德国FM 试验机系列产品

德国FM 试验机进入中国市场

Universal Testing Machines

Tensile, compression and bending tests depending on the accessories for force, displacement or deformation control - depending on the expansion stage - in the closed-loop control loop of the servo-hydraulics on materials

Universal Testing Machine Type EM

Universal testing machines of the EM series offer a wide range of test loads with graduated nominal forces between 5 kN - 1200 kN. Due to their modular design, they are suitable for tensile, compression and flexure tests as well as for universal testing with widely varying test requirements.

Universal Testing Machine Type TTM

Due to their modular design, servo-hydraulic testing machines are used for the universal execution of tests with very different test requirements and specimen dimensions. The series is designed for the latest materials and component testing technology. Their design opens up a wide range of possibilities.

Universal Testing Machine UP 50 HK-2DH

static and dynamic testing; tensile, compression and bending testing; fatigue testing; force-, distance- and deformation controlled testing

Bending Testing Machine UP 200 HK-2

For the bending tensile strength test according to standards on: concrete joists, concrete, concrete kerb stones, concrete paving stones, natural stone paving stones, natural stone, natural stone kerb stones

Universal Testing Machine UP 400

Testing machine for universal compression tests with heavy specimens made of different materials. Test frame for very flexible compression tests with a wide variety of superstructures.

Universal Testing Machine UP 1000

Testing machine for universal compression tests with heavy specimens made of different materials. Test frame for very flexible compression tests with a wide variety of superstructures.

Universal Testing Machine Type EM

Universal testing machines of the EM series offer a wide range of test loads with graduated nominal forces between 5 kN - 1200 kN.

Due to their modular design, they are suitable for tensile, compression and flexure tests as well as for universal testing with widely varying test requirements. Numerous other tests can be implemented with a very extensive range of accessories consisting of specimen grips and test fixtures. Special solutions for special testing tasks are quickly designed by our own development department and manufactured in-house.

Size: Fnom: 5 - 1200 kN

demanding static and quasistatic tests in research/development and quality control

standard test pieces, components and parts in the destructive and non-destructive test range (e.g.: metals, elastomers, composites)

TENSILE-, COMPRESSION- and BENDING TESTS depending on accessories

flexible configuration

Standards:

DIN EN ISO 7500-1: ASTM E4

Accuracy:

class 1 (0.5 optionally) according to DIN EN ISO 7500-1: ASTM E4

Configuration:

Frame: modern design considering the ergonomic needs of the operator; very rigid two-room test frame for flexible tests

Drive: powerful, maintenance-free, digitally controlled electromechanical drive; pre-stressed ball screws, free from play

Hand Wheel: for the manual drive of the test cylinder - steplessly adjustable movement speed

Force Measurement: strain gauge force transducer for tensile and compressive forces - optionally mounted on the piston rod or on the baseplate

Options / Accessories: broad range of specimen holders, tensioning equipment, compression plates, bending tables, T-slot tables, transport devices, climate chambers, protective equipment and integrated operating elements

Universal Testing Machine EM 10

demanding static and quasi-static testing tasks in development/research and quality assurance

Electromechanical Testing Machine EM 50

demanding static and quasi-static testing tasks in development/research and quality assurance

Electromechanical Testing Machine EM 100 S

demanding static and quasi-static testing tasks in development/research and quality assurance

Electromechanical compression testing machine EM 100-4 S

This EM series electromechanical compression testing machine is used to simulate the compression of packaging stacks. It generates a pressure of up to 10 tons. The maximum size of the test samples is 2700 millimetres in height and 2000 x 1500 mm in area. All parameters have been recorded and implemented in a customer-specific manner. Due to the specimen dimensions, the inspection system is very solid and rigid. High accuracy and reproducibility were taken into account in the design. Of course, the simplest possible introduction of the test specimens into the test room is elementary here.

Electromechanical Testing Machine EM 200

demanding static and quasi-static testing tasks in development/research and quality assurance

Universal Testing Machine EM 400

This electromechanical universal testing machine of the EM series is used for continuous calibrations in the direction of tensile and compressive forces up to 400 kN (40 t) and achieves highly precise and repeatable accuracies (<0.25 %). The test unit is very compact and equipped for universal testing possibilities. This means that a large number of different types, sizes and designs of force sensors from the customer spectrum can be tested.

Universal Testing Machine Type TTM

Due to their modular design, servo-hydraulic testing machines are used for the universal execution of tests with very different test requirements and specimen dimensions. The series is designed for the latest materials and component testing technology. Due to their design there are various possibilities, which can be realized by fast conversions. Flexible special solutions for special testing tasks are quickly designed by our own development department and manufactured in-house.

Universal Testing Machine TTM 250 PK-2

Tensile, compression and bending tests each according to accessories for the load, displacement or deformation control – depending on the level of attachments – in the closed loop of the servo-hydraulic on: metallic materials, stone specimens, soil specimens

Universal Testing Machine UP 600 PK-2

Precise, reproducible, demanding inspection tasks for a variety of different applications due to the flexible design Fatigue and fracture mechanics tests are selected and offered from the wide range of possibilities for this series, depending on the customer's applications and test procedures.

Universal Testing Machine UP 50 HK-2DH

static and dynamic testing

tensile, compression and bending testing

fatigue testing

force-, distance- and deformation controlled testing

Standards:

DIN EN 1062-7

coating material and coating systems for mineral substrates and concrete in outdoor area - part 7: determination of crack bridging characteristicsDIN EN 14224

sealing systems for concrete bridges and other traffic areas made of concrete – determination of crack bridging ability

Accuracy:

class 1 acc. to DIN EN ISO 7500-1

Equipment:

individual test cylinder EPZ-H 50

load sensor incl. thermic dividing plate

hydraulically adjustable cross-head

holder for hydraulic installation

T-slot table

climate chamber

hydraulic parallel grip heads for a temperature range from

-40° C up to +200° Cinductive displacement transducer, suitable for operation in the climate chamber

digital control system with universal test software

safety enclosure acc. to EC machinery directive

关于我们 form+test

60多年来,我们一直在德国的Riedlingen镇开发和生产试验机系列测试机器。

FORM+TEST这个曾经的小企业经过多年发展成为国际公认的测试机械制造商。 E. Seidner的老公司已经被管理层和一个忠诚的员工团队重组为FORM+TEST一家现代化的测试系统公司。 有了最先进的生产技术,我们可以实现甚至最严格的愿望和要求,由科学和工业的高质量测试系统。

FORM+TEST有最先进的生产技术,我们可以实现甚至最严格的愿望和要求,由科学和工业的高质量测试系统。

FORM+TEST在过去的几年里,只有坚定、质量保证、质量控制和提高质量,我们才能继续扩大我们积极的公司形象。

FORM+TEST拥有80名员工,在现代化的功能性建筑中开发和生产我们的产品,生产面积约7515平方米(总面积16098平方米)。

FORM+TEST发展

我们的核心竞争力之一是根据客户的个性化要求设计和生产高质量的专用测试设备。 我们有经验丰富的工程师和技术人员团队,可以实现最严格的设计,从最小的机器小牛顿力到10000 kN的试验机系列产品。

我们与领先的机构和学院的密切联系,我们总是在最新的测试技术。 对您来说,这意味着我们成为德国工厂和机械制造商协会(VDMA)的成员,部分测试机器,是面向未来的技术,卓越的质量和可靠的服务的保证。

我们的测试机器几乎完全由液压驱动。 为此所需的驱动站由我们自己单独规划和实现,以适应各自的机器或机器组合。 只使用经过多年试验和测试的、来自合格、可靠的分包合作伙伴的高质量的集料和组件。

FORM+TEST生产

作为一个制造公司,我们可以实现您的特殊的定制产品,按照要求在最短的时间内,我们的现代化的机械范围。

我们的测试机的测试油缸、活塞和膨胀油缸悬挂轴是在最先进的加工中心制造的。 这要求极高的精度和相当多的加工经验。

FORM+TEST质量保证

我们有自己的质量保证部门。 对您来说,这意味着我们将继续保持众所周知的“Swabian 质量”。 当然,除此之外,我们还遵守国际标准。 由于我们的质量管理是根据DIN EN ISO 9001认证的,我们保证只有高质量的材料离开我们的作品,并给予“原始形式+测试”的质量印章。

FORM+TEST测试

我们在生产过程中广泛的材料测试设定了高标准。 例如,在安装之前,每个压力板都要经过数次强度测试。 这保证只有高质量的材料和产品离开我们的作品,并给予质量的形式+测试密封。

FORM+TEST校准

我们的每一台测试机器在交付前都在工厂进行校准,以确认其高度符合标准。

FORM+TEST认证

通过DIN EN ISO 9001认证,测试和测量设备受到持续控制。 对于这种控制,我们使用精度为1/1000毫米的线性测量系统。

只有这样,我们的测试机器的高精度才能得到保证。

我们的测试机器要经过非常严格的最后检验。 这确保了在客户的设施DAkkS(德国校准服务)验收。

Dynamic Testing at elevated Temperatures

With the UP 500, Form+Test supports material research of new materials at a renowned Russian university. The test machine was designed according to the customer's requirements in terms of machine frames and machine performance. Samples and even entire components can be tested at up to 10 Hz and 500 kN at up to 500°C. The climate chamber can be easily moved into and out of the rehearsal room. To ensure that the machine itself stays cool, the load strand is equipped with a separate cooling circuit. Simply a turn-key solution by FORM+TEST.

更多![]()

PF-QNM技术揭示质子交换膜电解水阳极催化剂层(ACL)退化机制

厂商

2024.08.09

探索寡核苷酸杂质分离|Shim-pack Scepter Claris液相色谱柱

厂商

2024.08.19

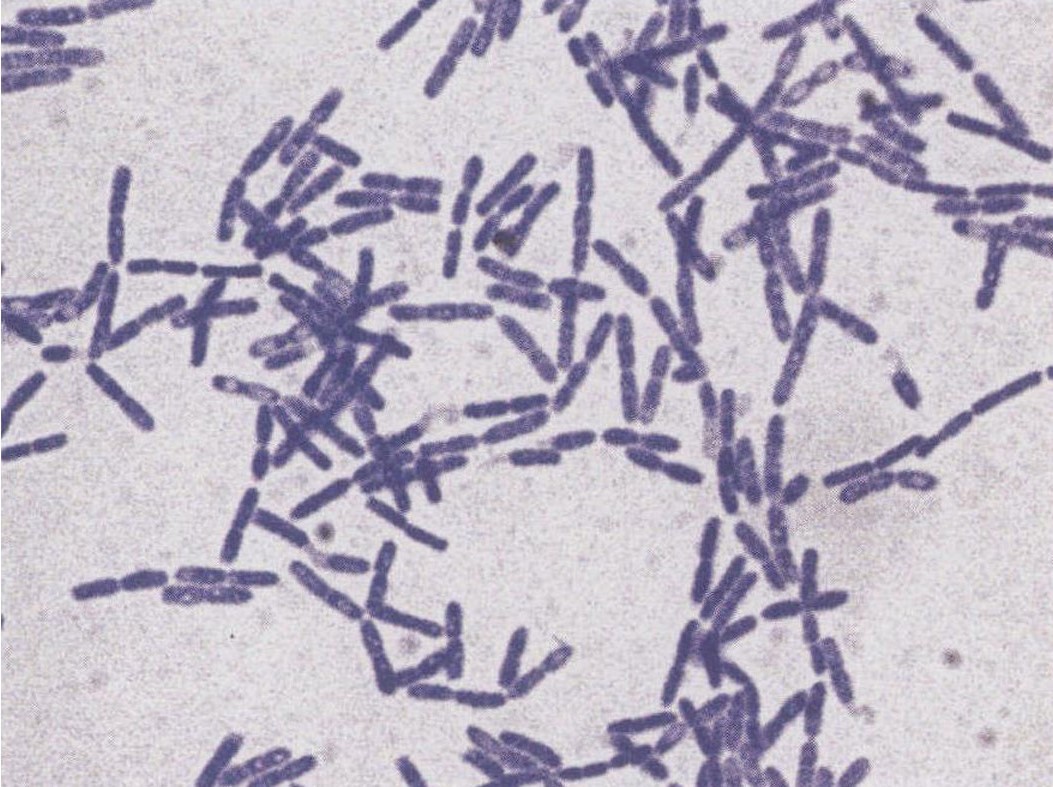

近期频上热搜的“炭疽”到底是什么病?

厂商

2024.08.19

集成能谱场发射扫描电镜Apreo ChemiSEM新品发布会

新品

2024.08.20