方案详情

文

在接近室温下,样气在气体状态下被燃烧及分析。原本存在于样气中或燃烧过程中生成的水分,必须在气态下被移除,以使样气气体的化学组成保持不变,并防止在传感器上结露。

方案详情

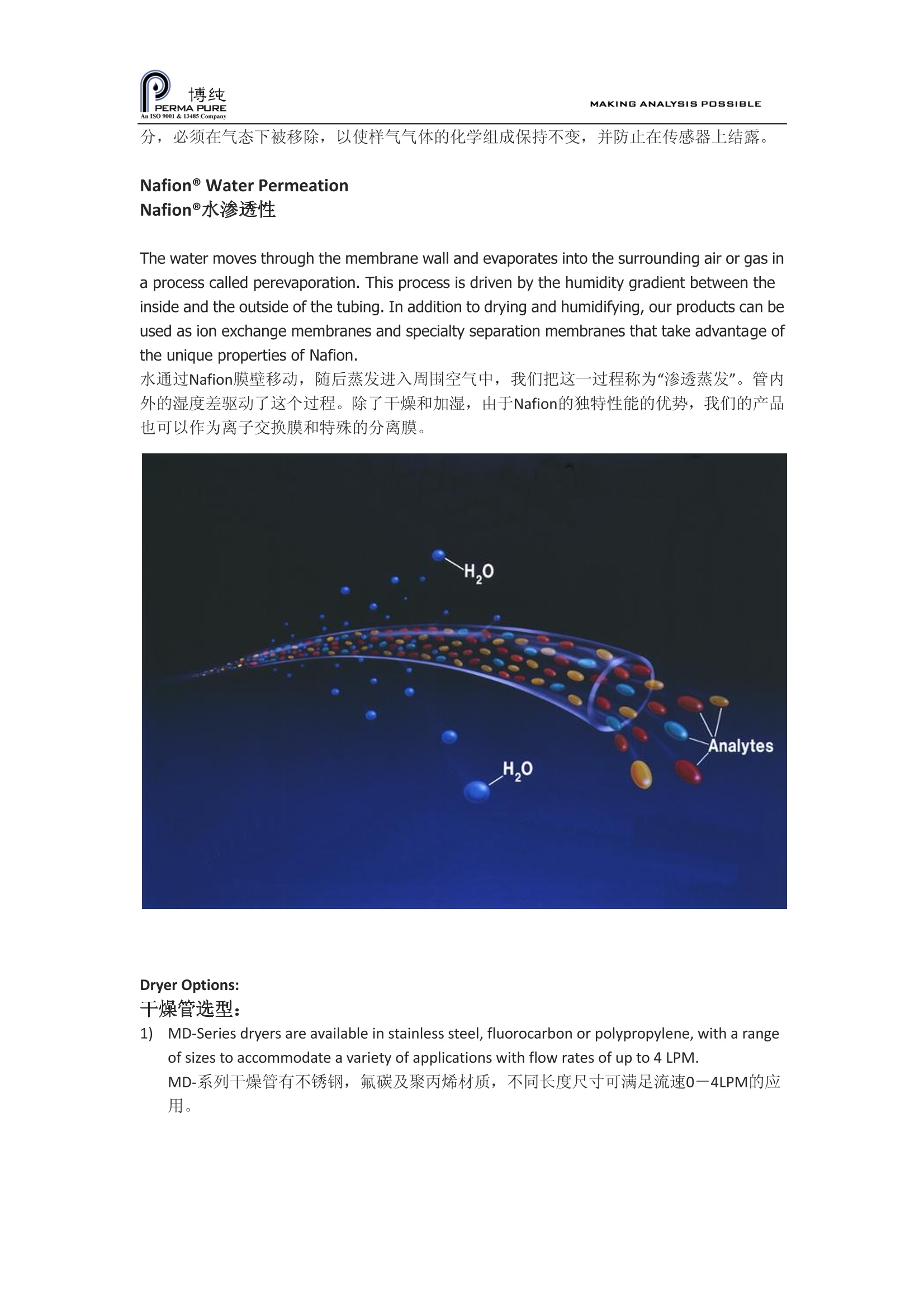

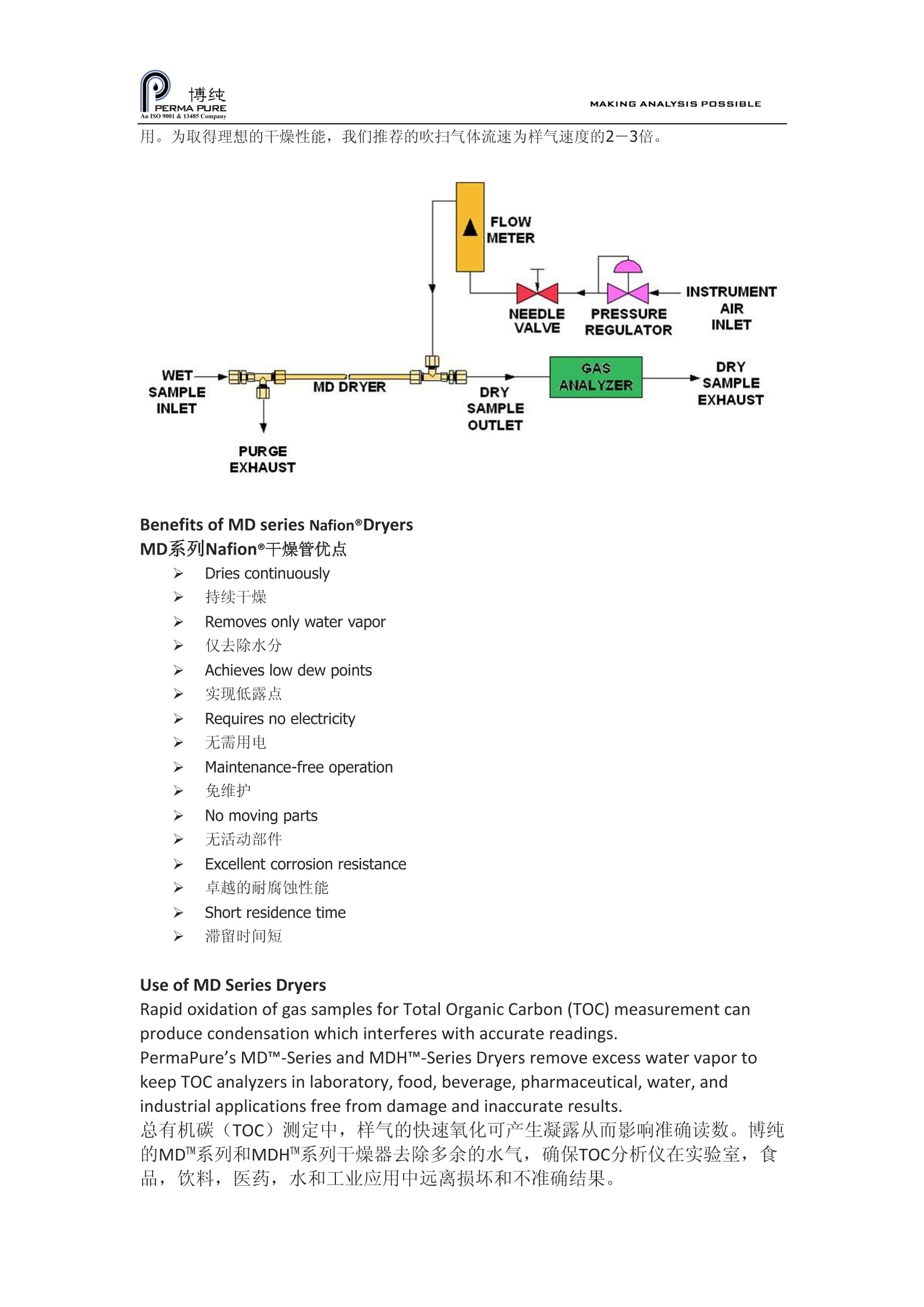

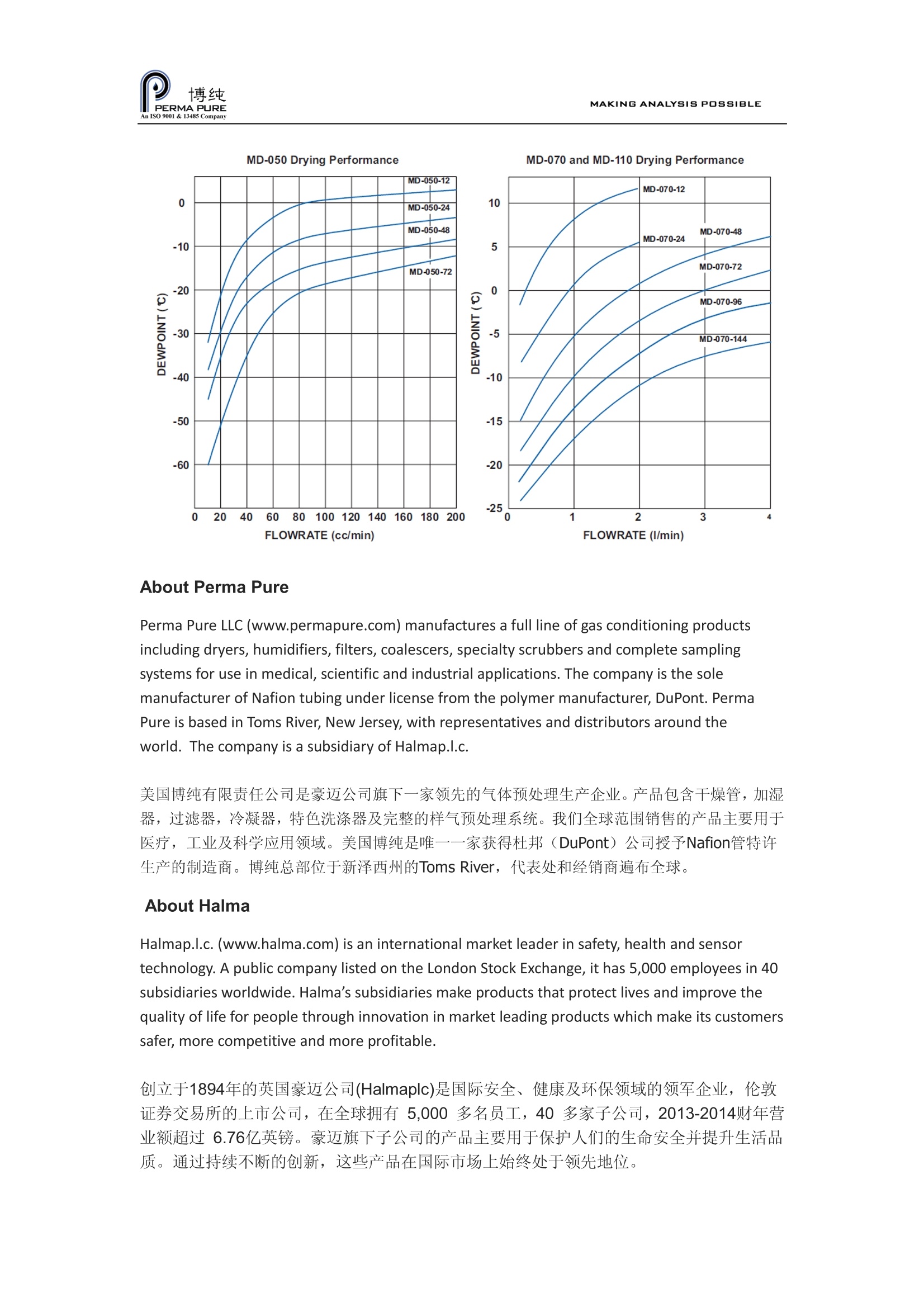

MAKING ANALYSISPOSSIBLE The use of MD dryers in TOC AnalyzersMD 干燥管在 TOC 分析仪的应用 ● What is TOC? TOC is Total Organic Carbon, it is the amount of carbon bound in an organic compound and isoften used as a non-specific indicator of water quality or cleanliness of pharmaceuticalmanufacturing equipment. A typical analysis for TOC measures both the total carbon present as well as the inorganic carbon(IC), Subtracting the inorganic carbon from the total carbon yields TOC. 什么是 TOC? TOC 是总有机碳,是以碳的含量表示有机物总量的一个指标,通常用作水质或药剂的制造设备是否洁净的非特异性指标。 用于 TOC 测量方式的一一个典型分析,总碳量及无机碳(IC)总和,减去从总从产出 TOC 中的无机碳。 ●Why need TOC analysis? TOC detection is an important measurement because of the effects it may have on theenvironment, human health, and manufacturing processes. TOC is a highly sensitive, non-specificmeasurement of all organics present in a sample. It, therefore, can be used to regulate theorganic chemical discharge to the environment in a manufacturing plant. In addition, low TOC canconfirm the absence of potentially harmful organic chemicals in water used to manufacturepharmaceutical products. 为什么要 TOC分析? TOC 检测是一个重要的测量,因为它可能对环境,人体健康,以及制造过程造成影响。TOC是存在于样气中的所有有机物的一个高度敏感的,非特异性的测量。因此,在制造工厂中它可以用来调节有机化学在环境中排放。此外,低 TOC可以确认有无用于制造药剂制品在水中具有潜在危害的有机化学物质。 TOC analysis process TOC 分析过程 Whether the analysis of TOC is byTC-IC or NPOC methods, it may be broken into three mainstages: 无论 TOC 的分析通过 TC-IC 或 NPOC 方法,,它可分成三个主要阶段: 1) Acidification: The first stage is acidification of the sample for the removal of the IC and POC gases. The releaseof these gases to the detector for measurement or to the air is dependent upon which type of analysis is of interest, the former for TC-IC and the latter for TOC (NPOC). 1)酸化: 第一阶段是将样品酸化,以除去 IC 和 POC 气体。这些气体释放到检测器用于测量或释放到空气中,取决于所感兴趣的分析类型,前者为 TC-IC 和后者用于 TOC (NPOC). 2)Oxidation The second stage is the oxidation of the carbon in the remaining sample in the form of carbondioxide (CO2) and other gases.Modern TOC analyzers perform this oxidation step by oneseveralprocesses: 1. High Temperature Combustion 2. High temperature catalytic (HTCO) oxidation 3. Photo-oxidation alone 4.Thermo-chemical oxidation 5. Photo-chemical oxidation 2)氧化 第二阶段是在二氧化碳(CO2)等气体的形式,其余样品中碳的氧化。近代的 TOC 分析仪通过一个多道工序进行氧化步骤: 1,高温燃烧 2,高温催化(HTCO)氧化 3,光氧化独 4,热化学氧化 5,光化学氧化 3) Analysis: Accurate detection and quantification are the most vital components of the TOC analysis process.Conductivity and non-dispersive infrared (NDIR) are the two common detection methods used inmodern TOC analyzers. 3)分析: 精确的检测和定量是 TOC 分析过程中最重要的组成部分。导电性和非色散红外(NDIR)是在近代 TOC 分析仪中所用的两种常见检测方法。 Combustion method TOC analyzer 燃烧法 TOC 分析仪 In a combustion analyzer, half the sample is injected into a chamber where it is acidified, usuallywith phosphoric acid, to turn all of the inorganic carbon into carbon dioxide as per the followingreaction: 在燃烧分析仪,有一半的样品被注入到腔体被酸化,通常用磷酸,按照以下反应方程式把所有的无机碳转化为二氧化碳: This is then sent to a detector for measurement. The other half of the sample is injected into acombustion chamber which is raised to between 600-700℃, some even up to 1200℃. Here, allthe carbon reacts with oxygen, forming carbon dioxide. It's then flushed into a cooling chamber,and finally into the detector. Usually, the detector used is a non-dispersiveinfrared spectrophotometer. By finding the totalinorganic carbon and subtracting it from the total carbon content, the amount of organic carbonis determined. 这然后被送到检测器进行测定。样品的另一半被半入到燃烧室,温度被提升到600-700℃之间,有的甚至高达1200℃。这里,所有的碳与氧反应,从而形成二氧化碳。然后冲入冷却室,最后进入检测器。 通常,所使用的检测器是一个非色散红外分光光度计。通过找出总无机碳,从总碳含量中减去它确定有机碳量。 MD-Series Dryers are the ideal choice for drying the carrier gas that moves the sample acrossthe flow-through-cell. MD 系列干燥器是用于干燥载气及样气的理想选择,随后气体穿过流通室。 Nafion@-based gas dryers take advantage of the unique moisture transfer properties of Nafion @intubing form. 气体干燥器使用独有的Nafion选择性渗透膜管去除水气,可对气体持续干燥。 They function on a principle of selection on the basis of affinity for the sulfonic acid groupin thematerial's structure, allowing water to be transferred chemically from one side of themembraneto another. Depending on the relative water vapor pressure difference between the inside and theoutside ofthe tube, moisture will rapidly move from one side of themembrane to the other. Pressure isnot required to drive the process, unlike othermethods, the tubing isextremelyselective, onlytransferring moisture out of a gas stream while leaving the other componentsintact. This makes Nafion@ideal for gas conditioning applications. When configured properly, Nafion@ based dryers can easily reachdew points below -20℃. Samplesare combusted and analyzed in the gaseous state at atemperature close to ambient.Themoisture originally present in the sample or generated by thecombustion process mustberemoved in the vapor phase so that the chemical composition ofthe sample gas remainsintactand condensation on the sensor is prevented. 该选择性的原理是在材料结构中磺酸基团的存在而赋予Nafion不同寻常特性,允许进行化学转水从膜的一侧到另一侧。 根据管内和管外部之间的相对的水蒸汽压力差,水分会迅速移动从膜的一侧到另一侧。干燥过程无需压力进行驱动,不象其它方法,该管是非常有选择性的,只传送潮湿的气流同时保持其它组分不变。这使得Nafion@成为气体调节所理想的应用。 如果配置正确, Nafion@干燥管可以轻松将样气露点达到低于-20℃。 在接近室温下,样气在气体状态下被燃烧及分析。原本存在于样气中或燃烧过程中生成的水 分,必须在气态下被移除,以使样气气体的化学组成保持不变,并防止在传感器上结露。 Nafion@ Water Permeation Nafion@水滲透性 The water moves through the membrane wall and evaporates into the surrounding air or gas ina process called perevaporation. This process is driven by the humidity gradient between theinside and the outside of the tubing. In addition to drying and humidifying, our products can beused as ion exchange membranes and specialty separation membranes that take advantage ofthe unique properties of Nafion. 水通过Nafion膜壁移动,随后蒸发进入周围空气中,我们把这一过程称为“渗透蒸发”。管内外的湿度差驱动了这个过程。除了干燥和加湿,由于Nafion的独特性能的优势,我们的产品也可以作为离子交换膜和特殊的分离膜。 Dryer Options: 干燥管选型: 1))MD-Series dryers are available in stainless steel, fluorocarbon or polypropylene, with a rangeof sizes to accommodate a variety of applications with flow rates of up to 4 LPM. MD-系列干燥管有不锈钢,氟碳及聚丙烯材质,不同长度尺寸可满足流速0一4LPM的应用。 2) MDH-Series dryers are designed for gas flows of up to 1 LPM, with as much as 30% water byvolume. Either model can be incorporated easily into analyzer cabinets or used as a stand-alonedevice. MDH-系列干燥管的设计用于处理1LPM流速,高达30%体积比水分的气体。该型号可以简单地在分析仪内配套使用,也可作为独立部件使用。 For gas samples with above-ambient dew points, the integral heater and thermostat in theMDH-Series dryers control temperature and prevent condensation throughout the drying process.This integrated design simplifies installation and operation. 当样气高于环境温度露点,MDH系列干燥管中的加热器和恒温器控制温度,防止在干燥过程中产生冷凝水。此整体设计简化了安装与操作。 How to use Nafion@dryers on the TOC analyzers: 如何在TOC分析仪中使用Nafion@干燥管: Dried compressed or "Instrument" Air is typically found at most industrial plants and in manylabs and serves as an excellent purge gas. The dew point of this purge gas is typically -40°to-45°C.Most of our performance curves have been made from test data using instrument air. Werecommend the purge gas flow be 2-3x of the sample gas flow for optimal drying performance.干燥的压缩空气或仪表风一般都可在工业工厂和许多实验室找到,并可用作非常理想的吹扫气体。常规吹扫气的露点为-40°到-45°℃。我们大多数性能曲线的制作,数据都来源于使用仪表风的应 用。为取得理想的干燥性能,我们推荐的吹扫气体流速为样气速度的23倍。 Benefits of MD series Nafion@Dryers MD系列Nafion@干燥管优点 > Dries continuously > 持续干燥 > Removes only water vapor 仅去除水分 Achieves low dew points > 实现低露点 > Requires no electricity > 无需用电 > Maintenance-free operation > 免维护 No moving parts 无活动部件 > Excellent corrosion resistance > 卓越的耐腐蚀性能 > Short residence time > 滞留时间短 Use of MD Series Dryers Rapid oxidation of gas samples for Total Organic Carbon (TOC) measurement canproduce condensation which interferes with accurate readings. PermaPure’s MDTM-Series and MDHTM-Series Dryers remove excess water vapor tokeep TOC analyzers in laboratory, food, beverage, pharmaceutical, water, andindustrial applications free from damage and inaccurate results. 总有机碳(TOC)测定中,样气的快速氧化可产生凝露从而影响准确读数。博纯的MD"系列和MDH"系列干燥器去除多余的水气,确保TOC分析仪在实验室,食品,饮料,医药,水和工业应用中远离损坏和不准确结果。 About Perma Pure Perma Pure LLC (www.permapure.com) manufactures a full line of gas conditioning productsincluding dryers, humidifiers, filters, coalescers, specialty scrubbers and complete samplingsystems for use in medical, scientific and industrial applications. The company is the solemanufacturer of Nafion tubing under license from the polymer manufacturer, DuPont. PermaPure is based in Toms River, New Jersey, with representatives and distributors around theworld. The company is a subsidiary of Halmap.l.c. 美国博纯有限责任公司是豪迈公司旗下一家领先的气体预处理生产企业。产品包含干燥管,加湿器,过滤器,冷凝器,特色洗涤器及完整的样气预处理系统。我们全球范围销售的产品主要用于医疗,工业及科学应用领域。美国博纯是唯一一家获得杜邦(DuPont)公司授予Nafion管特许生产的制造商。博纯总部位于新泽西州的Toms River, 代表处和经销商遍布全球。 About Halma Halmap.l.c.(www.halma.com) is an international market leader in safety, health and sensortechnology. A public company listed on the London Stock Exchange, it has 5,000 employees in 40subsidiaries worldwide. Halma’s subsidiaries make products that protect lives and improve thequality of life for people through innovation in market leading products which make its customerssafer, more competitive and more profitable. 仓立于1894年的英国豪迈公司(Halmaplc)是国际安全、健康及环保领域的领军企业,伦敦证券交易所的上市公司,在全球拥有 5,000 多名员工,40多家子公司,2013-2014财年营业额超过6.76亿英镑。豪迈旗下子公司的产品主要用于保护人们的生命安全并提升生活品质。通过持续不断的创新,这些产品在国际市场上始终处于领先地位。

确定

还剩5页未读,是否继续阅读?

美国博纯有限责任公司上海代表处为您提供《废水中有机污染物检测方案 》,该方案主要用于废水中有机物综合指标检测,参考标准--,《废水中有机污染物检测方案 》用到的仪器有美国博纯-MD™单管干燥器、美国博纯-MDH™ 带加热MD单管干燥器、美国博纯MD700颗粒物分析专用大直径Nafion干燥管

推荐专场

PM2.5/PM10/PM1/TSP大气颗粒物监测仪

相关方案

更多