方案详情

文

采用意大利VELP dkl20和udk169测定水、废水和污泥中TKN,结果可靠,重现性好,符合预期范围。

方案详情

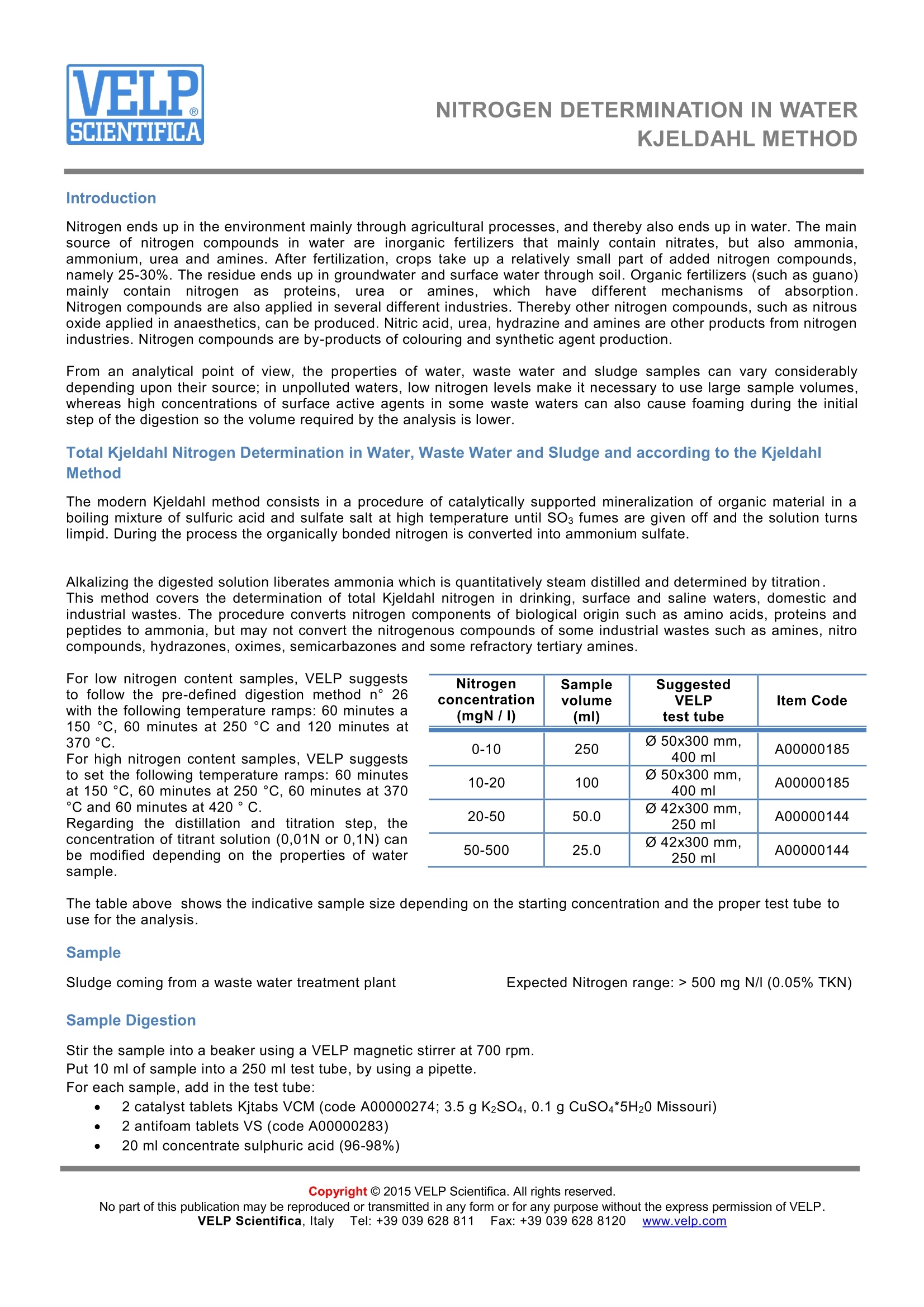

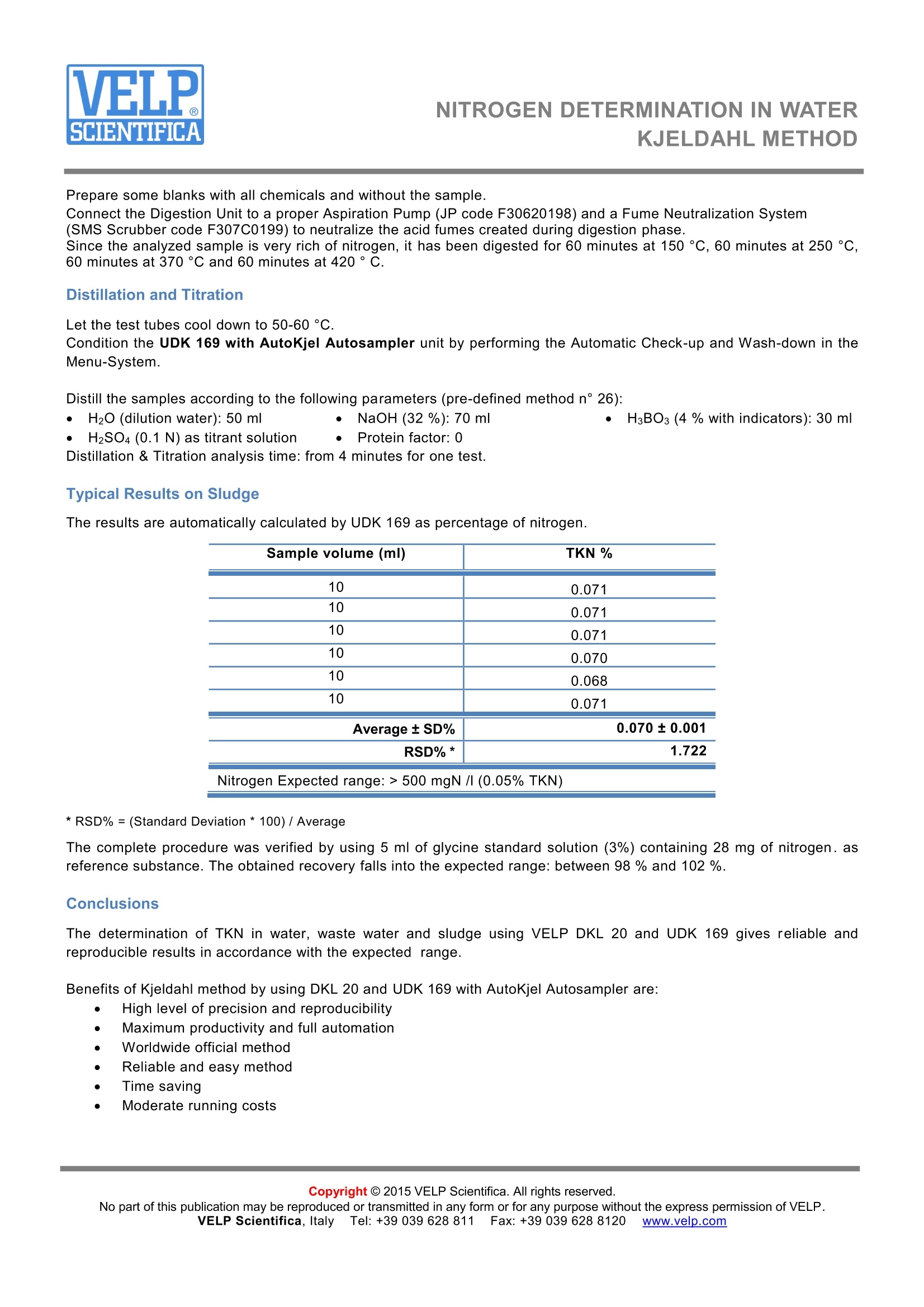

APPLICATION NOTE NITROGEN DETERMINATION IN WATERKJELDAHL METHOD E-K-001-2015/A1 TKN Determination in Water.r. WasteWater and Sludge according to theKjeldahl method Reference: AOAC 973.48 Nitrogen (Total) in Water; EPA 351.3; Standard Method EN 25663, ISO 5663-1984 Tested with VELP Scientifica DKL 20 Automatic Kjeldahl Digestion Unit (Code S30100210) and UDK 169 Automatic Kjeldahl Analyzer with AutoKjel Autosampler (Code S30200160) Introduction Nitrogen ends up in the environment mainly through agricultural processes, and thereby also ends up in water. The mainsource of nitrogen compounds in water are inorganic fertilizers that mainly contain nitrates, but also ammonia,ammonium, urea and amines. After fertilization, crops take up a relatively small part of added nitrogen compounds,namely 25-30%. The residue ends up in groundwater and surface water through soil. Organic fertilizers (such as guano)mainly containnitrogennasproteins,ureaor amines, whichhave differentmechanismsof absorption.Nitrogen compounds are also applied in several different industries. Thereby other nitrogen compounds, such as nitrousoxide applied in anaesthetics, can be produced. Nitric acid, urea, hydrazine and amines are other products from nitrogenindustries. Nitrogen compounds are by-products of colouring and synthetic agent production. From an analytical point of view, the properties of water, waste water and sludge samples can vary considerablydepending upon their source; in unpolluted waters, low nitrogen levels make it necessary to use large sample volumes,whereas high concentrations of surface active agents in some waste waters can also cause foaming during the initialstep of the digestion so the volume required by the analysis is lower. Total Kjeldahl Nitrogen Determination in Water, Waste Water and Sludge and according to the KjeldahlMethod The modern Kjeldahl method consists in a procedure of catalytically supported mineralization of organic material in aboiling mixture of sulfuric acid and sulfate salt at high temperature until SO3 fumes are given off and the solution turnslimpid. During the process the organically bonded nitrogen is converted into ammonium sulfate. Alkalizing the digested solution liberates ammonia which is quantitatively steam distilled and determined by titration.This method covers the determination of total Kjeldahl nitrogen in drinking, surface and saline waters, domestic andindustrial wastes. The procedure converts nitrogen components of biological origin such as amino acids, proteins andpeptides to ammonia, but may not convert the nitrogenous compounds of some industrial wastes such as amines, nitrocompounds, hydrazones, oximes, semicarbazones and some refractory tertiary amines. For low nitrogen content samples, VELP suggeststo follow the pre-defined digestion method n° 26with the following temperature ramps: 60 minutes a150°C, 60 minutes at 250 °C and 120 minutes at370°C. For high nitrogen content samples, VELP suggeststo set the following temperature ramps: 60 minutesat 150 °C, 60 minutes at 250C, 60 minutes at 370°C and 60 minutes at 420 °C. Regarding the distillation and titration step, theconcentration of titrant solution (0,01N or 0,1N) canbe modified depending on the properties of watersample. Nitrogen concentration (mgN71) Samplevolume(ml) SuggestedVELPtest tube Item Code 0-10 250 O 50x300 mm,400 ml A00000185 10-20 100 0 50x300 mm.400 ml A00000185 20-50 50.0 0 42x300 mm. 250 ml A00000144 50-500 25.0 042x300 mm.250 ml A00000144 The table above shows the indicative sample size depending on the starting concentration and the proper test tube touse for the analysis. Sample Sludge coming from a waste water treatment plant Expected Nitrogen range: > 500 mg N/I (0.05% TKN) Sample Digestion Stir the sample into a beaker using a VELP magnetic stirrer at 700 rpm.Put 10 ml of sample into a 250 ml test tube, by using a pipette. For each sample, add in the test tube: ● 2 catalyst tablets Kjtabs VCM (code A00000274;3.5 gK2SO4,0.1 g CuSO4*5H20 Missouri) 2 antifoam tablets VS (code A00000283) 20 ml concentrate sulphuric acid (96-98%) VELP Scientifica, Italy Tel: +39 039 628811 Fax: +390396288120 www.velp.com Prepare some blanks with all chemicals and without the sample.Connect the Digestion Unit to a proper Aspiration Pump (JP code F30620198) and a Fume Neutralization System(SMS Scrubber code F307C0199) to neutralize the acid fumes created during digestion phase.Since the analyzed sample is very rich of nitrogen, it has been digested for 60 minutes at 150 °C, 60 minutes at 250 °C, 60 minutes at 370 °C and 60 minutes at 420°C. Distillation and Titration Let the test tubes cool down to 50-60°C. Condition the UDK 169 with AutoKjel Autosampler unit by performing the Automatic Check-up and Wash-down in theMenu-System. Distill the samples according to the following parameters (pre-defined method n°26): HH2O(dilution water): 50 ml ● NaOH (32%): 70 ml .H3BO3(4% with indicators): 30 mlH H2SO4(0.1 N) as titrant solution Protein factor: 0 Distillation & Titration analysis time: from 4 minutes for one test. Typical Results on Sludge The results are automatically calculated by UDK 169 as percentage of nitrogen. Sample volume (ml) TKN % 10 0.071 10 0.071 10 0.071 10 0.070 10 0.068 10 0.071 Average±SD% 0.070±0.001 RSD%* 1.722 Nitrogen Expected range: > 500 mgN/I(0.05% TKN) *RSD%=(Standard Deviation * 100)/ Average The complete procedure was verified by using 5 ml of glycine standard solution (3%) containing 28 mg of nitrogen. asreference substance. The obtained recovery falls into the expected range: between 98 % and 102 %. Conclusions The determination of TKN in water, waste water and sludge using VELP DKL 20 and UDK 169 gives reliable andreproducible results in accordance with the expected range. Benefits of Kjeldahl method by using DKL 20 and UDK 169 with AutoKjel Autosampler are: High level of precision and reproducibility ● Maximum productivity and full automation Worldwide official method Reliable and easy method ● Time saving Moderate running costs VELP Scientifica, Italy Tel: +39 039 628 811 Fax:+39 039 628 8120 www.velp.com Copyright ◎ VELP Scientifica. All rights reserved.No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of VELP.VELP Scientifica, Italy Tel: + Fax:+ www.velp.com 样 品:来自污水处理厂的污泥,预计氮含量范围> 500 mg N/l (0.05% TKN)仪 器:意大利VELP全自动凯氏定氮仪 UDK 169 with AutoKjel Autosampler+DKL 20实验结果: 用含28毫克氮的5毫升甘氨酸标准溶液(3%)对整个过程进行验证。参考物质。所得回收率在98% ~ 102%之间,符合预期范围。 从分析的角度看,水、废水和污泥样品的性质随其来源的不同而有很大的不同;在未受污染的水体中,由于氮含量低,需要使用大量的样品,而一些废水中表面活性剂浓度高,在消化的初始阶段也会产生泡沫,因此分析所需的体积较低。研究意义: 测凯氏氮可以全面的反映污水中现有及潜在氨氮的总和。有利于污水处理设计时全面考虑。

确定

还剩1页未读,是否继续阅读?

北京盈盛恒泰科技有限责任公司为您提供《污水中TKN检测方案(定氮仪)》,该方案主要用于废水中营养盐检测,参考标准--,《污水中TKN检测方案(定氮仪)》用到的仪器有VELP全自动凯氏定氮仪UDK169 and AutoKjel

推荐专场

相关方案

更多

该厂商其他方案

更多