新技术!增材减材一体化新系统,不同工艺无缝切换,加工精度优于100 nm!

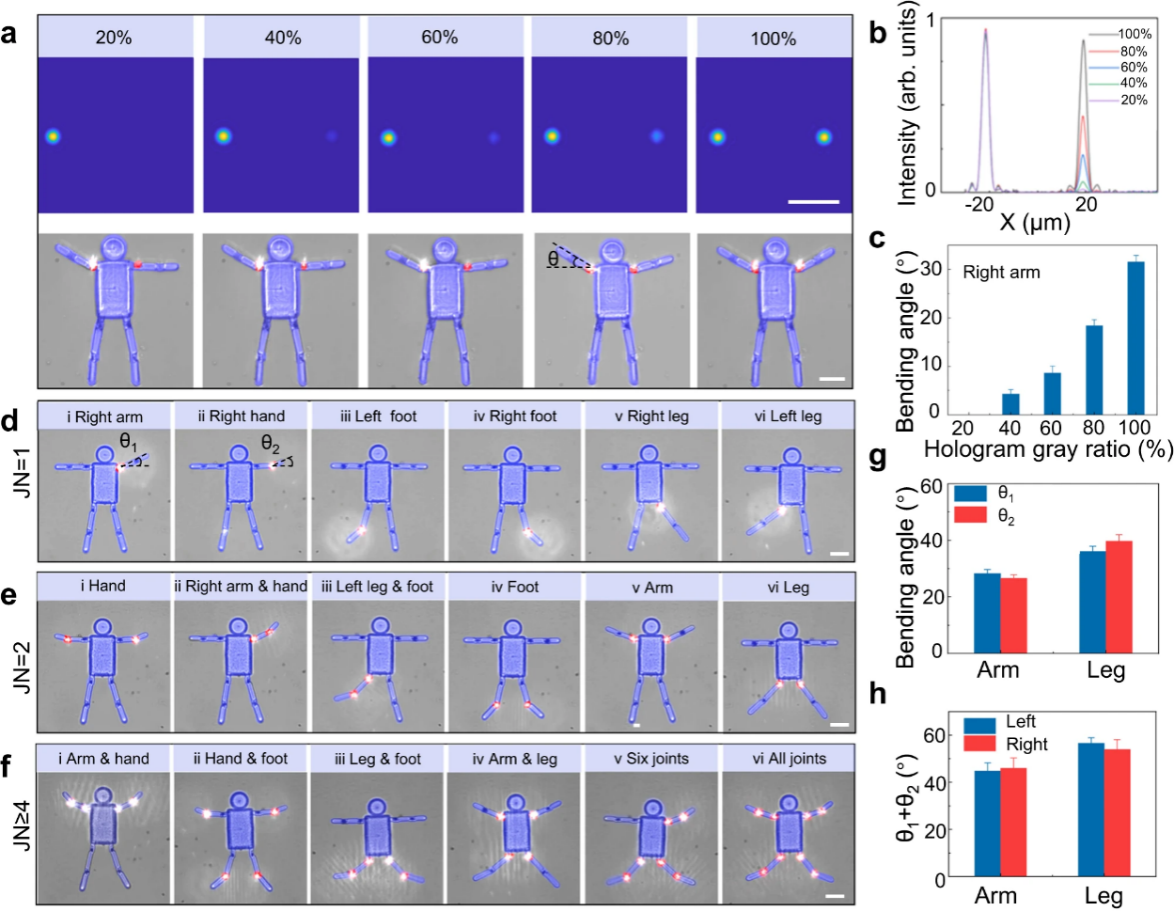

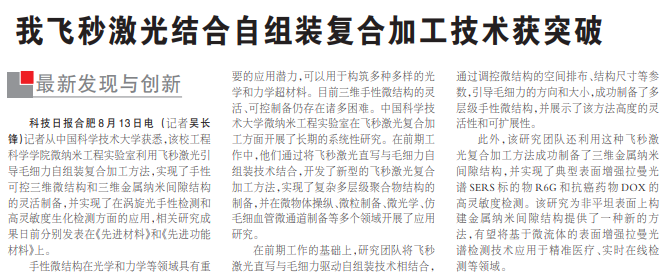

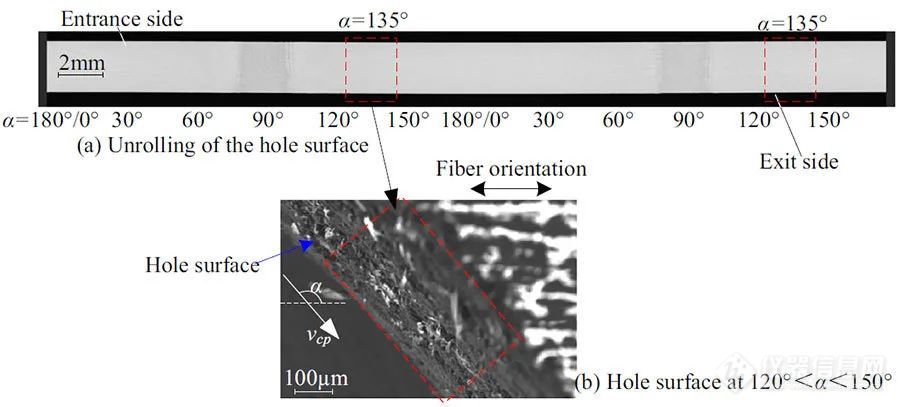

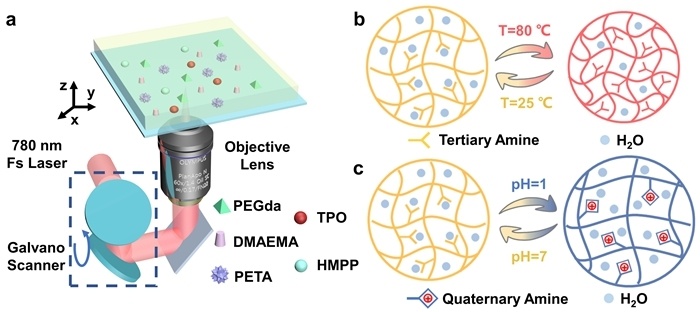

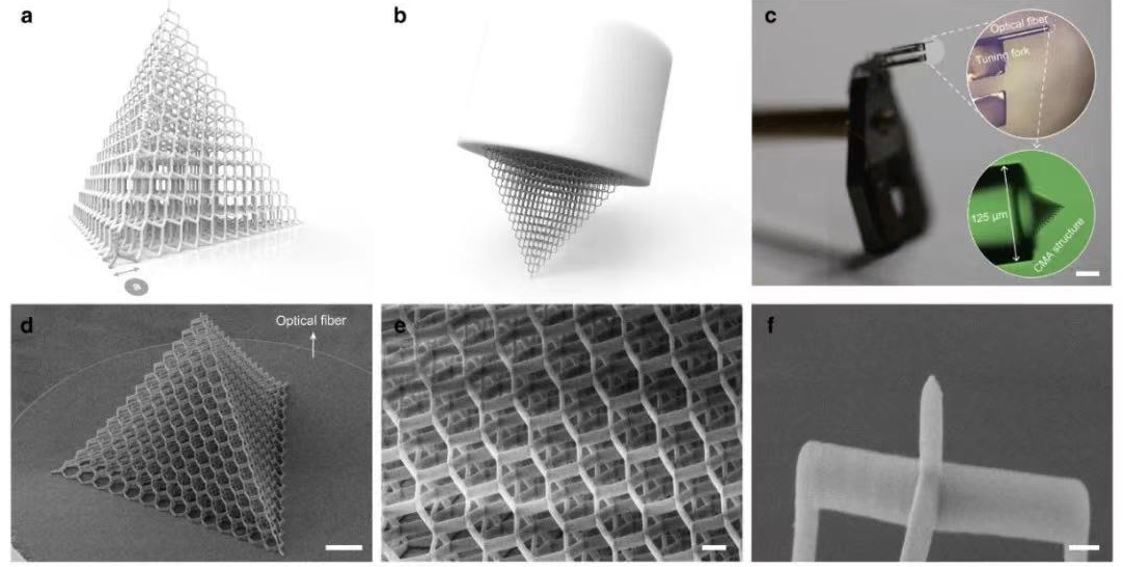

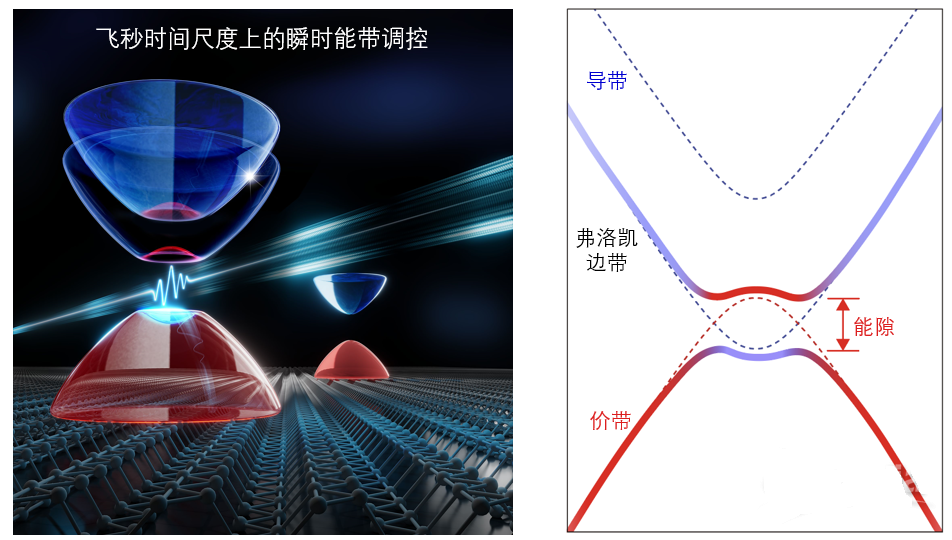

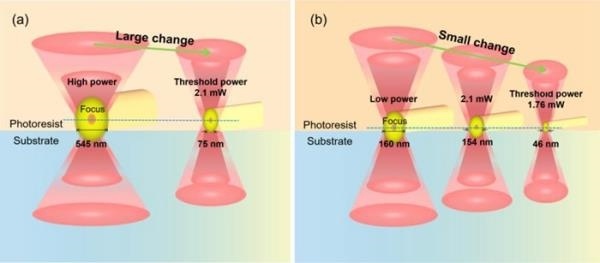

增材减材复合神器随着材料加工、微纳机电、微流控、新型医疗设备、微电子器件等领域的发展,对不同材料的精细激光加工的需求越来越多。借助激光加工技术不仅可以对材料进行减材制造,还可以对特定材料进行增材制造。近日,Quantum Design中国公司引进了Femtika公司设计并生产的飞秒激光微纳加工综合系统-Laser Nanofactory,以满足科研或工业界对精细激光加工的需求。Laser Nanofactory是一款集增材与减材制造于一体的综合微纳加工系统。Laser Nanofactory与传统的微纳3D打印设备相比不仅可用于光子学聚合物微纳结构的加工,还可以用于石英,陶瓷,玻璃和金属等材料从毫米到微米尺度的精确加工。得益于Femtika国际领先的飞秒激光技术,Laser Nanofactory加工速度可高达50 mm/s,加工精度优于100 nm,加工过程中无拼接痕迹。Laser Nanofactory可以提供不同功率的激光,满足您从工业生产到科研探索的多方面需求。Femtika飞秒激光微纳加工综合系统-Laser Nanofactory 精选案例2.1多光子聚合(Multi-Photon Polymerization)微纳加工光学微结构左图为菲涅尔微透镜,右图为微棱镜 生物医药左图为微针阵列,右图为生物用微支架 MEMS/传感器左图为可活动的微锁链,右图为微型弹簧 2.2激光选择性刻蚀 微流控加工左图为在熔融石英玻璃上制备的微流道,右图为在玻璃中刻蚀的特斯拉阀 MEMS左图为微型间歇齿轮,右图为特殊3D喷嘴 2.3激光刻蚀 金属加工左图为在金属上制备直径为30 μm的微洞,右图为长度500 μm的二维码 表面改性左图为在金属表面上制备的疏水微结构,右图为在金属表面上制备的亲水微结构利用飞秒激光在钛金属表面产生不同厚度的氧化层 2.4 综合加工应用利用激光刻蚀制备出较大的微流道,再通过多光子聚合技术在流道的特定位置形成微滤网 已有用户发表文章[1] A. Butkut&edot , G. Merkininkait&edot , T. Jurk&scaron as, J. Stan&ccaron ikas, T. Baravykas, R. Vargalis, T. Ti&ccaron kūnas, J. Bachmann, S. &Scaron akirzanovas, V. Sirutkaitis, and L. Jonu&scaron auskas, “Femtosecond Laser Assisted 3D Etching Using Inorganic-Organic Etchant”, Materials 2022,15, 2817, (2022).[2] G. Kontenis, D. Gailevi&ccaron ius, N. Jimenez, and K. Staliunas, “Optical Drills by Dynamic High‑ Order Bessel Beam Mixing”, Phys. Rev. Applied 17, 034059, (2022).[3] D. &Ccaron ere&scaron ka, A. &Zcaron emaitis, G. Kontenis, G. Nemickas, and L. Jonu&scaron auskas, “On‑ Demand Wettability via Combining fs Laser Surface Structuring and Thermal Post-Treatment”, Materials 2022,15, 2141, (2022).[4] A. Butkut&edot , and L. Jonu&scaron auskas, “3D Manufacturing of Glass Microstructures Using Femtosecond Laser”,Micromachines 2021,12, 499, (2021).[5] D. Andrijec, D. Andriukaitis, R. Vargalis, T. Baravykas, T. Drevinskas, O. Korny&scaron ova, A. Butkut&edot , V. Ka&scaron konien&edot , M. Stankevi&ccaron ius, H. Gricius, A. Jagelavi&ccaron ius, A. Maru&scaron ka, and L. Jonu&scaron auskas, “Hybrid additive subtractive femtosecond 3D manufacturing of nanofilter based microfluidic separator”, Applied Physics A (2021).[6] D. Gonzalez-Hernandez, S. Varapnickas, G. Merkininkait&edot , A. &Ccaron iburys, D. Gailevi&ccaron ius, S. &Scaron akirzanovas, S. Juodkazis, and M. Malinauskas,”Laser 3D Printing of Inorganic Free‑ Form Micro-Optics”, Photonics 2021,8, 577, (2021).[7] D. Andriukaitis, A. Butkut&edot , T. Baravykas, R. Vargalis, J. Stan&ccaron ikas, T. Ti&ccaron kūnas, V. Sirutkaitis, and L. Jonu&scaron auskas, “Femtosecond Fabrication of 3D Free-Form Functional Glass Microdevices: Burst-Mode Ablation and Selective Etching Solutions”, 2021 Conference on Lasers and Electro-Optics Europe & European Quantum Electronics Conference, (2021).[8] A. Butkut&edot , T. Baravykas, J. Stan&ccaron ikas, T. Ti&ccaron kūnas, R. Vargalis, D. Paipulas, V. Sirutkaitis, and L. Janu&scaron auskas, “Optimization of selective laser etching (SLE) for glass micromechanical structure fabrication”, Optical Express 23487, Vol. 29, No. 15, 19.07.2021, (2021).[9] A. Maru&scaron ka, T. Drevinskas, M. Stankevi&ccaron ius, K. Bimbirait&edot -Survilien&edot , V. Ka&scaron konien&edot , L. Jonu&scaron auskas, R. Gadonas, S. Nilsson, and O. Korny&scaron ova, “Single-chip based contactless conductivity detection system for multi-channel separations”, Anal. Methods, 2021,13,141–146, (2021).[10] L. Bakhchova, L. Jonu&scaron auskas, D. Andrijec, M. Kurachkina, T. Baravykas, A. Eremin, and U. Steinmann,“Femtosecond Laser-Based Integration of Nano-Membranes into Organ-on-a-Chip Systems”, Materials 2020, 13, 3076 (2020).[11] T. Ti&ccaron kūnas, D. Paipulas, and V. Purlys, “Dynamic voxel size tuning for direct laser writing,” Opt. Mater. Express 10, 1432-1439 (2020).[12] T. Ti&ccaron kūnas, D. Paipulas, and V. Purlys, “4Pi multiphoton polymerization”, Appl. Phys. Lett. 116, 031101 (2020).[13] L. Jonu&scaron auskas, T. Baravykas, D. Andrijec, T. Gadi&scaron auskas, and V. Purlys, “Stitchless support-free 3D printing of free-form micromechanical structures with feature size on-demand”, Sci Rep 9, 17533 (2019).[14] S. Gawali. D. Gailevi&ccaron ius, G. Garre-Werner, V. Purlys, C. Cojocaru, J. Trull, J. Montiel-Ponsoda, and K. Staliunas, “Photonic crystal spatial filtering in broad aperture diode laser”, Appl. Phys. Lett. 115, 141104 (2019).[15] L. Jonu&scaron auskas, D. Gailevi&ccaron ius, S. Rek&scaron tyt&edot , T. Baldacchini, S. Juodkazis, and M. Malinauskas, “Mesoscale laser 3D printing,” Opt. Express 27, 15205-15221 (2019).[16] L. Jonu&scaron auskas, D. Mackevi&ccaron iūt&edot , G. Kontenis and V. Purlys, “Femtosecond lasers: the ultimate tool for high precision 3D manufacturing”, Adv. Opt. Technol., 20190012, ISSN (Online) 2192-8584, (2019).[17] L. Grineviciute, C. Babayigit, D. Gailevicius, E. Bor, M. Turduev, V. Purlys, T. Tolenis, H. Kurt, and K. Staliunas,“Angular filtering by Bragg photonic microstructures fabricated by physical vapour deposition”, Appl. Surf. Sci., 481, 353-359 (2019).[18] D. Gailevi&ccaron ius, V. Padolskyt&edot , L. Mikoliūnait&edot , S. &Scaron akirzanovas, S. Juodkazis, and M. Malinauskas, “Additive manufacturing of 3D glass-ceramics down to nanoscale resolution”, Nanoscale Horiz., 4, 647-651 (2019).[19] E. Yulanto, S. Chatterjee, V. Purlys, and V. Mizeikis, “Imaging of latent three-dimensional exposure patterns created by direct laser writing in photoresists”, Appl. Surf. Sci., 479, 822-827 (2019).[20] L. Jonu&scaron auskas, S. Juodkazis, and M. Malinauskas, “Optical 3D printing: bridging the gaps in the mesoscale”, J. Opt., 20(05301) (2018).[21] E. Skliutas, S. Kasetaite, L. Jonu&scaron auskas, J. Ostrauskaite, and M. Malinauskas “Photosensitive naturally derived resins toward optical 3-D printing,” Opt. Eng. 57(4), 041412 (2018).[22] L. Jonu&scaron auskas, S. Rek&scaron tyte, R. Buividas, S. Butkus, R. Gadonas, S. Juodkazis, and M. Malinauskas,“Hybrid subtractive-additive-welding microfabrication for lab-on-chip applications via single amplified femtosecond laser source,” Opt. Eng. 56(9), 094108 (2017).