澄清度检查伞棚灯产品特点及功能科普

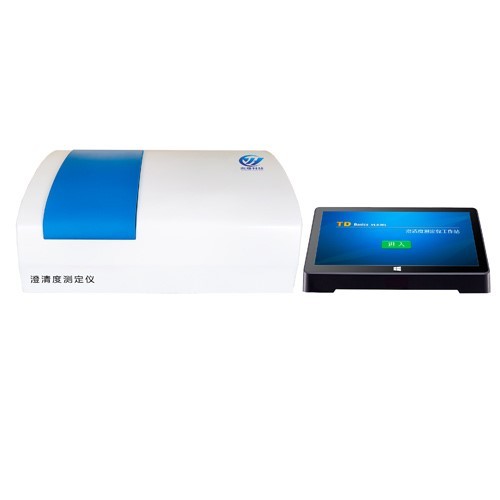

在医药、化工、食品等众多领域,溶液的澄清度检查是一个至关重要的环节。为了满足这一需求,澄清度检查伞棚灯应运而生,成为行业内的得力助手。今天,我们就来科普一下这款产品的特点及功能。 首先,让我们聚焦于产品的特点。澄清度检查伞棚灯严格遵循《中国药典》中关于澄清度检查法的各项技术规定,确保了测试的准确性和可靠性。它专门用于澄清度检查的测试,无论是有色溶液还是无色溶液,都能进行精准的澄清度检查。此外,产品采用了弧形观察窗口设计,使得光照强度更为均一,为测试者提供了更舒适、更准确的观察环境。 接下来,我们来了解一下产品的参数及功能。首先,澄清度检查伞棚灯的光照强度可在0-6000Lux范围内调节,以满足不同溶液的测试需求。此外,产品内置了24种不同颜色的光,测试者只需一键点选,即可轻松切换,大大提高了测试的灵活性和便捷性。 值得一提的是,该产品还具有记录观察时间及提醒功能。在药典规定中,观察时间通常为20秒,而澄清度检查伞棚灯能够精准记录观察时间,并在到达规定时间时发出提醒,确保测试者能够严格按照规定进行操作。 此外,澄清度检查伞棚灯的输入电压、频率范围为220V/50HZ,采用三孔插座设计,确保了产品的稳定供电和安全性。在尺寸方面,产品长380mm,宽678mm,高337mm,体积适中,方便携带和存放。 澄清度检查伞棚灯凭借其符合药典规定、功能多样、操作便捷等特点,在医药、化工等领域发挥着重要作用。它不仅能够提高测试的准确性和效率,还能为测试者提供更为舒适、安全的观察环境。随着科技的不断进步,相信未来会有更多创新型的澄清度检查设备涌现,为行业的发展注入新的活力。

企业动态

2024.04.11

可溶性微针贴剂原理介绍及理化检查项目介绍

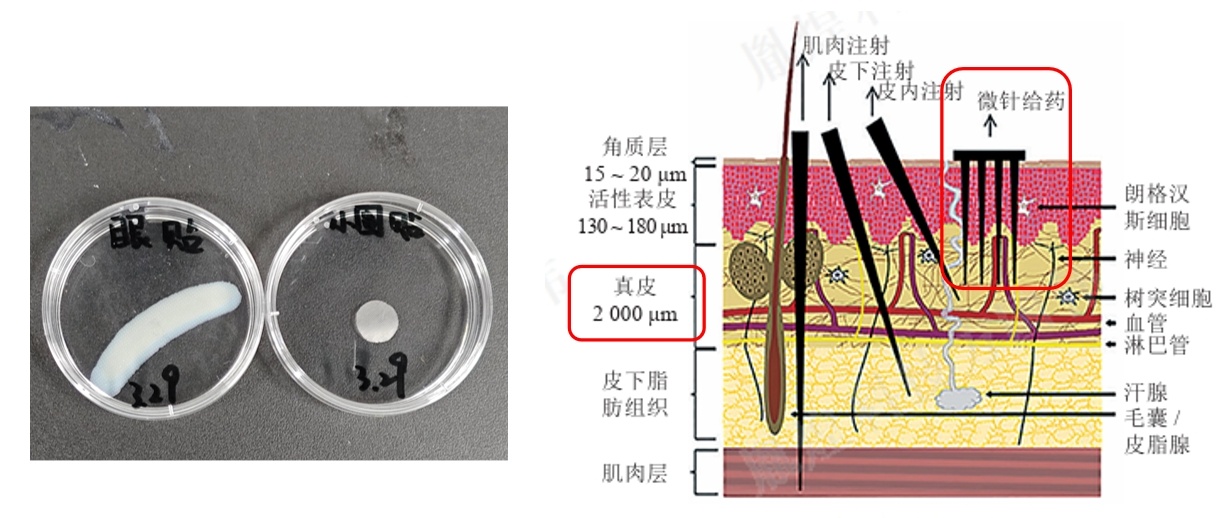

可溶性微针贴剂,作为一种新型的药物传递系统,近年来在医疗领域引起了广泛关注。它的核心原理在于利用微针穿透皮肤角质层,从而实现药物的局部释放。微针通常由水溶性材料制成,这些微针在刺入皮肤后会迅速溶解,释放出所携带的药物,从而达到治疗目的。 这种给药方式具有诸多优点。首先,微针给药不易刺激神经末梢,因此患者几乎不会感受到疼痛。其次,由于微针能够直接穿透角质层,药物可以更快速地进入皮肤深层,提高了药物的吸收效率。此外,可溶性微针贴剂的制备工艺相对简单,材料选择丰富,使得其生产成本相对较低,更易于推广应用。 然而,为了确保可溶性微针贴剂的安全性和有效性,理化检查项目至关重要。这些检查项目主要包括对微针贴剂的物理性质、化学性质以及生物相容性等方面的评估。 物理性质检查主要关注微针的尺寸、形状、硬度等参数,确保它们能够顺利地刺入皮肤并溶解。化学性质检查则是对微针贴剂中的药物成分、含量、稳定性等进行检测,以保证药物的有效性和安全性。此外,生物相容性检查也是必不可少的一环,它通过对微针贴剂与人体组织的相互作用进行评估,来确保微针贴剂在使用过程中不会对人体造成不良影响。 值得一提的是,可溶性微针贴剂作为一种新型给药方式,其应用前景广阔。它不仅可以用于皮肤疾病的治疗,还可以用于疫苗接种、疼痛管理等多个领域。随着研究的深入和技术的不断进步,相信可溶性微针贴剂将在未来为人类的健康事业作出更大的贡献。 总之,可溶性微针贴剂以其独特的给药方式和优良的性能特点,在医疗领域展现出了巨大的潜力。而理化检查项目则是确保其安全性和有效性的重要保障。未来,随着科技的进步和研究的深入,我们有理由相信可溶性微针贴剂将为人类的健康事业带来更多的福音。 以上就是苏州胤煌精密仪器整理分享的关于可溶性微针贴剂原理介绍及理化检查项目介绍。想了解更多相关资讯,欢迎持续关注。

应用实例

2024.04.10

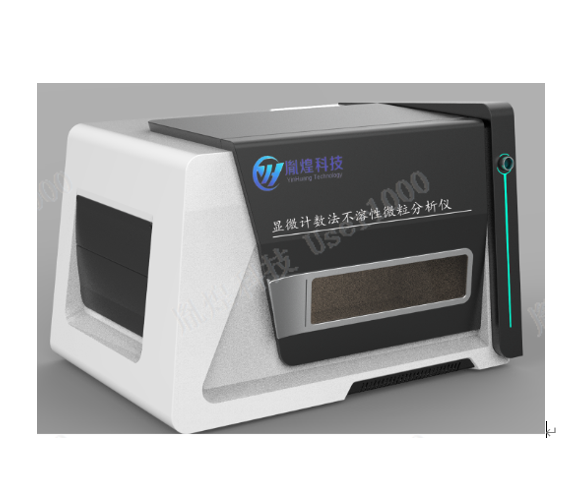

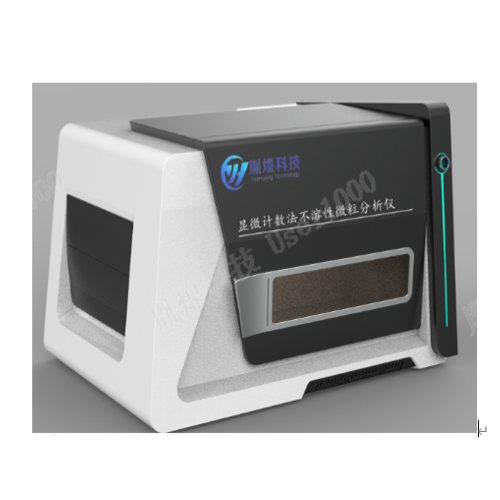

乳剂注射剂不溶性微粒检测首选方案-显微计数法!【案例分享】

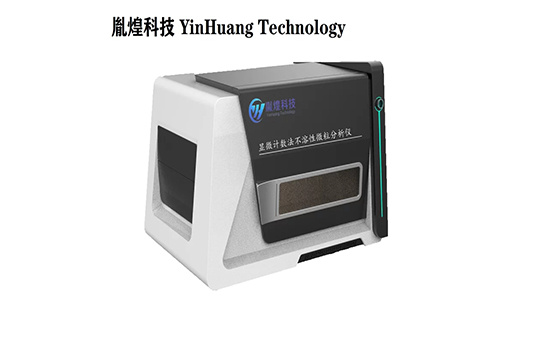

乳剂注射剂是医疗领域常用的药物剂型之一,然而在使用过程中,其不溶性微粒的问题备受关注。不溶性微粒不仅可能影响药物的稳定性和有效性,还可能对患者的安全构成威胁。因此,对乳剂注射剂中不溶性微粒的检测显得尤为重要。在众多检测方法中,显微计数法因其直观、准确的特点,成为首选方案。 案例说明: 乳剂通常用作载药剂型,对药物具有缓释、控释、靶向定位的优势,在抗肿瘤、抗微生物等领域具有广阔的发展前景,目前药用静脉注射乳剂已成为当今药物释放体系的热门研究对象。 图1:样品实物图 具有不同尺寸粒径的乳剂一般会呈现不同的外观形态,对于O/W型乳剂来讲,当乳的粒径较大时,药物则出现乳白色浑浊的外观。美国药典章节中指出,乳剂这类注射剂不适宜使用光阻法对样品进行不溶性微粒检测,进而引出应当采用显微镜法进行不溶性微粒检测。 样品描述:乳白色浑浊液体 测试方法分析: 光阻法的测试原理是:激光照射在流动池上,经过流动池的粒子会造成一个光消减信号,这个信号会被转换成为电子脉冲,被记录下来,并且将其与粒子的等效圆直径联系起来。光阻法仅能够测量不透明、或者折射率与周围液体显著不同的颗粒,当样品呈现乳白色时,折射率的异常会导致测试结果出现偏差。当采用显微镜法对此类制剂进行检测则可以直接避免基于测试原理带来的错误结果。 测试流程: 制样:打开容器瓶,将其倒入覆有滤膜的抽滤装置中,在低压状态下进行抽滤,得到的滤膜放置在平皿中,低温干燥; 测试:干燥结束后,将膜放置在YH-MIP 0103显微计数法不溶性微粒分析仪的镜头下,调整参数,进行测试。 注意事项:下所有工作均在洁净的工作台内进行操作。 结果讨论: 在测试过程中,由于乳剂粒子形状的可变性,样品经过滤膜之后,乳剂粒子会被滤出,而不溶性微粒则会被保留在滤膜上。与使用光阻法进行不溶性微粒检测相比,使用显微镜法可以很好的避免乳剂粒子被误判为不溶性微粒,从而保证了测试数据的准确性。从样品的测试结果可以看到样品里面有非常多的微小颗粒,虽然这些尺寸的颗粒及数量不在药典的注射剂的不溶性微粒标准的要求之内,但是这些微小颗粒的数据报告仍然可以为乳剂质量提供一些有效的实用判断标准。 测试仪器:YH-MIP 0103显微计数法不溶性微粒分析仪 技术优势 √ 全滤膜自动扫描,操作简单,节约时间; √ 全自动颗粒计数,保护眼睛,减少人为操作误差; √ 符合各国药典/ 国标法规,一键自动出具对应报告; √ 符合21CFR Part11 及GMP 对数据完整性的要求。 显微计数法作为乳剂注射剂不溶性微粒检测的首选方案,具有直观、准确的特点。在实际应用中,我们可以结合其他检测方法和技术手段,共同确保乳剂注射剂的安全性和有效性。

应用实例

2024.04.09

胤煌|微粒分析仪校准规范

在现代科技领域,微粒分析仪作为一种精密测量工具,广泛应用于医药、化工、环保等多个行业,对微小颗粒的检测与分析发挥着至关重要的作用。为了确保微粒分析仪的测量准确性,其校准工作显得尤为重要。下面,我们将详细介绍胤煌微粒分析仪的校准规范。 首先,校准工作应遵循科学、严谨、准确的原则。在进行校准前,应详细阅读微粒分析仪的使用说明书,了解仪器的结构、工作原理、操作方法及注意事项。同时,准备好所需的校准工具、试剂和标准样品,确保它们的质量可靠、性能稳定。 其次,校准过程中应严格控制环境条件。微粒分析仪对环境温度、湿度、气压等因素较为敏感,因此在校准时应确保实验室内的环境条件稳定,并符合仪器说明书的要求。此外,还应避免电磁干扰、震动等不利因素对校准结果的影响。 在具体校准步骤上,一般包括以下内容:一是零点校准,通过调整仪器参数使仪器在无颗粒状态下的输出为零;二是量程校准,使用不同浓度的标准样品对仪器进行校准,确保仪器在不同浓度范围内的测量准确性;三是重复性校准,通过多次测量同一标准样品,检验仪器的测量稳定性;四是精度校准,通过对比仪器的测量结果与标准值,评估仪器的测量精度。 完成校准后,应对校准结果进行记录和分析。记录内容包括校准时间、校准人员、环境条件、校准步骤及结果等。通过分析校准数据,可以了解仪器的性能状况,及时发现潜在问题,并采取相应措施进行改进。 需要强调的是,微粒分析仪的校准工作并非一劳永逸。随着仪器的使用和环境条件的变化,其性能可能会发生变化。因此,应定期对仪器进行校准,确保其始终处于良好的工作状态。 胤煌微粒分析仪的校准规范是一项严谨、细致的工作,对于确保仪器测量准确性具有重要意义。我们应严格按照规范进行操作,以保证微粒分析仪的可靠性和稳定性。

企业动态

2024.04.08

自动药物溶液颜色分析仪:科技助力药物品质检测

在药物生产过程中,对药物溶液颜色的精确分析是确保药品质量和安全性的重要环节。YH-COS-0101自动药物溶液颜色分析仪应运而生,它采用了先进的科技手段,为药物溶液颜色分析提供了高效、准确的解决方案。 这款分析仪严格遵循《中国药典》中《0901 溶液颜色检查法-第三法(色差计法)》的规定,确保了测量结果的合规性和可靠性。其核心是采用D65组合LED光源进行透射式测量,能够精确地捕捉药物溶液的颜色信息。 YH-COS-0101自动药物溶液颜色分析仪不仅具备传统的色度色差测量功能,更内置了《中国药典》标准比色液数据库。这一创新设计使得分析仪能够直接测量出待测溶液的色号,极大地简化了操作流程,提高了工作效率。 在技术规格方面,YH-COS-0101表现出色。它拥有宽广的测量波长范围(360-780nm),确保了测量结果的全面性和准确性。同时,采用0/0(垂直照射,垂直接收)的照明方式,完全符合2020版中国药典色度标准。观察者角度为2°/10°,提供了丰富的观察视角选择。 此外,该分析仪在测量速度和准确性方面也表现出色。测量间隔时间仅为1秒,测量时间更是达到了惊人的0.3秒,大大提高了检测效率。而台间差总色差∆*的RSD≤1.5%,重复性标准偏差在0.05%以内,确保了测量结果的稳定性和可靠性。 在显示功能方面,YH-COS-0101同样表现出色。它能够显示透射图/数据、样品色度值、色差值/图、中国药典标准比色液最接近色号等信息,让操作人员能够全面了解药物溶液的颜色特性。同时,还具备合格/不合格结果判断、颜色偏向分析等功能,为药物品质检测提供了全面的数据支持。 此外,YH-COS-0101还内置了数据库功能,不仅包含《中国药典》参考数据,还可选配EP或USP药典数据,甚至支持自建数据。这使得分析仪能够适应不同国家和地区的药典标准,满足不同用户的需求。 总的来说,YH-COS-0101自动药物溶液颜色分析仪是一款高效、准确、功能全面的药物品质检测工具。它的出现将为药物生产和品质控制带来变化,助力医药行业的持续发展和进步。

企业动态

2024.04.07

粉体干法图像粒度仪动态图像粒度粒形分析系统产品详情

粉体干法图像粒度仪动态图像粒度粒形分析系统是一款先进的分析设备,专门用于粗的、粒状材料的粒度粒形分析。在多个领域,如金刚砂、研磨材料、机制沙、河沙等的粒度粒形分析中,它都发挥着不可替代的作用。 该系统的核心在于其独特的测试过程。使用者只需将约20克的样品放入储料漏斗,随后通过电磁振动加料器和布料槽将颗粒均匀分散。当颗粒在布料槽的末端自由下落时,高速摄像机便会迅速捕捉这些颗粒的动态图像。这些图像随后被传输到电脑中进行深入的分析,最终得出粒度与粒形数据。 具体来说,YH-DIPS-10型号的产品采用了先进的自重/负压进样方式(负压方式可选配),确保测试的准确性和稳定性。其量程超过2um,这意味着它能够测试非常微小的颗粒。而专业远心变倍镜头的应用,不仅兼容了多种类型粒子的测试,更杜绝了形貌畸变的可能,保证了测试的精准性。 此外,该系统还引入了FIPS超分辨算法及AI智能算法等多种算法,确保了数据的准确性。这些先进的算法不仅提高了分析的精度,还大大提高了分析的效率。同时,配置AI分类功能,使得系统能够溯源颗粒物来源,为用户提供了更全面的颗粒分析数据。 更为值得一提的是,YH-DIPS-10型号产品的检测范围宽广,覆盖了2μm至3mm的粒度范围,这使得它能够满足多种不同粒度颗粒的测试需求。同时,其结果输出包括粒度分布、多种颗粒形态学参数统计以及单颗粒形态学分析,为用户提供了丰富而全面的数据支持。 总之,粉体干法图像粒度仪动态图像粒度粒形分析系统是一款功能强大、性能稳定的粒度粒形分析设备。它凭借先进的技术和精确的测试结果,为科研、生产等领域提供了强大的技术支持,是粒度粒形分析领域的理想选择。 以上就是苏州胤煌精密仪器整理分享的关于粉体干法图像粒度仪动态图像粒度粒形分析系统产品详情。想了解更多相关资讯,欢迎持续关注。

企业动态

2024.04.03

图像法粒度仪-微流成像颗粒分析系统产品详情

图像法粒度仪——微流成像颗粒分析系统是一种基于图像法原理的先进颗粒分析设备。该系统通过高速相机实时采集流动中的颗粒图像,并运用先进的算法进行颗粒分析,为各行各业提供了高效、准确的颗粒检测解决方案。 在实际应用中,颗粒的形貌对产品的性能具有重要影响。因此,FIPS 10流式动态图像法粒度仪不仅能够检测粒度分布,还能够获取颗粒的形貌信息,为产品质量的提升提供了有力支持。 该粒度仪具有多项技术优势。首先,它拥有宽广的检测范围,能够覆盖从0.2微米到3毫米的颗粒,满足了不同行业对颗粒检测的需求。其次,它采用了专业远心变倍镜头,兼容不同类型粒子的测试,避免了形貌畸变的发生。此外,FIPS超分辨算法及AI智能算法的运用,确保了测试数据的准确性。 FIPS 10流式动态图像法粒度仪还具有出色的数据输出能力。它能够同时给出粒子的形貌、尺寸分布等信息,为用户提供了最真实、最全面的统计结果。此外,该粒度仪还符合21 CFR part 11及GMP对数据完整性的要求,为用户的颗粒检测工作提供了有力保障。 在技术参数方面,FIPS 10流式动态图像法粒度仪表现出色。其检测范围广泛,进样体积小,流速可调,镜头类型多样,放大倍率可调,光源稳定可靠。此外,该粒度仪还具备电动调焦距功能,能够轻松应对不同样品的测试需求。 总的来说,FIPS 10流式动态图像法粒度仪——微流成像颗粒分析系统是一款功能强大、性能卓越的颗粒分析设备。它不仅能够满足各行业对颗粒检测的高要求,还能够为用户提供全面、准确的颗粒形貌和尺寸信息,为产品质量的提升提供了有力支持。 以上就是苏州胤煌精密仪器整理分享的关于图像法粒度仪-微流成像颗粒分析系统产品详情。想了解更多相关资讯,欢迎持续关注。

企业动态

2024.04.02

全自动显微计数法不溶性微粒分析仪再创新点

全自动显微计数法不溶性微粒分析仪作为一种高精尖的分析仪器,其技术创新一直引领着行业的发展。近期,新一代的YH-MIP-0205 Pro型全自动显微计数法不溶性微粒分析仪以其卓越的性能和创新的技术特点,再次成为行业瞩目的焦点。 传统的不溶性微粒分析方法通常存在操作复杂、结果易受人为因素影响等问题,而YH-MIP-0205 Pro型全自动显微计数法不溶性微粒分析仪则通过一系列创新技术,解决了这些难题。该仪器实现了从样品过滤、干燥、上样到自动扫描、计数、出具报告的全程自动化,极大地提高了分析效率和准确性。 更值得一提的是,该仪器在原有超分辨算法的基础上,加入了AI智能算法。这一创新不仅提升了微粒识别的精度,还能对不溶性微粒的来源进行分类和整理,为科研人员提供了更多有价值的信息。同时,通过AI技术的引入,仪器在数据处理和报告生成方面也更加智能化,使得整个分析过程更加便捷高效。 此外,YH-MIP-0205 Pro型全自动显微计数法不溶性微粒分析仪还符合中国药典、美国药典、欧洲药典及日本药典等各国药典的不溶性微粒检查要求,确保了其在药品、医疗器械等领域的广泛应用。同时,该仪器也符合21CFR Part11及GMP对数据完整性的要求,为药品生产和质量控制提供了有力的技术支持。 总之,YH-MIP-0205 Pro型全自动显微计数法不溶性微粒分析仪以其全新的技术特点和卓越的性能,再次展现了其在不溶性微粒分析领域的领先地位。随着科技的不断发展,相信这种全自动化的分析仪器将会在未来的科研和工业生产中发挥更加重要的作用。 以上就是苏州胤煌精密仪器整理分享的关于全自动显微计数法不溶性微粒分析仪再创新点。想了解更多相关资讯,欢迎持续关注。

企业动态

2024.04.01

半固体制剂晶型分析仪应用行业

半固体制剂晶型分析仪,作为一种先进的科学仪器,在多个行业领域中发挥着不可或缺的作用。它专门用于观察和分析半固体制剂的晶型特性,为产品研发、质量控制和科学研究提供了重要的数据支持。下面,我们将详细科普半固体制剂晶型分析仪在各个领域的应用。 首先,在医药行业中,半固体制剂晶型分析仪的应用尤为广泛。无论是原料药、半固体软膏还是液体制剂,其晶型特性对于药物的疗效和稳定性都至关重要。分析仪能够精确测量这些制剂的粒度大小、形状特征等参数,帮助科研人员了解药物的晶型状态,进而优化生产工艺,提高药品质量。 其次,在食品行业中,半固体制剂晶型分析仪同样发挥着重要作用。食品中的添加剂、调味剂以及某些半固体成分,其晶型特性对于食品的口感、保质期等方面具有重要影响。分析仪能够对这些成分进行精确分析,帮助食品企业控制产品质量,提升食品安全性。 此外,在化工行业中,半固体制剂晶型分析仪也扮演着重要角色。化工产品的晶型特性直接关系到其物理性质、化学稳定性和使用效果。通过分析仪的精确测量,科研人员可以了解化工产品的晶型结构,为产品研发和工艺改进提供有力支持。 不仅如此,半固体制剂晶型分析仪在科研领域也具有重要价值。它能够为科研人员提供大量的实验数据,帮助他们深入了解物质的晶型特性与性能之间的关系,推动相关领域的科学研究进展。 总之,半固体制剂晶型分析仪在医药、食品、化工和科研等多个行业中都发挥着重要作用。它的应用不仅提高了产品质量和安全性,也为科研人员的研发工作提供了有力支持。随着科技的不断发展,半固体制剂晶型分析仪的应用领域还将进一步拓展,为更多行业的发展贡献力量。 以上就是苏州胤煌精密仪器整理分享的关于半固体制剂晶型分析仪应用行业。想了解更多相关资讯,欢迎持续关注。

企业动态

2024.03.29

四川CHDF纳米粒度仪测试范围

四川CHDF纳米粒度仪是一种先进的粒度测量设备,其测试范围广泛,涵盖了从纳米到微米级别的粒子。在纳米材料、生物医药、食品化工等众多领域中,它都发挥着至关重要的作用。 首先,我们来了解一下纳米粒度仪的工作原理。四川CHDF纳米粒度仪主要基于光散原理,通过测量光在粒子中的散射情况来推算出粒子的粒度分布。这种测量方式具有非接触、高灵敏度和高分辨率等特点,能够准确地反映出样品中粒子的真实情况。 四川CHDF纳米粒度仪的测试范围非常广泛,涵盖了从5纳米到3微米的粒子。这一范围涵盖了众多领域中的关键粒度尺寸,如纳米材料、生物医药、食品化工等。无论是研究纳米颗粒的性质,还是监控生产过程中的粒度变化,CHDF纳米粒度仪都能提供准确的数据支持。 在测试过程中,四川CHDF纳米粒度仪展现出了出色的测试精度和分辨率。它的高分辨率能力可以确保测量结果的准确性和可靠性,帮助用户更好地理解和控制样品的粒度特性。同时,该仪器还具备高粒子检测灵敏度,即使对于浓度较低的样品,也能进行有效的测量。 此外,四川CHDF纳米粒度仪还具备广泛的动态范围检测能力。在主要粒子群中,该仪器能够对次要粒子群进行大动态范围检测,从而捕捉到更多关于样品粒度分布的信息。这一特点使得CHDF纳米粒度仪在复杂样品的分析中表现出色,能够提供更加全面和准确的粒度数据。 此外,四川CHDF纳米粒度仪的操作也非常简便,通过人性化界面即可完成全部操作。同时,其自动化采样器能够实现自动分析,大大提高了工作效率。 总之,四川CHDF纳米粒度仪以其广泛的测试范围、出色的测试精度和分辨率以及简便的操作方式,为众多领域的研究和应用提供了强有力的支持。在未来,随着纳米技术的不断发展,CHDF纳米粒度仪将继续发挥其在粒度测量领域的重要作用。 以上就是苏州胤煌精密仪器整理分享的四川CHDF纳米粒度仪测试范围 ,想了解更多相关资讯,欢迎持续关注。

企业动态

2024.03.28

色差计法溶液颜色测定仪:使用指南与科普解读

色差计法溶液颜色测定仪是一种用于精确测定溶液颜色的科学仪器。它基于色差计法原理,能够准确、定量地测定溶液的颜色和色差,为科研、生产和质量控制等领域提供了重要的技术支持。 在使用色差计法溶液颜色测定仪时,首先需要确保仪器处于良好的工作状态。这包括检查仪器的电源、显示屏、测量头等部件是否正常,以及清洁测量仪器的光学部件,确保无灰尘或杂质存在。同时,还应准备待测的溶液样品,确保样品无污渍、无气泡,并与标准样品的形状和颜色一致。 接下来,按照以下步骤进行溶液颜色的测定: 样品准备:将待测溶液倒入干净的容器中,容器的形状和颜色应与标准样品一致,以避免对测量结果产生影响。 仪器设置:打开仪器电源,根据测量需求选择相应的测量模式和参数。例如,选择透射测量模式,并输入相应的目标值(如水的L※、a※、b※值)。 校零与校白:进行仪器的校零和校白操作,确保测量结果的准确性。 样品测量:将容器放到测量仪器的测量台上,确保容器平稳并与仪器接触良好。在操作面板上选择“测量”功能,仪器将自动探测并测量样品的颜色数值。等待仪器测量完成后,可以在显示屏上查看色差数值。 结果分析:根据色差数值,判断样品与标准样品之间的颜色差异程度。可以根据需要绘制标准曲线,进一步分析溶液颜色的变化趋势和规律。 此外,为了保证测量结果的准确性和可靠性,还需要注意以下事项:定期清洁仪器,确保测量部件的清洁和完好;对仪器进行定期维护和校准,以保证其长期稳定运行;同时,操作人员应具备一定的专业知识和操作经验,能够正确、熟练地使用色差计法溶液颜色测定仪。 通过以上科普解读和使用指南,相信大家对色差计法溶液颜色测定仪有了更深入的了解。这种科学仪器在科研、生产和质量控制等领域发挥着重要作用,为我们提供了准确、可靠的颜色测定手段。

企业动态

2024.03.26

微流成像图像法粒度仪在注射剂中的应用

随着现代医疗技术的飞速发展,注射剂作为一种重要的药物剂型,其质量和安全性受到了广泛关注。在注射剂的生产和使用过程中,颗粒的粒度及形貌是影响其疗效和安全性的关键因素之一。近年来,微流成像图像法粒度仪作为一种先进的粒度分析技术,在注射剂领域的应用日益广泛。 微流成像图像法粒度仪采用动态流式成像原理,通过捕捉流经微流通道的样品颗粒的实时图像,进而分析颗粒的大小、形貌等特征。这一技术的优势在于其直观性和可视化,使得复杂液体制剂、混悬液、微球等颗粒分析变得更为简单、准确。 在注射剂中,微流成像图像法粒度仪的应用主要体现在颗粒的粒度及形貌检测上。通过对注射剂中颗粒的精确测量,可以评估其均一性、分散性以及稳定性,从而确保注射剂的质量符合标准。此外,该技术还能有效检测注射剂中的异物和杂质,进一步保障患者的用药安全。 值得一提的是,微流成像图像法粒度仪在分析球形和短丝状体颗粒时具有独特优势。由于这些颗粒在体内更容易被细胞吸收,因此,对它们的粒度及形貌进行精确测量,有助于优化注射剂的配方和制备工艺,提高药物的生物利用度。 此外,微流成像图像法粒度仪还能为注射剂的临床应用提供有力支持。通过对不同批次、不同生产工艺的注射剂进行粒度及形貌分析,可以评估其批次间的差异和稳定性,为临床用药提供科学依据。 微流成像图像法粒度仪在注射剂领域的应用具有广阔的前景和重要的实际意义。随着技术的不断进步和完善,相信这一技术将为注射剂的质量控制和安全性评估提供更加可靠、高效的手段。

企业动态

2024.03.25

美国MAS毛细管高分辨纳米粒度仪产品优势科普

在现代科研与工业领域,纳米颗粒的粒度测量变得日益重要。美国MAS毛细管高分辨纳米粒度仪凭借其卓越的性能和独特的技术优势,成为这一领域的佼佼者。 首先,MAS毛细管高分辨纳米粒度仪采用先进的毛细管流体动力分馏技术(CHDF)。这一技术能够实现对纳米颗粒的精确分离和测量,提供高分辨率的粒度数据。无论是对于均匀还是非均匀样品,MAS粒度仪都能提供准确、可靠的测量结果,为科研人员提供了强有力的数据支持。 其次,该仪器具有宽广的粒径检测范围,从几纳米到数百微米不等。这意味着MAS粒度仪能够适用于多种不同类型的纳米材料测量,满足不同领域的研究需求。无论是化妆品、医药、还是环保领域,MAS粒度仪都能发挥其独特的优势。 此外,MAS粒度仪还具有出色的操作简便性和稳定性。仪器界面友好,用户只需按照提示进行操作即可完成测量。同时,设备还具备自动校准和温度控制功能,确保了测量结果的准确性和可靠性。这种高度的自动化和智能化设计,大大减轻了用户的工作负担,提高了工作效率。 值得一提的是,MAS粒度仪还具备多种附加功能,如Zeta电位测量、电导率检测等。这些功能使得该仪器能够更全面地了解纳米颗粒的性质和行为,为科研工作者提供更为丰富的研究手段。 美国MAS毛细管高分辨纳米粒度仪凭借其先进的技术、宽广的检测范围、操作简便性和稳定性以及丰富的附加功能,成为了纳米粒度测量领域的领先产品。它将为科研工作者提供更为准确、可靠的数据支持,推动纳米科技的快速发展。

企业动态

2024.03.21

CHDF4000纳米粒度仪测试范围科普

CHDF4000纳米粒度仪是一款基于光散原理的高分辨率仪器,其测试范围广泛且精准,对于纳米级别粒度的测量尤为出色。该仪器使用最新的技术,可以对粒子的大小、形状以及分布进行精确的测量,从而为用户提供全面的粒度分析数据。 首先,CHDF4000纳米粒度仪的测试范围覆盖了从5纳米到3微米的粒子。这一范围涵盖了众多领域中的关键粒度尺寸,如纳米材料、生物医药、食品化工等。无论是研究纳米颗粒的性质,还是监控生产过程中的粒度变化,CHDF4000都能提供准确的数据支持。 其次,CHDF4000纳米粒度仪具有出色的测试精度和分辨率。其高分辨率能力可以确保测量结果的准确性和可靠性,从而帮助用户更好地理解和控制样品的粒度特性。同时,该仪器还具备高粒子检测灵敏度,即使对于浓度较低的样品,也能进行有效的测量。 此外,CHDF4000纳米粒度仪还具备广泛的动态范围检测能力。在主要粒子群中,该仪器能够对次要粒子群进行大动态范围检测,从而捕捉到更多关于样品粒度分布的信息。这一特点使得CHDF4000在复杂样品的分析中表现出色,能够提供更加全面和准确的粒度数据。 值得一提的是,CHDF4000纳米粒度仪的操作简便且自动化程度高。用户只需将样品放入仪器中,即可自动进行粒度分析,无需复杂的设置和操作。这一特点不仅降低了用户的操作难度,还提高了测量效率和数据可靠性。 总之,CHDF4000纳米粒度仪以其广泛的测试范围、出色的测试精度和分辨率、广泛的动态范围检测能力以及简便的操作方式,成为了纳米粒度测量领域的佼佼者。无论是科研实验还是工业生产,该仪器都能为用户提供准确、可靠的粒度分析数据,助力科研和生产的进步。

企业动态

2024.03.20

分馏法原液高分辨纳米粒度仪优势及技术参数

分馏法原液高分辨纳米粒度仪是一种基于毛细管流体分离(CHDF)技术的先进粒度分析设备,其在纳米科技、材料科学、生物医药等领域具有广泛的应用。胤煌将详细介绍该设备的优势及技术参数,帮助读者更好地了解和使用这一设备。 一、分馏法原液高分辨纳米粒度仪优势 高分辨率测量:该设备采用毛细管流体分离技术,能够精确测量粒径在5nm至3μm范围内的胶体粒子,分辨率高,测量准确。 真实PSD数据:通过粒子分离技术,设备能够提供真实、完整的PSD数据,无需对粒子大小分布的形状进行假设,从而更准确地反映样品的粒度特性。 高灵敏度探测:设备使用新的光散原理技术,具有高灵敏度探测能力,能够检测出微量的粒子,确保测量结果的可靠性。 自动化操作:设备操作简便,通过个性化界面即可完成全部操作,大大减轻了实验人员的工作负担。 广泛的应用领域:该设备可用于质量控制、研发以及在线控制等多个方面,适用于多种行业的需求。 二、分馏法原液高分辨纳米粒度仪技术参数 样品瓶数量与尺寸:设备配备72个样品瓶,每个样品瓶尺寸为12mm,容量为2ml,满足大量样品的测量需求。 注射次数与数据保存:每个样品可以重复运行至少15次,确保测量结果的稳定性和可靠性。数据可以自动保存和打印,方便后续分析和处理。 自动样品混合与针冲洗:设备具有自动样品混合功能,有效防止粒子沉降;同时配备针冲洗瓶,保持针外表面清洁,提高测量精度。 注射器体积与精度:设备采用250μL注射器,确保样品的精确取样。测量精度小于±0.5% RSD,满足高精度测量的要求。 材质与耐用性:设备采用防潮材质如聚四氟乙烯和316不锈钢,确保设备的稳定性和耐用性。 尺寸与重量:设备尺寸为24cm(宽)×59cm(深)×52cm(高),净重为42kg,方便实验室摆放和移动。 分馏法原液高分辨纳米粒度仪具有诸多优势和技术参数上的特点,能够满足不同领域对纳米粒度测量的需求。通过使用该设备,用户可以准确、快速地获取样品的粒度分布信息,为科研和生产提供有力支持。

企业动态

2024.03.19

澄清度检查分析仪特点及技术参数科普

澄清度检查分析仪又名澄清度测定仪,是一种广泛应用于水质监测领域的仪器,其采用先进的光学散射原理,可以快速、准确地测定液体的澄清度。该仪器不仅具备高精度、高稳定性的测量性能,还具备智能化、自动化的操作特点,为水质监测工作提供了极大的便利。 在技术参数方面,澄清度检查分析仪展现了出色的性能。其测定原理基于90°散射光,这种散射光方式可以确保测量结果的准确性和可靠性。同时,仪器采用LED光源,波长为860nm,保证了光源的稳定性和长寿命。 测量范围是仪器的一个重要指标,澄清度检查分析仪具有自动可变量程的特点,可以根据不同样品的澄清度自动选择合适的测量范围,包括0~10 NTU、10~100 NTU、100~1000 NTU三个量程。此外,仪器的分辨率也非常高,可以根据不同的测量范围自动调整,确保测量结果的精确性。 在性能方面,澄清度检查分析仪的示值误差仅为±2%F.S,重复性≤0.5%,零点漂移±0.5%F.S,这些指标均优于同类产品,显示出其卓越的测量稳定性。 仪器校准是确保测量结果准确性的重要环节,澄清度检查分析仪支持1~5点自动校准,可以方便地根据需要进行校准操作。同时,仪器还具备数据完整性保障措施,具有4级权限管理功能,可以确保数据的安全性和可靠性。 此外,澄清度检查分析仪还具备强大的数据存储和传输能力。其存储容量高达128G,可以无限制地存储测量数据。同时,仪器支持多种接口方式,包括USB、RS232、RS485、CAN等,方便与计算机或其他设备连接,实现数据的快速传输和共享。 在环境适应性方面,澄清度检查分析仪也表现出色。其可以在室温至65℃的广泛温度范围内正常工作,且电源功率为220V,50Hz,符合一般实验室和现场使用的电源要求。 澄清度检查分析仪以其高精度、高稳定性、智能化和自动化的特点,以及强大的数据存储和传输能力,成为了水质监测领域不可或缺的重要工具。

企业动态

2024.03.18

静态图像法粒度仪:设备技术优势一览

在粒度分析领域,静态图像法粒度仪作为一种先进的设备,为研究者提供了诸多便利。下面我们将详细探讨这种设备的几项主要技术优势。 1. 配合自动制样装置,操作简单,数据稳定 静态图像法粒度仪通常配备自动制样装置,能够快速、准确地制备样品。这种自动制样方式不仅简化了操作流程,还大大提高了数据的稳定性和可靠性。通过自动化技术,避免了人为操作可能带来的误差,确保了实验结果的准确性。 2. 手动选择区域,区域范围可选择,方便快捷 静态图像法粒度仪提供了手动选择区域的功能,使用户能够根据实际需求灵活地调整分析区域。这一设计使得用户能够快速定位到感兴趣的区域,进行有针对性的粒度分析。同时,区域范围的灵活性也增强了该设备的实用性,适用于各种不同类型的粒度分析任务。 3. 视野范围内颗粒自动计数,且可多视野叠加 静态图像法粒度仪具备自动计数的功能,能够快速准确地统计视野范围内的颗粒数量。这一功能极大地提高了分析效率,减少了人工计数带来的误差。此外,该设备还支持多视野叠加,通过将多个视野的图像进行叠加处理,进一步提高了分析的准确性。这种叠加技术能够有效地减小误差,提高数据的可靠性。 4. 节约分析时间,减少人为操作误差 静态图像法粒度仪通过自动化和智能化的设计,大大缩短了分析时间。这不仅提高了工作效率,还降低了长时间观察对实验人员造成的疲劳和误差的可能性。这种高效的分析方式为企业和研究机构节省了宝贵的时间和资源。 5. 丰富的数据展现形式、数据报告模板可选择 静态图像法粒度仪提供了多样化的数据展现形式,包括图表、曲线、表格等。这些形式直观地展示了粒度分布情况,使得用户能够更快速地理解和分析数据。此外,该设备还配备了多种数据报告模板可供选择,使用户能够根据需要生成专业、规范的数据报告。这种灵活的数据处理方式满足了不同领域的实际需求,为用户提供了便捷的数据分析和展示工具。 6. 兼容黑白/彩色模式、偏光模式,观察药物晶型 静态图像法粒度仪具有出色的兼容性,支持黑白、彩色和偏光模式下的观察和分析。这种多模式支持使得该设备在药物晶型观察等领域具有广泛的应用价值。通过不同的观察模式,用户能够更全面地了解药物晶型的特征和变化,为药物研发和质量控制提供有力支持。 7. 可选配固体分散/半固体分散制样装置 为了满足不同固体分散物和半固体分散物的制样需求,静态图像法粒度仪还提供了一系列可选配的制样装置。这些装置能够根据样品的特点进行定制化处理,确保制样过程的准确性和可靠性。这种灵活性使得该设备在固体分散物和半固体分散物的粒度分析中具有独特优势,为用户提供了全面的解决方案。

企业动态

2024.01.29

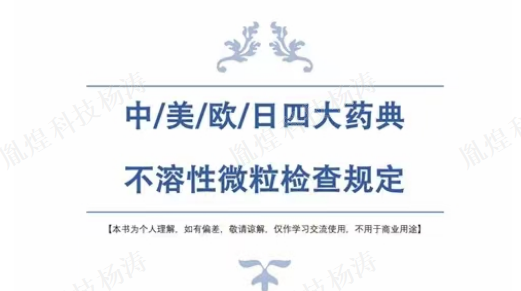

不溶性微粒检查 你需要这样一本书

不溶性微粒检查,是一个很大的应用场景,一般我们指的都是大医药行业里面质量检查的一个项目,特别是各种类型的注射液。对于不溶性微粒检查,我们首先想到的就是法规是如何规定的,测试方法是什么,如何测试,判定标准是什么等等。所以不溶性微粒检查,有这样一本书你值得拥有。中美欧日四大药典不溶性微粒检查法规的汇整版,外加中英文双语对照版,对您更好的理解法规,了解各国法规之间的区别起到一定的帮助。不溶性微粒检查药典法规分享的这本书里面,包含了中国药典2020版CP0903章节、美国药典USP787、USP788、USP789、USP1787、USP1788、欧洲药典EP2.9.19、日本药典JP6.07、JP6.08 全部章节的原本及中英文对照内容,欢迎大家联系我们领取和沟通。不溶性微粒检查药典法规分享相关书籍及目录如下:

应用实例

2023.08.25

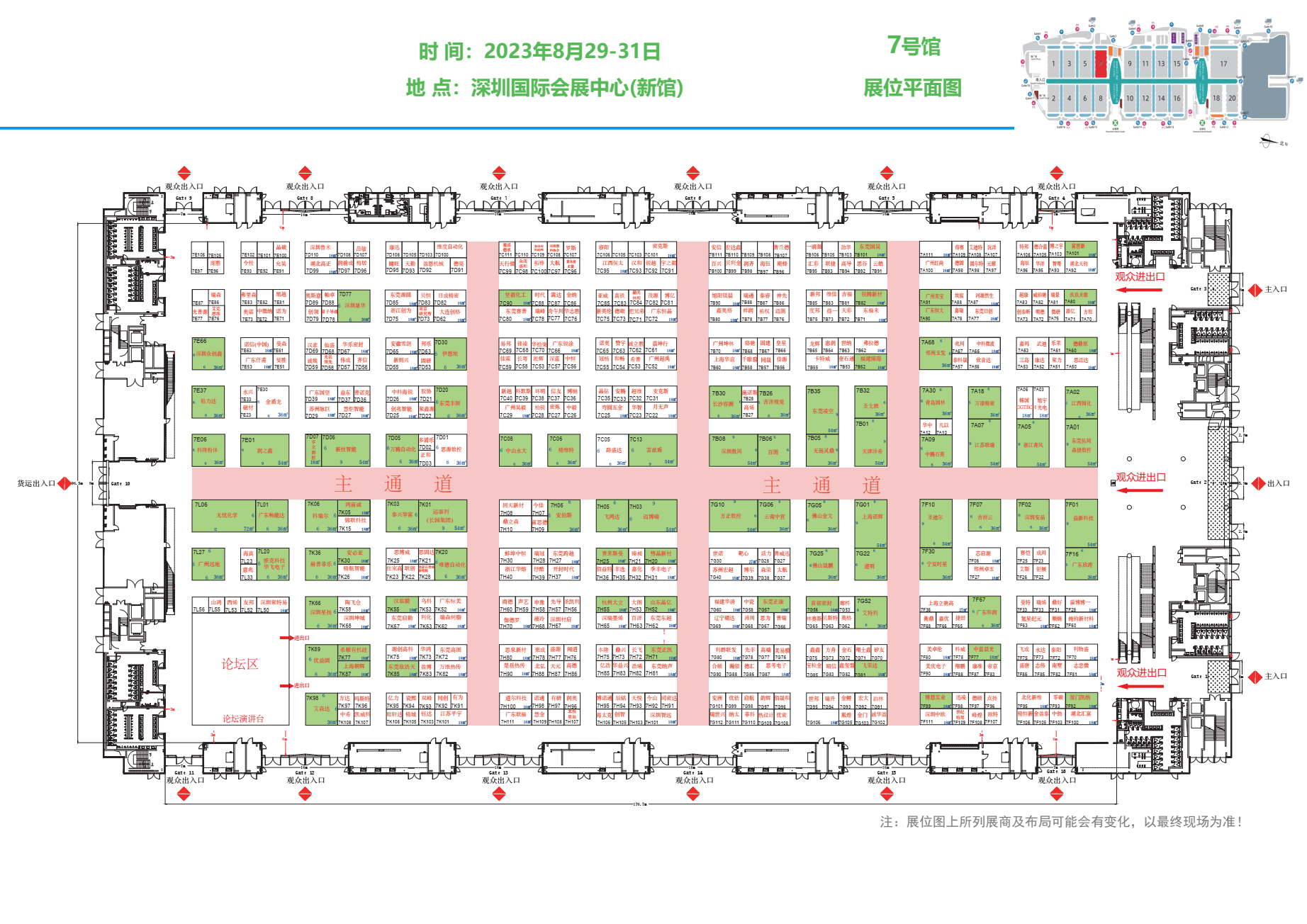

胤煌科技YinHuang Technology 诚邀您参加2023中国(深圳)国际半导体展览会

2023年中国(深圳)国际半导体展览会将于2023年8月29日-8月31日召开,胤煌科技YinHuang Technology作为受邀展商将亮相展会,欢迎各位朋友来我们展位莅临指导。展会相关信息如下:展会时间:2023年8月29日-31日地点:深圳国际会展中心(新馆)展位号:7G105胤煌科技(YinHuang Technology)是一家专注于为医药、半导体及化工材料等行业提供检测分析设备及技术服务的高科技公司,致力于为客户提供全面、准确的检测分析和解决方案。主营产品包括不溶性微粒分析仪,可见异物检查分析仪,原液粒度及Zeta电位分析仪,CHDF高精度纳米粒度仪,高分辨纳米粒度仪,溶液颜色测定仪,澄清度测定仪等,公司自主研发的YH-MIP系列显微计数法不溶性微粒仪、YH-FIPS系列流式动态图像法粒度仪,YH-FIPS系列微流成像颗粒分析仪已经在生物医药、半导体及材料化工领域得到广泛应用.

企业动态

2023.08.09

胤煌科技不溶性微粒-药典新规解读(专题三)将于2022年6月29日晚19:00与您线上相约

胤煌科技不溶性微粒-药典新规解读(专题三)将于2022年6月29日晚19:00与您线上相约大家期待已久的胤煌科技不溶性微粒-药典新规解读(专题三)来啦,此次会议将由胤煌科技创始人、时任总经理柳钟丽为大家做汇报交流。届时将跟大家分享我司为不同客户测样过程中发现的问题、总结的经验及技术的更新,欢迎一同沟通探讨!学无止境,希望大家广邀好友参与我司沟通交流会,邀请排行榜前10名在会后将获得我司寄出的京东购物卡作为奖励。2022年6月29日晚19:00,我们线上等您!

企业动态

2022.06.24

胤煌科技 5W带您浅析显微计数法不溶性微粒分析仪

胤煌科技 5W带您浅析显微计数法不溶性微粒分析仪一、WHAT:什么是显微计数法不溶性微粒分析仪?名词解析,“显微计数法”取自中国药典0903不溶性微粒检查法第二法,即显微计数法,是不溶性微粒检查的一种一直存在的方法,但由于其操作麻烦而不被人喜欢(但其结果准确),“不溶性微粒”是指药品在生产或使用过程中经由各种途径产生或混入的微粒性杂质,粒径在1~50 μm、肉眼不可见,但因其可随血液流动却不能被代谢而可能对人体造成难以发现和潜在的严重危害,“分析仪”即检查注射液中不溶性微粒的仪器。二、WHO:什么人需要用显微计数法不溶性微粒分析仪? 首先我们了解下哪些人更关心注射剂不溶性微粒的安全:药物研发企业的研发人员、质量控制人员、药物审批单位人员、药物监察单位人员等。对于注射剂中不溶性微粒的数量,药典中有硬性标准,微粒超标就会增加对人体造成伤害的可能,这在研发、报批、生产等环节是不被允许的,所以相关人员是显微计数法不溶性微粒分析仪的直接使用者。三、WHY:为何要用显微计数法不溶性微粒分析仪检查注射剂中的不溶性微粒? 中国药典2020版0903不溶性微粒检查法包括光阻法和显微计数法。当光阻法测定结果不符合规定或供试品不适于用光阻法测定时,应采用显微计数法进行测定,并以显微计数法的测定结果作为判定依据。光阻法的测定原理是通过微粒对光的阻挡被传感器进行接收而判定微粒的大小及数量,因此光阻法不适用于黏度过高和易析出结晶的制剂,也不适用于进入传感器时容易产生气泡的注射剂,此时就需要用显微计数法不溶性微粒分析仪进行不溶性微粒检查。 显微计数法不溶性微粒仪计数环节无需人眼观察,计算机直接按照药典规定出具检测分析报告;计数环节全部由计算机完成,测试结果重复性高,且可以自动进行数据比较;仪器全自动进行滤膜全扫描,并进行颗粒图片分析,让颗粒物无处遁行;可以区分颗粒形貌,判定该不溶性微粒是金属还是纤维或是其他,鉴别不溶性微粒的来源(是外源还是内生?),并在实验或生产过程中加以控制或避免。四、WHICH:哪些药物需要用显微计数法不溶性微粒分析仪检查?中国药典2020版0903不溶性微粒检查法具体要求:本法系用以检查静脉用注射剂(溶液型注射液、注射用无菌粉末、注射用浓溶液)及供静脉注射用无菌原料药中不溶性微粒的大小及数量。上文说明一个事实,那就是静脉用注射液如传统的打吊瓶、屁股针、打疫苗及特殊病症用药如胰岛素等注射液最终会进入静脉血管的,都需进行不溶性微粒检查。五、WHERE:显微计数法不溶性微粒分析仪被哪些单位所使用?当前显微计数法不溶性微粒分析仪在研发端头部眼药企业、脂质体企业及mrna企业所广泛欢迎,在放行端也进入了多个省份及省会城市的药品检验所。相信在未来会有越来越多关注注射剂不溶性微粒安全的企业会对我们的显微计数法不溶性微粒分析仪敞开怀抱。胤煌科技显微计数法不溶性微粒分析仪具体简介如下:1、显微计数法不溶性微粒仪(型号:YH-MIP-0103): 1、计数环节无需人眼观察,计算机直接按照药典规定出具检测分析报告;2、计数环节全部由计算机完成,测试结果重复性高,且可以自动进行数据比较;3、全自动进行滤膜全扫描,并进行颗粒图片分析,让颗粒物无处遁行;4、可以区分颗粒形貌,判定该不溶性微粒是金属还是纤维或是其他,鉴别不溶性微粒的来源(是外源还是内生?),并在实验或生产过程中加以控制或避免。2、全自动显微计数法不溶性微粒仪(型号YH-MIP-0205 Pro): 在上一代仪器已有的技术优势下,进行了全新升级,新的产品在原有分步式自动扫描、自动测试、自动计数的基础上,将自动过滤、自动干燥、自动上样等功能进行了集成,真正意义上做到了如光阻法检测一样的简单且可无人值守,同时在原有超分辨算法的基础上,加入AI智能算法,方便客户更好的对不溶性微粒的来源进行判断,以便对不溶性微粒的来源进行判断和避免。

应用实例

2022.06.11

胤煌科技 显微计数法不溶性微粒仪 ——观察注射剂中不溶性微粒世界的“眼睛”

注射剂(injection)系指药物制成的供注入体内的无菌溶液(包括乳浊液和混悬液)以及供临用前配成溶液或混悬液的无菌粉末或浓溶液。 注射剂作用迅速可靠,不受pH、酶、食物等影响,无首过效应,可发挥全身或局部定位作用,适用于不宜口服药物和不能口服的病人,但注射剂研制和生产过程复杂,安全性及机体适应性差,成本较高,而在研发生产过程中其中的不溶性微粒超标对人体健康是个很大危害。 注射剂中的不溶性微粒是指药品在生产或使用过程中经由各种途径产生或混入的微粒性杂质,粒径在1~50 μm、肉眼不可见,但因其可随血液流动却不能被代谢而可能对人体造成难以发现和潜在的严重危害。20世纪30年代起研究人员开始认识到不溶性微粒的危害,并于60、70年代间对此开展了大量的实验及临床研究,随后不溶性微粒控制被纳入注射剂质量标准,且其检测方法得到不断改进。现在,有关注射剂中不溶性微粒可能对人体造成危害的观念已为临床广泛接受,过敏反应、静脉炎、血管栓塞、微循环堵塞、动脉硬化、热原反应、肉芽肿、肺栓塞等多种与不溶性微粒有关的不良反应都会引起医护人员的重视。不溶性微粒的伤害 《中国药典2020版》对注射剂中不溶性微粒的控制要求仅限于粒径≥10和25 μm的微粒数,对粒径<10μm的却没有具体要求,实际上,人体最小的毛细血管内径仅有4~7 μm,婴、幼儿的毛细血管更细,只有粒径在2 μm以下的微粒才可能通过肾交换被排出体外,而粒径为2~10 μm的微粒无法被排出。微粒进入体内造成危害的部位一般多在肺、脑、肾、眼等处,较大的微粒会直接造成局部循环障碍、引起血管栓塞或导致肉芽肿,且有短期内可见的特点,而粒径为2~10 μm的微粒则可能造成潜伏性的更大危害。颗粒的千奇百态下面我将为大家呈现显微计数法不溶性微粒仪下注射剂中微粒的聚集现象:颗粒的聚集过程聚集的颗粒无法洗去 由图可见,注射用乳剂随着时间的流逝其中不溶性微粒已经发生了聚集现象,2-10μm的粒子已经长大到10μm以上,甚至25μm以上,足以堵塞人体的静脉血管。显微镜下的颗粒形貌 如上图,是某在研注射液在显微计数法不溶性微粒仪下的真实照片,可见其中有金属颗粒和橡胶颗粒,颗粒粒径<50μm,为肉眼不可见。所以我们认为的澄清注射液中却大有乾坤。这些不溶性微粒经过注射器就会进入我们的血管,然后通过血液流动而流经全身,且无法被人体溶解和肾脏排出,从而造成血管壁的聚集和堵塞,造成血栓,是药三分段,用错药错用药很容易治病不成而造成二次伤害。 针对药物研发生产过程中的不溶性微粒检查,胤煌科技显微计数法不溶性微粒仪系列产品已经有两种提供给客户,具体如下:一、显微计数法不溶性微粒仪(型号:YH-MIP-0103):1、计数环节无需人眼观察,计算机直接按照药典规定出具检测分析报告;2、计数环节全部由计算机完成,测试结果重复性高,且可以自动进行数据比较;3、全自动进行滤膜全扫描,并进行颗粒图片分析,让颗粒物无处遁行;4、可以区分颗粒形貌,判定该不溶性微粒是金属还是纤维或是其他,鉴别不溶性微粒的来源(是外源还是内生?),并在实验或生产过程中加以控制或避免。二、全自动显微计数法不溶性微粒仪(型号YH-MIP-0205 Pro):在上一代仪器已有的技术优势下,进行了全新升级,新的产品在原有分步式自动扫描、自动测试、自动计数的基础上,将自动过滤、自动干燥、自动上样等功能进行了集成,真正意义上做到了如光阻法检测一样的简单且可无人值守,同时在原有超分辨算法的基础上,加入AI智能算法,方便客户更好的对不溶性微粒的来源进行判断,以便对不溶性微粒的来源进行判断和避免。

应用实例

2022.05.18

显微计数法不溶性微粒仪带您走进注射剂中的微小世界

显微计数法不溶性微粒仪带您走进注射剂中的微小世界 注射剂中的不溶性微粒是指药品在生产或使用过程中经由各种途径产生或混入的微粒性杂质,粒径在1~50 μm、肉眼不可见,但因其可随血液流动却不能被代谢而可能对人体造成难以发现和潜在的严重危害。20世纪30年代起研究人员开始认识到不溶性微粒的危害,并于60、70年代间对此开展了大量的实验及临床研究,随后不溶性微粒控制被纳入注射剂质量标准,且其检测方法得到不断改进。现在,有关注射剂中不溶性微粒可能对人体造成危害的观念已为临床广泛接受,过敏反应、静脉炎、血管栓塞、微循环堵塞、动脉硬化、热原反应、肉芽肿、肺栓塞等多种与不溶性微粒有关的不良反应都会引起医护人员的重视。 《中国药典》对注射剂中不溶性微粒的控制仅限于粒径≥10和25 μm的微粒数,对粒径<10μm的却没有具体要求,实际上,人体最小的毛细血管内径仅有4~7 μm,婴、幼儿的毛细血管更细,只有粒径在2 μm以下的微粒才可能通过肾交换被排出体外,而粒径为2~10 μm的微粒无法被排出。微粒进入体内造成危害的部位一般多在肺、脑、肾、眼等处,较大的微粒会直接造成局部循环障碍、引起血管栓塞或导致肉芽肿,且有短期内可见的特点,而粒径为2~10 μm的微粒则可能造成潜伏性的更大危害。 已有多项研究表明,粒径>10 μm的微粒只占注射剂中微粒的极小部分。 我选取了两组用显微计数法不溶性微粒仪(YH-MIP-0103)测试某企业生产的两批注射蛋白药中不溶性微粒按粒径的数量分布报告如下: 由上图计算可知,粒径<10μm的颗粒数分别占比88.69%和96.95%,而此类颗粒在进行配伍或复溶过程极有可能产生>10μm的颗粒物;并且2-10μm不溶性微粒本身就可以对人体毛细血管造成巨大伤害。 显微计数法不溶性微粒仪(YH-MIP-0103/YH-MIP-0205PRO)是由胤煌科技自主研发生产的符合药典标准的不溶性微粒检查设备,外观及特点如下:技术优势:√全自动的测试系统,自动扫描、计数、出具报告,减少人为操作的误差;√全自动检测系统,减少在使用过程中对测试人员眼睛的伤害;√可以区分颗粒性质,鉴别不溶性微粒的来源,是金属还是纤维;√符合中国药典、美国药典、欧洲药典、日本药典等各国药典对于不溶性微粒检查的要求。 全新一代YH-MIP-0205 Pro型全自动显微计数法不溶性微粒分析仪在上一代仪器已有的技术优势下,进行了全新升级,新产品在原有分步式自动扫描、自动测试、自动计数的基础上,进行了自动过滤、自动干燥、自动上样等功能的集成,真正做到了无人值守即可做到原有显微计数法的复杂操作流程;同时在原有超分辨算法的基础上,加入AI智能算法,方便客户更好的对不溶性的来源进行分类和整理,在今后的实验生产过程中加以避免。如下图,为该试剂在显微计数法不溶性微粒仪下的粒子分布图的一角: 见微知著,对于我们肉眼难见的注射剂不溶性微粒,却可以对我们人类的毛细血管造成灾难性的破坏。今年以来,药监局多次发文重视用药安全和安全用药,特别是大量被使用的疫苗安全更是多次被提及,相信随着人民生活水平及人们认知的不断提高,对于药物不溶性微粒的关注会越来越多,而相应管控也会越来越严。这就要求药企在研发和生产过程中更要了解每支、每批次样品中不溶性微粒的可能来源及大小数量,并加以控制和改进。

应用实例

2022.05.16

【新品发布】流式动态图像法粒度仪YH-FIPS-10隆重登场!

【新品发布】流式动态图像法粒度仪YH-FIPS-10隆重登场! 随着科技不断进步,产品质量快速提升,各行各业对颗粒检测的要求也越来越高。而在实际生产过程中,往往颗粒呈现出不规则形状。颗粒的形貌会影响到产品的稳定性,溶解性,流动性等。因此,颗粒分析不仅仅要做粒度分布的检测,还需要得到颗粒的形貌这一关键信息。 FIPS 10流式动态图像法粒度仪,是采用高速相机实时采集图片,再进行颗粒分析的一种粒度仪。样品在流动过程中实时拍摄,具有足够多的颗粒图片被采集到,使得测试结果具有代表性和统计学意义。技术优势√ 宽广的检测范围(0.3 μm-3 mm)、检测浓度可高达1*107个/mL;√ 专业远心变倍镜头,兼容不同类型粒子测试,杜绝形貌畸变;√ FIPS专利的超分辨算法及AI智能算法相结合,确保数据准确性;√ 数据同时给出粒子形貌、尺寸分布等信息,以达到最“真”统计;√ 符合21 CFR part 11及GMP对数据完整性的要求;测试结果·颗粒的直观形貌&不同尺寸粒子的粒径分布 应用领域YH-FIPS-10流式动态图像法粒度仪不仅可以得到样品中的粒子浓度、不同尺寸粒子的比例分布等详细的PSD信息,实现亚微米到微米级颗粒的计数功能,还可以得到样品的实际颗粒形貌信息,以达样品颗粒的最真实统计。可广泛应用在生物医药、半导体、材料化工、食品卫生等多个领域。企业简介胤煌科技是一家专注于为医药、半导体、面板及材料行业提供粒度及Zeta电位分析设备及技术服务的高科技公司,公司拥有检测平台可以为客户提供专业的第三方检测服务。目前公司自主研发的产品有光阻法不溶性微粒分析仪、显微计数法不溶性微粒分析仪、流式动态图像法粒度粒形分析仪等;还有代理产品伞棚灯、粒度及Zeta电位分析仪、高分辨率纳米粒度仪、原液纳米粒度及Zeta电位分析仪等检测分析设备,可以为mRNA/核酸疫苗、脂质体、乳剂、蛋白注射液等相关领域提供专业的检测分析设备。胤煌科技期待与您合作!

新品

2022.05.11

为什么一定要用显微计数法不溶性微粒仪进行注射剂不溶性微粒检查?

为什么一定要用显微计数法不溶性微粒仪进行注射剂不溶性微粒检查?一、我们先来了解什么是注射剂中的不溶性微粒及其对人体的危害:注射剂中的不溶性微粒是指药品在生产或使用过程中经由各种途径产生或混入的微粒性杂质,粒径在1~50 μm、肉眼不可见,但因其可随血液流动却不能被代谢而可能对人体造成难以发现和潜在的严重危害。具体表现为:过敏反应、静脉炎、血管栓塞、微循环堵塞、动脉硬化、热原反应、肉芽肿、肺栓塞等多种与不溶性微粒有关的不良反应。二、注射剂中的不溶性微粒的具体来源有哪些:注射剂中的不溶性微粒来源于其生产和使用过程,而目前在药品生产和使用的管理方面对此两环节均有相应的规范和制度来保证药品的安全。例如,生产过程中的GMP、《中国药典》对注射剂的检测标准、国家标准化管理委员会关于一次性输液器的国家标准等都对控制不溶性微粒的危害起着重要作用。 三、中国药典关于注射剂中不溶性微粒检测的质量标准: 对注射剂中不溶性微粒的检测标准及方法,《中国药典》已从最初的仅通过目视法检查澄明度发展到目前使用两种方法检测并限定粒径≥10和25 μm的微粒数,且其2010年版中还增加了对供生产注射用的无菌原料药的微粒检查项目。换言之,随着人们对不溶性微粒造成的危害的认识不断深入,《中国药典》对注射剂中微粒的控制也越来越严格。 四、《中国药典》对注射剂中不溶性微粒检查的规定中有两点应予以注意: 1)《中国药典》对注射剂中微粒的控制仅限于粒径≥10和25 μm的微粒数,对粒径<10μm的却没有相应控制。实际上,人体最小的毛细血管内径仅有4~7 μm,婴、幼儿的毛细血管更细,只有粒径在2 μm以下的微粒才可能通过肾交换被排出体外,而粒径为2~10 μm的微粒无法被排出。微粒进入体内造成危害的部位一般多在肺、脑、肾、眼等处,较大的微粒会直接造成局部循环障碍、引起血管栓塞或导致肉芽肿,且有短期内可见的特点,而粒径为2~10 μm的微粒则可能造成潜伏性的更大危害。 2)《中国药典》仅对注射剂成品进行微粒控制,而未对注射剂使用过程中的复溶(复配)及稀释后的输液作出相似规定。绝大多数注射剂在使用时都需要复配或稀释,而复配在操作环境、操作方法和配伍输液等方面均与药典对注射剂中不溶性微粒的检测过程不同,是注射剂在使用过程中引入或形成不溶性微粒的关键环节。有关研究表明,在输液中添加药物、尤其是粉针剂和中草药制剂后会产生明显数量的微粒。 五、《中国药典》2020版对注射剂中不溶性微粒检查具体要求:0903不溶性微粒检查法包括光阻法和显微计数法。当光阻法测定结果不符合规定或供试品不适于用光阻法测定时,应采用显微计数法进行测定,并以显微计数法的测定结果作为判定依据。光阻法的测定原理是通过微粒对光的阻挡被传感器进行接收而判定微粒的大小及数量,因此光阻法不适用于黏度过高和易析出结晶的制剂,也不适用于进入传感器时容易产生气泡的注射剂。两种测定法判定结果仅仅关注于粒径≥10和25 μm的微粒数,对粒径<10μm的却没有相应控制,但实验过程却需进行小粒径个数相应的数量及形貌进行关注。六、为什么一定要用显微计数法不溶性微粒仪进行注射剂不溶性微粒检查:显微计数法不溶性微粒仪计数环节无需人眼观察,计算机直接按照药典规定出具检测分析报告;计数环节全部由计算机完成,测试结果重复性高,且可以自动进行数据比较;仪器全自动进行滤膜全扫描,并进行颗粒图片分析,让颗粒物无处遁行;可以区分颗粒形貌,判定该不溶性微粒是金属还是纤维或是其他,鉴别不溶性微粒的来源(是外源还是内生?),并在实验或生产过程中加以控制或避免。

应用实例

2022.05.09

胤煌科技实现显微镜法检测不溶性微粒仪器设备新突破!

胤煌科技实现显微镜法检测不溶性微粒仪器设备新突破!是否还在为使用传统显微镜法进行制剂中不溶性微粒检测感到苦恼?操作繁琐、人工计数、劳动强度大、主观因素影响大、检测结果不可追溯、验证重复性差…….一切的因素都使得采用显微镜法进行不溶性微粒检测变得困难重重。宝宝心里苦,能怎么办呢?胤煌科技致力于让颗粒检测分析更专业,隆重推出全新一代全自动显微计数法不溶性微粒分析仪! 仪器型号:YH-MIP-0205Pro工作原理:显微计数法/图像法检测范围:1 μm-500 μm 产品创新点介绍·可以完成自动过滤、干燥、测试、出具报告等多项流程;·超分辨算法、AI智能算法等多种图像处理方式的引入,能有效确保测试数据的准确性;·在完美弥补常规显微镜法不溶性微粒检测的缺陷的同时,能准确保留样品中每个粒子的原始形貌,对不溶性微粒的来源或者形成机制都具有警示作用;·符合中国药典、美国药典、欧洲药典及日本药典等各国药典不溶性微粒检查的仪器要求。技术参数仪器型号YH-MIP-0205 Pro测试范围1 μm-500 μm检测原理显微计数法/静态图像法数字摄像头600万彩色高清摄像机放大倍率50-1000倍最大分辨率0.01 μm物镜标配:5X、10X;选配:20X、50X、100X分辨率≥95%照明系统自动LED照明系统电动控制系统XYZ-三轴移动滤膜夹具25 mm/13 mm电源220 V软件运行环境Win 10及以上电脑配置要求CPUI7-11700F/运行内存32G或以上配置; 6G独立显卡,256SSD+2T硬盘; IPS 旋转升降 低蓝光高分辨显示屏;显微计数法不溶性微粒仪让颗粒无处遁形! 企业简介:上海胤煌科技有限公司是一家专注于为医药生物、半导体、面板及材料等行业提供粒度及Zeta电位分析设备及技术服务的高科技公司,公司拥有检测平台可以为客户提供专业的第三方检测服务。目前公司自主研发的产品有光阻法不溶性微粒分析仪、显微计数法不溶性微粒分析仪、流式动态图像法粒度粒形分析仪等;还代理有伞棚灯、粒度及Zeta电位分析仪、高分辨率纳米粒度仪、原液纳米粒度及Zeta电位分析仪等检测分析设备,可以为mRNA、核酸疫苗、药物递送等相关领域提供专业的检测分析设备。 上海胤煌科技有限公司期待与您合作!

新品

2022.05.05

中/美/欧/日四大药典溶液颜色检查规范 --参考与比较