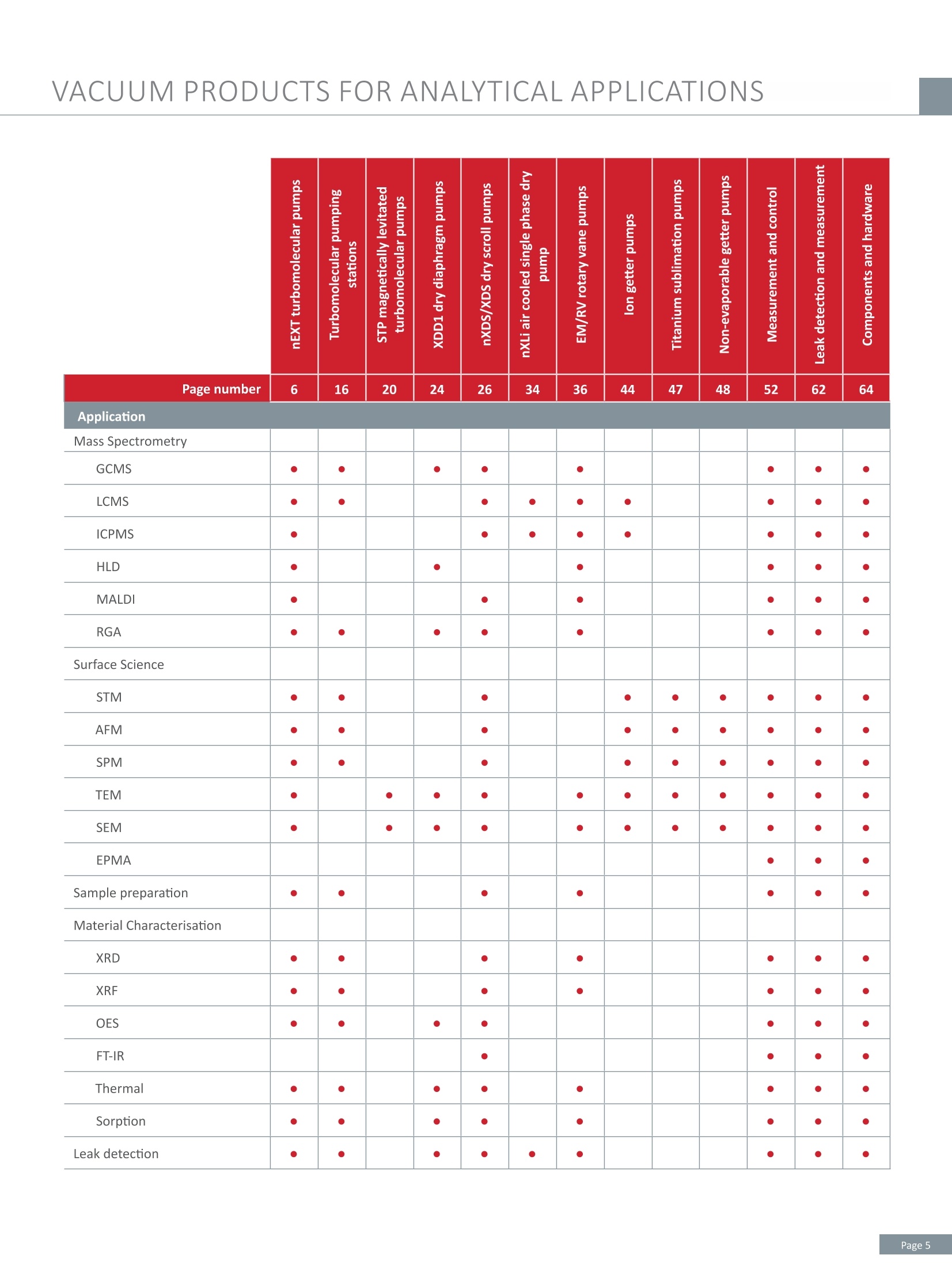

针对质谱、表面分析、样品制备、材料表征等分析方法及分析仪器,Edwards拥有全系列真空产品、真空知识及应用经验,可选型、搭配出合适的真空解决方案,为客户实现洁净可靠的真空环境,并避免重复、昂贵的试错环节。

方案详情