Bearing Test

Bearing Test

Systems

BRG 3000 Overview

The Model BRG 3000 is a bench top system for measuring the Torque characteristics of Anti Friction Bearings-滑动轴承 and Bearing Assemblies-轴承组合件. Contained in the system are a customized computer, monitor, keyboard, and the necessary circuitry for performing a test and processing the results. User-friendly menus enable the operator to rapidly become proficient with the operation of this National Instruments Labview based system.

Standard features such as 2 serial ports, one parallel port, a diskette drive and a CD ROM drive are provided. 标准接口驱动系统

Test configurations are stored in memory and are retrievable with the click of a mouse key, avoiding time consuming setups. Test results can be stored in memory or on a disk and then transported to other peripheral devices for further analysis and processing. 试验操作简单,数据储存处理和分析系统

Testing Capabilities 测试范围及能力

Both starting torque-启动扭距 and running torque-转速扭距 can be measured with the same system, the same tooling and in the same test cycle.

Bearing Contamination 轴承污染

Retainer Hang-up

Brinelled or Pitted Raceways

Poor Geometry

Structural Defects. 轴承构架缺陷

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 System Information系统信息

Electronics: The electronic portion of this system consists of a computer packaged in a desktop configuration in accordance with Vibrac Specification CP 3000. This specification basically defines the components and packaging that is required for all Vibrac 3000 series instrumentation. 电子控制系统

Component Specifications: The following component list is contained in the CP 3000 specification. CP-3000部件说明

Pentium processor ( 2.8 GHz Minimum )

80 GB Hard Disk Drive ( Minimum )

1 Meg RAM ( Minimum )

3.5" Flexible Disk Drive

17" Flat Panel Monitor

101A Keyboard & Optical Mouse

Windows XP ® Software

1 Parallel Port

1 Serial Port

3000 Data Acquisition and Control Card 数据控制卡

3001 Test Head Drive Control Card Section 驱动控制卡

Operating Specifications: 操作环境

Input Power: 115 VAC 60 HZ ( 220 VAC 50 HZ optional )

Temperature Environment: 60 to 90 degrees F.

Humidity Environment: Up to 95 % non-condensing.

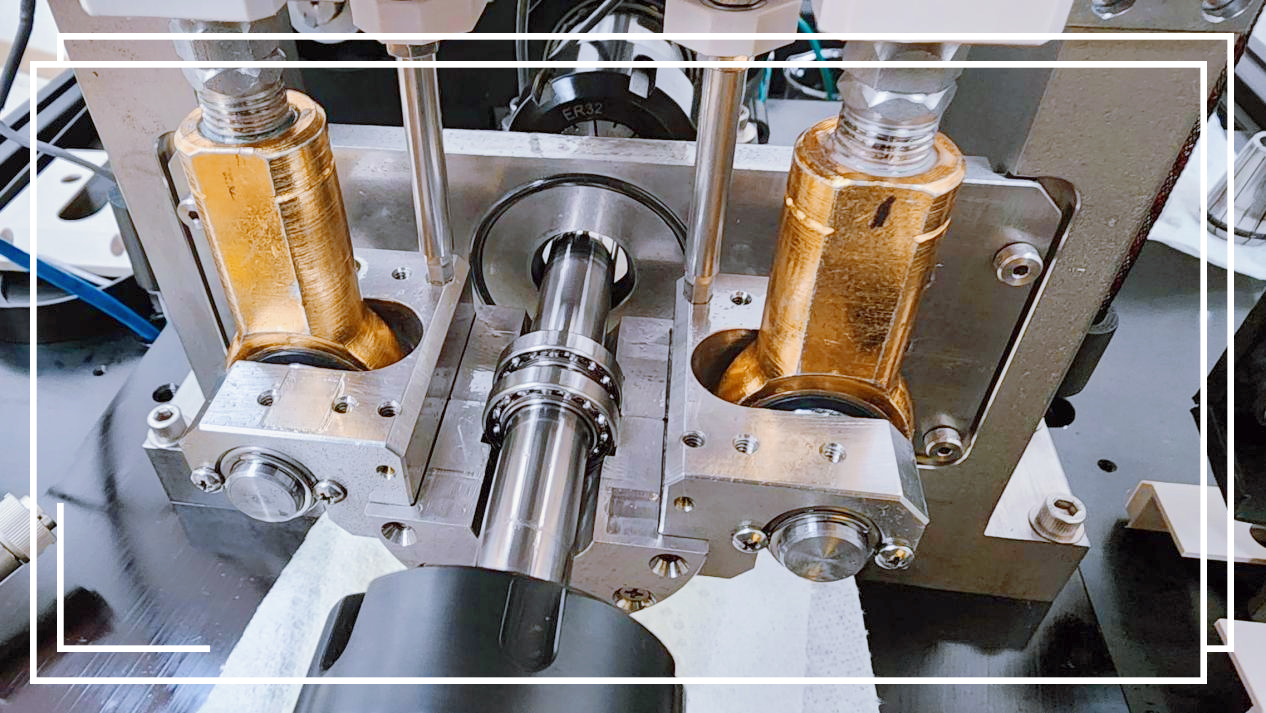

Test Head: A Vibrac Model 9405A test head is the mechanical testing portion of the BRG 2000 Bearing Test System. This test head combines an Optical Torque Transducer光学扭距传感器, an Optical Encoder光编码器 and a Variable Speed Synchronous Drive. This combination enables the system to rotate the bearing at a constant and precise speed while measuring both torque and position.

Torque Transducer: A Vibrac Mini Series Static torque transducer is used in this test head.

扭距传感器

The principal of operation for these torque transducers is pictured below.

Standard Torque Transducers: The torque measuring capability of the test head can be changed by simply changing the transducer and then selecting it in the software window shown below.

标准扭距传感器软件系统显示

Torque Transducer Specifications:

扭距传感器规格说明

TQ

Size Range

(oz-in) Accuracy

% Full Scale

.05 0.0 - .05 +/- .5

.10 0.0 - .10 +/- .5

.20 0.0 - .20 +/- .5

.50 0.0 - .50 +/- .25

1.0 0.0 – 1.0 +/- .25

5.0 0.0 - 5.0 +/- .25

10.0 0.0 - 10.0 +/- .25

Note: Consult factory for other torque values.

Optical Encoder: 光电编码器

Line Count: 9000

Accuracy: +/- .02 degrees.

Drive Motor: 马达驱动系统

The system is supplied with a variable speed synchronous drive with a Speed Range of 0.5 to 10 RPM .

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Software Features

The software for this is a Windows XP ® based software package.

CrystalClear Front Panel

The Front Panel is the window through which the user interacts with the software. This window is designed to look and operate in a manner that is consistent with other Windows ® type programs.

Pull–Down Menuing

A menu bar provides quick and easy access to pull-down menus.

Simple Programming

For a starting torque test just enter the desired values in the screen shown.

For a running torque test just enter the desired values in the screen shown.

Customized End of Test Reports 实验报告

Select the desired engineering units for torque and position.

Select the measurements that should be included in a summary report.

View the data and edit its format in a Windows Note Pad®.

Produce hard copy on any Windows printer.

Export all of the measured values to an Excel Spreadsheet.

Produce strip charts of torque vs. position with the optionally supplied strip chart printer.

Sample reports can be found here.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

Performing A Test With the BRG 3000

This section describes the step-by-step procedure for performing a test. 按照程序操作系统软件说明

Selecting and Loading a Test Configuration

In the Front Panel, shown below, select File.

In the file menu select Load Configuration.

In the load test configuration screen select the desired test configuration and then press Load.

The software will now return the user to the front panel.

Running A Test

Press Zero to put the torque transducer in calibration.

Load the sample to be tested in the supplied tooling and the press Start.

That’s all it takes to perform a test.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Sample Test Reports

Here are a couple of examples of the test reports that can be generated by the BRG 3000 Bearing Tester.

Summary Data Report实验数据报告

中国联系人 李晓锋 13581584194

China Sino-Precision Technology Co., Ltd (SPT)

Room 408, Caizhi Building

5 Changzhi Road, Haidian District

Bejing 100089

China

Phone: (8610) 88587586

Fax: (8610) 88587586

Email: Fli@cetr.com

Website: www.spttek.com

Bearing Test

Systems

BRG 3000 Overview

The Model BRG 3000 is a bench top system for measuring the Torque characteristics of Anti Friction Bearings-滑动轴承 and Bearing Assemblies-轴承组合件. Contained in the system are a customized computer, monitor, keyboard, and the necessary circuitry for performing a test and processing the results. User-friendly menus enable the operator to rapidly become proficient with the operation of this National Instruments Labview based system.

Standard features such as 2 serial ports, one parallel port, a diskette drive and a CD ROM drive are provided. 标准接口驱动系统

Test configurations are stored in memory and are retrievable with the click of a mouse key, avoiding time consuming setups. Test results can be stored in memory or on a disk and then transported to other peripheral devices for further analysis and processing. 试验操作简单,数据储存处理和分析系统

Testing Capabilities 测试范围及能力

Both starting torque-启动扭距 and running torque-转速扭距 can be measured with the same system, the same tooling and in the same test cycle.

Bearing Contamination 轴承污染

Retainer Hang-up

Brinelled or Pitted Raceways

Poor Geometry

Structural Defects. 轴承构架缺陷

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 System Information系统信息

Electronics: The electronic portion of this system consists of a computer packaged in a desktop configuration in accordance with Vibrac Specification CP 3000. This specification basically defines the components and packaging that is required for all Vibrac 3000 series instrumentation. 电子控制系统

Component Specifications: The following component list is contained in the CP 3000 specification. CP-3000部件说明

Pentium processor ( 2.8 GHz Minimum )

80 GB Hard Disk Drive ( Minimum )

1 Meg RAM ( Minimum )

3.5" Flexible Disk Drive

17" Flat Panel Monitor

101A Keyboard & Optical Mouse

Windows XP ® Software

1 Parallel Port

1 Serial Port

3000 Data Acquisition and Control Card 数据控制卡

3001 Test Head Drive Control Card Section 驱动控制卡

Operating Specifications: 操作环境

Input Power: 115 VAC 60 HZ ( 220 VAC 50 HZ optional )

Temperature Environment: 60 to 90 degrees F.

Humidity Environment: Up to 95 % non-condensing.

Test Head: A Vibrac Model 9405A test head is the mechanical testing portion of the BRG 2000 Bearing Test System. This test head combines an Optical Torque Transducer光学扭距传感器, an Optical Encoder光编码器 and a Variable Speed Synchronous Drive. This combination enables the system to rotate the bearing at a constant and precise speed while measuring both torque and position.

Torque Transducer: A Vibrac Mini Series Static torque transducer is used in this test head.

扭距传感器

The principal of operation for these torque transducers is pictured below.

Standard Torque Transducers: The torque measuring capability of the test head can be changed by simply changing the transducer and then selecting it in the software window shown below.

标准扭距传感器软件系统显示

Torque Transducer Specifications:

扭距传感器规格说明

TQ

Size Range

(oz-in) Accuracy

% Full Scale

.05 0.0 - .05 +/- .5

.10 0.0 - .10 +/- .5

.20 0.0 - .20 +/- .5

.50 0.0 - .50 +/- .25

1.0 0.0 – 1.0 +/- .25

5.0 0.0 - 5.0 +/- .25

10.0 0.0 - 10.0 +/- .25

Note: Consult factory for other torque values.

Optical Encoder: 光电编码器

Line Count: 9000

Accuracy: +/- .02 degrees.

Drive Motor: 马达驱动系统

The system is supplied with a variable speed synchronous drive with a Speed Range of 0.5 to 10 RPM .

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Software Features

The software for this is a Windows XP ® based software package.

CrystalClear Front Panel

The Front Panel is the window through which the user interacts with the software. This window is designed to look and operate in a manner that is consistent with other Windows ® type programs.

Pull–Down Menuing

A menu bar provides quick and easy access to pull-down menus.

Simple Programming

For a starting torque test just enter the desired values in the screen shown.

For a running torque test just enter the desired values in the screen shown.

Customized End of Test Reports 实验报告

Select the desired engineering units for torque and position.

Select the measurements that should be included in a summary report.

View the data and edit its format in a Windows Note Pad®.

Produce hard copy on any Windows printer.

Export all of the measured values to an Excel Spreadsheet.

Produce strip charts of torque vs. position with the optionally supplied strip chart printer.

Sample reports can be found here.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

Performing A Test With the BRG 3000

This section describes the step-by-step procedure for performing a test. 按照程序操作系统软件说明

Selecting and Loading a Test Configuration

In the Front Panel, shown below, select File.

In the file menu select Load Configuration.

In the load test configuration screen select the desired test configuration and then press Load.

The software will now return the user to the front panel.

Running A Test

Press Zero to put the torque transducer in calibration.

Load the sample to be tested in the supplied tooling and the press Start.

That’s all it takes to perform a test.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Sample Test Reports

Here are a couple of examples of the test reports that can be generated by the BRG 3000 Bearing Tester.

Summary Data Report实验数据报告

中国联系人 李晓锋 13581584194

China Sino-Precision Technology Co., Ltd (SPT)

Room 408, Caizhi Building

5 Changzhi Road, Haidian District

Bejing 100089

China

Phone: (8610) 88587586

Fax: (8610) 88587586

Email: Fli@cetr.com

Website: www.spttek.com

Bearing Test

Systems

BRG 3000 Overview

The Model BRG 3000 is a bench top system for measuring the Torque characteristics of Anti Friction Bearings-滑动轴承 and Bearing Assemblies-轴承组合件. Contained in the system are a customized computer, monitor, keyboard, and the necessary circuitry for performing a test and processing the results. User-friendly menus enable the operator to rapidly become proficient with the operation of this National Instruments Labview based system.

Standard features such as 2 serial ports, one parallel port, a diskette drive and a CD ROM drive are provided. 标准接口驱动系统

Test configurations are stored in memory and are retrievable with the click of a mouse key, avoiding time consuming setups. Test results can be stored in memory or on a disk and then transported to other peripheral devices for further analysis and processing. 试验操作简单,数据储存处理和分析系统

Testing Capabilities 测试范围及能力

Both starting torque-启动扭距 and running torque-转速扭距 can be measured with the same system, the same tooling and in the same test cycle.

Bearing Contamination 轴承污染

Retainer Hang-up

Brinelled or Pitted Raceways

Poor Geometry

Structural Defects. 轴承构架缺陷

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 System Information系统信息

Electronics: The electronic portion of this system consists of a computer packaged in a desktop configuration in accordance with Vibrac Specification CP 3000. This specification basically defines the components and packaging that is required for all Vibrac 3000 series instrumentation. 电子控制系统

Component Specifications: The following component list is contained in the CP 3000 specification. CP-3000部件说明

Pentium processor ( 2.8 GHz Minimum )

80 GB Hard Disk Drive ( Minimum )

1 Meg RAM ( Minimum )

3.5" Flexible Disk Drive

17" Flat Panel Monitor

101A Keyboard & Optical Mouse

Windows XP ® Software

1 Parallel Port

1 Serial Port

3000 Data Acquisition and Control Card 数据控制卡

3001 Test Head Drive Control Card Section 驱动控制卡

Operating Specifications: 操作环境

Input Power: 115 VAC 60 HZ ( 220 VAC 50 HZ optional )

Temperature Environment: 60 to 90 degrees F.

Humidity Environment: Up to 95 % non-condensing.

Test Head: A Vibrac Model 9405A test head is the mechanical testing portion of the BRG 2000 Bearing Test System. This test head combines an Optical Torque Transducer光学扭距传感器, an Optical Encoder光编码器 and a Variable Speed Synchronous Drive. This combination enables the system to rotate the bearing at a constant and precise speed while measuring both torque and position.

Torque Transducer: A Vibrac Mini Series Static torque transducer is used in this test head.

扭距传感器

The principal of operation for these torque transducers is pictured below.

Standard Torque Transducers: The torque measuring capability of the test head can be changed by simply changing the transducer and then selecting it in the software window shown below.

标准扭距传感器软件系统显示

Torque Transducer Specifications:

扭距传感器规格说明

TQ

Size Range

(oz-in) Accuracy

% Full Scale

.05 0.0 - .05 +/- .5

.10 0.0 - .10 +/- .5

.20 0.0 - .20 +/- .5

.50 0.0 - .50 +/- .25

1.0 0.0 – 1.0 +/- .25

5.0 0.0 - 5.0 +/- .25

10.0 0.0 - 10.0 +/- .25

Note: Consult factory for other torque values.

Optical Encoder: 光电编码器

Line Count: 9000

Accuracy: +/- .02 degrees.

Drive Motor: 马达驱动系统

The system is supplied with a variable speed synchronous drive with a Speed Range of 0.5 to 10 RPM .

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Software Features

The software for this is a Windows XP ® based software package.

CrystalClear Front Panel

The Front Panel is the window through which the user interacts with the software. This window is designed to look and operate in a manner that is consistent with other Windows ® type programs.

Pull–Down Menuing

A menu bar provides quick and easy access to pull-down menus.

Simple Programming

For a starting torque test just enter the desired values in the screen shown.

For a running torque test just enter the desired values in the screen shown.

Customized End of Test Reports 实验报告

Select the desired engineering units for torque and position.

Select the measurements that should be included in a summary report.

View the data and edit its format in a Windows Note Pad®.

Produce hard copy on any Windows printer.

Export all of the measured values to an Excel Spreadsheet.

Produce strip charts of torque vs. position with the optionally supplied strip chart printer.

Sample reports can be found here.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

Performing A Test With the BRG 3000

This section describes the step-by-step procedure for performing a test. 按照程序操作系统软件说明

Selecting and Loading a Test Configuration

In the Front Panel, shown below, select File.

In the file menu select Load Configuration.

In the load test configuration screen select the desired test configuration and then press Load.

The software will now return the user to the front panel.

Running A Test

Press Zero to put the torque transducer in calibration.

Load the sample to be tested in the supplied tooling and the press Start.

That’s all it takes to perform a test.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Sample Test Reports

Here are a couple of examples of the test reports that can be generated by the BRG 3000 Bearing Tester.

Summary Data Report实验数据报告

中国联系人 李晓锋 13581584194

China Sino-Precision Technology Co., Ltd (SPT)

Room 408, Caizhi Building

5 Changzhi Road, Haidian District

Bejing 100089

China

Phone: (8610) 88587586

Fax: (8610) 88587586

Email: Fli@cetr.com

Website: www.spttek.com

Bearing Test

Systems

BRG 3000 Overview

The Model BRG 3000 is a bench top system for measuring the Torque characteristics of Anti Friction Bearings-滑动轴承 and Bearing Assemblies-轴承组合件. Contained in the system are a customized computer, monitor, keyboard, and the necessary circuitry for performing a test and processing the results. User-friendly menus enable the operator to rapidly become proficient with the operation of this National Instruments Labview based system.

Standard features such as 2 serial ports, one parallel port, a diskette drive and a CD ROM drive are provided. 标准接口驱动系统

Test configurations are stored in memory and are retrievable with the click of a mouse key, avoiding time consuming setups. Test results can be stored in memory or on a disk and then transported to other peripheral devices for further analysis and processing. 试验操作简单,数据储存处理和分析系统

Testing Capabilities 测试范围及能力

Both starting torque-启动扭距 and running torque-转速扭距 can be measured with the same system, the same tooling and in the same test cycle.

Bearing Contamination 轴承污染

Retainer Hang-up

Brinelled or Pitted Raceways

Poor Geometry

Structural Defects. 轴承构架缺陷

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 System Information系统信息

Electronics: The electronic portion of this system consists of a computer packaged in a desktop configuration in accordance with Vibrac Specification CP 3000. This specification basically defines the components and packaging that is required for all Vibrac 3000 series instrumentation. 电子控制系统

Component Specifications: The following component list is contained in the CP 3000 specification. CP-3000部件说明

Pentium processor ( 2.8 GHz Minimum )

80 GB Hard Disk Drive ( Minimum )

1 Meg RAM ( Minimum )

3.5" Flexible Disk Drive

17" Flat Panel Monitor

101A Keyboard & Optical Mouse

Windows XP ® Software

1 Parallel Port

1 Serial Port

3000 Data Acquisition and Control Card 数据控制卡

3001 Test Head Drive Control Card Section 驱动控制卡

Operating Specifications: 操作环境

Input Power: 115 VAC 60 HZ ( 220 VAC 50 HZ optional )

Temperature Environment: 60 to 90 degrees F.

Humidity Environment: Up to 95 % non-condensing.

Test Head: A Vibrac Model 9405A test head is the mechanical testing portion of the BRG 2000 Bearing Test System. This test head combines an Optical Torque Transducer光学扭距传感器, an Optical Encoder光编码器 and a Variable Speed Synchronous Drive. This combination enables the system to rotate the bearing at a constant and precise speed while measuring both torque and position.

Torque Transducer: A Vibrac Mini Series Static torque transducer is used in this test head.

扭距传感器

The principal of operation for these torque transducers is pictured below.

Standard Torque Transducers: The torque measuring capability of the test head can be changed by simply changing the transducer and then selecting it in the software window shown below.

标准扭距传感器软件系统显示

Torque Transducer Specifications:

扭距传感器规格说明

TQ

Size Range

(oz-in) Accuracy

% Full Scale

.05 0.0 - .05 +/- .5

.10 0.0 - .10 +/- .5

.20 0.0 - .20 +/- .5

.50 0.0 - .50 +/- .25

1.0 0.0 – 1.0 +/- .25

5.0 0.0 - 5.0 +/- .25

10.0 0.0 - 10.0 +/- .25

Note: Consult factory for other torque values.

Optical Encoder: 光电编码器

Line Count: 9000

Accuracy: +/- .02 degrees.

Drive Motor: 马达驱动系统

The system is supplied with a variable speed synchronous drive with a Speed Range of 0.5 to 10 RPM .

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Software Features

The software for this is a Windows XP ® based software package.

CrystalClear Front Panel

The Front Panel is the window through which the user interacts with the software. This window is designed to look and operate in a manner that is consistent with other Windows ® type programs.

Pull–Down Menuing

A menu bar provides quick and easy access to pull-down menus.

Simple Programming

For a starting torque test just enter the desired values in the screen shown.

For a running torque test just enter the desired values in the screen shown.

Customized End of Test Reports 实验报告

Select the desired engineering units for torque and position.

Select the measurements that should be included in a summary report.

View the data and edit its format in a Windows Note Pad®.

Produce hard copy on any Windows printer.

Export all of the measured values to an Excel Spreadsheet.

Produce strip charts of torque vs. position with the optionally supplied strip chart printer.

Sample reports can be found here.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

Performing A Test With the BRG 3000

This section describes the step-by-step procedure for performing a test. 按照程序操作系统软件说明

Selecting and Loading a Test Configuration

In the Front Panel, shown below, select File.

In the file menu select Load Configuration.

In the load test configuration screen select the desired test configuration and then press Load.

The software will now return the user to the front panel.

Running A Test

Press Zero to put the torque transducer in calibration.

Load the sample to be tested in the supplied tooling and the press Start.

That’s all it takes to perform a test.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Sample Test Reports

Here are a couple of examples of the test reports that can be generated by the BRG 3000 Bearing Tester.

Summary Data Report实验数据报告

中国联系人 李晓锋 13581584194

China Sino-Precision Technology Co., Ltd (SPT)

Room 408, Caizhi Building

5 Changzhi Road, Haidian District

Bejing 100089

China

Phone: (8610) 88587586

Fax: (8610) 88587586

Email: Fli@cetr.com

Website: www.spttek.com Bearing Test

Systems

BRG 3000 Overview

The Model BRG 3000 is a bench top system for measuring the Torque characteristics of Anti Friction Bearings-滑动轴承 and Bearing Assemblies-轴承组合件. Contained in the system are a customized computer, monitor, keyboard, and the necessary circuitry for performing a test and processing the results. User-friendly menus enable the operator to rapidly become proficient with the operation of this National Instruments Labview based system.

Standard features such as 2 serial ports, one parallel port, a diskette drive and a CD ROM drive are provided. 标准接口驱动系统

Test configurations are stored in memory and are retrievable with the click of a mouse key, avoiding time consuming setups. Test results can be stored in memory or on a disk and then transported to other peripheral devices for further analysis and processing. 试验操作简单,数据储存处理和分析系统

Testing Capabilities 测试范围及能力

Both starting torque-启动扭距 and running torque-转速扭距 can be measured with the same system, the same tooling and in the same test cycle.

Bearing Contamination 轴承污染

Retainer Hang-up

Brinelled or Pitted Raceways

Poor Geometry

Structural Defects. 轴承构架缺陷

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 System Information系统信息

Electronics: The electronic portion of this system consists of a computer packaged in a desktop configuration in accordance with Vibrac Specification CP 3000. This specification basically defines the components and packaging that is required for all Vibrac 3000 series instrumentation. 电子控制系统

Component Specifications: The following component list is contained in the CP 3000 specification. CP-3000部件说明

Pentium processor ( 2.8 GHz Minimum )

80 GB Hard Disk Drive ( Minimum )

1 Meg RAM ( Minimum )

3.5" Flexible Disk Drive

17" Flat Panel Monitor

101A Keyboard & Optical Mouse

Windows XP ® Software

1 Parallel Port

1 Serial Port

3000 Data Acquisition and Control Card 数据控制卡

3001 Test Head Drive Control Card Section 驱动控制卡

Operating Specifications: 操作环境

Input Power: 115 VAC 60 HZ ( 220 VAC 50 HZ optional )

Temperature Environment: 60 to 90 degrees F.

Humidity Environment: Up to 95 % non-condensing.

Test Head: A Vibrac Model 9405A test head is the mechanical testing portion of the BRG 2000 Bearing Test System. This test head combines an Optical Torque Transducer光学扭距传感器, an Optical Encoder光编码器 and a Variable Speed Synchronous Drive. This combination enables the system to rotate the bearing at a constant and precise speed while measuring both torque and position.

Torque Transducer: A Vibrac Mini Series Static torque transducer is used in this test head.

扭距传感器

The principal of operation for these torque transducers is pictured below.

Standard Torque Transducers: The torque measuring capability of the test head can be changed by simply changing the transducer and then selecting it in the software window shown below.

标准扭距传感器软件系统显示

Torque Transducer Specifications:

扭距传感器规格说明

TQ

Size Range

(oz-in) Accuracy

% Full Scale

.05 0.0 - .05 +/- .5

.10 0.0 - .10 +/- .5

.20 0.0 - .20 +/- .5

.50 0.0 - .50 +/- .25

1.0 0.0 – 1.0 +/- .25

5.0 0.0 - 5.0 +/- .25

10.0 0.0 - 10.0 +/- .25

Note: Consult factory for other torque values.

Optical Encoder: 光电编码器

Line Count: 9000

Accuracy: +/- .02 degrees.

Drive Motor: 马达驱动系统

The system is supplied with a variable speed synchronous drive with a Speed Range of 0.5 to 10 RPM .

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Software Features

The software for this is a Windows XP ® based software package.

CrystalClear Front Panel

The Front Panel is the window through which the user interacts with the software. This window is designed to look and operate in a manner that is consistent with other Windows ® type programs.

Pull–Down Menuing

A menu bar provides quick and easy access to pull-down menus.

Simple Programming

For a starting torque test just enter the desired values in the screen shown.

For a running torque test just enter the desired values in the screen shown.

Customized End of Test Reports 实验报告

Select the desired engineering units for torque and position.

Select the measurements that should be included in a summary report.

View the data and edit its format in a Windows Note Pad®.

Produce hard copy on any Windows printer.

Export all of the measured values to an Excel Spreadsheet.

Produce strip charts of torque vs. position with the optionally supplied strip chart printer.

Sample reports can be found here.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

Performing A Test With the BRG 3000

This section describes the step-by-step procedure for performing a test. 按照程序操作系统软件说明

Selecting and Loading a Test Configuration

In the Front Panel, shown below, select File.

In the file menu select Load Configuration.

In the load test configuration screen select the desired test configuration and then press Load.

The software will now return the user to the front panel.

Running A Test

Press Zero to put the torque transducer in calibration.

Load the sample to be tested in the supplied tooling and the press Start.

That’s all it takes to perform a test.

Bearing Test Systems

BRG 3000 Overview

System Information

Additional Software Features

Running a Test

Sample Reports

BRG 3000 Sample Test Reports

Here are a couple of examples of the test reports that can be generated by the BRG 3000 Bearing Tester.

Summary Data Report实验数据报告

中国联系人 李晓锋 13581584194

China Sino-Precision Technology Co., Ltd (SPT)

Room 408, Caizhi Building

5 Changzhi Road, Haidian District

Bejing 100089

China

Phone: (8610) 88587586

Fax: (8610) 88587586

Email: Fli@cetr.com

Website: www.spttek.com

更多![]()

会议预告丨Rtec与您共赴浙江宁波第十四届全国青年表面工程学术会议

厂商

2024.05.07

Ashlie Martini教授与您探索二硫化钼润滑剂在太空的应用丨研讨会邀请函

厂商

2024.04.23

RTEC仪器在摩擦学、微纳米力学、三维光学领域全力支持科研设备更新

厂商

2024.03.22

RTEC轴承试验机:评定轴承摩擦学性能的新的利器

新品

2024.03.15