, store the electrode in 0.01 M potassium standard. Thefill solution in the potassium electrode should not be allowed to evaporate, causing crystallization. For longer storage periods, refer to the electrode instruction manual. When the potassium electrode does notperform well, disassemble and reassemble the electrode, taking care not to over tighten the cap. If the electrodestill does not perform as described, replace the sensing module and repeat the slope check. If the slope checkstill fails, replace the electrode handle. Equipment Setup Electrode Setup-ionplus°electrode 1. Remove the electrode sensing module from the plastic vial package. Make sure both o-rings are in place onthe sensing module. Remove the electrode handle from the box. 2. Grasp the outer sleeve of the electrode handle, with the fill hole end towards the electrode cap, and gentlypush the electrode inner stem through the outer sleeve. 3. Slide the outer sleeve, spring, and cap down the electrode cable until the outer sleeve is beyond the innerstem. .44.With one hand, grasp the middle of the inner stem without touching the reference pellet. With the otherhand, screw the sensing module onto the stem until it stops and the sensing module is flush against thestem. Then tighten an additional one-quarter turn and stop. Do not over tighten. The sensing moduleshould be firmly attached to the inner stem.1. 5.Holding the electrode cable, slide the outer sleeve, spring and cap over the inner stem. 6.With one hand grasp the outer sleeve; do not touch the sensing membrane. With the other hand, pull onthe cable and gently screw the cap onto the inner stem. Stop when resistance is felt. Do not over tightenor continue to turn the cap, the cap will not completely stop. If the inner body turns at all, the cap is tootight and removal of the cap and reassembly is necessary. 7. Lift the filling solution bottle’s spout to a vertical position. 8.Insert the spout into the filling hole in the outer sleeve of the electrode and add a small amount of fillingsolution to the chamber. Then tip the electrode to moisten the o-ring at the top and return electrode to avertical position. 9.). HIolding the electrode by the barrel with one hand, use the thumb to push down on the electrode cap,allowing a few drops of filling solution to drain wetting the inner cone. 10. Fill outer body with Optimum Results""E filling solution to approximately 1/4 full. Release the electrodecap allowing the electrode’s outer sleeve to return to its original position immediately. If the outer sleevedoes not return to its original position, immediately check to see if the o-ring is moist and repeat steps 8-10until the outer sleeve has returned to its original position. Add more filling solution until the amount of.....filling solution within the electrode body is level with the bottom edge of the electrode filling hole. 11. Check the membrane surface of the sensing module to make sure it is dark and homogeneous with nobubbles on the inner surface. To ensure electrode continuity, grasp the outer sleeve and electrode cap andshake the sensing module end firmly. Meter Setup-4 star For initial meter setup, follow the steps on the Quick Reference Guide that is attached to the meter itself. TheQuick Start Guide included with each meter also contains a layout of the meter keypad for reference. Thewords in this method represented in all capital letters, such as POWER, indicate a key on the meter, and wordsin quotations such as“Unit"indicate information on the meter display. 1. Connect the electrode to the meter 2Connect the stirrer to the meter.3Press the POWERkey on the meter to turn the meter on. 4. Note that the arrow on the left of the screen indicates the active line. If the top line is not active, press theLINE SELECTION key to change the selected line to the top line. 5. Press the SETUP key. Press the up and down keys to enter ISE setup. Press the LINE SELECTIONkey to select the bottom line. Press the UP or DOWN arrow keys to select“3”for “rES” which is anabbreviation for resolution or number of significant digits. Press the LINE SELECTION key to acceptvalue. .6 Press the LINE SELECTION key to select the middle line, and press the DOWN arrow key to select “nLIn"which is an abbreviation for non-linear blank correction. 7 Press the LINE SELECTION key to select the bottom line. Press UP or DOWN arrow keys to select“off” for“nL ln". Press the LINE SELECTION key to accept setting. 8 Press the LINE SELECTION key to select middle line, and press the DOWN arrow key to select “rAng"which is an abbreviation for measurement range. 9 Press the LINE SELECTION key to select the bottom line. Press the UP or DOWN arrow keys to select“HigH" for “rAng”. Press the LINE SELECTION key to accept setting. 10. Press the LINE SELECTION key to select the middle line, and press the DOWN arrow key to select“Unit”. 11. Press the LINE SELECTION key to select the bottom line. Press the UP or DOWN arrow keys to select“mgL" for “Unit". Press the LINE SELECTION key to accept setting. 12. Press the MEASURE key to return to the measurement mode. If all steps were followed correctly the meter display will show three digits in the top line and “ISE: mg/L”tothe right of the top line. The meter and electrode are now ready for calibration. Note: The Orion Benchtop Stirrer must be turned on in General Instrument setup before analysis,please see the Quickstart guide for instructions. www.thermo.com ofof of of

确定

还剩1页未读,是否继续阅读?

赛默飞中国实验室产品事业部为您提供《婴幼儿配方乳粉中钾离子检测方案 》,该方案主要用于婴幼儿配方乳粉中营养成分检测,参考标准--,《婴幼儿配方乳粉中钾离子检测方案 》用到的仪器有台式pH/ORP/ISE/溶解氧/电导率测量仪、Orion 4-Star台式(便携式)pH/离子浓度测量仪

推荐专场

相关方案

更多

该厂商其他方案

更多