改性纳米SiC粉体强化奥氏体不锈钢中力学性能和耐腐蚀性能检测方案(电化学工作站)

本文在生产条件下采用冲入法制备改性纳米SiC粉体强化奥氏体不锈钢材料,研究了纳米SiC粉体对不锈钢的组织、力学性能和耐腐蚀性能的影响及其作用机理。试验用的纳米SiC粉体预先经过表面改性处理,粒径为20-80nm。在细化晶粒方面,其作用机理与孕育剂相类似,但与常规孕育剂不同的是,该纳米SiC粉体与飞速发展的纳米技术相结合,相同质量的改性纳米SiC粉体,能够提供更多的结晶核心,从而以微量的纳米SiC粉体便能明显地细化铸造不锈钢的组织,提高其性能。对自然冷却后得到的不同纳米SiC粉体含量的不锈钢试样进行固溶处理。采用金相检验、布氏硬度检测、拉伸试验、冲击试验、化学浸泡试验、电化学分析等方法检测了不锈钢的晶粒组织、力学性能和耐腐蚀性能,并进一步讨论了不同纳米SiC粉体加入量对不锈钢的组织、力学性能和耐腐蚀性能的影响。研究结果表明:经改性纳米SiC粉体强化处理后的不锈钢组织明显细化,力学性能、耐点蚀性能和耐晶间腐蚀性能均得到有效提高,当纳米SiC粉体加入量为0.1%时,不锈钢的延伸率和断面收缩率分别提高了10.69%和12.30%,硬度、抗拉强度和冲击韧性分别提高了6.33%、4.70%和19.97%,点蚀速率和晶间腐蚀速率分别降低了16.05%和42.39%;断口分析结果表明:经强韧化处理后,不锈钢的断裂方式为典型的韧性断裂;极化曲线表明:当纳米SiC粉体含量为0.1%

时,不锈钢的电极电位提高了3倍;能谱分析结果表明,经强化处理后,不锈钢的铬成分偏析减轻,有效改善了晶界等易发生点蚀和晶间腐蚀部位的贫铬现象。该纳米粉体强韧化技术水平先进,设备工艺简单,操作方便,附加值高,能有效提高不锈钢的综合性能,降低能源消耗,可在铸件的生产中广泛应用,并能实现绿色生产和可持续发展。

检测样品:

粗钢

检测项:

可靠性能

天津市兰力科化学电子高技术有限公司

查看联系电话

前往展位

CNO 选购项钢中低碳、氮和氧的直读光谱分析检测方案(光电直读光谱)

直读光谱法分析钢中低浓度 C,N 和O 取得了重大进展。减少或控制这些元素以及 P,S 和 H 的浓度,以获得“洁净钢”。因为这些元素或他们的结合物对钢材性能产生很大影响,如强度,成形性,韧性,可焊性,抗疲劳等,例如车身面板,通常C,N 和O 都必须低于 20ppm。持续改善钢的洁净度是生产质量不断提高和更具竞争力的钢铁产品的必要,因此,在钢铁厂对上述元素开展越来越低含量水平的定量分析意义重大。热电科技生产的 ARL 4460 在性能上完全满足了钢厂对 C,N 和 O 的最新分析要求。

检测样品:

粗钢

检测项:

含量分析

参考标准:

HJ 777-2015 空气和废气 颗粒物中金属元素的测定 电感耦合等离子体发射光谱法

朗铎科技(北京)有限公司

查看联系电话

前往展位

钢液脱气中节能干式真空泵组检测方案(真空泵)

普发真空解决方案

普发真空开发了两种基于机械真空泵的钢水脱气系统的概念。这些系统可以根据客户的具体要求单独定制。三级或三级以上的泵组都能根据具体应用要求进行整合。

这些泵级包括气体循环冷却罗茨泵(OktaLine G)、罗茨泵(OktaLine)和螺杆泵(HeptaDry)。

这两套解决方案的核心是OktaLine G型气冷罗茨泵,使用该泵可以减少螺杆泵的数量,而且由于它们的特殊设计,可以快速地从大气压启动抽气,即使是在高压差情况下,也无过热问题。

在称为“SKID”的解决方案中,在一个框架上装配了Okta 25000、带集成气体冷却器的Okta 4000 G和Hepta 600。skid方案包括泵间的管道和相应的控制接口。需要的抽气速度通过相同模块的并联获得,并联的数量根据具体应用而设计。

在称为”STAGE“的解决方案中,确定了最优的各级泵的数量。然后单一泵级通过路管相互连接。如果有必要的话,系统可以设计为四级或五级,甚至同一泵但在不同的工况下,可以切换成不同的级数。

通过优化现有系统,Pfeiffer Vacuum成功减少了所需的泵数量,从而能耗和系统成本相对较低。比如我们之前为45吨的VD / VOD成功开发的泵组只需要十一台泵。这套泵组共有三级,分别为五台OktaLine,三台OktaLine G和三台HeptaDary干泵。

该系统的优点:

1.与蒸汽喷射泵系统相比能耗较低

2.泵数量少

3.设计紧凑

4.成本节省明显

为进一步节省成本,客户可以用较小较便宜的泵代替较大的罗茨泵(小批量生产),因为他们的生产成本低。

检测样品:

粗钢

检测项:

理化分析

普发真空技术(上海)有限公司

查看联系电话

前往展位

不锈钢中铅检测方案(原子吸收光谱)

重金属元素铅对人体的危害表现为对体内金

属离子和酶系统产生影响,引起植物神经功能紊

乱贫血、免疫力低下等。不锈钢广泛应用于容器,

厨具,五金制品等领域,它作为原材料,铅含量是

必检项目之一。不锈钢中铅的分析,一般采用化

学分析方法[1],原子发射光谱法[2],X射线荧光光

谱法[3]。应用原子吸收光谱法测定不锈钢中

铜[4]、铬[5]、镍[6-7],锰[7],砷[8]等的含量已有报道,

但对于不锈钢中低含量铅的测定报道较少。不锈

钢的成分复杂,其中含有铬、镍、锰,硅,硫、磷等元

素。故在分析不锈钢样品时,需考虑来自大量基

体及共存元素的影响。标准加入法能有效地消除

基体效应,是原子吸收分析中常被推荐的校准方

法之一[9]。

本文研究了火焰原子吸收法测定不锈钢中铅

的分析方法。结果表明,样品经王水溶解后,采用

氘灯进行背景校正和标准加入法可有效消除背景

干扰和基体效应。方法应用于实际样品中铅的测

定,结果满意。

检测样品:

粗钢

检测项:

含量分析

上海光谱仪器有限公司

查看联系电话

前往展位

不锈钢中表面的显微测量和特性描述检测方案(白光干涉测厚)

冷轧和拉丝不锈钢表面的显微测量和特性描述

使用仪器:BMT WLI Lab (20倍物镜) 短相干干涉仪

使用此仪器测量两个工件约0.8mm×0.7mm面积的表面轮廓。测量结果如图1。图2显示假彩色高度轮廓。图3为两条垂直加工方向的轮廓线。我们可轻松看出两个表面的区别,表1也列出了测量出的粗糙度参数。平均区域粗糙度参数Sa不能独立反映相关功能表面的特性,如耐磨性和密封性等。

轧制过程使大的区域变平,可看到图2中由于酸处理出现的刻蚀孔。此表面结构显示出一些表面微凸体和许多气孔,图4是典型的振幅分布函数和Abbott曲线。图中的数值参数给定为Ssk=-1.97。数值小于0反映了带有一个平台和一个相对深的凹谷的表面轮廓。这样一个表面同样也表示Svk/Spk比值会很大Svk/Spk=7.7(表1),这是一个典型的特点。

而且在拉丝表面上的凹槽比轮廓峰要明显。但是这个差异比轧制表面的情形小得多,而且振幅分布接近于高斯函数。所以Ssk以及Svk/Spk的比值(系数)要小些。

检测样品:

粗钢

检测项:

理化分析

佰汇兴业(北京)科技有限公司

查看联系电话

前往展位

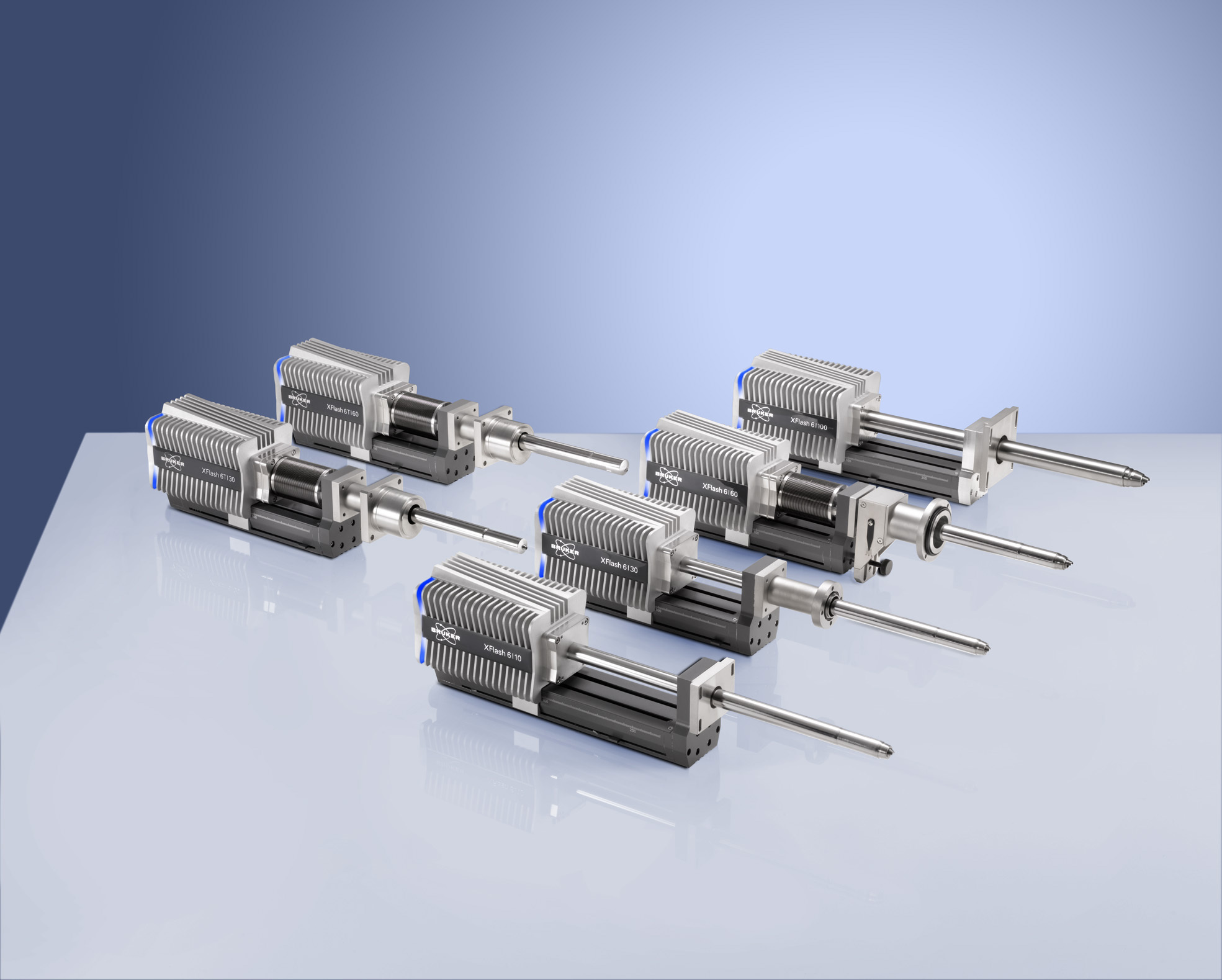

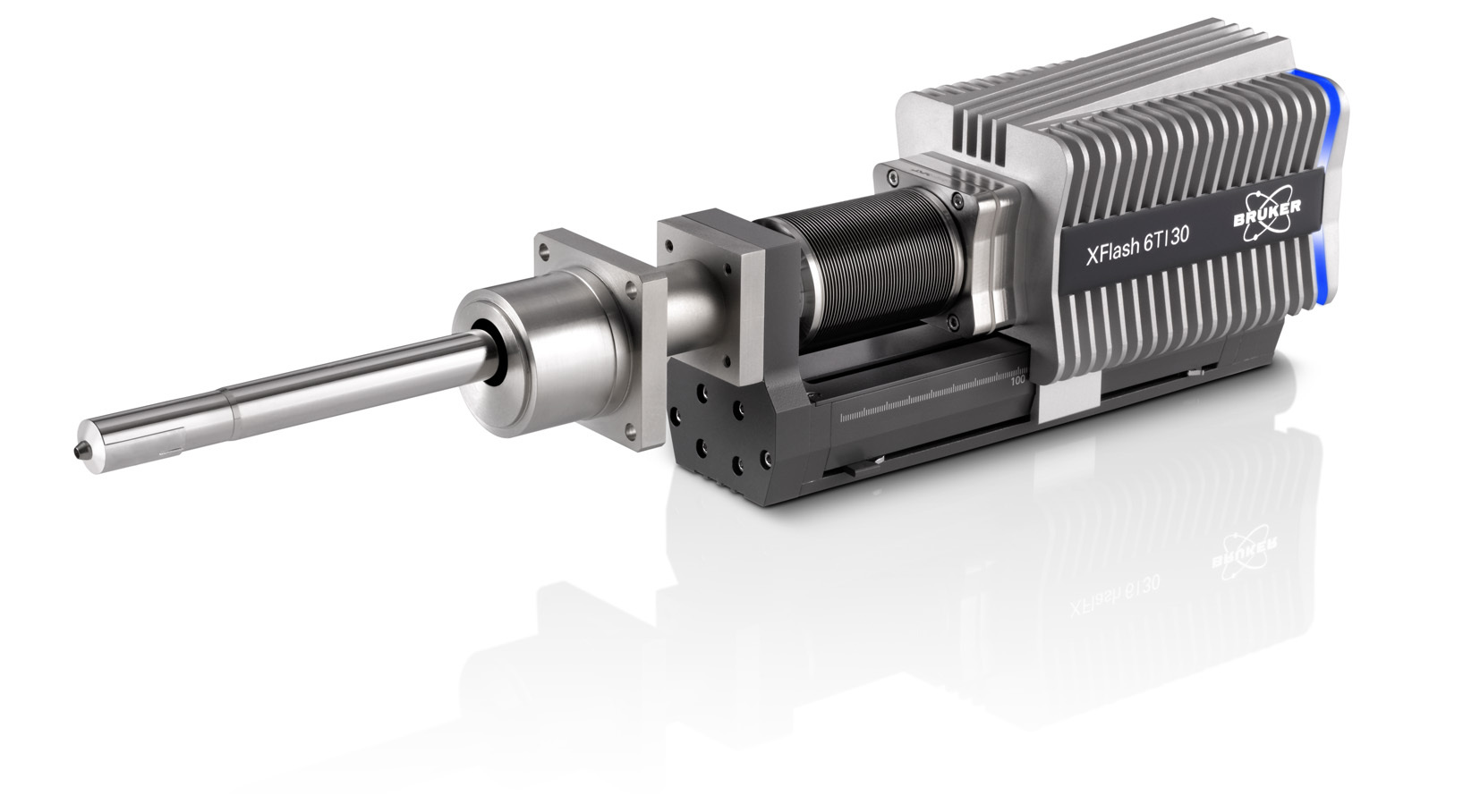

Cr-Ni钢中元素含量检测方案(X射线能谱仪)

The measurements discussed in this document relate to a

Cr-Ni-steel sample, the composition of which was originally

determined with XRF and S-OES. Steel analysis using EDS

generally deals with calculating the content of elements in

the intermediate atomic number range through evaluation of

the K-lines of the X-ray spectrum.

检测样品:

粗钢

检测项:

含量分析

布鲁克电子显微纳米分析仪器部

查看联系电话

前往展位

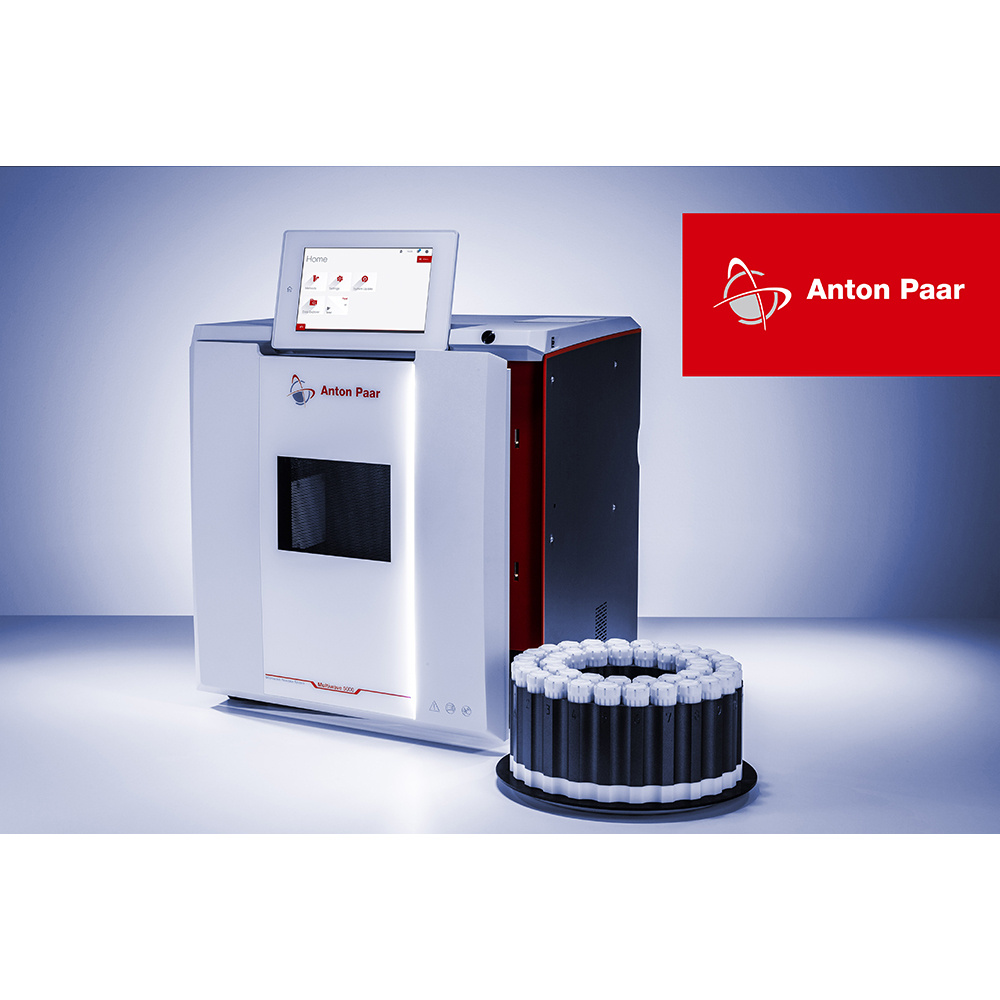

钢及其合金中Al元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

Al元素

安捷伦科技(中国)有限公司

查看联系电话

前往展位

钢及其合金中Co元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

含量分析

安捷伦科技(中国)有限公司

查看联系电话

前往展位

钢及其合金中Cr元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

含量分析

安捷伦科技(中国)有限公司

查看联系电话

前往展位

钢及其合金中Ni元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

含量分析

安捷伦科技(中国)有限公司

查看联系电话

前往展位

钢及其合金中P元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

含量分析

安捷伦科技(中国)有限公司

查看联系电话

前往展位

钢及其合金中S元素检测方案(ICP-AES)

Steel manufacturers conduct quality control testing for a range of metals and trace elements to ensure the grade and performance of their final product. The Standardization Administration of China uses their GB/T 20125-2006 standard “Low-alloy steel – Determination of multi-element contents – Inductively coupled plasma atomic emission spectrometric method” to control the quality of manufactured steel products. Different grades of steel have different specifications for elemental content, with most steel and stainless steel grades required to have less than 0.05 % by weight of Sulfur and 0.04 % by weight of Phosphorus. With the Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) technique easily able to measure elements at this concentration within a sample, laboratories are looking beyond whether an instrument can ‘do the job’ to whether a specific instrument can improve their sample throughput, lower their costs, simplify sample preparation and instrument operation, and deliver reliable results throughout the analysis of a large batch of samples. 2 This application note demonstrates the performance and benefits of Agilent’s 5100 Vertical Dual View (VDV) ICP-OES instrument in the analysis of steel samples, using the GB/T 20125-2006 method. The instrument offers many advantages for this application, which involves the rapid analysis of a large number of challenging steel samples.

检测样品:

粗钢

检测项:

含量分析

安捷伦科技(中国)有限公司

查看联系电话

前往展位

仪器信息网行业应用栏目为您提供107篇粗钢检测方案,可分别用于,参考标准主要有《HJ 777-2015 空气和废气 颗粒物中金属元素的测定 电感耦合等离子体发射光谱法》等