搜全站

搜展位

BGI-VSCC旋风式PM2.5切割器

|

© April 2002 Version 1.3 email: info@bgiusa.com |

| 58 Guinan Street Waltham, MA 02451 | Tel: 781-891-9380 Fax: 781-891-8151 |

| Internet Catalogue with Instruction and Information Manuals http://www.bgiusa.com | |

|

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

VERY SHARP CUT CYCLONE VSCC

INSTRUCTIONS FOR USE AND MAINTENANCE

1.0 Introduction

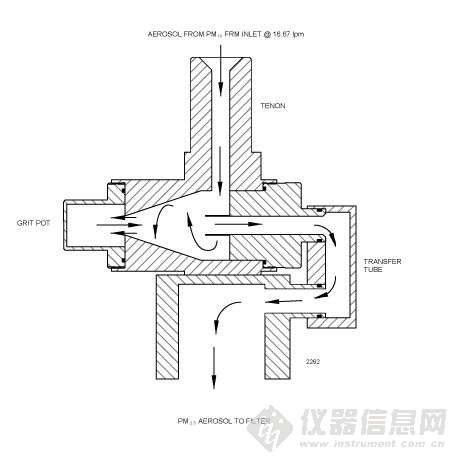

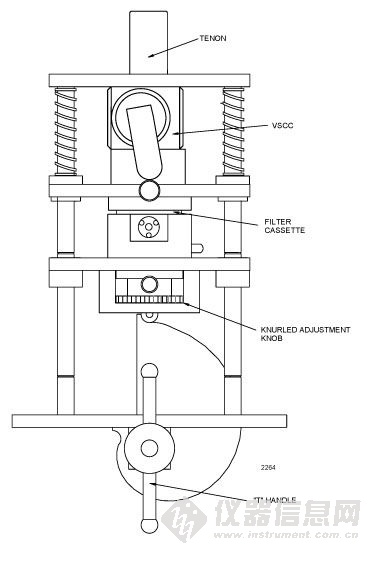

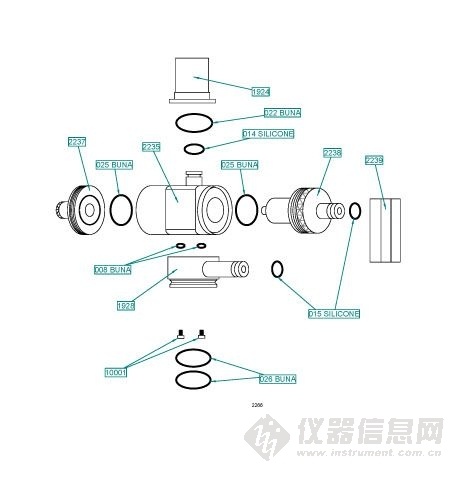

The BGI Very Sharp Cut Cyclone (VSCC) is designed and manufactured only by BGI Incorporated. The VSCC intended use is as an equivalent fine particulate matter separator in place of the US EPA WINS Impactor for PM2.5 sampling in any commercial model of the U.S. EPA Federal Reference Method (FRM) Samplers. The VSCC is a fine-tuned US EPA verified new cyclone design, which exactly agrees with the EPA WINS penetration data. The VSCC originated from the family of BGI Sharp Cut Cyclones (SCC). BGI is the designer of several models of Sharp Cut Cyclone PM2.5 and PM1 inlets used for low flow photometer applications, chemical speciation and ambient particulate continuous monitor inlets. When the VSCC is used with the BGI Model PQ200/PQ200A FRM samplers, they become designated a Federal Equivalent Method (FEM). The FEM designation number is EQPM-0202-142(7). The VSCC has been developed, laboratory and field verified by BGI to have several operational advantages compared to the WINS, insofar as it is a dry separator and requires cleaning at infrequent intervals (1), (2),(3) (4) (5) (6). Inasmuch as ambient chemical speciation sampling for particulates is not governed by an EPA FRM sampler, the VSCC may be freely utilized as a PM2.5 separator on a FRM type sampler and used for particulate mass, metal collection and sulfate and nitrate particulate collection. The VSCC can be utilized as a Fine Particle separator on continuous particulate monitors such as the TEOM , BAM, Light Scatter and Beta Samplers. BGI manufactures two versions of the VSCC. They are the VSCC-A, which is a direct replacement for any commercial FRM system utilizing the standard WINS impactor, such as the Rupprecht & Patashnick (Partisol ), Graseby/Anderson (RAAS with use of exit adapter 2302). The VSCC-B is intended for installation only in the BGI PQ200 and PQ200A FRM samplers. See Figures 1 through 4. The flow path through a VSCC is shown, in a cut-away view in Figure 1. PM10 “Coarse” aerosol enters tangentially after being pre-separated by the PM10 FRM inlet. Particles greater that PM2.5 (MMD-AED) are removed to the grit pot on the side of the VSCC and the PM2.5 sample is ducted through the cyclone separator to the filter holder. Field and laboratory tests indicate the VSCC can operate up to a period of 90 days between cleaning frequencies, even in high urban loading sites. 2.0 Installation – VSCC-A Model. (For replacement of the EPA WINS in the Rupprecht and Patashnick Partisol , Graseby/Anderson RAAS and use as a PM2.5 Separator for PM2.5 Continuous Monitors) The VSCC-A is an exact replacement for the standard WINS impactor as described in the FRM (4). It may be substituted in any commercial FRM instrument, which currently utilizes a standard WINS, except for the Graseby/Anderson RAAS which requires the additional VSCC exit adapter, BGI p/n2302. The dimensions of the socket and tenon are identical to the WINS and the overall height is the same. Therefore, the VSCC-A may simply be “plugged in” as an exact replacement for the WINS in any instrument currently using the FRM standard WINS impactor. Additionally, all BGI VSCC cyclones are serial and part numbered, and Verification of Manufacture marked to identify the VSCC as an original BGI design and not an unverified copy article. The VSCC may also be fitted to any instrument operating at 16.7-lpm, which utilizes the EPA standard socket and tenon dimensions, such as an ambient continuous fine particulate monitor. E.g. PQ100 and continuous particulate monitors. A generic installation is shown in Figure 2. Note: The application of the VSCC to a non-designated instrument will produce non-designated data. Also data produced by use of the BGI Sharp Cut Cyclone (SCC) or commercial copies, are not US EPA designated and do not necessarily agree with gravimetric and fine particle separation to the BGI VSCC. Please consult the BGI factory for details. 2.1 Installation – VSCC-B Model (For use in the BGI Model PQ200 and PQ200A FRM sampler) The VSCC-B is internally identical to the VSCC-A model, but is intended to be installed only in the BGI PQ200/PQ200A, as a direct replacement for the WINS impactor. When the EPA WINS impactor is replaced with the BGI VSCC the sampler is no longer an EPA Reference Method and becomes an EPA Equivalent Method (EQPM-0202-142). Each VSCC is clearly identified on its side with a part number and individual serial number. Additionally, BGI has added a (VM) stamp, verification of manufacture to insure the unit is not a copy. Each VSCC is supplied with a new sampler identification label which the operator should attach to the panel of the sampler and mark appropriately to identify the samplers EPA designation as configured. The WINS removal and VSCC installation process in a BGI PQ200 or 200A is as follows: Step 1. Remove the FRM PM10 first stage inlet and one-foot long sample transport tube and set aside. Step 2. Open the Impactor/Filter mechanism by turning the “T” handle counter clockwise. Remove the WINS Impactor cup and 47mm filter cassette. Step 3. Loosen the round knurled tension knob, which secures the lower WINS/upper filter housing. Lift out the lower WINS housing and set aside. Step 4. Firmly grasp the upper WINS housing, pull down and remove. This tenon part is sealed into the top of the sampler weather enclosure by an O ring. Care should be taken not to damage the O ring. If this “O” ring appears worn or damaged it should be replaced, to prevent entry of water into the sampler cabinet. Step 5. Replace the upper WINS housing with the VSCC upper adapter. (See Figure 1 and 4b). The male tenon of the VSCC should pass through the top of the sampler weather seal. Step 6. Install the VSCC main body and rotate so the transfer tube is pointing outwards towards the operator. Tighten the round knurled knob to apply sealing pressure on the system. Step 7. Install the filter cassette and close the mechanism by rotating the “T” handle clockwise. Step 8. Adjust the clamping pressure, if required and perform a leak test as described in the PQ200 operator manual. ( The VSCC-B is shown installed in Figure 3 ) 3.0 Operation. After installation of the VSCC, the instrument may be run in the normal manner at a flow rate of 16.67 Alpm as described in the manufacturers operation manual and 40CFR Part 53 specification. It is important to note the performance and operation of the VSCC is based on volumetric “actual” flow rate and not STP corrected flows. 4.0 Maintenance. The intervals between cleaning of the VSCC was dictated by the US EPA for designation at a frequency of not to exceed 30 days of 24 hour sampling. Testing by BGI under 40CFR part 53.65 EPA requirements for designation has demonstrated a validated cleaning interval up to 90 days(5). However for quality assurance reasons EPA and BGI agreed to 30 days maintenance frequency. For use of the VSCC on fine particulate “continuous monitors” i.e: TEOM , Beta attenuation monitors or light scatter units, the operator can clean the device on a 90 day continuous operation basis. Exploded views of the VSCC is shown in Figure 4 a-c. Recommended cleaning materials are cleaning with use of mineral free water and lint free lab wipes. In cases, where stubborn deposits are observed, ultrasonic cleaning ins soap and water is recommended. To disassemble a BGI VSCC: Step 1. Remove the VSCC from its installed position in the instrument. Step 2. Pull off the side transfer tube. If it is too tight to remove by hand, pry it off with a rigid plastic lever. Care should be taken to not damage the two “O” ring seals. Step 3. Remove the top cap and grit pot by unscrewing. Step 4. Wet a lint free wipe with water and remove all visible deposits. These are most likely to be found at the bottom of the cone and inside the grit pot. Step 5. Inspect all “O” rings for shape and integrity. If at all suspect, replace. Lubricate all “O” rings with light grease. It is important to well lubricate the transfer tube to avoid difficult disassembly. Step 6. Assemble in reverse order and reinstall. Step 7. Perform a leak check according to manufacturers operating manual specifications. 4.1References: 1.Kenny L.C. et al (2000) Development of a Sharp Cut cyclone for Ambient Aerosol Monitoring Applications, Aerosol Science and Technology, Vol.32: 338-358 2.Kenny L.C. et al (2000) A Direct Approach to the Design of Cyclones for Aerosol-Monitoring Applications, Aerosol Science, Vol. 31: 1407-1420. 3.Federal Register 40 CFR part 50, July 18, 1997. Figs. L-20 through L-24. 4.Kenny L.C. et al (2001) Evaluation of VSCC Cyclones, Health & Safety Laboratory Report # IR/L/EXM/01/01 5.Thorpe A. et al (2001) Effects of Dust Loading on the Performance of the VSCC Cyclone, Health & Safety Laboratory Report # IR/L/EXCON/O1/09 Federal Register/Volume 67, Number 63/ Tuesday, April 2, 2002/ Notices Page 15566 “Ambient air Monitoring Reference and Equivalent Methods: Designation of One New Reference Method for PM10, Four New Equivalent Methods for PM2.5, and One New Reference Method for NO2” |

|

|

|

Figure 1: BGI Very Sharp Cut Cyclone (VSCCTM) Flow Path

|

|

Figure 2: Generic FRM Sampler Showing VSCC Installed

|

|

Figure 3: Drawing of VSCC-BTM Installed in the BGI PQ200 or PQ200A

|

|

Figure 4a: Exploded View of VSCC-ATM

|

|

Figure 4b: Exploded View of VSCC-BTM

|

|

Figure 4c: Exploded view of VSCC-ATM Showing 2302 Outlet

Adaptor for Graseby/Anderson RAASTM System

|

|

最新动态

更多![]()

小颗粒,大视野-大气颗粒物电镜分析联合实验室

厂商

2021.12.20

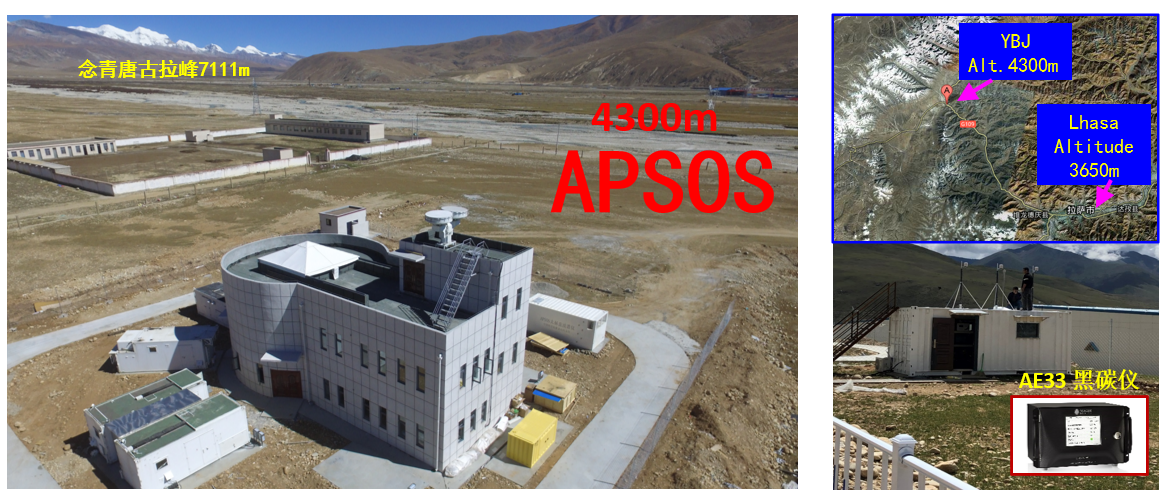

前沿成果 | 疫情期间北京和青藏高原地区黑碳对人为源减排的不同响应

厂商

2021.12.20

赛克玛精彩亮相“第三届中国大气臭氧污染防治研讨会”

厂商

2021.05.13

会议邀请|赛克玛与您相约第三届中国大气臭氧污染防治研讨会

厂商

2021.05.13

推荐产品

供应产品