方案详情

文

基于MEMS的微流体高温高剪切粘度计,主要用于研究高温下流体特性。

温度对流体的粘度起到决定性作用,RheoSense温控系统提供精度的热稳定性,(+/-0.07 °C)。标准的VROC和温控系统可以操作4-105°C,但对于特别的应用,如ISO/ASTM测量方法,其要求特别的温度。例如,测定润滑油特性需要的温度

方案详情

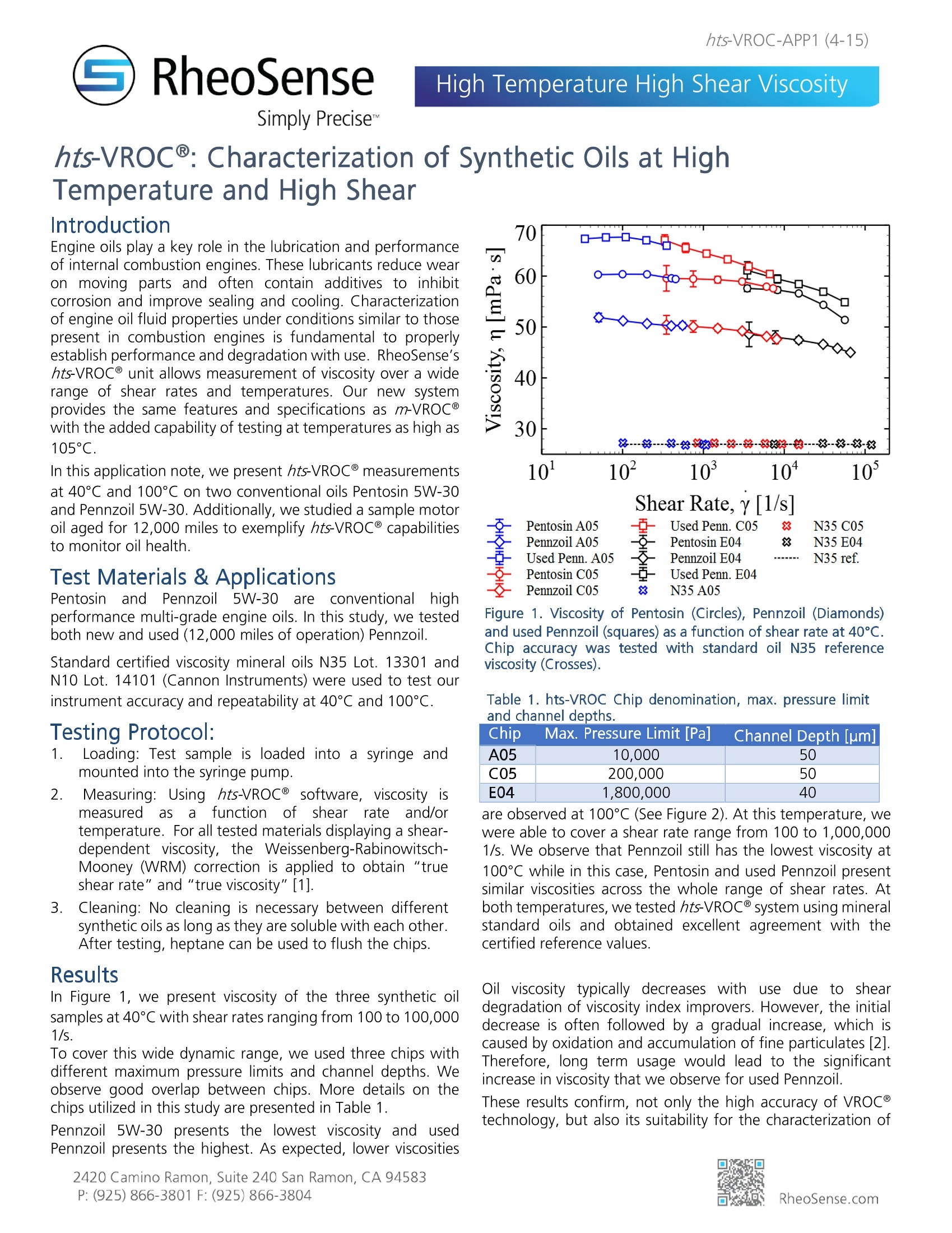

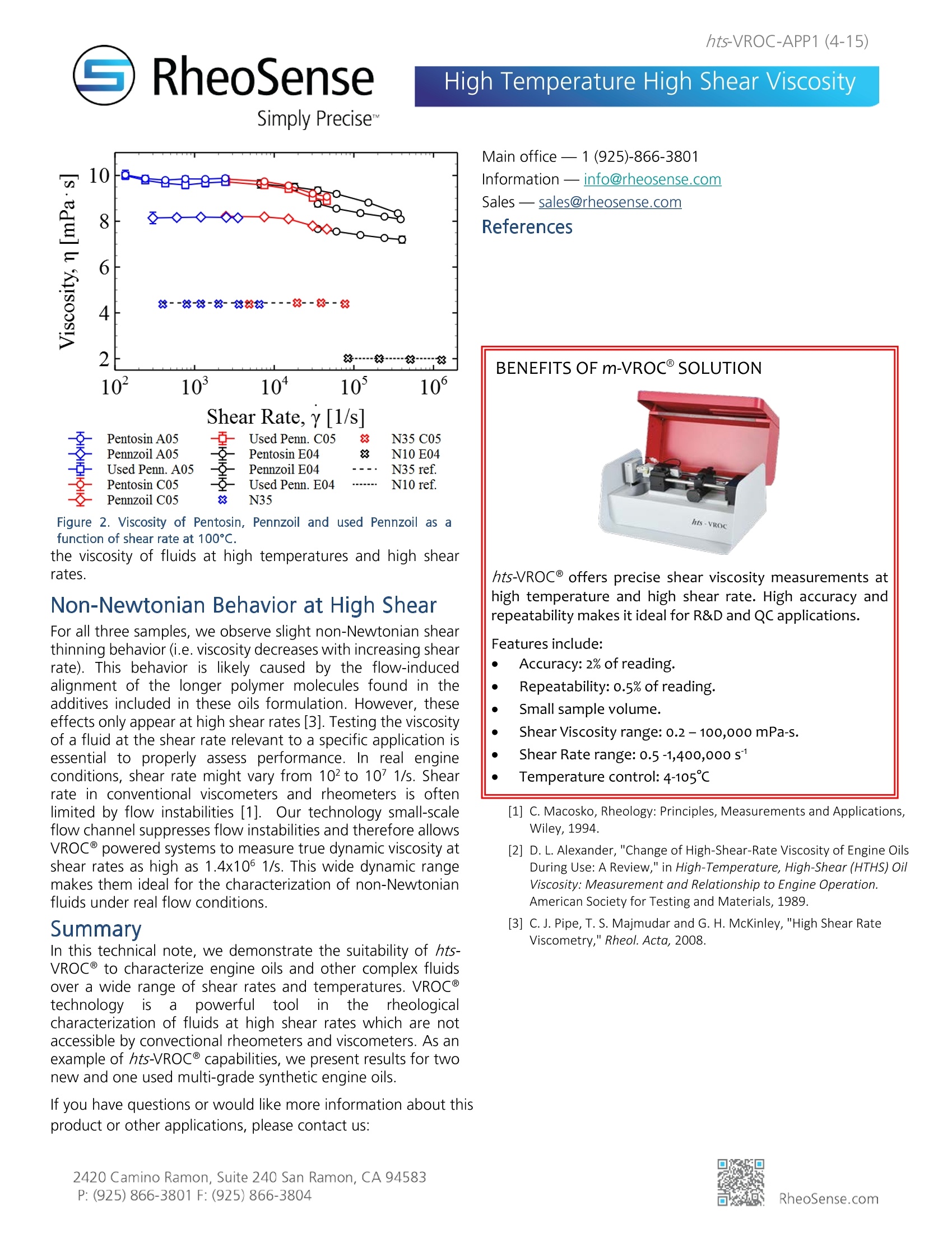

hts-VROC-APP1 (4-15)RheoSenseHigh Temperature High Shear ViscositySimply Precisew hts-VROC-APP1(4-15)RheoSense hts-VROC@: Characterization of Synthetic Oils at HighTemperature and High Shear Introduction Engine oils play a key role in the lubrication and performanceof internal combustion engines. These lubricants reduce wearonmoving parts and often contain additives to inhibitcorrosion and improve sealing and cooling. Characterizationof engine oil fluid properties under conditions similar to thosepresent in combustion engines is fundamental to properlyestablish performance and degradation with use. RheoSense'shts-VROC@ unit allows measurement of viscosity over a widerange of shear rates and temperatures. Our new systemprovides the same features and specifications as m-VROC@with the added capability of testing at temperatures as high as105°C. In this application note, we present hts-VROC@ measurementsat 40°C and 100°C on two conventional oils Pentosin 5W-30and Pennzoil5W-30. Additionally, we studied a sample motoroil aged for 12,000 miles to exemplify hts-VROC@ capabilitiesto monitor oil health. Test Materials & Applications Pentosin1 anddPPennzoil5W-30) are conventionallhighperformance multi-grade engine oils. In this study, we testedboth new and used (12,000 miles of operation) Pennzoil. Standard certified viscosity mineral oils N35 Lot. 13301 andN10 Lot. 14101 (Cannon Instruments) were used to test ourinstrument accuracy and repeatability at 40℃ and 100℃. Testing Protocol: 1. .LLoading: Test sample is loaded into a syringe andmounted into the syringe pump. 2. /easuring: Using hts-VRoce software, viscosity ismeasuredasaatunction of: shear rateeaand/ortemperature. For all tested materials displaying a shear-dependent viscosity, the Weissenberg-Rabinowitsch-Mooney (WRM) correction is applied to obtain “trueshear rate" and"true viscosity"[1]. 3.Cleaning: No cleaning is necessary between differentsynthetic oils as long as they are soluble with each other.After testing, heptane can be used to flush the chips. In Figure 1, we present viscosity of the three synthetic oilsamples at 40℃ with shear rates ranging from 100 to 100,0001/s. To cover this wide dynamic range, we used three chips withdifferent maximum pressure limits and channel depths. Weobserve good overlap between chips. More details on thechips utilized in this study are presented in Table 1. Pennzoil5W-30presents the lowest viscosity and usedPennzoil presents the highest. As expected, lower viscosities 口—七 O ◇-+-◇ Shear Rate,y[1/s]Pentosin A05 Used Penn. C05 N35 C05Pennzoil A05 lPPentosin E04 N35 E04送Used Penn. A05Pennzoil E04 N35 ref.Pentosin C05 Used Penn. E04Pennzoil C05 N35 A05 Figure 1. Viscosity of Pentosin (Circles), Pennzoil (Diamonds)and used Pennzoil (squares) as a function of shear rate at 40°℃.Chip accuracy was testedwith standard oil lN35 referenceviscosity(Crosses). Table 1. hts-VROC Chip denomination, max. pressure limitand channel depths. Chip Max. Pressure Limit [Pa] A05 10,000 50 C05 200,000 50 E04 1,800,000 40 are observed at 100℃(See Figure 2). At this temperature, wewere able to cover a shear rate range from 100 to 1,000,0001/s. We observe that Pennzoil still has the lowest viscosity at100℃ while in this case, Pentosin and used Pennzoil presentsimilar viscosities across the whole range of shear rates. Atboth temperatures, we tested hts-VROC@ system using mineralstandard oils and obtained excellent agreement with thecertified reference values. Oil viscosity typically decreases withusedue to sheardegradation of viscosity index improvers. However, the initialdecrease is often followed by a gradual increase, which iscaused by oxidation and accumulation of fine particulates [2].Therefore, long term usage would lead to the significantincrease in viscosity that we observe for used Pennzoil. These results confirm, not only the high accuracy of VROC@technology, but also its suitability for the characterization of Simply Precise" Figure 2. Viscosity of Pentosin, Pennzoiland usedPennzoilas afunction of shear rate at 100°C.the viscosity of fluids at high temperatures and high shearrates. Non-Newtonian Behavior at High Shear For all three samples, we observe slight non-Newtonian shearthinning behavior(i.e. viscosity decreases with increasing shearrate). This behavior is likely caused by the flow-inducedalignment of the longer polymer molecules found in theadditives included in these oils formulation. However, theseeffects only appear at high shear rates [3]. Testing the viscosityof a fluid at the shear rate relevant to a specific application isessential to properly assess performance. In real engineconditions, shear rate might vary from 102to 101/s. Shearrate in conventional viscometers and rheometers is oftenlimited by flow instabilities [1]. Our technology small-scaleflow channel suppresses flow instabilities and therefore allowsVROC@ powered systems to measure true dynamic viscosity atshear rates as high as 1.4x106 1/s. This wide dynamic rangemakes them ideal for the characterization of non-Newtonianfluids under real flow conditions. Summary In this technical note, we demonstrate the suitability of hts-VROC@ to characterize engine oils and other complex fluidsover a wide range of shear rates and temperatures.VROC@technology IS powerful toolitin rheologicalcharacterization of fluids at high shear rates which are notaccessible by convectional rheometers and viscometers. As anexample of hts-VROC@ capabilities, we present results for twonew and one used multi-grade synthetic engine oils. If you have questions or would like more information about thisproduct or other applications, please contact us: Main office-1 (925)-866-3801 Information一 info@rheosense.com Sales—sales@rheosense.com References hts-VROC@ offers precise shear viscosity measurements athigh temperature and high shear rate. High accuracy andrepeatability makes it ideal for R&D and QC applications. Features include: Accuracy: 2%of reading. ● Repeatability: o.5% of reading. Small sample volume. Shear Viscosity range: 0.2-100,000 mPa-s. Shear Rate range: 0.5-1,400,000 S Temperature control: 4-105℃ [1] C. Macosko, Rheology: Principles, Measurements and Applications,Wiley, 1994. [2] D. L. Alexander,"Change ofHigh-Shear-Rate Viscosity of Engine OilsDuring Use: A Review," in High-Temperature, High-Shear (HTHS) OilViscosity: Measurement and Relationship to Engine Operation.American Society for Testing and Materials, 1989. [3] C. J. Pipe, T. S. Majmudar and G. H. McKinley,"High Shear RateViscometry," Rheol.Acta, 2008. Camino Ramon, Suite San Ramon, CA : (:( heoSense.com 基于MEMS的微流体高温高剪切粘度计,主要用于研究高温下流体特性。温度对流体的粘度起到决定性作用,RheoSense温控系统提供精度的热稳定性,(+/-0.07 °C)。标准的VROC和温控系统可以操作4-105°C,但对于特别的应用,如ISO/ASTM测量方法,其要求特别的温度。例如,测定润滑油特性需要的温度。 特性:最小进样量25 μL粘度范围:0.2-100,000cP剪切速率:0.5-14000s-1温控范围:4-105(125°C)温控精度:+/- 0.07 °C精准度:+/- 2%(读数)重复性:+/- 0.5% (读数)具备剪切扫描和温控扫描测试时间:小于1分钟牛顿和非牛顿解决方案 行业应用:新润滑油形成喷墨、化妆品、食品添加剂研发理解温度对药物稳定性的影响聚合物使用中改进,如绘画颜料,涂料性能 EOR流体 普通化学领域粘度特性研究

确定

还剩1页未读,是否继续阅读?

美国安普科技中心为您提供《油品中高温下流体特性检测方案(其它流变仪/粘度计)》,该方案主要用于油品中高温下流体特性检测,参考标准--,《油品中高温下流体特性检测方案(其它流变仪/粘度计)》用到的仪器有

相关方案

更多