方案详情

文

Microscopic examination is an important inspection

technique widely used in the research, quality control and failure analysis of very hard materials. To properly reveal the microstructure of these very hard materials, it is critical to use the proper equipment (usually automated), along with suitable high-quality consumable products, such as cutting blades, mounting compounds, abrasives, lubricants and working surfaces with proven preparation methods.

方案详情

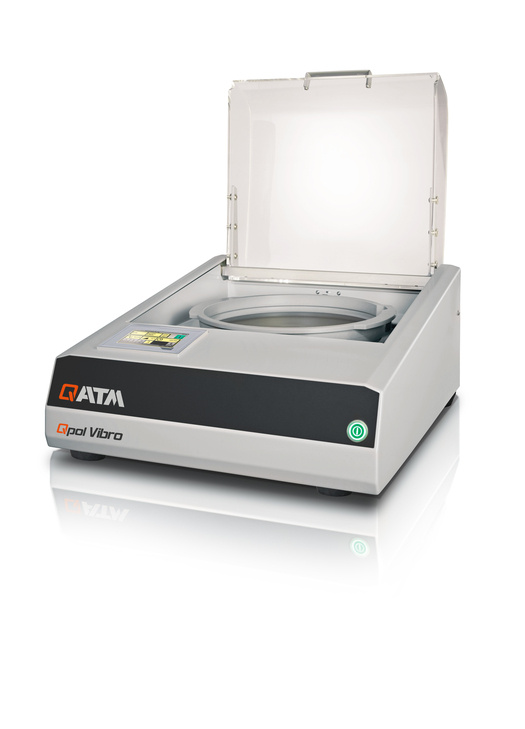

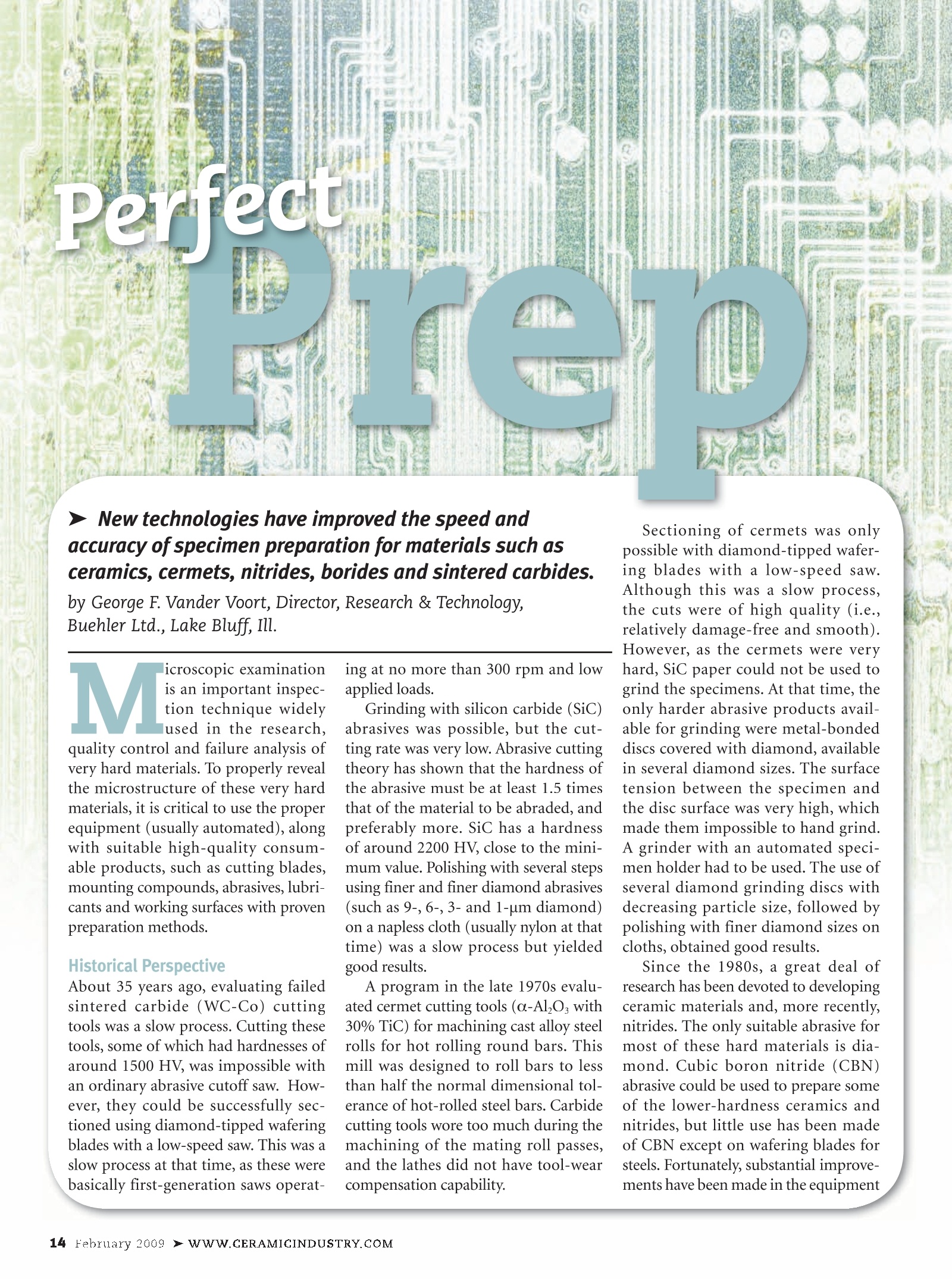

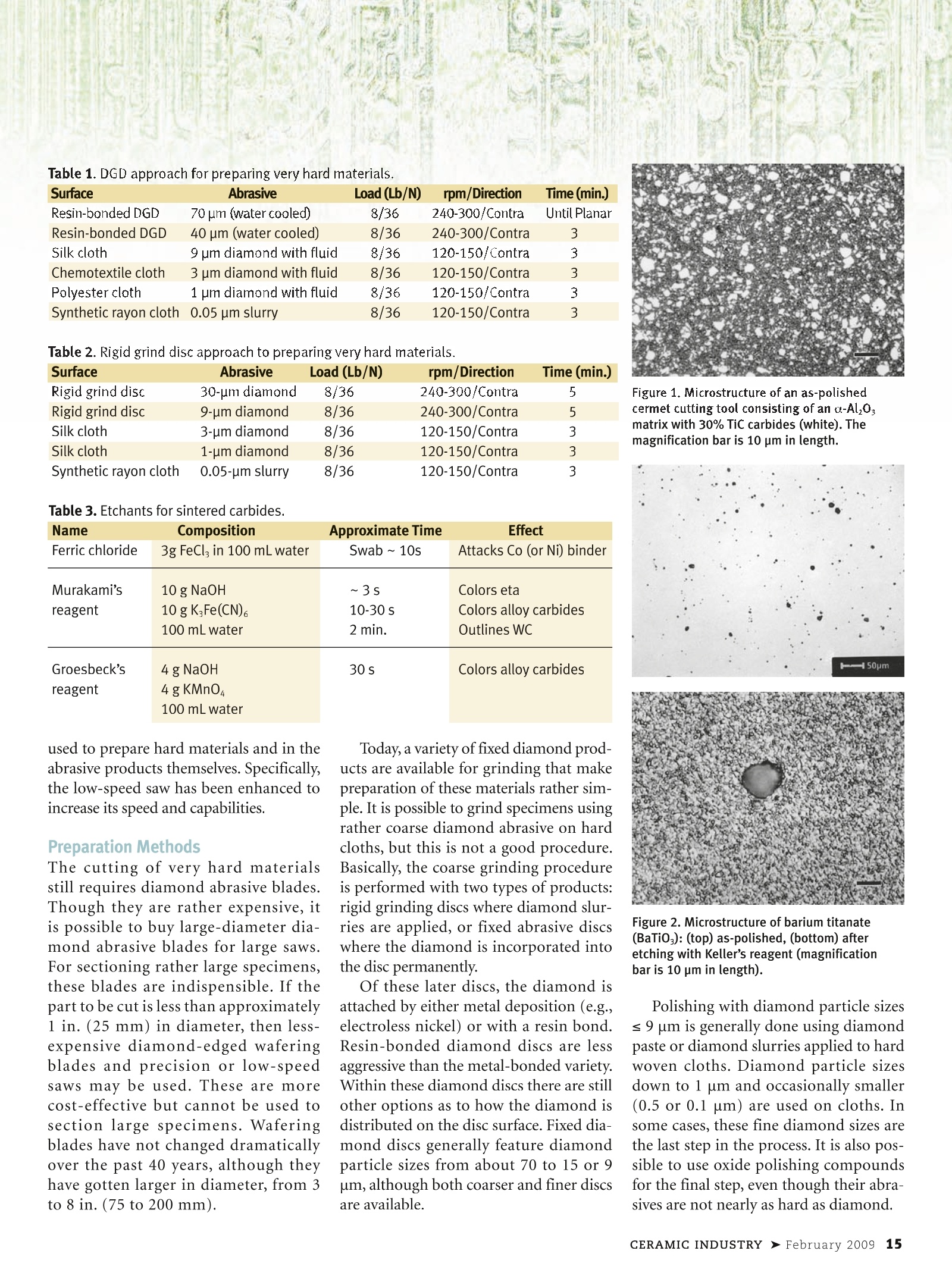

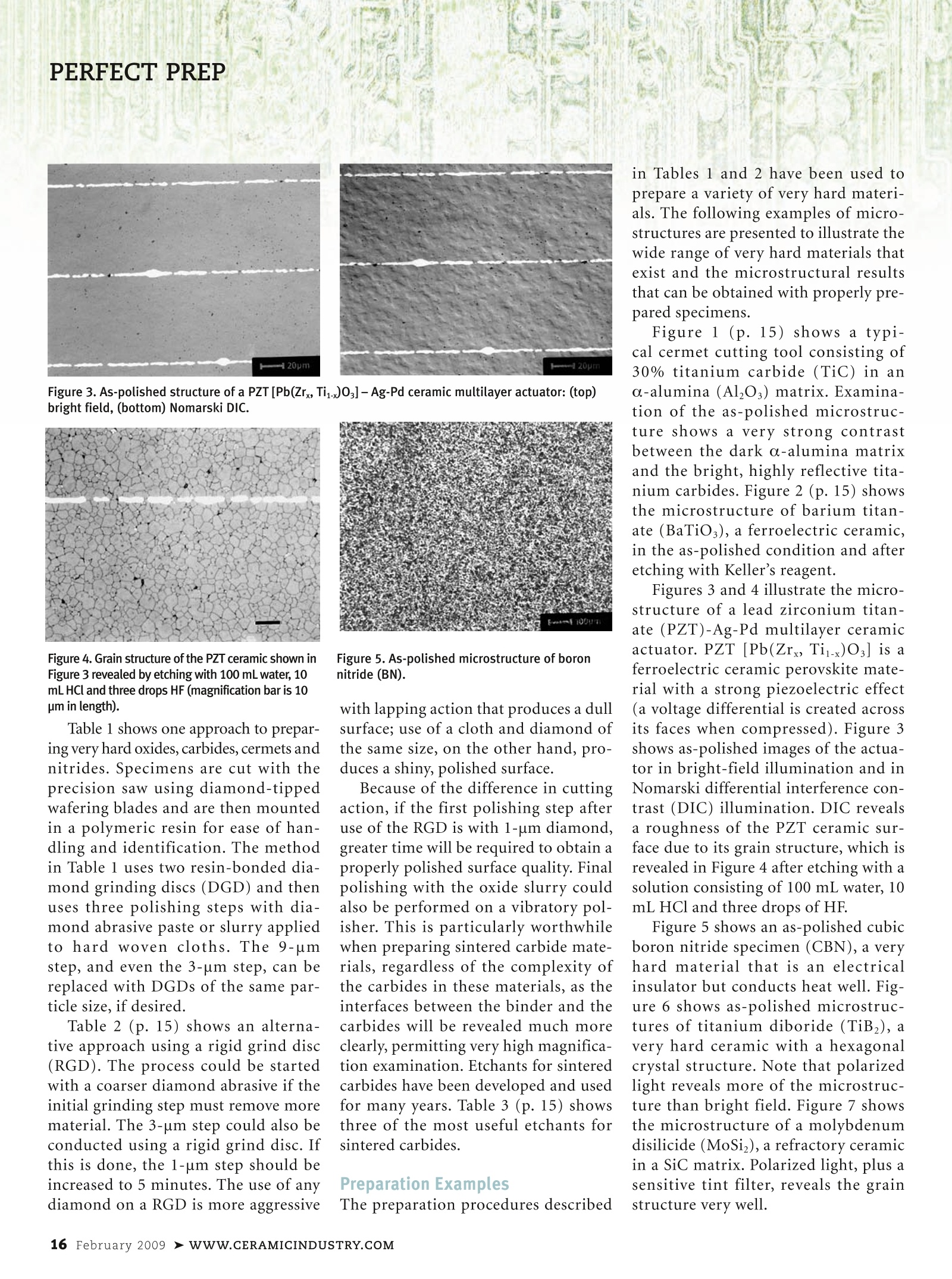

February 20091vIVolume 1591Issue Number 2www.ceramicindustry.com AM The Exclusive Global Voice of Ceramic & Glass Business and Manufacturing Sample Preparation Glass Manufacturing lmpact Testing > New technologies have improved the speed andaccuracy of specimen preparation for materials such asceramics, cermets, nitrides, borides and sintered carbides. by George F.Vander Voort, Director, Research & Technology,Buehler Ltd., Lake Bluff, Ill. icroscopic examinationis an important iMnspec-tion technique widelylused in the research1,quality control and failure analysis ofvery hard materials. To properly revealthe microstructure of these very hardmaterials, it is critical to use the properequipment (usually automated), alongwith suitable high-quality consum-able products, such as cutting blades,mounting compounds, abrasives,lubri-cants and working surfaces with provenpreparation methods. Historical Perspective About 35 years ago, evaluating failedsintered carbide (WC-Co) cuttingtools was a slow process. Cutting thesetools, some of which had hardnesses ofaround 1500 HV, was impossible withan ordinary abrasive cutoff saw. How-ever, they could be successfully sec-tioned using diamond-tipped waferingblades with a low-speed saw. This was aslow process at that time, as these werebasically first-generation saws operat- ing at no more than 300 rpm and lowapplied loads. Grinding with silicon carbide (SiC)abrasives was possible, but the cut-ting rate was very low. Abrasive cuttingtheory has shown that the hardness ofthe abrasive must be at least 1.5 timesthat of the material to be abraded, andpreferably more. SiC has a hardnessof around 2200 HV, close to the mini-mum value. Polishing with several stepsusing finer and finer diamond abrasives(such as 9-,6-,3-and 1-um diamond)on a napless cloth (usually nylon at thattime) was a slow process but yieldedgood results. A program in the late 1970s evalu-ated cermet cutting tools (a-Al O with30% TiC) for machining cast alloy steelrolls for hot rolling round bars. Thismill was designed to roll bars to lessthan half the normal dimensional tol-erance of hot-rolled steel bars. Carbidecutting tools wore too much during themachining of the mating roll passes,and the lathes did not have tool-wearcompensation capability. Sectioning of cermets was onlypossible with diamond-tipped wafer-ing blades with a low-speed saw.Although this was a slow process,the cuts were of high quality (i.e.,relatively damage-free and smooth).However, as the cermets were veryhard, SiC paper could not be used togrind the specimens. At that time,theonly harder abrasive products avail-able for grinding were metal-bondeddiscs covered with diamond, availablein several diamond sizes.The surfacetension between the specimen andthe disc surface was very high, whichmade them impossible to hand grind.A grinder with an automated speci-men holder had to be used. The use ofseveral diamond grinding discs withdecreasing particle size, followed bypolishing with finer diamond sizes oncloths, obtained good results. Since the 1980s, a great deal ofresearch has been devoted to developingceramic materials and, more recently,nitrides. The only suitable abrasive formost of these hard materials is dia-mond. Cubic boron nitride (CBN)abrasive could be used to prepare someof the lower-hardness ceramics andnitrides, but little use has been madeof CBN except on wafering blades forsteels. Fortunately, substantial improve-ments have been made in the equipment Table 1. DGD approach for preparing very hard materials. Surface Abrasive Load (Lb/N) rpm/Direction Time (min.) Resin-bonded DGD 70 um (water cooled) 8/36 240-300/Contra Until Planar Resin-bonded DGD 40 um (water cooled) 8/36 240-300/Contra 3 Silk cloth 9 um diamond with fluid 8/36 120-150/Contra 3 Chemotextile cloth 3 pm diamond with fluid 8/36 120-150/Contra 3 Polyester cloth 1 um diamond with fluid 8/36 120-150/Contra 3 Synthetic rayon cloth 0.05 um slurry 8/36 120-150/Contra 3 Table 2. Rigid grind disc approach to preparing very hard materials. Surface Abrasive Load (Lb/N) rpm/Direction Time (min.) Rigid grind disc 30-um diamond 8/36 240-300/Contra 5 Rigid grind disc 9-um diamond 8/36 240-300/Contra 5 Silk cloth 3-um diamond 8/36 120-150/Contra 3 Silk cloth 1-um diamond 8/36 120-150/Contra 3 Synthetic rayon cloth 0.05-pmslurry 8/36 120-150/Contra 3 Table 3. Etchants for sintered carbides. Name Composition Approximate Time Effect Ferric chloride 3g FeCl, in 100 mL water Swab ~ 10s Attacks Co (or Ni) binder Murakami's 10 g NaOH ~3s Colors eta reagent 10gKFe(CN)6 10-30 s Colors alloy carbides 100 mL water 2 min. Outlines WC Groesbeck's 4g NaOH 30s Colors alloy carbides reagent 4gKMnO4 100 mLwater used to prepare hard materials and in theabrasive products themselves. Specifically,the low-speed saw has been enhanced toincrease its speed and capabilities. Preparation Methods The cutting of very hard materialsstill requires diamond abrasive blades.Though they are rather expensive, itis possible to buy large-diameter dia-mond abrasive blades for large saws.For sectioning rather large specimens,these blades are indispensible. If thepart to be cut is less than approximately1 in. (25 mm) in diameter, then less-expensive diamond-edged waferingblades and precision or low-speedsaws may be used. These are morecost-effective but cannot be used tosection large specimens. Waferingblades have not changed dramaticallyover the past 40 years, although theyhave gotten larger in diameter, from 3to 8 in. (75 to 200 mm). Today, a variety of fixed diamond prod-ucts are available for grinding that makepreparation of these materials rather sim-ple. It is possible to grind specimens usingrather coarse diamond abrasive on hardcloths, but this is not a good procedure.Basically, the coarse grinding procedureis performed with two types of products:rigid grinding discs where diamond slur-ries are applied, or fixed abrasive discswhere the diamond is incorporated intothe disc permanently. Of these later discs, the diamond isattached by either metal deposition (e.g.electroless nickel) or with a resin bond.Resin-bonded diamond discs are lessaggressive than the metal-bonded variety.Within these diamond discs there are stillother options as to how the diamond isdistributed on the disc surface. Fixed dia-mond discs generally feature diamondparticle sizes from about 70 to 15 or 9um, although both coarser and finer discsare available. Figure 1. Microstructure of an as-polishedcermet cutting tool consisting of an o-Al20:matrix with 30% TiC carbides (white). Themagnification bar is 10 um in length. Figure 2. Microstructure of barium titanate(BaTiO,): (top) as-polished, (bottom) afteretching with Keller’s reagent (magnificationbar is 10 pm in length). Polishing with diamond particle sizess 9 um is generally done using diamondpaste or diamond slurries applied to hardwoven cloths. Diamond particle sizesdown to 1 um and occasionally smaller(0.5 or 0.1 um) are used on cloths. Insome cases, these fine diamond sizes arethe last step in the process. It is also pos-sible to use oxide polishing compoundsfor the final step, even though their abra-sives are not nearly as hard as diamond. PERFECT PREP Figure 3. As-polished structure of a PZT[Pb(Zr, Ti)0;]-Ag-Pd ceramic multilayer actuator: (top)bright field, (bottom) Nomarski DIC. Figure 4. Grain structure of the PZT ceramic shown inFigure 3 revealed by etching with 100 mL water, 10mL HCl and three drops HF (magnification bar is 10um in length). Table 1 shows one approach to prepar-ing very hard oxides, carbides, cermets andnitrides. Specimens are cut with theprecision saw using diamond-tippedwafering blades and are then mountedin a polymeric resin for ease of han-dling and identification. The methodin Table 1 uses two resin-bonded dia-mond grinding discs (DGD) and thenuses three polishing steps with dia-mond abrasive paste or slurry appliedto hard woven cloths. The 9-umstep, and even the 3-um step, can bereplaced with DGDs of the same par-ticle size, if desired. Table 2 (p.15) shows an alterna-tive approach using a rigid grind disc(RGD). The process could be startedwith a coarser diamond abrasive if theinitial grinding step must remove morematerial. The 3-um step could also beconducted using a rigid grind disc. Ifthis is done, the 1-um step should beincreased to 5 minutes. The use of anydiamond on a RGD is more aggressive Figure 5. As-polished microstructure of boronnitride (BN). with lapping action that produces a dullsurface; use of a cloth and diamond ofthe same size, on the other hand, pro-duces a shiny, polished surface. Because of the difference in cuttingaction, if the first polishing step afteruse of the RGD is with 1-um diamond,greater time will be required to obtain aproperly polished surface quality. Finalpolishing with the oxide slurry couldalso be performed on a vibratory pol-isher. This is particularly worthwhilewhen preparing sintered carbide mate-rials, regardless of the complexity ofthe carbides in these materials, as theinterfaces between the binder and thecarbides will be revealed much moreclearly, permitting very high magnifica-tion examination. Etchants for sinteredcarbides have been developed and usedfor many years. Table 3 (p. 15) showsthree of the most useful etchants forsintered carbides. in Tables 1 and 2 have been used toprepare a variety of very hard materi-als. The following examples of micro-structures are presented to illustrate thewide range of very hard materials thatexist and the microstructural resultsthat can be obtained with properly pre-pared specimens. Figure 1 (p. 15) shows a typi-cal cermet cutting tool consisting of30% titanium carbide (TiC) in ana-alumina (Al,O3) matrix. Examina-tion of the as-polished microstruc-ture shows a very strong contrastbetween the dark a-alumina matrixand the bright, highly reflective tita-nium carbides. Figure 2 (p.15) showsthe microstructure of barium titan-ate (BaTiO3), a ferroelectric ceramic,in the as-polished condition and afteretching with Keller’s reagent. Figures 3 and 4 illustrate the micro-structure of a lead zirconium titan-ate (PZT)-Ag-Pd multilayer ceramicactuator. PZT [Pb(Zr, Til-x)O3] is aferroelectric ceramic perovskite mate-rial with a strong piezoelectric effect(a voltage differential is created acrossits faces when compressed). Figure 3shows as-polished images of the actua-tor in bright-field illumination and inNomarski differential interference con-trast (DIC) illumination. DIC revealsa roughness of the PZT ceramic sur-face due to its grain structure, which isrevealed in Figure 4 after etching with asolution consisting of 100 mL water, 10mL HCl and three drops of HF. Figure 5 shows an as-polished cubicboron nitride specimen (CBN), a veryhard material that is an electricalinsulator but conducts heat well. Fig-ure 6 shows as-polished microstruc-tures of titanium diboride (TiB2), avery hard ceramic with a hexagonalcrystal structure. Note that polarizedlight reveals more of the microstruc-ture than bright field. Figure 7 showsthe microstructure of a molybdenumdisilicide (MoSiz), a refractory ceramicin a SiC matrix. Polarized light, plus asensitive tint filter, reveals the grainstructure very well. Figure 6. As-polished microstructure of titanium diboride (TiB,): (top) bright field,(bottom) polar-ized light (same field and magnification). Best Practices Metallographic examination of veryhard, inert ceramics, cermets, nitrides,borides and carbides can be readilyperformed using modern equipmentand consumable products. Due to thesematerials'high hardness, diamond isthe chief abrasive used. Specimens can be prepared withSPa high degree of flatness and edge retention while avoiding damage tothe material due to plucking or exces-sive fracturing. The metallographershould not overlook the use of polar-ized light or Nomarski DIC to exam-ine specimens. While many of thesematerials may be rather difficult toetch to reveal the grain structure,solutions and procedures are avail-able for most of these materials. Figure 7. As-polished composite of MoSiz in SiCviewed with polarized light plus sensitive tint(magnification bar is 50 pm in length). For more information regarding samplepreparation for hard materials, contactBuehler Ltd., 41 Waukegan Rd., LakeBluff, IL 60044; (847) 295-6500; fax (847)295-7979; e-mail info@-buehler.com; orvisit www.buehler.com. Retractable Water Hose and 360°Bowl RinseSystem Repeatable Sample Preparation Every Time BUEHLER 41 Waukegan Road,Lake Bluff, Illinois 60044P: +1847 295 6500 |800 BUEHLER (800 283 4537)W:www.buehler.comE: info@buehler.com 亚洲总部 BUEHLER标乐中国-上海依工测试测量仪器(上海)有限公司P: (86) 400 111 8683F: (86)21 6410 6671W: www.buehler.com.cnE:info.cn@buehler.com ebruary > WWW.CERAMICINDUSTRY.COM ERAMIC INDUSTRY > February Microscopic examination is an important inspection technique widely used in the research, quality control and failure analysis of very hard materials. To properly reveal the microstructure of these very hard materials, it is critical to use the proper equipment (usually automated), along with suitable high-quality consumable products, such as cutting blades, mounting compounds, abrasives, lubricants and working surfaces with proven preparation methods.

确定

还剩3页未读,是否继续阅读?

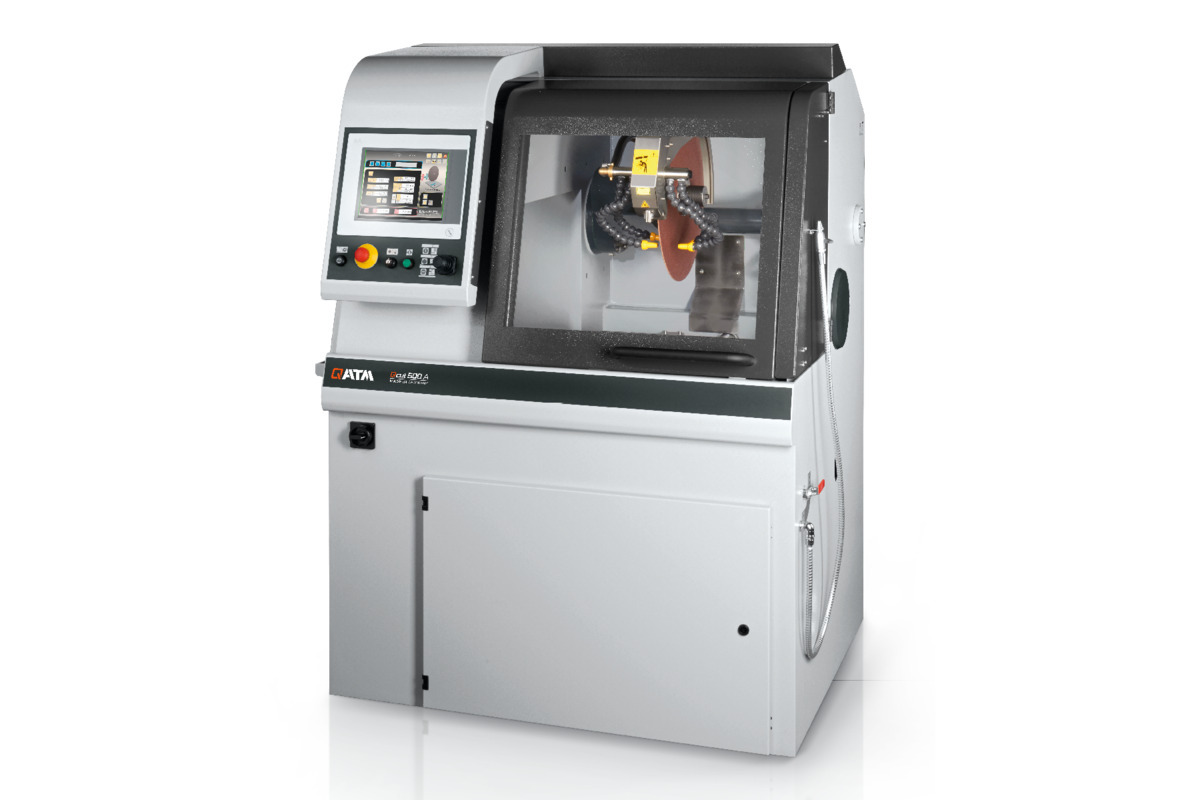

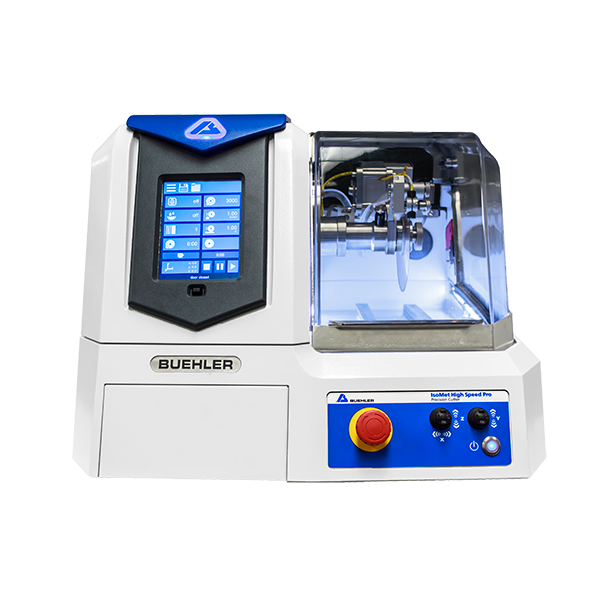

美国标乐为您提供《陶瓷中金相检测方案(切割机)》,该方案主要用于建筑陶瓷中金相检测,参考标准--,《陶瓷中金相检测方案(切割机)》用到的仪器有美国标乐 Buehler | IsoMet HS 高速精密切割机、美国标乐 Buehler | SimpliMet 4000自动镶嵌机、美国标乐 Buehler | AutoMet™ 250 研磨抛光机、维氏/努氏硬度计VH1102/1202 | 美国威尔逊硬度计

相关方案

更多