恒温油浴在电缆设备温控系统中的应用

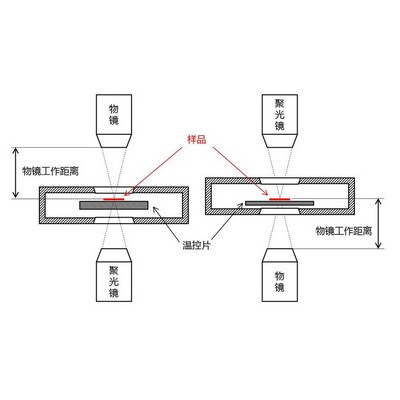

在电线电缆的制造过程中,设备温径系统的正确与否,直接关系到工艺参数的执行,进而影啊产品质量。因此,对于温控仪表的检定显得非常重要。在热工仪表的日常检定中,常用的检定仪器由直流电子电位差计、电阻箱、SR501测温仪表检定仪、rC900智能仪表校对仪,或HC系列万用现场校验仪等组成。检定方法是输入某一热电偶信号(毫伏值)或某一电阻值(热电阻),与标准值进行比寝v在规定的精度范围内,来判断温控仪表的合格与否.但这种方法存在一个局限,即对一个由热电偶叹热电阻与温控仪表组成的温控系统存在的偏差还不能客观及时地反映出来。另一个问题是温控仪表虽经检定是合格的,但热电偶却是新的,这两者组成的温控系统在实际应用中往往会出现一定的偏差,个别的偏差较大,如某厂生产的热电偶出厂的分度号是E型,而实际检测中用J型参数值带入才基本符合。即热电偶的出厂分度号与实际不相符合而出现偏差。因此要解决以上出现的问题,对一个挤塑设备温控系统进行测量,判断准确与否,较好的方法是用一个可调且能够移动的温控场,方便直观迅速地对一个温控系统偏差作出判断,并加以修正,这便是本文要讨论的问题。