仪器种类: 精密切割机

产地类别: 进口

为您推荐相似的切割机

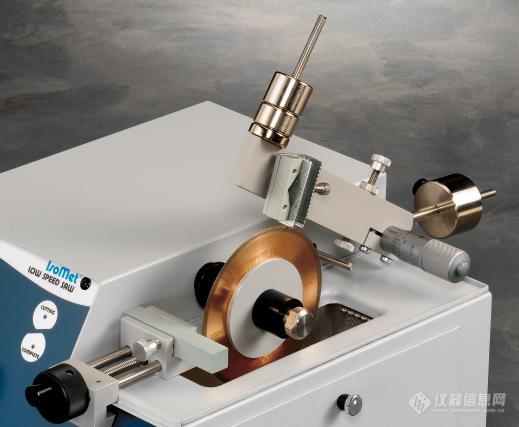

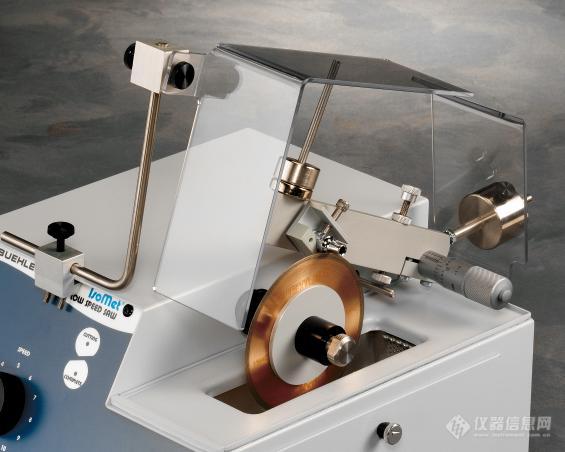

标乐 IsoMet™ 低速精密切割机

产品简介:

IsoMet 低速精密切割机是美国标乐专为各种材料的低变形切割而设计的低速精密切割机。采用了先进成熟的低变形切割技术,其切口损失率低,可切割出几乎没有任何损伤和变形的截面;配有种类齐全的夹具和法兰,可夹持各种不同外形和组态的样品;精确的千分尺调节器,用于在切割前调整样品位置,使样品定位简便精确;这款切割机几乎可以切割任何材料,包括:脆性/韧性金属,复合材料,陶瓷,塑料,层压制品,电子器件和生物材料等,是现代实验室最理想的精密切割工具。

出色的易碎试样切割质量

· 重力进给切割力可减少脆弱试样的变形

· 为各种各样的材料提供不同的切割质量

· 转速范围为0-300RPM 的切割机可以切割几乎任何材料,包括:脆性/韧性金属、复合材料、陶瓷、层压制品、塑料、电子器件以及生物材料。

精确的切割定位控制

· 通过一个自动千分尺可使切割精度达到±0.0001in [±5μm]

· 多功能的样品架实现所有需要的切口形状和配置。

| IsoMet LS 低速精密切割机产品参数 | |

| 频率 | 通用 |

| 电压 | 115, 220 |

| 相数 | 1 |

| 切割容量 | 1.50[in], 38.00[mm] |

| 切割片直径 | 5.00[in] |

| 控制 | 按钮 |

| 切割类型 | 重力进给直切 |

| 编程 | 不可编程 |

| 连续切割 | 不适用 |

| 切割片直径 | 127[mm] |

| 转速 @60 | Hz: 300 |

如需了解更多有关 SimpliVac的技术参数、附件及耗材信息欢迎咨询!

关于标乐(Buehler)

标乐(Buehler)是材料制备、图像分析和硬度测试所用仪器、附件、耗材和相关技术的出色供应商。标乐(Buehler)产品涵盖众多行业,包括金属、汽车、航空航天、电子、医疗、能源等。

标乐公司与 ASM International(美国材料信息学会)、American Society for Testing and Materials(美国材料和测试协会)和 International Metallographic Society(国际金相学学会)等联盟机构保持着行业合作伙伴传统。标乐公司自 1946 年起便赞助 ASM Francis F. Lucas Metallographic Award 金相奖,并赞助了 International Metallographic Society(国际金相学学会)的 Pierre Jacquet Award 奖项,为材料科学的研究做出贡献。

标乐(Buehler)隶属于美国ITW集团(伊利诺伊工具公司),总部坐落在美国伊利诺伊州莱克布拉夫市。ITW是一家美国财富200强企业,在全球从事增值耗材、特种设备的工业产品制造并提供相关服务。 标乐公司于1936年建立,是最早为材料分析行业制造科学设备和材料的厂商。2011年标乐和威尔逊硬度计合并,提供了更全的材料制备和分析检测设备。标乐现已在9个国家成立办事处、在100多个国家设立销售网点并拥有超过45个标乐解决方案中心。

- 标乐中国 -

依工测试测量仪器(上海)有限公司

标乐(Buehler)&威尔逊(Wilson)厂家

保修期: 1年

是否可延长保修期: 是

现场技术咨询: 有

免费培训: 面议

免费仪器保养: 面议

保内维修承诺: 面议

报修承诺: 面议

PetroThin™ 薄片切割系统

型号:PetroThin™ Thin Sectioning System 20万 - 50万

Delta 手动砂轮切割机

型号:Delta™ Manual Action Cutter 1 - 9999

AbrasiMatic™ 300 砂轮切割机

型号:AbrasiMatic™ 300 20万 - 50万

IsoMet 1000精密切割机

型号:IsoMet 1000 10万 - 20万IsoMet® Low Speed 是一款低速精密切割机, 专门用于切割多种材料, 并保证产生的变形最小。 其具有切割材料损耗小及可夹持不同大小形状试样的特点, 几乎适用于所有实验室材料, 包括脆韧性金属、 复合材料、 水泥、 塑料、 薄片、 电子和生物材料。

标乐切割机IsoMet™ Low Speed Cutter的工作原理介绍

切割机IsoMet™ Low Speed Cutter的使用方法?

标乐IsoMet™ Low Speed Cutter多少钱一台?

切割机IsoMet™ Low Speed Cutter可以检测什么?

切割机IsoMet™ Low Speed Cutter使用的注意事项?

标乐IsoMet™ Low Speed Cutter的说明书有吗?

标乐切割机IsoMet™ Low Speed Cutter的操作规程有吗?

标乐切割机IsoMet™ Low Speed Cutter报价含票含运吗?

标乐IsoMet™ Low Speed Cutter有现货吗?

最多添加5台