方案详情

文

以哈尔滨红香肠为研究对象,采用固相微萃取-气相色谱-质谱联用技术(SPME-GC/MS)结合电子鼻(E-nose)和电子舌(E-tongue)对传统和传统加工方法制备的红香肠的挥发性成分和口感进行了研究。

方案详情

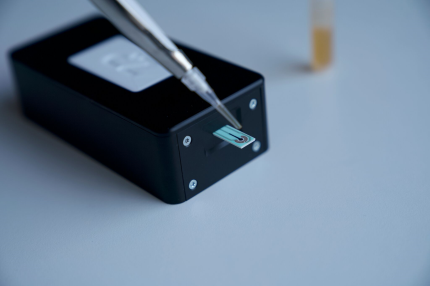

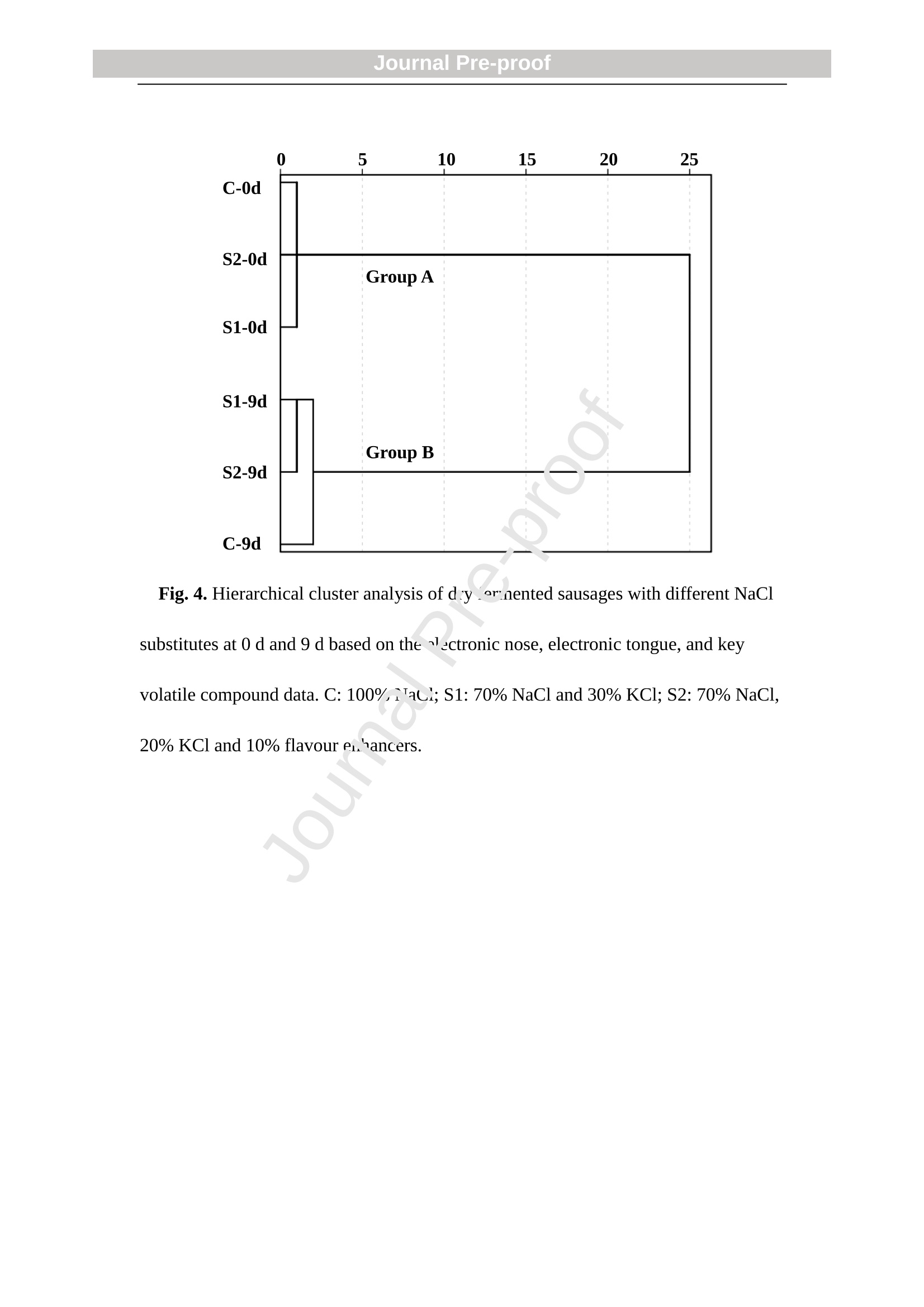

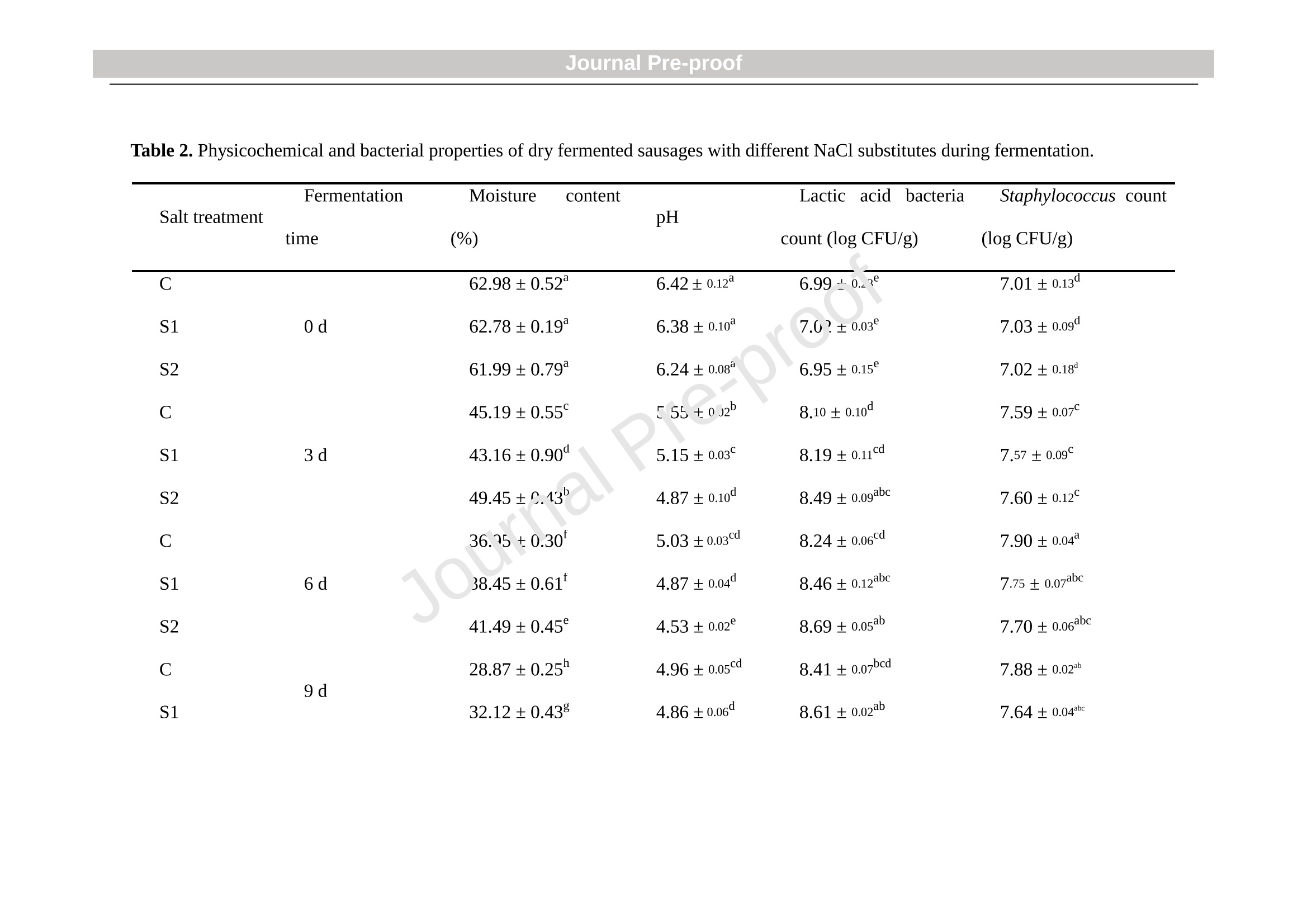

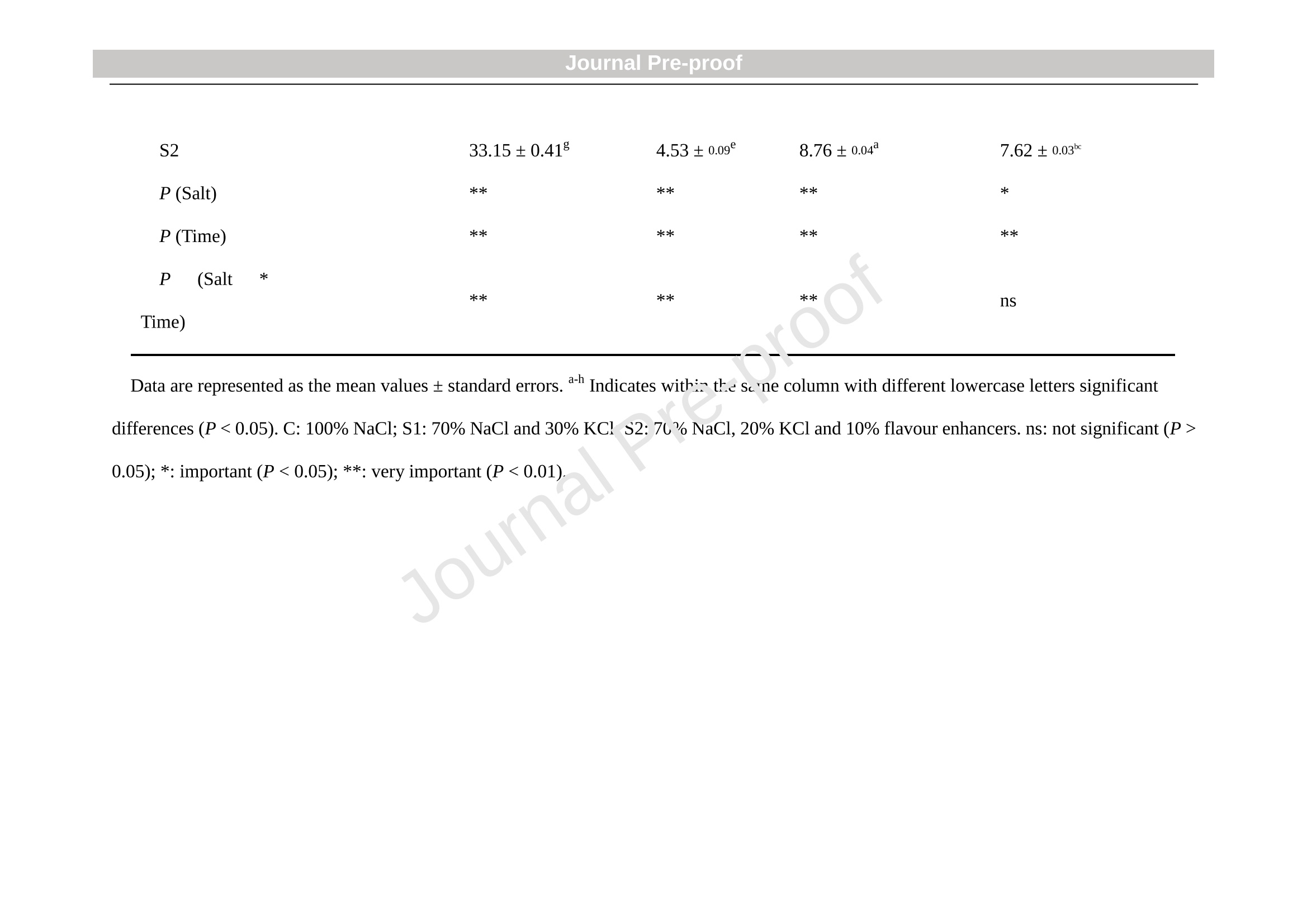

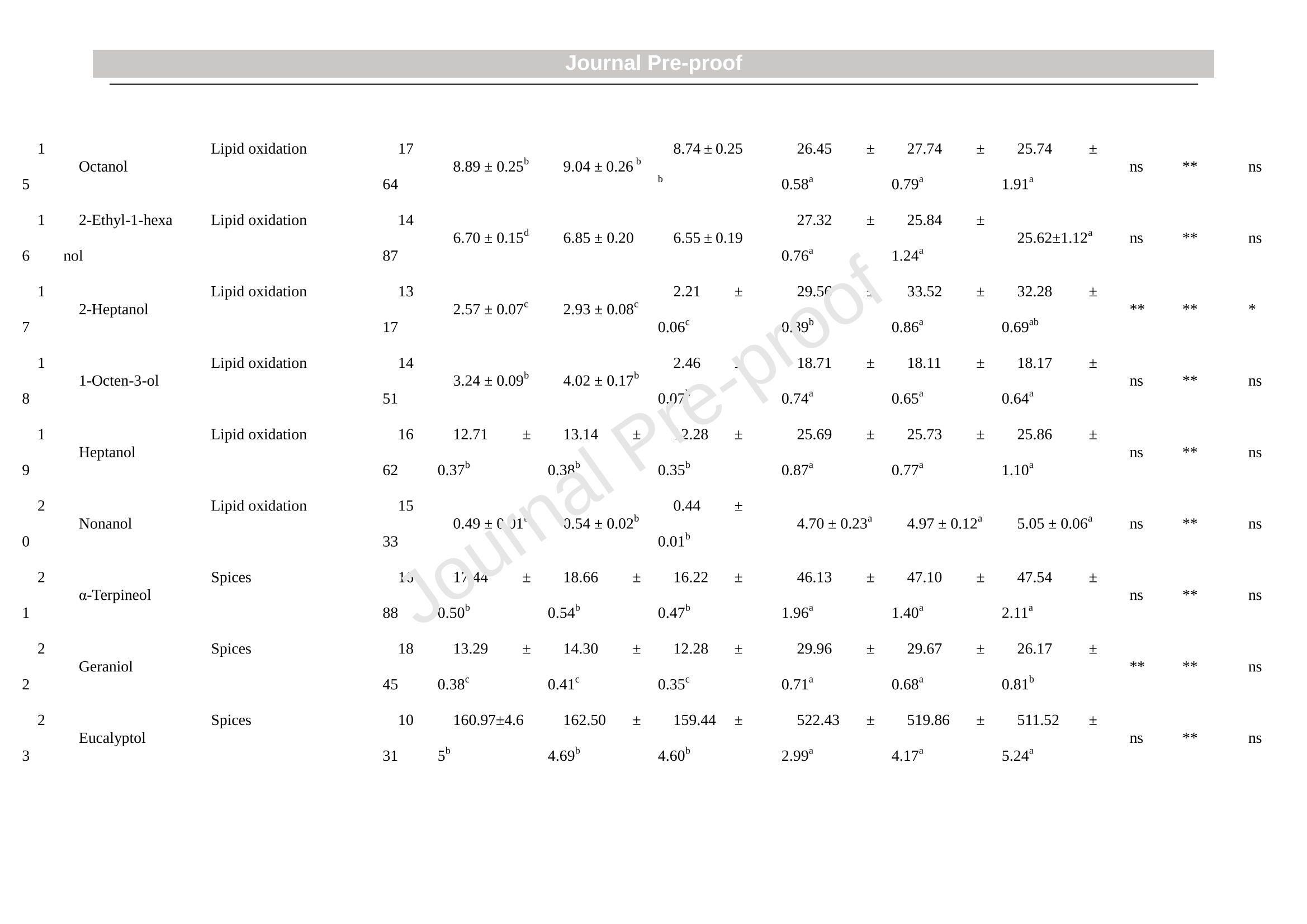

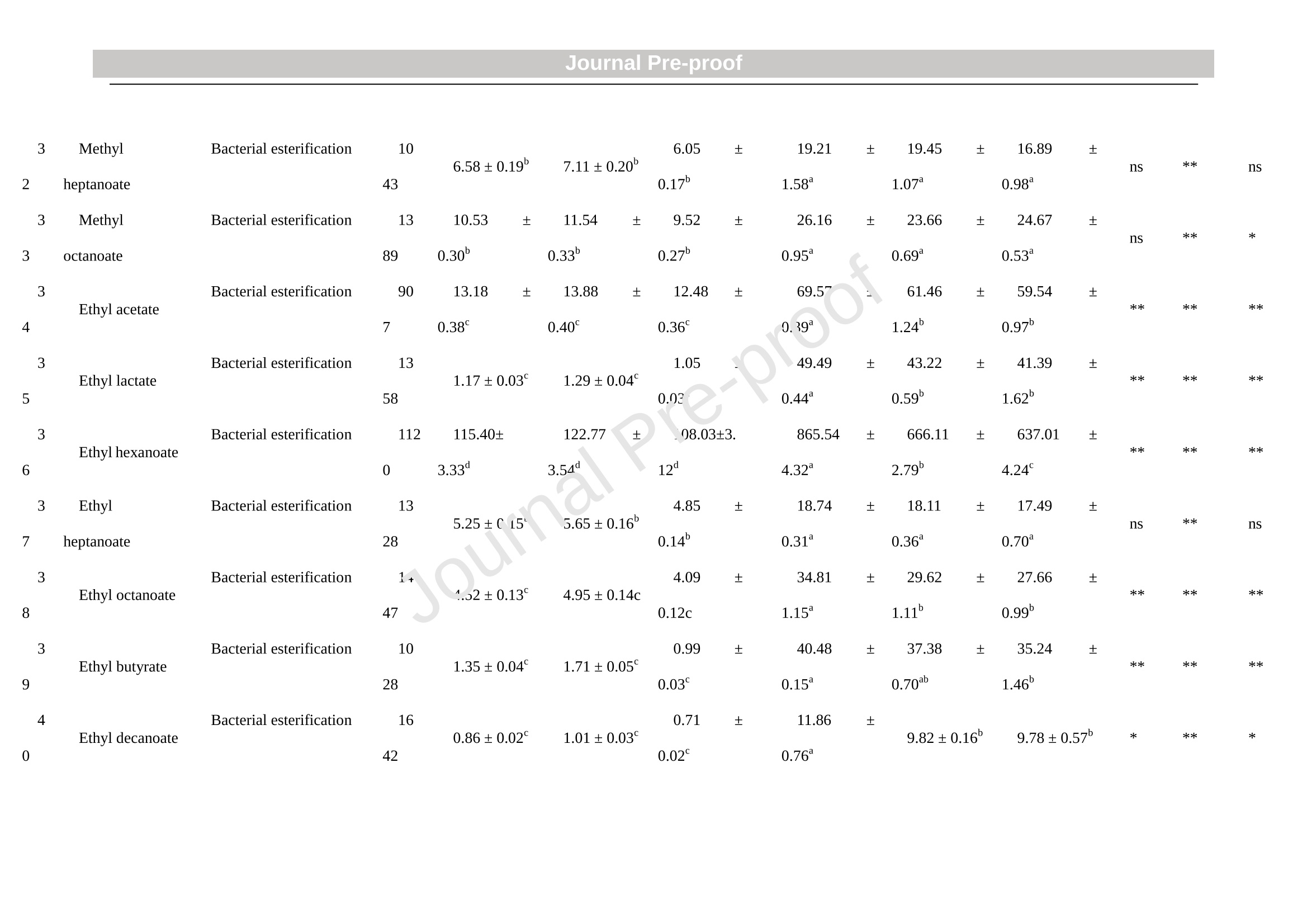

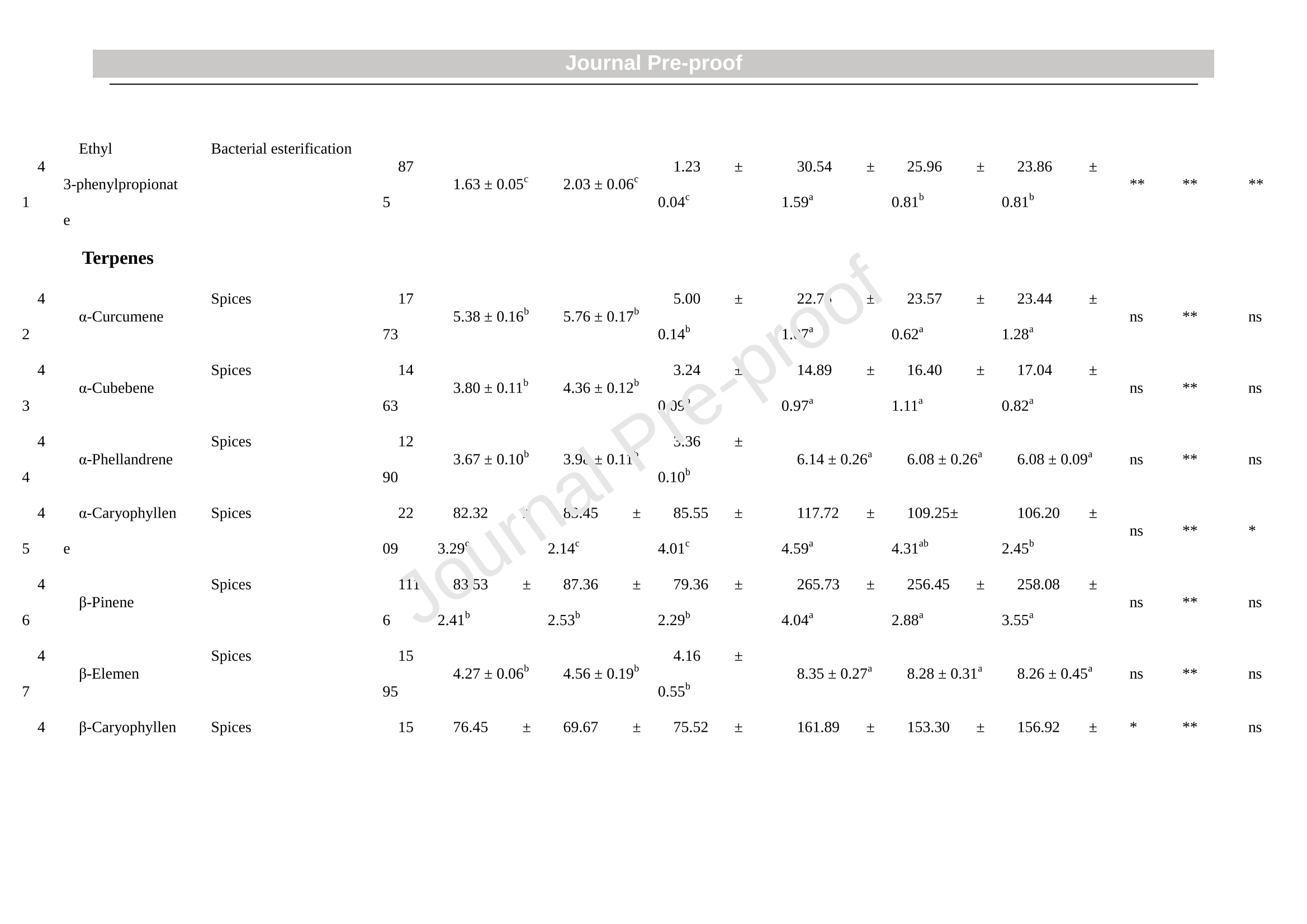

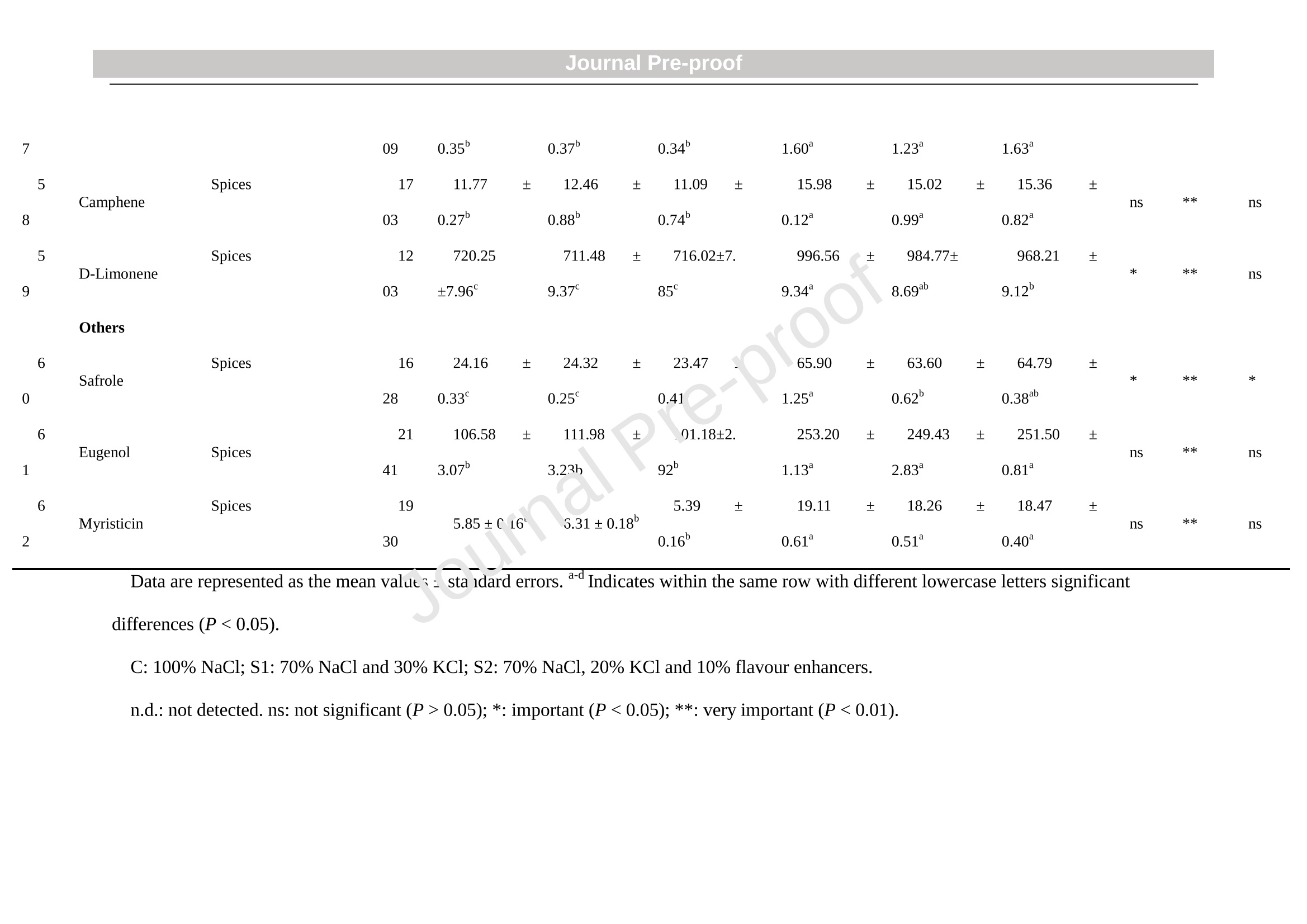

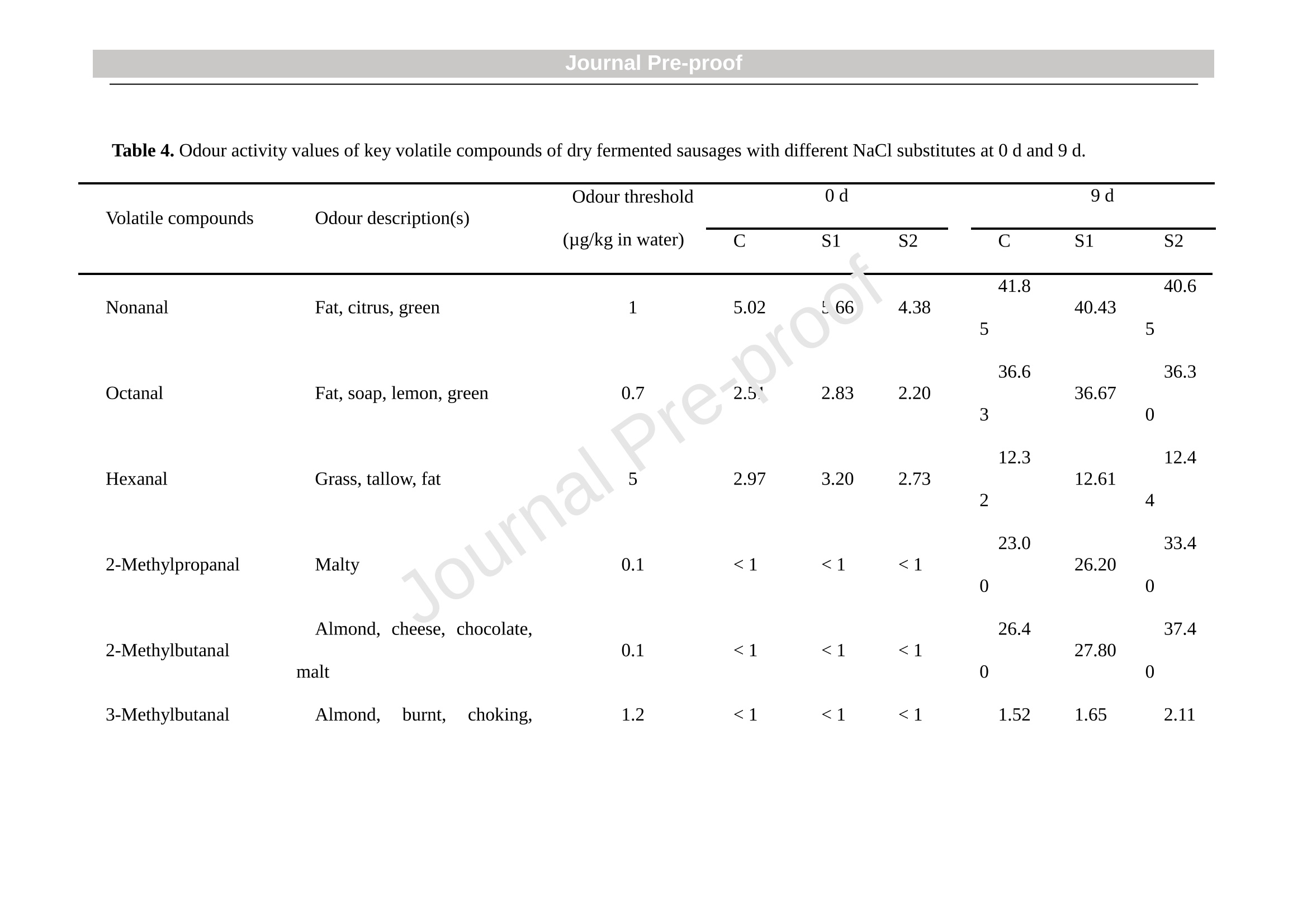

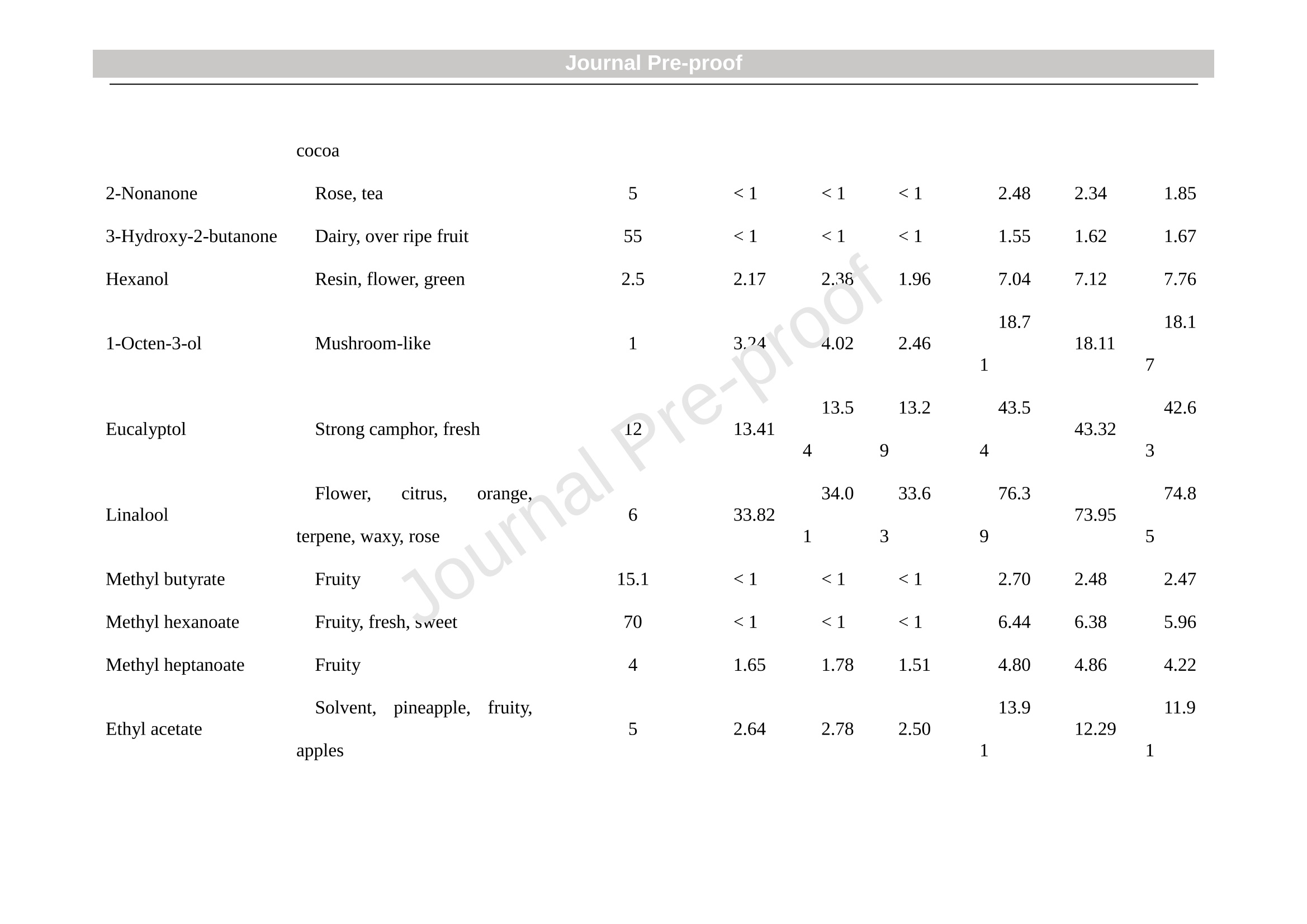

Journal Pre-proof Journal Pre-proof Characterisation of the flavour profile of dry fermented sausageswith differentNaCl substitutes using HS-SPME-GC-MScombined with electronic nose and electronic tongue Qian Chen, Yingying Hu, Rongxin Wen, Yan Wang, Ligang Qin,Baohua Kong PII: S0309-1740(20)30770-1 DOI: https://doi.org/10.1016/j.meatsci.2020.108338 Reference: MESC 108338 To appear 1n: Meat Science Received date: 1 July 2020 Revised date: 3 October 2020 Accepted date: 6 October2020 Please cite this article as: Q. Chen, Y. Hu, R. Wen, et al., Characterisation of the flavourprofile of dry fermented sausages with different NaCl substitutes using HS-SPME-GC-MScombined with electronic nose and electronic tongue, Meat Science (2020), https://doi.org/10.1016/j.meatsci.2020.108338 This is a PDF file of an article that has undergone enhancements after acceptance, suchas the addition of a cover page and metadata, and formatting for readability, but it isnot yet the definitive version of record. This version will undergo additional copyediting,typesetting and review before it is published in its final form, but we are providing thisversion to give early visibility of the article. Please note that, during the productionprocess, errors may be discovered which could affect the content, and all legal disclaimersthat apply to the journal pertain. 2020 Published by Elsevier. Characterisation of the flavour profile of dry fermented sausages with differentNaCl substitutes using HS-SPME-GC-MS combined with electronic nose and electronic tongue Qian Chen, Yingying Hu , Rongxin Wen, Yan Wang, Ligang Qina*, Baohua Kong*loorp- College of Food Science, Northeast Ag ic oltaral University, Harbin, Heilongjiang 1/30, ChinaShimadzu (China) C., LiD., Shenyang, Liaoning, 110000, China nruo * Corresponding author E-mail address: qinligang@neau.edu.cn (L. Qin) E-mail address: kongbh63@hotmail.com(B. Kong). Abstract The effects of different sodium substitutes on the physical and bacterial properties,flavour profile and sensory evaluation of dry fermented sausage were investigated.There were three different salt formulations, including control (C: 100%NaCl), S1(70%NaCl and 30%KCl) and S2 (70%NaCl, 20%KCl and 10% flavour enhancers).Higher moisturecontenttaandlactic acid bacteria ccunt, and lower pH andStaphylococcus count were observed in NaCl substitution tre: tments compared to thecontrol (P<0.05). Sixty-two volatiles were detecter in sausages, and 26 compoundswere regarded as key volatile compounds based the odour activity values. Theelectronic tongue result and sensory eval ia. or showed that the taste profile of S2treatment was similar to control treatu.t; and the electronic nose, volatile compoundresults and hierarchical cluster arasi showed that the sodium substitutes had a moresignificant effect on the ocour profile. Overall, S2 may be an ideal low-sodiumsubstitute to achieve a 30% eduction in NaCl and provide a better flavour profile offermented sausages Keywords: Sodium substitutes; Flavour enhancers; Dry fermented sausage; Flavourprofile; Electronic nose; Electronic tongue 1. Introduction Sodium chloride (NaCl) is an essential ingredient in meat products, and it improvestexture and decreases water activity, which guarantees the quality and safety of meatproducts (De Almeida et al., 2018). However, excessive sodium intake in the humandiet may lead to hypertension and cardiovascular disease (Paik, Wendel, & Freeman,2005). The main source of sodium intake in diets are procer sed meat products, such assausage, bacon and ham (Ruusunen & Puolanne, 2005; Zl ang et al., 2017). Especially,fermented sausages have the highest levels of NaC ameig meat products because ofthe dehydration process undergone during their Dis luction (Campagnol, dos Santos,Wagner, Terra, & Mar, 2011,Desmod, 2005 Sch as Salami, a typical dry fermentedsausage, its NaCl content reaches as high as 4.6%-4.8% on a wet weight (Desmod,2006). The substitution of NaCl、 ith potassium chloride (KCl) is widely used to preservethe quality of meat produ ts. KCl is considered to be the best sodium substitutebecause it has a sa finss and an antimicrobial efficiency that is equivalent to NaCl(Bidlas & Lambert, 2008). Besides, the intake of KCl is not correlated to hypertensionand cardiovascular diseases (Buemi et al., 2002). However, a high level of KCl(30%-40%) produces bitter and metallic tastes (Guardia, Guerrero, Gelabert, Gou, &Arnau, 2008; Morris et al., 2010; dos Santos, Campagnol, Morgano, & Pollonio, 2014).And increasing KCl levels in foods could increase risk of diabetes, chronic kidneydisease, end stage renal disease, severe heart failure and adrenal insufficiency (Van Buren, Dotsch-Klerk, Seewi, & Newson, 2016). The reported doses of KCl causingabove adverse effects ranged from 1 to 94 g/day in adults and from 1.5 to 7 g/day ininfants (Steffensen et al., 2018). To mask the defects of KCl, flavour enhancers thatimprove taste and aroma,including glutamate, amino acids and citric acid, are used assodium substitutes (Campagnol, dos Santos, Morgano, Terra, & Pollonio, 2011; dosSantos eet al., 2014). Our previous studies partially srbstituted NaCl with KClcombined with some enhancers and improved the sensory fact rs and texture of Harbindry sausage (Chen et al., 2019). The substitutes deccased the lipid and proteinoxidation and promoted the flavour development iHarbin dry sausage (Wen et al.,2019). These flavour enhancers included 1 si.e maltodextrin, alanine, calcium lactateand citric acid, which mask the undesile flavour of KCl and increase the saline taste. Flavour is an important qualit,yttrbute for determining consumer acceptance andpreference (Chen, Song, E. Meng, & Wu, 2018). The microbial communitycomposition primarily effec the flavour development of fermented foods (Wu et al.,2015).Inoculation t e starter cultures shortens the fermentation time, inhibits thepathogenic or spoilage bacteria and improves the quality characteristics of the finalproducts. Our previous studies found that several bacterial strains isolated from Harbindry sausage (Lactobacillus curvatus, Pediococcus pentosaceus and Staphylococcusxylosus) promoted the hydrolysis of lipids and proteins to generate the precursors offlavour compounds or flavour compounds, which contributed to the taste and aromaprofile of dry sausage (Chen, Kong, Han, Liu, & Xu, 2016; Hu et al., 2019; Chen,Kong, Han, Xia, & Xu, 2017). Salt is a major factor that affects the growth of bacteria.However, little is known about the effects of the sodium substitutes on the flavourdevelopment of the dry sausage inoculated with these bacteria strains. Headspace solid phase micro-extraction gas chromatography-mass spectrometry(HS-SPME-GC-MS) has been widely used recently to identify the volatile compounds(Dong et al., 2018). Electronic nose (E-nose) and electrcnic tongue (E-tongue) arelargely used in flavour analysis (Peris & Escuder-Gilabe1,2016; Wasilewski, Migon,Gebicki, & Kamysz, 2019), and these devices are pe verul tools to distinguish flavourprofiles and characterize the differences in odour ataste of foods without subjectivefactors and judgements (Donglu et al,011; Zaragozzaa et al., 2013). Hence,HS-SPME-GC-MS combined with Ese and E-tongue can be used to characterizethe flavour profiles of dry fernted sausages with different sodium substitutes,which may providea rerencefor establishing more comprehensive rapididentification method b flavour characteristics of dry fermented sausage. Therefore,the present study iinvestigated the effects of the sodium substitute with flavourenhancers on the flavour profile of dry sausage inoculated with a mixed starter culture(L. curvatus, P. pentosaceus and S. xylosus), and the physical properties, bacterialcounts and sensory evaluation of dry fermented sausages were performed. 2. Materials and methods 2.1. Preparation of dry fermented sausages The dry fermented sausage was manufactured according to the method of Hu et al.(2020). Lean pork (3600 g) and pork back fat (400 g) were minced through a 1.5-cmplate with the following ingredients: NaCl (100 g), sodium nitrite (0.18 g), sodiumascorbate (0.20 g), dextrose (100 g), monosodium glutamate (6.0 g), wine (20.0 g)and mixed spices (6.0 g). The mixed spices contained round cardamom, Pericarpiumzanthoxyli, angelica, aniseed, fennel, Amomum villosum, ca,sia bark, clove and pepper.The mixed starter culture (10CFU/g sausage), includin L. urvatus, P. pentosaceusR1 and S. xylosus A2, was used for the sausage pre arauon. P. pentosaceus R1 and S.xylosus A2 were isolated from Harbin dry sausages, udL. curvatus was obtained fromthe China General Microbiological Culture C11ction Centre. Three independent batches of dry fermented sausages were prepared, and threesausage treatments were performuin cach batch: control (100%NaCl), S1 (70% NaCland 30%KCl) and S2(70%、Cl, 20%KCl, 4% lysine, 3.5% maltodextrin,1% alanine,1% calcium lactate and0.5.citric acid). The meat batter was thoroughly mixed andstuffed into naturainig intestine casings (diameter 3.0 cm) to produce sausages withfinal weights of approximately 0.15 kg. All batches of sausages were air-dried at 25 ±2C (30-50% relative humidity) for 1 d and then stored at 25±2℃ (75% to 80%relative humidity) in a well-ventilated chamber for 8 d. The sausage samples in eachtreatment were randomly taken on days 0, 3, 6 and 9 to measure the physicochemicalproperties, bacterial counts, and volatile compound contents and perform E-nose,E-tongue, and sensory evaluations. 2.2. Physicochemical and bacterial analysis The moisture content was measured according to AOAC procedures (AOAC, 1995).A total of 10.0 g of sausage was homogenized with 90.0 mL distilled water, and thepH of the mixture was measured using a pH metre (MettlerToledo Instruments Co.,Ltd., Shanghai, China). LAB count was determined on de Man, Rogosa and Sharpe(MRS) agar inoculated at 30℃ for 48 h. Staphylococ us ount was measured onMannitol Salt Agar (MSA) inoculated at 32 °C for 1h( nen et al., 2019). 2.3. Volatile compound analysis The volatile compounds of dry ferited sausages were extracted using HS-SPMEand analysed using a GC-MS sysen (GCMS-QP2020 NX, Shimadzu Corporation,Kyoto,Japan) according to te method of Wen et al. (2019). A total of 3.0 g mincedsausages was placed in 20-1 L headspace sample vials. The volatile compounds wereidentified via comp risn of the experimental mass spectra with a mass spectra libraryfrom NIST17 and/or via calculation of the retention index relative to a series ofstandard alkanes (C6-C20) to calculate the linear retention index (LRI). The contents ofthe volatile compounds are expressed as pg/kg. The contribution of each volatile compound to the overall odour was evaluated as theodour activity value (OAV). The OAV was calculated as the ratio of the content of eachcompound to its odour threshold value in water (Olivares, Navarro, & Flores, 2011). The odour thresholdvalues of volatile compoundswere obtained from theFlavour-Base 10th Edition (http://www.leffingwell.com/flavbase.htm). 2.4. Electronic nose analysis According to the previous report of Wu, Yue, Xu, and Zhang (2017), the PEN3portable E-nose (Airsense Analytics GmbH, Schwerin, G rmany) equipped with 10metal oxide semiconductor (MOS):sensors wasusedifoi E-nose analysis. Theinformation of each sensor is shown in Table 1. torp-2.5. Electronic tongue analysise E-tongue analysis was performed acrding to a previous method (Zhang et al.,2019)with some modifications. Briefl, 15.0 g of the minced dry sausage was mixed with225.0 mL of distilled water te extract the taste substances. After the mixed solution wascentrifuged 2265 ×g fer 10 .nin at 4C, the water phase was obtained for E-tongueanalysis using a Taute Cunsing System E-tongue (TS-5000Z, Insent Inc., Japan), whichwas equipped with five chemical sensors for umami (AAE), astringency (AE1),saltiness (CT0), sourness (CA0) and bitterness (C00) and two reference electrodes. 2.6. Sensory evaluation Sensory evaluation of a nine-day dry fermented sausage was performed according tothe method of Hu et al. (2020) with modifications. The sensory evaluation of the sausage samples was performed by twenty qualified panellists (10 males and 10 females) with prior experience in muscle food sensory tests who were selected from apool of faculty, staff, and graduate students across 3 sessions. Training sessions werecarried out for panelists prior to sensory evaluation. During the training sessions, thepanelists defined and developed sensory attributes of the samples until they reachedan agreement with the attributes according to the objective of the present work (Zhanet al., 2019). The session was held 4 times per week for 2 w xeks, with each trainingsession lasting for 2h (Zhang et al., 2018). Afte traming, the basic operation ofsensory evaluation and the quality standards of diftent attributes must be mastered bypanellists. A“warm-up”sample at the b gni ng of each session was evaluated toacquaint panellists with the scoring s, vem. Sausage slices (2-mm thick) were servedrandomly on white plastic plates adeu with randomized 3-digit numbers. The sensoryevaluation was determined baed on a 7-point intensity scale from 1 (low intensity) to 7(high intensity): colour 1=dark and dull;7 = red and shiny), odour (1=light meat,spice and fermenta on odour; 7= strong meat, spice and fermentation odour), saltytaste (1=light salty taste; 7=strong salty taste), acid taste (1 = light acid taste; 7 =strong acid taste), bitter taste (1= non-bitter; 7 = extremely bitter) and overallacceptability (1=low;7=high). The panellists cleansed their mouths/taste buds withwater between samples.The evaluations were performed under normal light at roomtemperature (approximately 25°C). 2.7. Statistical analysis Three independent batches of sausages (replicates) were prepared on different days,and a total of three treatments of sausages were prepared in each batch. Allexperimental measurements were performed in triplicate (triplicate observations) foreach batch of sausages. The results are expressed as the mean values ± standard errors(SE). To analyse the effects of factors and the interac ion between factors (salttreatment and fermentation time), two-way analysis of vriance (ANOVA) withTukey’s test was performed using Statistical software (version 5.0, StatSoft. Inc.,Tulsa,USA) at the significance level of 0.05. Biplot baseon principal component analysis(PCA) was performed using the SIMCA i.wre (version 14.1, Umea, Sweden) forvolatile compounds, E-nose and E-tone data. The hierarchical cluster analysis (HCA)was performed using SPSS 22.0 anaytical Software, New York, USA). Variations inmoisture content, pH, LAB.nd Staphylococcus counts, volatile compounds, E-noseand E-tongue were desribe d using a mixed model with different treatments (C, S1and S2) and differetimentation times (0, 3, 6 and 9 d) as fixed terms, and sausageand preparation day as random terms. For the analyses of factors affecting eachsennsscory trait (colour, aroma,saltytaste.,aciddtaste.e,bittertaste aand overallacceptability), a fixed term for full models included different treatments (C, S1 and S2)and random terms included sausage, preparation day and sensory panel (sessionnumber, tasting order and panellist number). 3. Results and discussion 3.1. Moisture content, pH and bacterial counts As presented in Table 2, the moisture contents decreased from 62.98%, 62.78% and61.99% at 0 d to 28.87%, 32.12% and 33.15% at 9 d for the control, S1 and S2treatments, respectively (P<0.05). There were higher moisture contents in the S1 andS2 treatments compared to the control treatment (P<0.0), which was attributed tothe lower Na content that inhibited the release of water ( lin, Grau, Baigts, & Barat,2009). The lower pH was determined in the S1 and s2 treatments than the controltreatment (P<0.05), which was primarily attributeo the higher LAB counts causedby the lowering of the NaCl addition level.、orover, the pH of the S2 treatment wasthe lowest of all three treatments (P、f.05) due to the use of amino acids (lysine andalanine), which are directly metlied by the microorganisms (Chen et al., 2019).LAB and Staphylococcus a. essential for developing the flavour and quality offermented meats (Ravvts,,De Vuyst, & Leroy, 2012). The LAB count sharplyincreased from appmately 7.0 log CFU/g to 8.41, 8.61 and 8.76 log CFU/g (P <0.05) for the control, S1 and S2 treatments, respectively, and the S1 and S2 treatmentshad higher LAB counts than the control treatment (P<0.05). As we know, the growthof Staphylococcus would be limited by the low pH and decreased oxygen contentscaused by LAB (Lisazo,Chasco,& Beriain, 1999). However, the Staphylococcus countfor the control, S1 and S2 treatments slowly increased from approximately 7.0 logCFU/g to 7.88, 7.64 and 7.62 log CFU/g after a nine-day fermentation, respectively (P < 0.05). It is worth noting that the Staphylococcus xylosus A2 was used as starterculture for the sausage preparation, and its inoculation level was approximately 7.0 logCFU/g. Therefore, the slight increase in Staphylococcus counts of sausages may beattributed to the high initial Staphylococcus counts. This result was consistent with thefindings of Xiao, Liu, Chen, Xie, and Li (2020). Besides, the Staphylococcus counts inthe S1 and S2 treatments were lower than the control treatr ent (P<0.05), which maybe ascribed to the halophilism of Staphylococcus and the owepH. 3.2. Volatile compound analysis orp-3.2.1. Volatile compound contentse Sixty-two volatile compounds wei etected in the dry fermented sausages duringfermentation and were compriseifoaldehydes, 4 ketones, 12 alcohols, 5 acids, 12esters, 18 terpenes and 33theis (Table 3). The compounds were generated viacarbohydrate metabolism.lipidoxidation.amino acidcatabolism.bacterialesterification and sice. (round cardamom, Pericarpium zanthoxyli, angelica, aniseed,fennel, Amomum villosum. cassiabark, clove aandpepper) (Flores, Corrala,Cano-Garciaa, Salvadora, & Bellochb, 2015;Chen et al., 2017). Carbohydrate metabolism has large effects on the flavour formation of fermentedsausages, which is primarily performed by the LAB that generated acids, alcohols andketones (Ravyts et al., 2012). As shown in Table 3, there were significant differences(P <0.05) not only in fermentation time and NaCl level, but also in the interaction between the fermentation time and NaCl level for the most compounds (except forethanol) derived from carbohydrate metabolism. The compounds originated fromcarbohydrate metabolism, including ethanol, 3-hydroxy-2-butanone, acetone, butanoicacid and acetic acid, were detected in all three treatments in the present. The contents of3-hydroxy-2-butanone, which is a characteristic flavour compound with dairy andoverripe fruit odours, significantly increased (P<0.05). Wh ile, the contents of ethanolsignificantly decreased during fermentation (P< 0.05), whi h may be because it isconverted into the corresponding acids, aldehydes a desters (Sun, Zhao, Zhao, Zhao,& Yang,2010). Notably, the contents ofacetic acid u butanoic acid increased, but thisincrease may not greatly affect the flavc ai development due to their higher odourthreshold values (Hu et al., 2020). As scribed by Corral, Salvador, and Flores (2013),a NaCl reduction affected the comovunds from carbohydrate metabolism. The S2treatment had the highest co. tents of these compounds in all three treatments in thepresent (P<0.05), which wis ascribed to the lowest NaCl contents in the S2 treatmentand promoted LAt owth and metabolism (Chen etal., 2015). Lipid autoxidation and incomplete lipid p-oxidation promote free fatty acids andother precursors to form volatile compounds via chemical and microbial reactions,respectively (Olivares et al., 2009). Most acids and aldehydes, such as octanoic acid,hexanoic acid, nonanoic acid, octanal, hexanal and nonanal, commonly originate fromlipid autoxidation and play significant roles in the flavour development of fermentedsausage (Chen et al., 2017; Cano-Garcia, Rivera-Jimenez, Belloch, & Flores, 2014). However, the contents of these compounds varied insignificantly in all three treatments(P >0.05). Additionally, 2-nonanone originated from lipid p-oxidation due to thepresence of Staphylococcus, which provides meat products with rose and tea odours(Shahidi, Rubin, & D'Souza, 1986; Flores et al., 2015). Among the compounds fromlipid oxidation, only the content of 2-nonanone wassignificantly influenced byfermentation time, NaCl level and their interactions (P <0.05). A lower content ofthis compound was found in the S2 treatment compared 1 th other treatments at 9 d(P<0.05). Amino acid catabolism is also a major pathway producing volatile compounds.(Herranz, Fernandez, de la Hoz, & Ordorz,2006). The a-keto acids, which are theimportant intermediates of aminoa 1 catabolism, are metabolized to form thecorresponding aldehyde.s ,andve aaldehydescan aalso be converted into thecorresponding alcohols and a ids, which may provide fruity, malty and sweaty odoursin the fermented sausages ( Iu et al.,2019). The present study demonstrated that thecontentsof 2-mchylutanal, 2-methylpropanal and 3-methylbutanalthattareoriginated from the catabolism of isoleucine, valine and leucine via the action of LAB(Herranz et al., 2006; Irigoyen, Ortigosa, Juansaras, Oneca, & Torre, 2007) wweresignificant influenced by the fermentation time and NaCl level as well as theirinteractions (P<0.05). The results showed that their contents were higher in the S2treatment than the other treatments (P<0.05). Bacterial esterification of fatty acids with alcohols greatly affects the formation of esters that provide fruity and sweet odours and mask a rancid odour (Cano-Garcia et al.,2014; Flores, Dura, Marco, & Toldra, 2004; Stahnke, 1994).Ethyl esters (includingethyl acetate, ethyl lactate, ethyl hexanoate, ethyl heptanoate, ethyl octanoate, ethylbutyrate, ethyl decanoate and ethyl 3-phenylpropionate) were the most abundant estersin the fermented sausages in the present study, which may be derived from theesterification of ethanol and acids and directly from t'ie wine used in sausagepreparation (Carroll, Desai,& Atsumi, 2016). The lower ont nts of most esters werefound in the S1 and S2 treatments compared to the contii treatment (P<0.05), whichmay be due to the esterification of Staphylococe..(Purrifos, Franco, Carballo, &Lorenzo, 2012;Papamanoli, Kotzekidou,Tzeetakis, & Litopoulou-Tzanetaki, 2002). Several studies reported that the tenes, such as humulene, p-pinene, 3-carene,a-curcumene, D-limonene, copafas and y-terpinolene, may be derived from the spices(Montanari et al., 2016; Peicevic, Radoveic, Lukic, Listes, & Medic, 2018). Anincreased content of th se(mpounds was found during fermentation in the presentstudy (P <0.05,) ,hih may be due to the drying and subsequent concentration ofspices. While, the effects ofNaCl level and the interaction between fermentation timeand NaCl level on the contents of these compounds were not significant (P>0.05). 3.2.2. Principal component analysis ofvolatile compounds To further highlight the differences of volatile profiles of dry fermented sausages withdifferent sodium substitutes, PCA was performed on the volatile compounds of the sausages. The first two principle components explained 97.00% and 1.90% of theoverall variance, respectively (Fig. 1). The first principal component (PC1) was themost important variable and positively correlated with all the volatile compoundsexcept for ethanol (13). A clear separation among sausages can be observed. Thesausages at 0 d were clustered in the negative PC1 axis, while the sausages at 9 d werearranged on the positive PC1 axis, which indicated that PC1 differentiated sausageswith respect to the fermentation. Toor3.2.3. Odour activity value analysisp- Flavour perception not only depends or.tontents of volatile compounds but isalso associated with the threshold valu、of the volatile compounds (Van Gemert,2011).OAV is an index combining th_stwo parameters to evaluate the contribution ofvolatile compounds (Olivare et ai., 2010). It is generally recognized that compoundswith an OAV > 1 play an important role in overall odour (Olivares et al., 2010).Compounds with v 1 and their odour descriptions are listed in Table 4. There were26 key volatile compounds with OAV>1, which were considered the main contributorsto the fermented odour in sausages during the whole fermentation. Compounds withOAV>1 and their odour descriptions are listed in Table 4. Compounds with an OAV>1 play an important role in overall odour (Olivares et al., 2009). There were 26 keyvolatile compounds with OAV >1, which were considered the main contributors to thefermentedi oodour in sausagesCduring: the whole; fermentiattaitoino.n. Particularly. 2-methylpropanal, 2-methylbutanal, octanal, nonanal, hexanal, hexanol, 1-octen-3-ol,eucalyptol, linalool, methyl butyrate,methyl hexanoate, ethyl acetate, ethyl hexanoate,ethyl heptanoate, ethyl butyrate, ethyl 3-phenylpropionate, copaene, B-caryophylleneand D-limonene (with OAV >5) greatly contributed to the overall odour of dryfermented sausages. For example, the compound with the highest OAV (OAV =108.03-865.54) in all sausages was ethyl hexanoate, which contributed apple peel andfruity odours to the sausages. D-limonene with a high OV(QAV=71.15-99.66) is amajor component of the pepper that was added dring the preparation of sausage,which contributed to the lemon note of the dry fernted sausages (Wilkins & Madsen,1989). erP3.3. Electronic nose analysis\a E-nose is an efficient t1 to distinguish odour profile, and it may acquirecomprehensive inform tion that is associated with volatile compounds in samples(Tiggemann et al.,2017. The response values of the E-nose of the fermented sausageswith different sodium substitutes are shown in Fig. 1A. The response values of W1C(sensitive to aromatic constituents, benzene), W3C (sensitive to aroma, ammonia),W5C (sensitive to short-chain alkane aromatic component), W1S (sensitive to methyl),W1W (sensitive to sulphides) and W2S (sensitive to alcohols, aldehydes and ketones)sensors increased (P<0.05), which suggested that aromatic constituents, methylcompounds, alcohols, aldehydes and ketones were generated in the fermented sausages. In contrast, the response values of W6S (sensitive to hydrides) and W3S (sensitive tolong-chain alkanes) sensors decreased (P <0.05), and the response values of W5S(sensitive to nitrogen oxides) and W2W (sensitive to organic sulphides) sensorsremained almost unchanged (P>0.05) in the fermented sausages from 0 d to 9 d. Theincreased response values of alcohols, aldehydes and ketones in the analysis of E-nosewere consistent with the results of the HS-SPME-GC-MS. As depicted in Fig. 1B, PC1 and PC2 explained 75.5 1% nd 13.90% of the totalvariance, respectively. PC1 was the most important vriavle for the differences betweentreatments (control, S1 and S2). All sausages at 0destered in the negative axis ofPC1,which were correlated to the sensors of W5V3S and W5S, and all sausages at 9 dclustered in the positive axis ofPC1,hch were associated with the other sensors. Theresults showed that these senss1lore effectively discriminated dry fermentedsausages with different ferme tation times. The E-nose data distribution of the S1 andS2 treatments was relati ely elose, indicating that they had similar odours. 3.4. Electronic tongue analysis As presented in Fig. 2A, the response values of the sourness, saltiness, bitterness,astringency, aftertaste-astringency (aftertaste-A), aftertaste-bitternesss (aftertaste-B)and richness increased (P<0.05), and the response value of umami decreased (P<0.05)in the fermented sausage from 0 d to 9 d. The increase in sourness may be caused by thegeneration of acids derived from the carbohydrate metabolism of LAB. The S2 treatment had the highest sourness value of all the treatments at 9 d, which wasconsistent with the pHresults. The increase in bitterness may be due to the addition ofKCl and the decrease in moisture content. Especially, the highest bitterness value wasfound in the S1 treatment. The increase in saltiness may be attributed to the decrease inmoisture content, which caused the salt content to increase. Besides, the increase inrichness after a nine-day fermentation may be explained ty the formation of varioustaste substances, such as free amino acids, which maybe produced from proteinhydrolysis (Zhao, Schieber, & Ganzle,2016). As shown in Fig. 2B, PC1 and PC2 explained;2.00% and 14.60% of the totalvariance, respectively. All sausages at 0 d l. te ed in the negative axis of PC1, whichwas associated with umami. All sauseas at 9 d clustered in the positive axis of PC1,令which was related to the other tasu seusors. The control treatment was close to the S2treatment, which may be resuted irom the similarity of saltiness, sourness, astringency,aftertaste-A and the richness of these flavours. However, the S1 treatment was far fromthe S2 and controleaments due to the differences of bitterness and aftertaste-B. Theresults also indicated that the E-tongue well discriminated the S1 and S2 treatments thatwere not distinguished by the E-nose. 3.5. Hierarchical cluster analysis ofdry fermented sausages In order to characterize the correlation of dry fermented sausages with differentsodium substitutes, HCA was applied to the fused dataset comprised of E-nose, E-tongue and key volatile compounds, employing the Euclidean distances to calculatethe interpoint distances among dry fermented sausagesWwith different sodiumsubstitutes (Zhu et al.,2020). As shown in Fig.4, the dendrogram clearly showed thatthe sausages were clustered into two major groups, including group A consisting ofthree sausages (C, S1 and S2 treatments at 0 d) and group B consisting of threesausages (C, S1 and S2 treatments at 9 d). The three saus.ges at 0 d had the similarflavour profile, whereas the S1 treatment was most simil. r as the S2 treatment at 9 d.This result was similar as the PCA results of volatil compounds and E-nose. That issay, the sodium substitute had a more significan rect on the odour profile of dryfermented sausages. erP3 .6. Sensory evaluationla As presented in Table 5, th. sensory evaluation showed that the colour and salty tastevaried insignificantly in all te treatments (P>0.05), which indicates that both sodiumsubstitutes providea snilar colour and salty taste as the control treatment. However,the S1 treatment had the highest score of all treatments for bitter taste, which may bedue to the higher content of KCl. Gou, Guerrero, Gelabert, and Arnau (1996) alsoreported that the bitter and metallic tastes were detected by the panellists at a 30%addition level of KCl in fermented sausage. The S2 treatment had the highest score ofall treatments for acid taste, which was likely attributed to the use of calcium lactateand citric acid or the lactic acid originating from carbohydrate metabolism. These results are consistent with the findings of the E-tongue. In terms of odour, the S1 andS2 treatments had higher scores than the control treatment (P<0.05), which was dueto the larger bacterial counts in these two treatments, and this result was consistentwith the findings of the E-nose. Altogether, the control and S2 treatments had higherscores for the overall acceptability than the S1 treatment, which indicates that theywere more favoured by the panellists. to4. Conclusions o r) The present study investigated the effects of sode substitutes on the dry fermentedsausage via analyses of physical properiebacterial counts, flavour profile andsensory evaluation during the entire fe.ientation. The substitution of 30% of the NaClwith KCl and flavour enhancers (2) increased the moisture content and LAB countand decreased the pH and St phyiococcus count compared to other treatments, whichleads to changes in the fla yur profile of fermented sausages. Furthermore, E-noseand HS-SPME-Gu MC analyses revealed that similarities of odour existed betweenS1 and S2 treatments, and the results of E-tongue distinguished the taste characteristicsof different treatments and demonstrated good consistency with the results of thesensory evaluation. These results reflected that the taste profile of the S2 treatment wassimilar to the control treatment. HCA indicated that the sodium substitutes had a moresignificant effect on the odour profile of dry fermented sausages. Therefore, S2 maybe used as a low-sodium substitute in dry fermented sausage to achieve better quality and flavour with a 30% reduction in NaCl. Acknowledgements This study was funded by the National Natural Science Foundation of China(31972139), the "YoungTalents" Project of Northeast: Agricultural University(18QC56) and the National Key Research and Developmet Program during the 13thFive-year Plan period in China (2016YFD0401504-0.).he volatile compoundanalysis was supported by Shimadzu (China) Co.Ltu. in the Shenyang analyticalcentre. References Alino, M., Grau,R., Baigts, D.,&Parat,J.M. (2009). Influence of sodium replacementon the salting kinetics ofrrk loin. Journal ofFood Engineering, 95, 551-557.AOAC. (1995). AOAC Asciation of official methods of analysis methods 925.04(16th ed.). Arling*u, VA: Association of Official Analytical Chemists. Bidlas, E., & Lambert,R.J.(2008). Comparing the antimicrobial effectiveness of NaCland KCl with a view to salt/sodium replacement. International Journal of FoodMicrobiology,124,98-102. Buemi, M., Senatore, M., Corica, F., Aloisi, C., Romeo, A., Tramontana, D., & Frisina,N. (2002). Diet and arterial hypertension: is the sodium ion alone important?Medicinal Research Reviews, 22,419-428. Campagnol, P. C. B., dos Santos,B. A., Morgano, M. A., Terra,N. N.,& Pollonio, M. A.R.(2011). Application of lysine, taurine, disodium inosinate and disodium guanylatein fermented cooked sausages with 50% replacement of NaCl by KCl. Meat Science,87,239-243. Campagnol, P. C. B., dos Santos, B. A., Wagner, R., Terra, N. N., & Pollonio, M. A. R.(2011). The effect of yeast extract addition on quality of fermented sausages at lowNaCl content. Meat Science, 87, 290-298. Cano-Garcia, L., Rivera-Jimenez, S., Belloch, C., & Floes. M. (2014). Generation ofaroma compounds in a fermented sausage mea nodel system by Debaryomyceshansenii strains. Food Chemistry,151,354373. Carroll, A. L., Desai, S. H., & AtsunS. (2016). Microbial production of scent andflavor compounds. Current Oruon in Biotechnology,37,8-15. Chen, J. X., Hu, Y. Y., Wen, R. X., Liu, Q., Chen, Q., Kong, B. H. (2019). Effect ofNaCl substitutes on the ptysical, microbial and sensory characteristics of Harbin drysausage. Meat Seienee, 156,205-213. Chen, Q., Kong, B., Han, Q., Liu, Q., & Xu, L. (2016). The role of bacterialfermentation in the hydrolysis and oxidation of sarcoplasmic and myofibrillarproteins in Harbin dry sausages. Meat Science, 121, 196-206. Chen, Q., Kong, B., Han, Q., Xia, X., & Xu, L. (2017). The role of bacterialfermentation in lipolysis and lipid oxidation in Harbin dry sausages and its flavourdevelopment. LWT-Food Science and Technology, 77, 389-396. Chen, Q., Liu, Q., Sun, Q., Kong, B., & Xiong, Y. (2015). Flavour formation fromhydrolysis of pork sarcoplasmic protein extract by a unique LAB culture isolatedfrom Harbin dry sausage. Meat Science, 100, 110-117. Chen, Q., Song, J., Bi, J., Meng, X., & Wu, X. (2018). Characterization of volatileprofile from ten different varieties of Chinese jujubes by HS-SPME/GC-MS coupledwith E-nose. Food Research International, 105,605-615 Corral, S., Salvador, A., & Flores,M. (2013). Salt reductio in: low fermented sausagesaffects the generation of aroma active compounds Meut Science, 93, 776-785. De Almeida, M. A.,Saldana, E., da Silva Pinto, J.S.,alacios,J., Contreras-Castillo, C.J., Sentandreu, M. A., & Fadda, S.G.(201epeptidomic approach of meat proteindegradation in a low-sodium ferme.ed sausage model using autochthonous startercultures. Food Research Interruional,109,368-379. Desmond, E. (2006). Reduci. o sait: A challenge for the meat industry. Meat Science,74,188-196. Dong, W. J., Hu, k. S.,Long, Y. Z., Li, H. H., Zhang, Y. J., Zhu, K. X.,& Chu, Z. (2018).Comparative evaluation of the volatile profiles and taste properties of roasted coffeebeans as affected by drying method and detected by electronic nose, electronictongue, and HS-SPME-GC-MS. Food Chemistry, 272, 723-731. Donglu, F., Wenjian, Y., Kimatu, B. M., Liyan, Z., Xinxin, A., & Qiuhui, H. (2017).Comparison of flavour qualities of mushrooms (Flammulina velutipes) packed withdifferent packaging materials. Food Chemistry, 232, 1-9. dos Santos, B. A., Campagnol, P. C., Morgano, M. A., & Pollonio, M. A. (2014).Monosodium glutamate, disodium inosinate, disodium guanylate, lysine and taurineimprove the sensory quality of fermented cooked sausages with 50% and 75%replacement of NaCl with KCl. Meat Science,96,509-513. Flores, M., Corrala, S., Cano-Garciaa, L., Salvadora, A., & Bellochb, C. (2015). Yeaststrains as potential aroma enhancers in dry fermentrd sausages. InternationalJournal of Food Microbiology,212,16-24. Flores, M., Dura, M. A., Marco, A.,& Toldrá, F. (20 )4). Effect of Debaryomyces spp.on aroma formation and sensory quality of dry-fe.ented sausages. Meat Science,68,439-446. Gou, P., Guerrero, L., Gelabert, J.,&A^nau, J. (1996). Potassium chloride, potassiumlactate and glycine as sodiurhlvride substitutes in fermented sausages and indry-cured pork loin. Meatcience, 42(1),37-48. Guardia, M. D., Guerrero,,L., Gelabert, J., Gou, P., & Arnau, J. (2008). Sensorycharacterisation nu consumer acceptability of small calibre fermented sausageswith 50% substitution of NaCl by mixtures of KCl and potassium lactate. MeatScience,80, 1225-1230. Herranz, B., Fernandez, M., de la Hoz, L., & Ordonez, J. A. (2006). Use of bacterialextracts to enhance amino acid breakdown in dry fermented sausages. Meat Science,72,318-325. Hu, Y. Y., Chen, Q., Wen, R. X., Wang, Y., Qin, L. G.,& Kong, B. H. (2019). Quality characteristics and flavor profile of Harbin dry sausages inoculated with lactic acidbacteria and Staphylococcus xylosus. LWT-Food Science and Technology, 114,108392. Hu, Y. Y., Zhang, L., Zhang, H., Wang, Y., Chen, Q., & Kong, B. H. (2020).Physicochemical properties and flavour profile of fermented dry sausages with areduction of sodium chloride.LWT-Food Science and Te hnology, 124,109061. Irigoyen, A., Ortigosa, M., Juansaras, I., Oneca, M., & Toire,(2007). Influence of anadjunct culture of Lactobacillus on the free amine icius and volatile compounds in aRoncal-type ewe’s-milk cheese. Food Chemistry,00, 71-80. Montanari, C., Bargossi, E., Gardini, A., Lercotti, R., Magnani, R., Gardini, F., &Tabanelli, G. (2016). Correlation tween volatile profiles of Italian fermentedsausages and their size and staculture. Food Chemistry, 192, 736-744. Morris, C., Labarre, C., Koliadris, A. L., Hewson, L., Wolf, B., Taylor, A. J., & Hort, J.(2010). Effect of pused delivery and bouillon base on saltiness and bitternessperceptions of sa’taelivery profiles partially substituted with KCl. Food Quality andPreference, 21, 489-494. Olivares,A., Navarro, J. L., & Flores, M. (2009). Establishment of the contribution ofvolatile compounds to the aroma of fermented sausages at different stages ofprocessing and storage. Food Chemistry, 115, 1464-1472. Olivares, A., Navarro, J. L., Flores, M. (2011). Effect of fat content on aromageneration during processing of dry fermented sausages. Meat Science, 87, 264-273. Paik, D. C., Wendel, T. D., & Freeman, H. P.(2005). Cured meat consumption andhypertension: analysis from NHANES ⅢI (1988-94). Nutrition Research, 25,1049-1060. Papamanoli, E.,Kotzekidou, P., Tzanetakis, N., & Litopoulou-Tzanetaki, E. (2002).Characterization of Micrococcaceae isolated from dry fermented sausage. FoodMicrobiology,19,441-449. Peris, M., & Escuder-Gilabert, L. (2016). Electronic nose an l tongues to access foodauthentication and adulteration. Trends in Food Srence and Technology,58, 40-54 Petridevic, S., Radovcic, N. M., Lukic, K., Lies, E., & Medic, H. (2018).Differentiation of dry-cured hams from a. fe ent processing methods by means ofvolatile compounds, physico-chen.al and sensory analysis. Meat Science,137, 217-227. Purrinos, L., Franco,D., Caallo, J., Lorenzo, J. M. (2012). Influence of the saltingtime on volatile cor nou .ds during the manufacture of dry-cured pork shoulder“lacon". Meat Seinee, 92, 627-634. Ravyts, F., De Vuyst, L., & Leroy, F. (2012). Bacterial diversity and functionalities infood fermentations. Engineering in Life Science,12, 356-367. Ruusunen, M., & Puolanne,E. (2005). Reducing sodium intake from meat products.Meat Science, 70, 531-541. Shahidi, F.,Rubin, L. J., & D’Souza,L. A. (1986) Meat flavor volatiles: a review of thecomposition, techniques of analysis, and sensory evaluation. Critical Reviews in Food Science and Nutrition, 20, 144-243. Stahnke, L. H. (1994). Aroma components from dried sausages fermented withStaphylococcus xylosus. Meat Science, 38, 39-53. Steffensen, I. L.,Frolich, W., Dahl,K. H., Iversen, P. O., Lyche, J. L.,Lillegaard, I. T. L.,& Alexander, J. (2018). Benefit and risk assessment of increasing potassium intakeby replacement of sodium chloride with potassium chloride in industrial foodproducts in Norway. Food and Chemical Toxicology, 1.1,319-340. Sun, W. Z., Zhao, Q. Z., Zhao, H. F., Zhao, M. ., & Yang, B. (2010). Volatilecompounds of Cantonese sausage released at ferent stages of processing andstorage. Food Chemistry,121,319-325. Tiggemann, L., Ballen, S. C., Bocalon.,C. M., Graboski, A. M., Manzoli, A., Steffens,J., Valduga, E., & Steffens, C017). Electronic nose system based on polyanilinefilms sensor array with .fferent dopants for discrimination of artificial aromas.Innovative Food Science cad Emerging Technologies, 43,112-116. Van Buren, L., Dou chKlerk, M., Seewi, G., & Newson, R. (2016).Dietary impact ofadding potassium chloride to foods as a sodium reduction technique. Nutrients, 8(4),235. Van Gemert, L. J. (2011). Compilations ofodour threshold values in air, water and othermedia (2011 ed.). The Netherlands: Oliemans Punter & Partners BV. Wasilewski, T., Migon, D., Gebicki, J., & Kamysz, W. (2019). Critical review ofelectronic nose and tongue instruments prospects in pharmaceutical analysis. Analytica Chimica Acta, 1077, 14-29. Wen, R. X., Hu, Y. Y., Zhang, L., Wang, Y., Chen, Q., & Kong, B. H. (2019). Effect ofNaCl substitutes on lipid and protein oxidation and flavor development of Harbin drysausage. Meat Science, 156,33-43. Wilkins, K., & Madsen, J. O. (1989). Paprika headspace constituents. Flavors andoff-flavors. In G. Charalambous (Ed.), Proceedings cf 6th international flavorconference (pp. 293-297). Amsterdam: Elsevier Scienc Pu lishers. Wu, H., Yue, T. L., Xu, Z. J.,& Zhang, C. (2017Sensor Array optimization anddiscrimination of apple juices according to vail ty by electronic nose. AnalyticalMethods, 9,921-928. Wu,R. N., Yu, M. L., Liu, X. Y., Meng, .S., Wang, Q. Q., Xue, Y. T., Wu, J. R., & Yue,X. Q. (2015). Changes in flaveand microbial diversity during natural fermentationof suan-cai, a traditional od made in Northeast China. International Journal ofFood Microbiology,211,..3-31. Xiao, Y., Liu, Y., Chel,., Xie, T., & Li, P. (2020). Effect of Lactobacillus plantarumand Staphylococcus xylosus on flavour development and bacterial communities inChinese dry fermented sausages. Food Research International, 135,109247. Zaragozá, P., Fuentes, A., Fernandez-Segovia, I., Vivancos, J. L., Rizo, A., Ros-Lis, J. V., Barat, J. M., & Martinez-Manez, R. (2013). Evaluation of sea bream (Sparusaurata) shelf life using an optoelectronic nose. Food Chemistry, 138, 1374-1380. Zhan, H., Hayat, K., Cui, H. P., Hussain, S., Ho, C. T., & Zhang, X. M. (2019). Characterization of flavor active non-volatile compounds in chicken broth andcorrelateeddc(ontributingconstituentcompoundsinmuscle throughsensoryevaluation and partial least square regression analysis. LWT-Food Science andTechnology,118,108786. Zhang, J. H., Cao, J., Pei, Z. S., Wei, P.Y., Xiang, D., Cao, X. Y., Shen, X. R., & Li, C.(2019).Volatile flavour componentsand the mec anismsunderlying theirproduction in golden pompano (Trachinotus blochii) fille s subjected to differentdrying methods: A comparative study using an ele tronic nose, an electronic tongueand SDE-GC-MS. Food Research International,123,217-225. Zhang, M., Chen, X., Hayat, K.,Duhorani 1E., Zhang, X. M., Xia, S. Q., Yu, J. Y.,& Xing, F. L. (2018). Characteriza. n of odor-active compounds of chicken brothand improved flavor by therra mudulation in electrical stewpots.Food ResearchInternational,109, 72-81 Zhang, W., Naveena, B. M., o, C., Sakata, R., Zhou, G., Banerjee,R., & Nishiumi,T.(2017). Technorolcui demands of meat processing-an Asian perspective. MeatScience, 132,35-44. Zhao, C. J., Schieber, A., & Ganzle, M. G. (2016). Formation of taste-active aminoacids, amino acid derivatives and peptides in food fermentations - a review.FoodResearch International,89, 39-47. Credit Author Statement Qian Chen: DaDtaat acuration,. Writing-Original draft preparation and Fundingacquisition. Yingying Hu: Investigation and Formal analysis. Rongxin Wen: Investigation and Formal analysis. Yan Wang: Data curation. Ligang Qin: Conceptualization, Writing-Reviewing an 1 Ec iting. Baohua Kong: Conceptualization, Methodology, Visuulization and Supervision. Journal Pre-c Declaration of interests xTThe authors declare that they have no known competing financial interests orpersonal relationships that could have appeared to influence the work reported in thispaper. The authors declare the following financial interests/pe son al relationships whichmay be considered as potential competinginterests( ore hruoJ 0 55 39 R2X1]=0.970 R2X[2]=0.019 Fig. 1. Principal component ar a, sis of volatile compound data for dry fermentedsausages with different NaCl ubstitutes at 0 d and 9 d. C: 100%NaCl; S1: 70% NaCland 30%KCl; S2: 70% NaC, 20%KCl and 10% flavour enhancers. W1C 1.5 0.5 S1-0 W3S 0 W6S S2 -0.5 -1 -1.5 -1.5 -1 Fig. 2. Radar chart (A) and principa omponent analysis (B) ofelectronic nose datafor dry fermented sausages with dere it NaCl substitutes at 0 d and9 d. C:100%NaCl;S1: 70% NaCl and 30%KCl, S2: 70% NaCl, 20% KCl and 10% flavour enhancers. urJo Umami C-0 -1.5 -1 Fig. 3. Radar chart (A) and princi al conponent analysis (B) of electronic tonguedata for dry fermented sausages with different NaCl substitutes at 0 d and 9 d. C: 100%NaCl; S1: 70% NaCl and 30% ; S2: 70% NaCl, 20% KCl and 10% flavourenhancers. rurJo Fig. 4. Hierarchical cluster analysis ofd yr nented sausages with different NaClsubstitutes at 0 d and 9 d based on theectronic nose, electronic tongue, and keyvolatile compound data. C: 100%acl; S1: 70%NaCl and 30%KCl; S2: 70% NaCl,20%KCl and 10% flavourehancers. ruoJ Highlights 1.. A total off 62 volatillee compounds in sausages wereidentifiedusingHS-SPME-GC-MS. 2. E-nose and E-tongue distinguished sausages with different sodium substitutes. 3. Sodium substitute with flavour enhancers (S2) replaced 30% of the NaCl insausages. 4. Sodium substitute S2 improved the flavour dev lopent of dry fermentedsausage. Journal Pre-prd Table 1. Information of 10 sensors for electronic nose. Sensor Representative material material Description(s) name species W1C Aromatic Sensitive to aromatic constituents, benzene W5S Broad range Sensitive to nitrogen oxides W3C Aromatic Sensitive to: roma, ammonia W6S Hydrogen Sensitive tc hyc rides W5C Arom-aliph Sensit ve tO short-chain alkane aromatic compo、nt W1S Broad-methane Sensitive to methyl W1W Sulphur-organic Sensitive to sulphides W2S Broad-alcohol Sensitive to alcohols, aldehydes and ketones W2W Sulph-chlor Sensitive to organic sulphides W3S Methane-alip Sensitive to long-chain alkanes Table 2. Physicochemical and bacterial properties of dry fermented sausages with different NaCl substitutes during fermentation. Salt treatment Fermentation Moisture content pH Lactic acid bacteria Staphylococcus count time (%) count (log CFU/g) (log CFU/g) C 0d 62.98±0.52° 6.42±0.12 6.99+0.3 7.01±0.13 S1 62.78±0.19° 6.38±0.10 7.0.±0.03° 7.03±0.09 S2 61.99±0.79° 6.24±0.08 6.95±0.15° 7.02±0.18 C 3d 45.19±0.55° 555±0)26 8.10±0.10 7.59±0.07 S1 43.16±0.90° 5.15±0.03 8.19±0.11cd 7.57±0.09° S2 49.45±43 4.87±0.10" 8.49±0.0gabc 7.60±0.12 C 6d 9d 36.25+0.30 5.03±0.03cd 8.24±0.06ed 7.90±0.04 S1 38.45±0.61¥ 4.87±0.04 8.46±0.12abc 7.75±0.07abc S2 41.49±0.45° 4.53±0.02 8.69±o.osab 7.70±0.06abc C 28.87±0.25" 4.96± 0.05cd 8.41±0.07bcd 7.88±0.02 S1 32.12±0.43° 4.86±0.06 8.61±0.02ab 7.64±0.04abc S2 33.15±0.41 4.53±0.09° 8.76±0.04 7.62±0.03bc P (Salt) ** ** ** * P (Time) ** ** ** ** (Salt * ** ** ns Time) Data are represented as the mean values standard errors. a-h Indicates withir the sune column with different lowercase letters significantdifferences (P<0.05). C: 100%NaCl;S1: 70% NaCl and 30%KC! S2·70%NaCl, 20% KCl and 10% flavour enhancers. ns: not significant (P>0.05); *: important (P<0.05); **: very important (P<0.01). Table 3. Volatile compounds identified and quantified (ug/kg) in dry fermented sausages with different NaCl substitutes at 0 d and 9 d. N Volatile 0d LR Source I C S1 S2 C P P 0 compounds S1 S2 (Salt) (Time) Aldehydes Lipid oxidation 13 4.38 士 40.43 40.65 士 Nonanal 5.02±0.64° 5.66±0.16° or ns ** 2 3 85 0.13 1.21 0.81 Lipid oxidation Octanal 12 1.76±0.05° 1.98±CJ6° 25.64 ± 25.67 25.41 ns ** 83 0.04 0.29* 0.43° 0.39* Hexanal Acetaldehyde Lipid oxidation 10 14.84 土 162 13.66 61.58 土 63.06 62.18 士 ns ** 85 0.43 0.46 0.39 0.89 1.37 0.58 4 5 Carbohydrate 110 140.03 1.08±0.03" 1.00 土 2.45±0.02° 3.54±0.01° 4.39±0.03° ** ** metabolism 8 0.03° Benzaldehyde Amino acid catabolism 15 2.67±0.08° 2.69±0.08° 2.65 士 13.38 13.41 13.50 士 ns ** 45 0.08 0.01 0.01° 0.01 2-Methylpropa nal 6 n.d. n.d. n.d. 2.30±0.03° 2.62±0.02° 3.34±0.04 ** ** 6 Amino acid catabolism 81 7 2-Methylbutana Amino acid catabolism 91 n.d. n.d. n.d. 2.64±0.04° 2.78±0.02° 3.74±0.03* ** ** ** 7 8 3-Methylbutana Amino acid catabolism 92 5 n.d. n.d. n.d. 1.83±0.05° 1.98±0.04 2.53±0.03° ** ** ** Ketones Carbohydrate 96 5.46±0.16" 5.73±0.16 5.19 ± 24.21 o. 26.85 土 29.12 + ** ** ** Acetone metabolism 5 0.15 6.18° 0.29 0.12 Spices 10 31.92 土 32.22 土 31.6 94.63 十 100.49 102.77 十 Fenchone ** ** ** 83 0.92* 0.93° 0.1 0.40 0.62° 0.36° Lipid oxidation 13 12.39 土 11.68 2-Nonanone 3-Hydroxy-2-b n.d. n. d. 9.26±0.23° ** ** ** 96 ac 0.37 0.41 Carbohydrate 13 10.14 土 10.28 土 10.00 土 85.07 89.21 土 91.92 土 ** ** ** utanone metabolism 09 ).29 0.30° 0.29° 0.36 0.13 0.26 Alcohols Ethanol Carbohydrate 92 135.62 土 132.58± 136.79±3. 115.09 土 121.62± 130.75 士 * ** ns metabolism 8 3.92 3.83ab 95° 0.76° 1.25 1.56ab Hexanol Lipid oxidation 13 5.43±0.16° 5.96±0.17 4.90 土 17.60 17.79 土 19,41 ns ** * 60 0.14° 0.43° 0.80° 0.46° Octano1 Lipid oxidation 17 8.89±0.25° 9.04±0.26° 8.74±0.25 26.45 27.74 士 25.74 士 ns 1.91° 5 64 b 0.58 0.79° 6 7 2-Ethyl-1-hexa nol Lipid oxidation 14 6.70±0.15 6.85±0.20 6.55±0.19 27.32 土 25.84 十 25.62±1.12 ns 87 0.76° 1.24 Lipid oxidation 13 2.21 士 29.56 33.52 土 32.28 十 2.57±0.07° 2.93±0.08 ** 17 0.06° 0.39 0.86* 0.69ab Lipid oxidation 14 2.46 18.71 土 18.11 十 18.17 十 3.24±0.09 4.02±0.17° ns 51 0.07 0.74 0.65 0.64 Lipid oxidation 16 12.71 土 13.14 土 2.28 土 25.69 土 25.73 土 25.86 土 ns 62 0.37 0.386 0.35 0.87 0.77 1.10° Lipid oxidation 15 0.44 土 0.49±Cu1' 0.54±0.02° 4.70±0.23° 4.97±0.12* 5.05±0.06° ns 33 0.01° 2-Heptanol 1-Octen-3-o1 8 9 2 0 2 Heptanol Nonanol c-Terpineol Spices 16 17 44 土 18.66 士 16.22 土 46.13 士 47.10 47.54 士 ns 88 0.50° 0.54 0,47° 1.96° 1.40° 2.11 2 2 Geraniol Spices 18 13.29 土 14.30 土 12.28 土 29.96 土 29.67 十 26.17 士 ** ns 45 0.38* 0.41° 0.35° 0.71 0.68 0.81' Eucalyptol Spices 10 160.97±4.6 162.50 土 159.44 土 522.43 土 519.86 士 511.52 3 31 sb 4,69 4.60° 2.99 4.17 5.24 2 Linalool 4 Spices 15 202.94±5.8 204.08 土 201.80 土 458.34 土 443.68 士 449.11 ns ** 52 6 5.89 5.82 3.27* 3.58 3.83 Acids 2 Acetic acid 5 Carbohydrate 14 14.41± 12.53 十 16.29 44.06 46.82 土 60.94 ** ** metabolism 50 0.42d 0.36 0.47° ±0.97° 0.33 1.44 Butanoic acid 6 Hexanoic acid 7 Carbohydrate 16 0.74±0.02 0.83±0.02 0.65 ± 26.93 31.38 ± 37.47 ** ** metabolism 09 0.02° .35° 0.596 0.59 Lipid oxidation 29 21.14 土 24.99 土 17.2° 十 184.34 十 178.28 180.34 十 ** ns 12 0.61° 0.72° Qe 0.515 8.23 9.18 7.64 2 Octanoic acid 8 Lipid oxidation 20 1.46±0.04° 1.5、±0.04 1.34 土 9.51±0.43* 10.45 士 11.07 士 ns ** 83 0.04 0.55 0.48 2 Nonanoic acid 9 Lipid oxidation 22 n. d. n. d. 4.58±0.14* 4.93±0.33° 4.25±0.05° ns ** 02 Esters 3 Methyl butyrate 0 Bacterial esterification 96 3.12 土 40.84 土 37.52 十 37.32 土 3.63±0.10° 4.14±0.12° ns ** 3 0,09 1.27° 1.24 0.53 3 Methyl Bacterial esterification 118 60.30 土 61.79 土 58.81 土 451.11 446.28 土 417.17 土 ** ** hexanoate 8 1.74 1.78° 1.70° 2.41 1.29* 0.65° 3 Methyl Bacterial esterification 10 6.58±0.19° 7.11±0.20 6.05 土 19.21 土 19.45 士 16.89 士 ns 2 heptanoate 43 0.17° 1.58 1.07° 0.98 ns 3 Methyl Bacterial esterification 13 10.53 土 11.54 土 9.52 土 26.16 土 23.66 土 24.67 土 3 octanoate 89 0.30 0.33 0.27° 0.95* 0.69 0.53 3 Ethyl acetate Bacterial esterification 90 13.18 土 13.88 土 12.48 士 69.57 61.46 59.54 ** 4 7 0.38° 0.40° 0.36° 0.39* 1.24° 0.97° 3 Ethyl lactate Bacterial esterification 13 1.17±0.03° 1.29±0.04 1.05 49.49 土 43.22 十 41.39 十 ** 5 58 0.03 0.44 0.59 1.62° 3 Ethyl hexanoate Bacterial esterification 112 115.40± 122.77 08.03±3. 865.54 土 666.11 土 637.01 土 ** 6 0 3.33" 3.54° 12° 4.32 2.79° 4.24° 3 Ethyl Bacterial esterification 13 5.25±C15' 5.65±0.16° 4.85 士 18.74 十 18.11 17.49 ns 7 heptanoate 28 0.14 0.31 0.36° 0.70 3 Ethyl octanoate Bacterial esterification 14 ..52±0.13° 4.95±0.14c 4.09 土 34.81 土 29.62 27.66 士 ** 8 47 0.12c 1.15° 1.11° 0.99 3 Ethyl butyrate Bacterial esterification 10 1.35±0.04° 1.71±0.05 0.99 土 40.48 土 37.38 35.24 士 ** 9 28 0.03° 0.15 0.70a 1.46° Ethyl decanoate Bacterial esterification 16 0.86±0.02 1.01±0.03 0.71 土 11.86 ± 9.82±0.16° 9.78±0.57° 0 42 0.02° 0.76* Ethyl 4 3-phenylpropionat Bacterial esterification 87 1.63±0.05° 2.03±0.06° 1.23 士 30.54 十 25.96 土 23.86 十 ** ** ** 5 0.04° 1.59 0.81 0.81 e Terpenes 4 a-Curcumene 2 4 a-Cubebene 4 a-Phellandrene 4 Spices 17 5.38±0.16° 5.76±0,17 5.00 土 22.7 土 23.57 + 23.44 ns ** ns 73 0.14 1. 0.62* 1.28 Spices 14 3.80±0.11° 4.36±0.12 3.24 14.89 土 16.40 十 17.04 十 ns ** ns 63 009 0.97 1.11 0.82 Spices 12 3.67±0.10° 3.9±0.11 3.36 土 6.14±0.26° 6.08±0.26° 6.08±0.09° ns ** ns 90 0.10 4 a-Caryophyllen Spices 22 82.32 8~.45 土 85.55 土 117.72 土 109.25± 106.20 ns ** 5 e 09 3.29° 2.14° 4.01° 4.59* 4.31ab 2.45 4 B-Pinene 6 Spices 11 83 53 87.36 79.36 265.73 + 256.45 + 258.08 ** ns 6 2.41 2.53° 2.296 4.04 2.88 3.55* ns 4 B-Elemen 7 Spices 15 4.27±0.06° 4.56±0.19° 4.16 十 8.35±0.27° 8.28±0.31“ 8.26±0.45 ns ** ns 95 0.556 4 B-Caryophyllen Spices i5 76.45 土 69.67 十 75.52 161.89 + 153.30 156.92 土 ns 8 e 94 2.13 1.795 3.33 4.58° 4.96° 6.33 4 y-Terpinolene 9 Spices 117 33.40 土 35.16 74.45 土 74.45 83.85 十 80.11 + ns 8 0.96 1.02° 4.13 4.13 1.60° 2.58 5 Allocimene B 0 5 3-Carene Spices 113 3.26±0.09° 3.46±0.10 3.06±0.09 10.40 士 10.72 12.95 + ns 2 0.49ab 0.78 0.86 ns Spices 114 12.29 土 13.52 土 11.06 ± 44.9, 44.66 土 43.75 6 0.35° 0.39 0.32 1.04 1.20 0.89 5 O-Cymene 2 5 Farnesene 3 Spices 12 52.39 土 52.91 土 51. 76.01 十 74.34 71.31 十 * 61 1.08° 0.56° 0.7° 1.25 1.61ab 2.77' Spices 土 17 4.76±0.22° 5.1、±1.37 b 4.95 7.92±0.33 7.60±0.98° 7.32±0.28° ns 25 0.83 5 Styrene 4 Spices 12 39.40 土 36.70 土 35.61 土 51.37 48.09 47.33 十 ** 41 ).25 0.30° 0.75 0.73 0.91° 0.17° 5 Copaene 5 Spices 14 65.42 土 72.16 土 58.68 土 159.61 士 156.97 150.48 十 * 88 1.89 2.08° 1.69 2.90 5.42 4.35 ns 5 Caryophyllene 6 Spices 15 92.82 士 95.33 土 90.31 土 171.91 土 168.30 十 163.08 土 83 2.68 2.75 2.61 1.76° 3.97* 2.47 5 Humulene Spices 22 12.23 土 12.74 土 11.72 士 33.04 土 34.40 土 36.25 土 ns 09 0.35 0.37 0.34 1.60° 1.23° 1.63 5 Camphene Spices 17 11.77 土 12.46 土 11.09 15.98 15.02 15.36 土 ns ** 03 0.27 0.88 0.74 0.12° 0.99° 0.82° 5 D-Limonene Spices i2 720.25 711.48 士 716.02±7. 996.56 土 984.77± 968.21 士** 03 ±7.96° 9.37° 85° 9.34 8.69ab 9.12 Others 6 Safrole Spices 16 24.16 土 24.32 土 23.47 65.90 土 63.60 64.79 土 * ** 28 0.33° 0.25° 0.41 1.25° 0.62° 0.38ab 6 Eugenol Spices 21 106.58 土 111.98 士 01.18±2. 253.20 土 249.43 251.50 土 土 ns ** 41 3.07 3.23h 92° 1.13° 2.83 0.81° 6 Myristicin Spices 19 6.31±0.18 5.39 ± 19.11 士 18.26 18.47 士 士 ns ** 30 0.16° 0.61 0.51 0.40* Data are represented as the mean valut7Ssta idard errors. a-d Indicates within the same row with different lowercase letters significant differences (P<0.05). C: 100% NaCl; S1: 70%NaCl and 30% KCl; S2: 70%NaCl, 20%KCl and 10% flavour enhancers. n.d.: not detected. ns: not significant (P>0.05); *: important (P<0.05); **: very important (P<0.01). Table 4.Odour activity values of key volatile compounds of dry fermented sausages with different NaCl substitutes at 0 d and 9 d. Volatile compounds Odour description(s) Odour threshold 0d 9d (ug/kg in water) iC S1 S2 C S1 S2 Nonanal Fat, citrus, green 5.02 666 4.38 41.8 5 36.6 3 12.3 2 23.0 0 26.4 0 40.43 40.6 5 36.3 0 12.4 4 33.4 0 37.4 0 Octanal Fasoap, 2.5 2.83 2.20 36.67 Hexanal Grass, tallow, fat 2.97 3.20 2.73 12.61 2-Methylpropanal Malty <1 <1 <1 26.20 Almond, cheese, chocolate, 2-Methylbutanal 0.1 malt <1 <1 <1 27.80 3-Methylbutanal Almond. burnt. choking, 1.2 <1 <1 <1 1.52 1.65 2.11 COcoa 2-Nonanone Rose,tea 5 <1 <1 <1 2.48 2.34 1.85 3-Hydroxy-2-butanone Dairy, over ripe fruit 55 <1 < <1 1.55 1.62 1.67 Hexanol Resin, flower, green 2.5 2.17 2.38 1.96 7.04 7.12 7.76 18.7 18.1 1-Octen-3-o1 Mushroom-like 4.02 2.46 18.11 7 13.5 13.2 43.5 42.6 Eucalyptol Strong camphor, fresh 13.41 4 9 4 43.32 3 Flower. citrus, orange, 34.0 33.6 76.3 74.8 Linalool 6 33.82 73.95 terpene, waxy, rose 3 9 5 Methyl butyrate Fruity c 15.1 <1 1 <1 2.70 2.48 2.47 Methyl hexanoate Fruity, fresh, sweet 70 <1 <1 <1 6.44 6.38 5.96 Methyl heptanoate Fruity 4 1.65 1.78 1.51 4.80 4.86 4.22 Ethyl acetate Solvent., pineapple, . ffrruity, 5 2.64 2.78 2.50 13.9 12.29 11.9 apples 115.40 2.62 122. 108. 865. 666.11 637. Ethyl hexanoate Apple peel, fruity 77 03 54 01 Ethyl heptanoate Pineapple, fruity 2 2.82 2.42 9.37 9.06 8.74 40.4 35.2 1.35 0 . 9 9 37.38Ethyl butyrateApple8 4 19.0 14.9 Ethyl Fruity, floral, sweet 1.6 1.27 <1 16.23 9 3-Phenylpropionate 12.0 26.6 25.0 9.78Copaene Wood, spice 10.90 26.16 3 0 8 Caryophyllene Wood, spice 64 1.45 1.49 1.41 2.69 2.63 2.55 p-Caryophyllene Wood, spice 64 1.19 1.09 1.18 2.53 2.40 2.45 Styrene Balsamic, gasuiine 44 <1 <1 <1 1.17 1.09 1.08 10 140 72.02 71.1 71.6 99.6 96.8 98.48 5 0 6 2 D-Limonene Lemon B-Pinene Pine, resin, turpentine <1 <1 <1 1.90 1.83 1.84 C: 100% NaCl: S1: 70% NaCl and 30%KCl: S2: 70%NaCl.20%KCl and 10% flavour enhancers. Journal Pre-prooi Table 5. Sensory analysis of dry fermented sausages with different NaCl substitutesafter a nine-day fermentation. Attributes C S1 S2 Colour 5.75±0.30° 6.01±0.35 5.94±0.49° Odour 4.68±0.08 5.32±0.08 5.34±0.14 Salty taste 5.39±0.34 5.31:0.15 5.19±0.29° Acid taste 5.43±0.07° 5.39±016 5.96±0.10* Bitter taste 3.52±0.11 4.2o±0.16 3.76±0.25° Overall acceptability 5.63±0.17° 4.86±0.19° 5.49±0.26° The sensory attributes were eval ate l on a scale from 1 to 7. The results arerepresented as the mean values ±suandard errors. a-Indicates within the same row withdifferent lowercase letters sigr.i cat differences (P <0.05). C: 100% NaCl: S1: 7C%aCl and 30% KCl: S2: 70% NaCl. 20% KCl and 10%flavour enhancers.Uo 以哈尔滨红香肠为研究对象,采用固相微萃取-气相色谱-质谱联用技术(SPME-GC/MS)结合电子鼻(E-nose)和电子舌(E-tongue)对传统和传统加工方法制备的红香肠的挥发性成分和口感进行了研究。风味检测设备:德国AIRSENSE电子鼻滋味检测设备:日本INSENT电子舌文献信息:Characterization of selected Harbin red sausages on the basis of their flavour profiles using HS-SPME-GC/MS combined with electronic nose and electronic tongue

确定

还剩52页未读,是否继续阅读?

北京盈盛恒泰科技有限责任公司为您提供《哈尔滨红肠中风味和滋味检测方案(感官智能分析)》,该方案主要用于腌腊肉制品中理化分析检测,参考标准--,《哈尔滨红肠中风味和滋味检测方案(感官智能分析)》用到的仪器有德国AIRSENSE品牌PEN3电子鼻

推荐专场

感官智能分析系统(电子鼻/电子舌)

相关方案

更多

该厂商其他方案

更多