Nafion干燥管具有气态除湿且在除湿的过程中完全保留低量程SO2和NOx的特性,非常适用于冷干直抽法CEMS的原位预处理。实验证明:Nafion干燥管能够在高湿度条件下基本保留低浓度的SO2.

方案详情

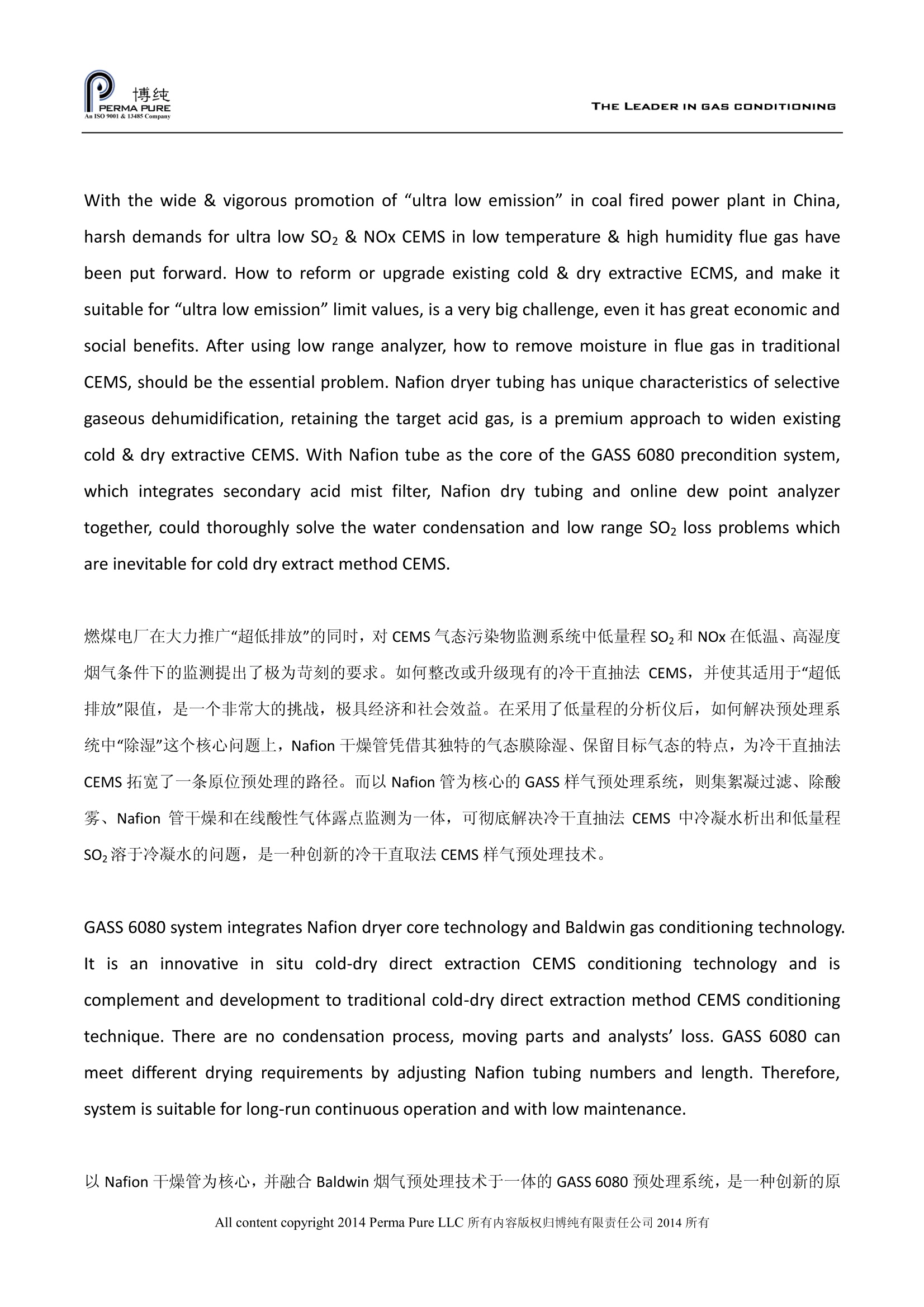

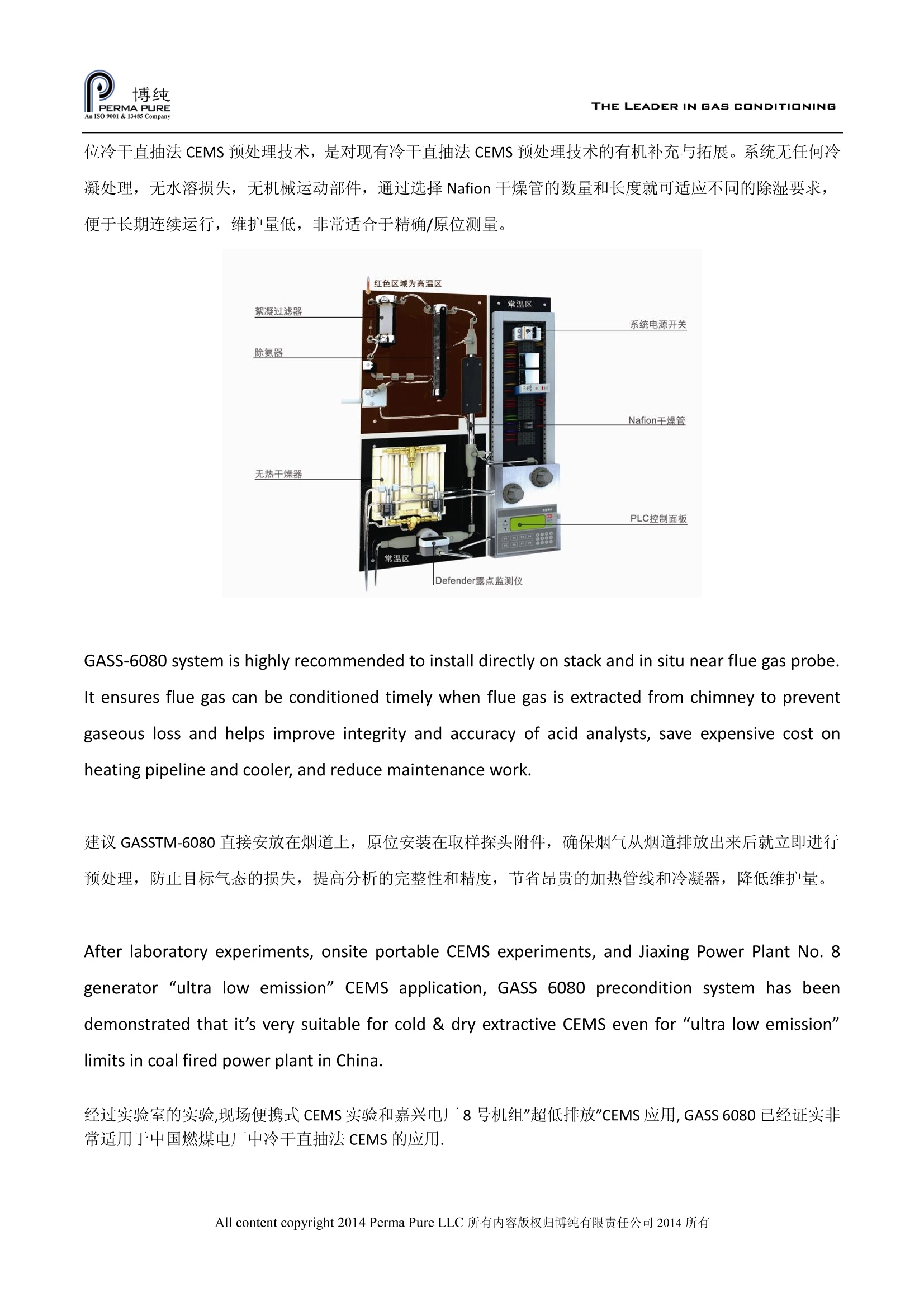

THE LEADERIN GAS CONDITIONING GASSTM6080 System Application inChina “Ultra Low Emission” Case 上海市长宁区娄山关路555号长房国际大厦1106室 邮编:200051 电话:021-60167678 传真:021-52068191 博纯中国网站:www.permapure.com.cn With the wide & vigorous promotion of"ultra low emission" in coal fired power plant in China,harsh demands for ultra low SO2 & NOx CEMS in low temperature & high humidity flue gas havebeen put forward. How to reform or upgrade existing cold & dry extractive ECMS, and make itsuitable for “ultra low emission" limit values, is a very big challenge, even it has great economic andsocial benefits. After using low range analyzer, how to remove moisture in flue gas in traditionalCEMS, should be the essential problem. Nafion dryer tubing has unique characteristics of selectivegaseous dehumidification, retaining the target acid gas, is a premium approach to widen existingcold & dry extractive CEMS. With Nafion tube as the core of the GASS 6080 precondition system,which integrates secondary acid mist filter, Nafion dry tubing and online dew point analyzertogether, could thoroughly solve the water condensation and low range SO2 loss problems whichare inevitable for cold dry extract method CEMS. 燃煤电厂在大力推广“超低排放”的同时,对 CEMS 气态污染物监测系统中低量程 SOz 和 NOx 在低温、高湿度烟气条件下的监测提出了极为苛刻的要求。如何整改或升级现有的冷干直抽法 CEMS, 并使其适用于“超低排放"限值,是一个非常大的挑战,极具经济和社会效益。在采用了低量程的分析仪后,如何解决预处理系统中“除湿"这个核心问题上, Nafion 干燥管凭借其独特的气态膜除湿、保留目标气态的特点,为冷干直抽法CEMS 拓宽了一条原位预处理的路径。而以 Nafion 管为核心的 GASS 样气预处理系统,则集絮凝过滤、除酸雾、Nafion 管干燥和在线酸性气体露点监测为一体,可彻底解决冷干直抽法 CEMS 中冷凝水析出和低量程SOz溶于冷凝水的问题,是一种创新的冷干直取法 CEMS 样气预处理技术。 GASS 6080 system integrates Nafion dryer core technology and Baldwin gas conditioning technology.It islSan innovative in situ cold-dry direct extraction CEMS conditioning technology andiscomplement and development to traditional cold-dry direct extraction method CEMS conditioningtechnique. There are no condensation process, moving parts and analysts’ loss. GASS 6080 canmeet different drying requirements by adjusting Nafion tubing numbers and length. Therefore,system is suitable for long-run continuous operation and with low maintenance. 以 Nafion 干燥管为核心,并融合 Baldwin 烟气预处理技术于一体的 GASS 6080 预处理系统,是--种创新的原 位冷干直抽法 CEMS 预处理技术,是对现有冷干直抽法 CEMS 预处理技术的有机补充与拓展。系统无任何冷凝处理,无水溶损失,无机械运动部件,通过选择 Nafion 干燥管的数量和长度就可适应不同的除湿要求,便于长期连续运行,维护量低,非常适合于精确/原位测量。 GASS-6080 system is highly recommended to install directly on stack and in situ near flue gas probe.It ensures flue gas can be conditioned timely when flue gas is extracted from chimney to preventgaseous loss and helps improve integrity and accuracy of acid analysts, save expensive cost onheating pipeline and cooler, and reduce maintenance work. 建议 GASSTM-6080 直接安放在烟道上,原位安装在取样探头附件,确保烟气从烟道排放出来后就立即进行预处理,防止目标气态的损失,提高分析的完整性和精度,节省昂贵的加热管线和冷凝器,降低维护量。 After laboratory experiments, onsite portable CEMS experiments, and Jiaxing Power Plant No. 8generator “ultra low emission” CEMS application, GASS 6080 precondition system has beendemonstrated that it’s very suitable for cold & dry extractive CEMS even for"ultra low emission”limits in coal fired power plant in China. 经过实验室的实验,现场便携式 CEMS 实验和嘉兴电厂8号机组"超低排放"CEMS 应用, GASS 6080 已经证实非常适用于中国燃煤电厂中冷干直抽法 CEMS 的应用. Applications: 应用领域: > Suitable for FGD gas desulfurization system (ammonia desulphurization,l,seawater desulfurization.Limestone wet desulphurization)CEMS; > 适用于 FGD 脱硫系统(氨法脱硫、海水脱硫、石灰石湿法脱硫等)CEMS 的预处理; > Suitable for SCR denitration system CEMS; 适用于 SCR 脱硝系统 CEMS 的预处理; Especially suitable for high moisture, low range after Wet Electrostatic Precipitator CEMS 尤其适用于湿法电除尘 WESP 后高湿度、低量程 CEMS 的预处理; > Apply to LNG total gas turbine exhaust/ denitration system CEMS > 适用于LNG燃机总排/脱硝系统 CEMS 的预处理; All content copyright Perma Pure LLC 所有内容版权归博纯有限责任公司有

确定

还剩2页未读,是否继续阅读?

美国博纯有限责任公司上海代表处为您提供《废气中超低排放CEMS检测方案 》,该方案主要用于废气中其他检测,参考标准--,《废气中超低排放CEMS检测方案 》用到的仪器有博纯GASS-6080烟气预处理系统

推荐专场

相关方案

更多