Answers:

1. Yes, I think your understanding is correct. In most cases, when you see some literature of an XPS depth profile and on X-axis it is showing "depth" it is converting the time to depth by the sputtering rate, while the sputtering rate in most cases would be calibrated either by Ta2O5 or SiO2 to be the most common cases. In fact, I think most appropriate way is that when showing the X-axis as depth, a statement explanation about how to get this depth conversion is necessary (e.g. depth conversion by sputtering rate xx nm/min on Ta2O5)

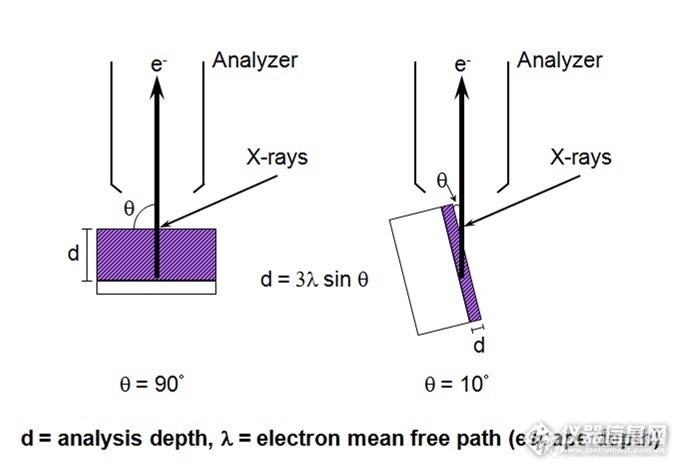

2. Please look at picture. The pictures you shown to me is more likely a sample orientation as geometry problem. I would say that indeed your sample surface is having more metal alloy. If continue to discuss about the geometry issue, sometimes you will get a shadow effect as there may be part of surface not able to reach by the X-ray. Anyhow, still back to my previous point about stage tilt would affect detection depth is as below.

![]()

3. You want to ask why some transition metal peak would result in a doublet? Like Ag3d5 and Ag3d3?