方案详情

文

美国环境保护委员会(EPA)制定的新环保法规要求极其严格的限制从水泥生产厂和发电厂(EGU)等行业排放的含有HCL的酸性气体。新的排放标准要求HCL的排放最高极限值在7%无水O2条件下,硅酸盐水泥制造废气排放为3 ppmv,而发电厂的废气排放是1ppmv。新排放法规要求装备更高感光度并能监测HCl酸性气体的连续排放监测系统(CEMS),同时适应含有腐蚀性气体,并且颗粒含量高的气流...

方案详情

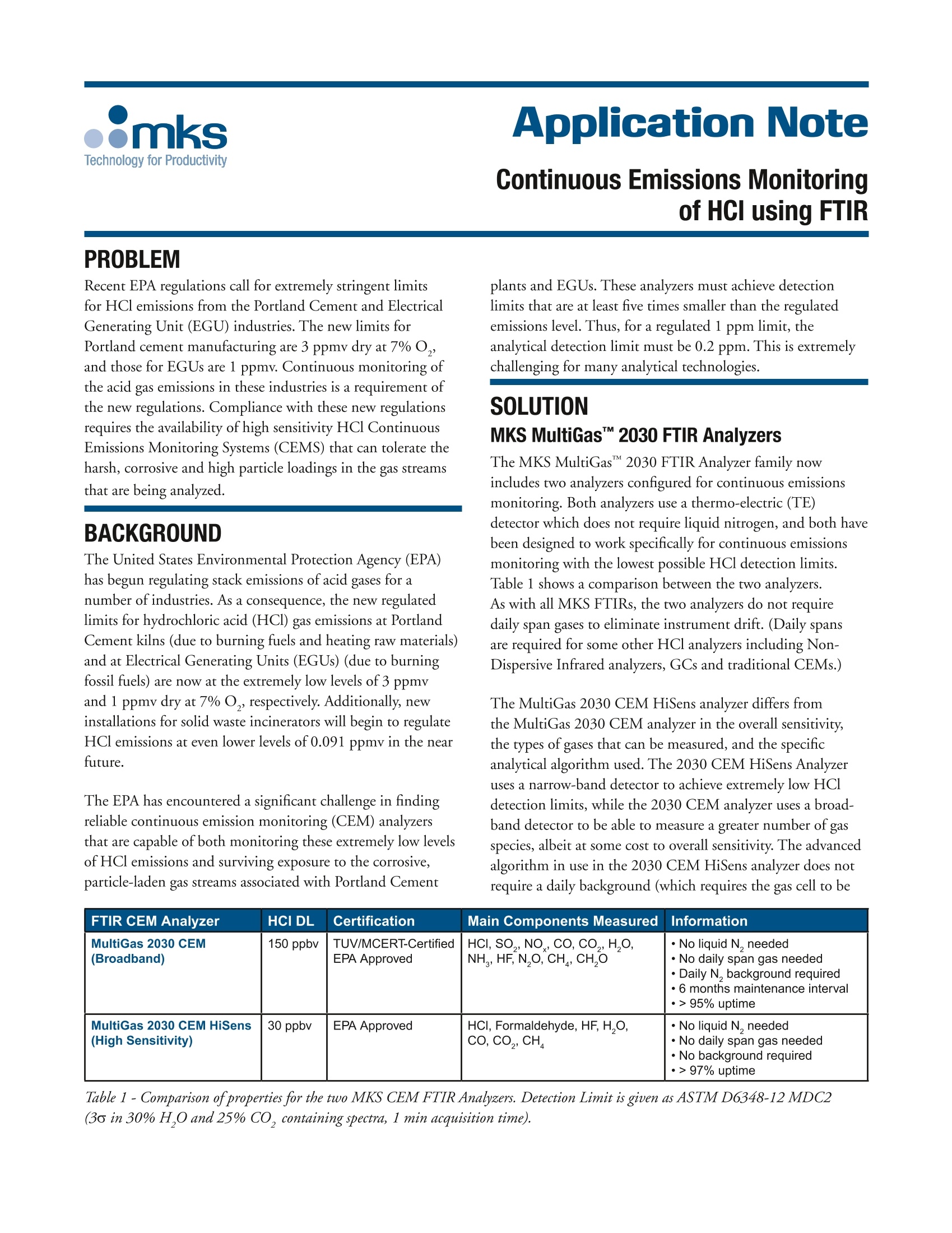

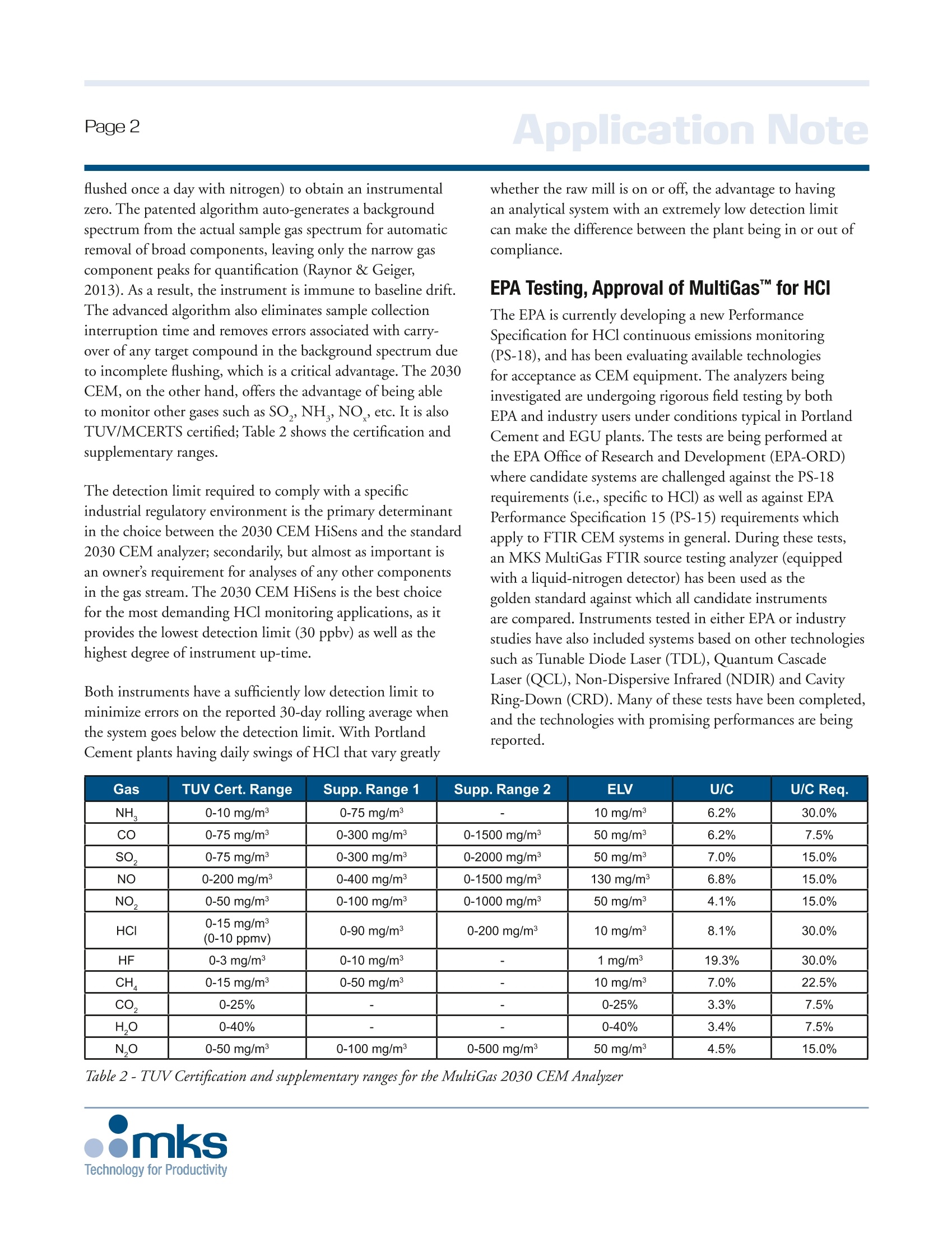

Technology for Productivity Page 4 Application NoteContinuous Emissions Monitoringof HCl using FTIR Recent EPA regulations call for extremely stringent limitsfor HCl emissions from the Portland Cement and ElectricalGenerating Unit (EGU) industries. The new limits forPortland cement manufacturing are 3 ppmv dry at 7% O,,and those for EGUs are 1 ppmv. Continuous monitoring ofthe acid gas emissions in these industries is a requirement ofthe new regulations. Compliance with these new regulationsrequires the availability of high sensitivity HCl ContinuousEmissions Monitoring Systems (CEMS) that can tolerate theharsh, corrosive and high particle loadings in the gas streamsthat are being analyzed. BACKGROUND The United States Environmental Protection Agency (EPA)has begun regulating stack emissions of acid gases for anumber of industries. As a consequence, the new regulatedlimits for hydrochloric acid (HCl) gas emissions at PortlandCement kilns (due to burning fuels and heating raw materials)and at Electrical Generating Units (EGUs) (due to burningfossil fuels) are now at the extremely low levels of 3 ppmvand 1 ppmv dry at 7%O, respectively. Additionally, newinstallations for solid waste incinerators will begin to regulateHCl emissions at even lower levels of 0.091 ppmv in the nearfuture. The EPA has encountered a significant challenge in findingreliable continuous emission monitoring (CEM) analyzersthat are capable of both monitoring these extremely low levelsof HCl emissions and surviving exposure to the corrosive,particle-laden gas streams associated with Portland Cement plants and EGUs. These analyzers must achieve detectionlimits that are at least five times smaller than the regulatedemissions level. Thus, for a regulated 1 ppm limit, theanalytical detection limit must be 0.2 ppm. This is extremelychallenging for many analytical technologies. SOLUTION MKS MultiGas2030 FTIR Analyzers The MKS MultiGas 2030 FTIR Analyzer family nowincludes two analyzers configured for continuous emissionsmonitoring. Both analyzers use a thermo-electric (TE)detector which does not require liquid nitrogen, and both havebeen designed to work specifically for continuous emissionsmonitoring with the lowest possible HCl detection limits.Table 1 shows a comparison between the two analyzers.As with all MKS FTIRs, the two analyzers do not requiredaily span gases to eliminate instrument drift. (Daily spansare required for some other HCl analyzers including Non-Dispersive Infrared analyzers, GCs and traditional CEMs.) The MultiGas 2030 CEM HiSens analyzer differs fromthe MultiGas 2030 CEM analyzer in the overall sensitivity,the types of gases that can be measured, and the specificanalytical algorithm used. The 2030 CEM HiSens Analyzeruses a narrow-band detector to achieve extremely low HCldetection limits, while the 2030 CEM analyzer uses a broad-band detector to be able to measure a greater number of gasspecies, albeit at some cost to overall sensitivity. The advancedalgorithm in use in the 2030 CEM HiSens analyzer does notrequire a daily background (which requires the gas cell to be FTIR CEM Analyzer HCIDL Certification Main Components Measured Information MultiGas 2030 CEM (Broadband) 150 ppbv TUV/MCERT-CertifiedEPA Approved HCI, SO,, NO,CO, CO,,H,O,NH,HF,N,O,CH, CH,O · No liquid N, needed ·No daily span gas needed· DailyN, background required·6 months maintenance interval·>95% uptime MultiGas 2030 CEM HiSens(High Sensitivity) 30 ppbv EPA Approved HCI, Formaldehyde, HF,H,O,CO, Co,,CH ·No liquid N, needed · No daily span gas needed·No background required ·> 97% uptime Table 1 - Comparison ofproperties for the two MKS CEM FTIR Analyzers. Detection Limit is given as ASTM D6348-12 MDC2(3o in 30% H,0 and 25% CO, containing spectra, 1 min acquisition time). flushed once a day with nitrogen) to obtain an instrumentalzero. The patented algorithm auto-generates a backgroundspectrum from the actual sample gas spectrum for automaticremoval of broad components, leaving only the narrow gascomponent peaks for quantification (Raynor & Geiger,2013). As a result, the instrument is immune to baseline drift.The advanced algorithm also eliminates sample collectioninterruption time and removes errors associated with carry-over of any target compound in the background spectrum dueto incomplete flushing, which is a critical advantage. The 2030CEM, on the other hand, offers the advantage of being ableto monitor other gases such as SO,,NH, NO,etc. It is alsoTUV/MCERTS certified; Table 2 shows the certification andsupplementary ranges. The detection limit required to comply with a specificindustrial regulatory environment is the primary determinantin the choice between the 2030 CEM HiSens and the standard2030 CEM analyzer; secondarily, but almost as important isan owner's requirement for analyses of any other componentsin the gas stream. The 2030 CEM HiSens is the best choicefor the most demanding HCl monitoring applications, as itprovides the lowest detection limit (30 ppbv) as well as thehighest degree of instrument up-time. Both instruments have a sufficiently low detection limit tominimize errors on the reported 30-day rolling average whenthe system goes below the detection limit. With PortlandCement plants having daily swings of HCl that vary greatly whether the raw mill is on or off, the advantage to havingan analytical system with an extremely low detection limitcan make the difference between the plant being in or out ofcompliance. EPA Testing, Approval of MultiGasfor HCI The EPA is currently developing a new PerformanceSpecification for HCl continuous emissions monitoring(PS-18), and has been evaluating available technologiesfor acceptance as CEM equipment. The analyzers beinginvestigated are undergoing rigorous field testing by bothEPA and industry users under conditions typical in PortlandCement and EGU plants. The tests are being performed atthe EPA Office of Research and Development (EPA-ORD)where candidate systems are challenged against the PS-18requirements (i.e., specific to HCl) as well as against EPAPerformance Specification 15 (PS-15) requirements whichapply to FTIR CEM systems in general. During these tests,an MKS MultiGas FTIR source testing analyzer (equippedwith a liquid-nitrogen detector) has been used as thegolden standard against which all candidate instrumentsare compared. Instruments tested in either EPA or industrystudies have also included systems based on other technologiessuch as Tunable Diode Laser (TDL), Quantum CascadeLaser (QCL), Non-Dispersive Infrared (NDIR) and CavityRing-Down (CRD). Many of these tests have been completed,and the technologies with promising performances are beingreported. Gas TUV Cert.Range Supp.Range 1 Supp. Range 2 ELV U/C U/C Req. NH, 0-10 mg/m³ 0-75 mg/m - 10 mg/m3 6.2% 30.0% CO 0-75 mg/m3 0-300 mg/m³ 0-1500mg/m³ 50 mg/m 6.2% 7.5% SO, 0-75 mg/m3 0-300 mg/m 0-2000 mg/m³ 50 mg/m 7.0% 15.0% NO 0-200 mg/m³ 0-400 mg/m³ 0-1500 mg/m 130 mg/m 6.8% 15.0% NO. 0-50 mg/m’ 0-100 mg/m³ 0-1000 mg/m3 50 mg/m3 4.1% 15.0% HCI 0-15 mg/m3 (0-10 ppmv) 0-90 mg/m’ 0-200 mg/m³ 10 mg/m³ 8.1% 30.0% HF 0-3 mg/m 0-10 mg/m3 - 1 mg/m 19.3% 30.0% CH 0-15 mg/m³ 0-50 mg/m3 - 10 mg/m3 7.0% 22.5% CO, 0-25% - - 0-25% 3.3% 7.5% HO 0-40% 一 0-40% 3.4% 7.5% NO 0-50 mg/m3 0-100 mg/m3 0-500 mg/m³ 50 mg/m 4.5% 15.0% Table 2- TUV Certification and supplementary ranges for the MultiGas 2030 CEM Analyzer All 3 MKS 2030 Analyzers (Standard CEM, HiSens CEMand Source Testing LN, versions) have been tested by EPA.All were found to provide viable analytical solutions formonitoring extremely low HCl emissions, with detectionlimits of 50 ppb (0.05 ppm) for the 2030 CEM HiSens,and 200 ppb (0.2 ppm) for the 2030 CEM. The detectionlimits were calculated using ASTM D3648-12 MDC2(3o in 30% H,O and 25% CO, sample matrix containingspectra, 30 sec acquisition time), and are consistent withthe MKS specifications from Table 1, which are given for 1minute acquisition time. From the EPA tests, both analyzersdemonstrated their ability to survive in harsh, corrosive gasstreams having high particulate loading common at cementplants, and in the less extreme but equally challengingenvironment at power plants. Both analyzers passed all of thePS-18 requirements, including demonstrating insensitivity tointerferences and high levels of recovery for dynamic spiking(which is a self-validating initial verification test referencemethod to ensure accuracy). Several of the other technologies tested by EPA failed dueto high detection limits, sensitivity to interferent gases suchas CH or formaldehyde, and/or too frequent maintenancerequirements for cleaning/replacing internal parts that hadbeen damaged by the high level of particulates. Industrial Testing A 15-day snapshot window is shown in Figure 1 in which the2030 CEM HiSens analyzer was deployed as part of a CEMSat a Portland cement plant. Because of high-particulate loadings found in cement plants, itis recommended that the CEMS sampling system include filterblowback to remove the “filter cake" which can accumulateon the filter. Filter cake can be especially problematic whenNH, is present, as HCl and NH, react to form condensingammonium chloride salts. However, significant accumulationof “filter cake”was found not to be an issue when performingthe dynamic spiking option required by draft PS-18, asrecovery levels above 95% were obtained. Analyzer Integration into CEM system The 2030 CEM analyzers are extremely easy to setup andincorporate into a full CEM system. Figure 2 shows examplesof integration. A list of CEM integrators can be obtainedby contacting MKS sales personnel or sending a requestvia the MKS web site at http://www.mksinst.com/product/onlineCONTACT.aspx. Figure 1 - Cement plant data for HCl, H,O and CO, Figure 2-MultiGas 2030 CEM Analyzers integrated in full CEM systems (Left: MGS300 System; Right: CEM Integration System (Courtesy ofCemtek Environmental, Inc.-www.cemteks.com) CONCLUSION MKS Instruments'2030 CEM and 2030 CEM HiSensMultiGas FTIR analyzers are configured for continuousemissions monitoring and have been approved by EPA forHCl CEM service. The 2030 CEM has an HCl detection limitof 0.15 ppmv (wet) while the 2030 CEM HiSens analyzer hasan HCl detection limit of 0.03 ppmv (wet). These analyzers donot need daily span and have maintenance intervals of greaterthan six months (per TUV certification). Uptime for bothanalyzers is high, rated at >95% to >97%. Dynamic spiking inthe field has been successfully demonstrated, with recovery ofmore than 99%. These analyzers have sufficiently low detection limits tomeet all of the requirements in the applicable EPA CEMPerformance Specification. Both analyzers can accurately andcontinuously monitor HCl in the high particle, corrosive andwet (up to 40% moisture) gas streams typical of PortlandCement plants and Electrical Generating Units. REFERENCES 1. MKS Publications: MultiGas 2030 CEM datasheet;MultiGas 2030 CEM HiSens datasheet 2.TTrace Gas Analysis of Specialty and Electronic Gases,Raynor, Mark W., and Geiger, William M. (eds), JohnWiley & Sons (2013). 3. “Performance Specification 15 - PerformanceSpecification for extractive FTIR continuous emissionsmonitor systems in stationary sources"www.epa.gov/ttnemc01/perfspec/ps-15.pdf For more information on MKS Instruments MultiGas 2030 CEM, link to our web site at: http://www.mksinst.com/docs/ur/cem-continuous-emission-monitoring.aspx For a general catalog of MKS Instruments' products, followthis link: http://www.mksinst.com/ For further information, call your local MKS Sales Engineer or contact the MKS Applications Engineering Group at800-227-8766.MultiGasproducts may not be exported to many end user countries without both US and local government export licenses under ECCN 2B351. mksinstand MultiGas"" are trademarks of MKS Instruments, Inc., Andover, MA. MKS Global Headquarters2 Tech Drive, Suite 201Andover, MA 01810978.645.5500800.227.8766 (within USA)www.mksinst.com Technology for Productivity

确定

还剩2页未读,是否继续阅读?

万机仪器(上海)有限公司为您提供《废气中分子态无机污染物检测方案 》,该方案主要用于废气中分子态无机污染物检测,参考标准--,《废气中分子态无机污染物检测方案 》用到的仪器有

相关方案

更多