搜全站

搜展位

同类推荐

更多![]()

联系方式

广州竞赢科学仪器有限公司

公司地址

广东省广州市天河区燕岭路25号1009

客服电话

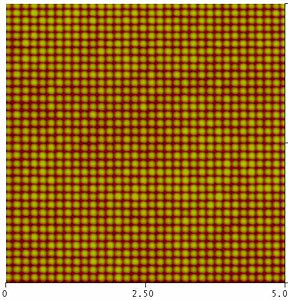

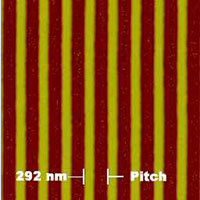

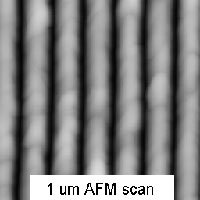

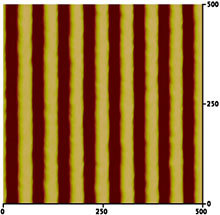

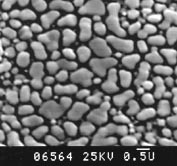

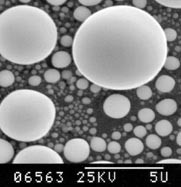

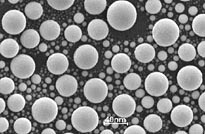

刑侦测试标样由广州竟赢仪器有限公司为您提供,货号60806-4,规格:0.5, 0.8, 1.2, 2.4, and 10um,CAS号:,如您想了解更多关于刑侦测试标样价格、刑侦测试标样结构式、批发、用途等信息,欢迎咨询。除供应刑侦测试标样外,还可为您提供栅格标样、高放大倍数高分辨率校准标样、AFM XYZ校准标样等试剂,公司有专业的客户服务团队,是您值得信赖的合作伙伴,竞赢科学客户服务电话,售前、售后均可联系。