用于移动显示器制造的飞秒激光加工Femtosecond laser processing for mobile display manufacturing

2016/09/09 10:29

阅读:385

分享:方案摘要:

产品配置单:

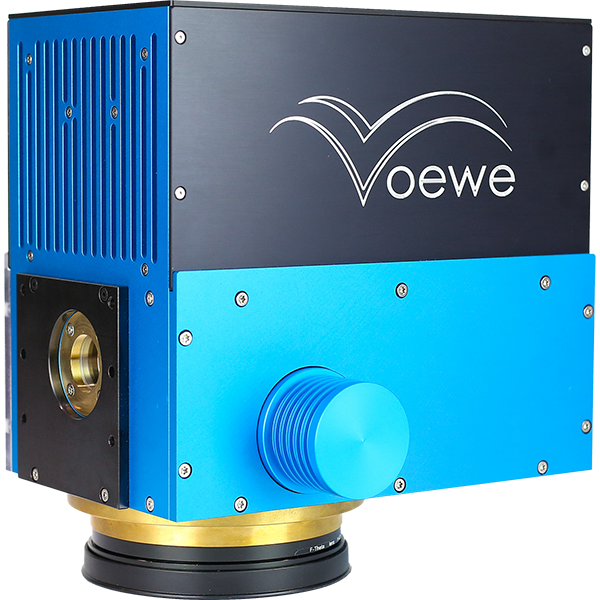

Amplitude紧凑型高重频高功率飞秒激光器Satsuma

型号: Satsuma

产地: 法国

品牌: Amplitude

€1000

参考报价

联系电话

方案详情:

Displays are key components of many of today’s mobile electronic devices such as smartphones, digital cameras, mp3 players, etc. As the market for mobile electronics expands, displays are required to fulfil more and more challenging requirements for power consumption, image quality and definition, as well as robustness.

The next generation of mobile displays offers a wider color gamut, better image contrast and lower power consumption. They also benefit from wider viewing angles, faster response and more compactness due to their thin multilayer architectures. New technologies, such as flexible displays, make extensive use of organic LEDs technology (OLED), and present significant manufacturing challenges. Production yield for such displays are currently very low; due to the complexity and the multilayer structure of the displays (up to 20 different materials). Many units come out of the production line with defects and are then discarded. The presence of dead, over-bright pixels and other imperfections are considered unacceptable in such a high added-value consumer item. As the mtechnology extends to larger volumes and large panel displays, better production yield become critical for display manufacturers. Current laser processing technologies face limitations such as the sensitivity of organic material to heating and the low thickness of thin film layers.

Femtosecond lasers allow non-thermal ablation of materials, owing to the extremely short interaction time of the laser-matter interaction. Therefore machining precision can be significantly improved using femtosecond laser ablation as heat affected zone and debris generation is greatly reduced [1,2]. In addition, non-thermal process is crucial for selective removal of multi-layer organic polymers that are susceptible to heat.

下载本篇解决方案:

更多![]()

飞秒激光器的突发模式对透明材料处理的影响Effects of burst mode on transparent materials processing

We investigated the effect of burstmode with nanosecond (ns) time delay between subpulses on sodalime glass volume machining. We observed in tight focusing configuration that the use of burstmode with ns time delay between subpulses does not increase the absorption efficiency and does not bring a significant effect on the heat affected zone diameter with respect to single pulse mode. On the contrary in loose focusing configuration the use of burst mode allows increasing the aspect ratio of the heat affected zone without extra energy absorption. This effect is highly interesting for filamentation glass cutting applications.

建材/家具

2016/09/02

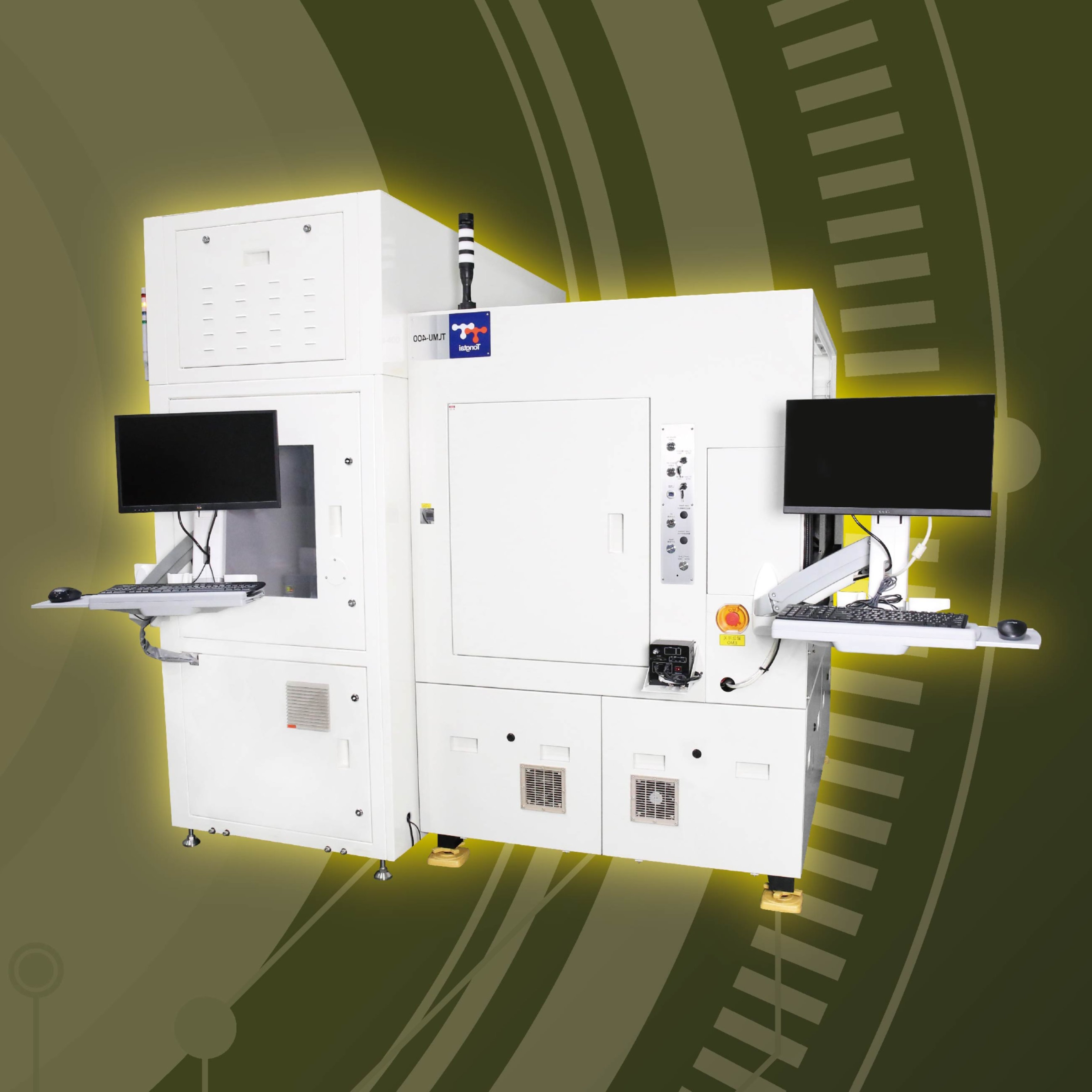

用二维X光检查材料和厚度识别

X光检测系统是PCB和半导体器件质量控制、成品率提高和失效分析的关键工具。在许多情况下,这些强大的工具提供了检查电子元件的唯一无损技术。在过去的几年中,X光检查能力(2D和3D)有了显著的改进。在本文中,我们报道了一种新的发展,允许通过二维x射线检查获得材料和厚度信息。

电子/电气

2021/05/08

X光无损检测及超声波无损检测应用手册

X光无损检测及超声波无损检测应用手册 X光和超声波成像是两个非常有益的工具,用于无损检测电子组件产品的质量。这两种技术都提供了关于组件完整性的不同方面的信息。

半导体

2021/05/08

在高速推力和高速拉力测试时,SnAgCu和SnPb焊料球的脆性破坏机制

脆性材料(如硅和玻璃)的强度主要取决于是否存在诸如划痕和缺口之类的微裂纹和表面缺陷。 在这些材料中,裂纹尖端的高压力无法通过塑料流缓解,因此,即使是非常小的缺陷也可能会导致低故障负荷。 Nordson DAGE 4000Plus 测试系统低测试力功能加上我们的专用工具支持微材料弯曲测量,以评估缺陷的严重程度。 可以对尺寸小至 1 平方毫米的样本执行三点和四点以及球面弯曲测量。

电子/电气

2016/04/22